ZX2

6

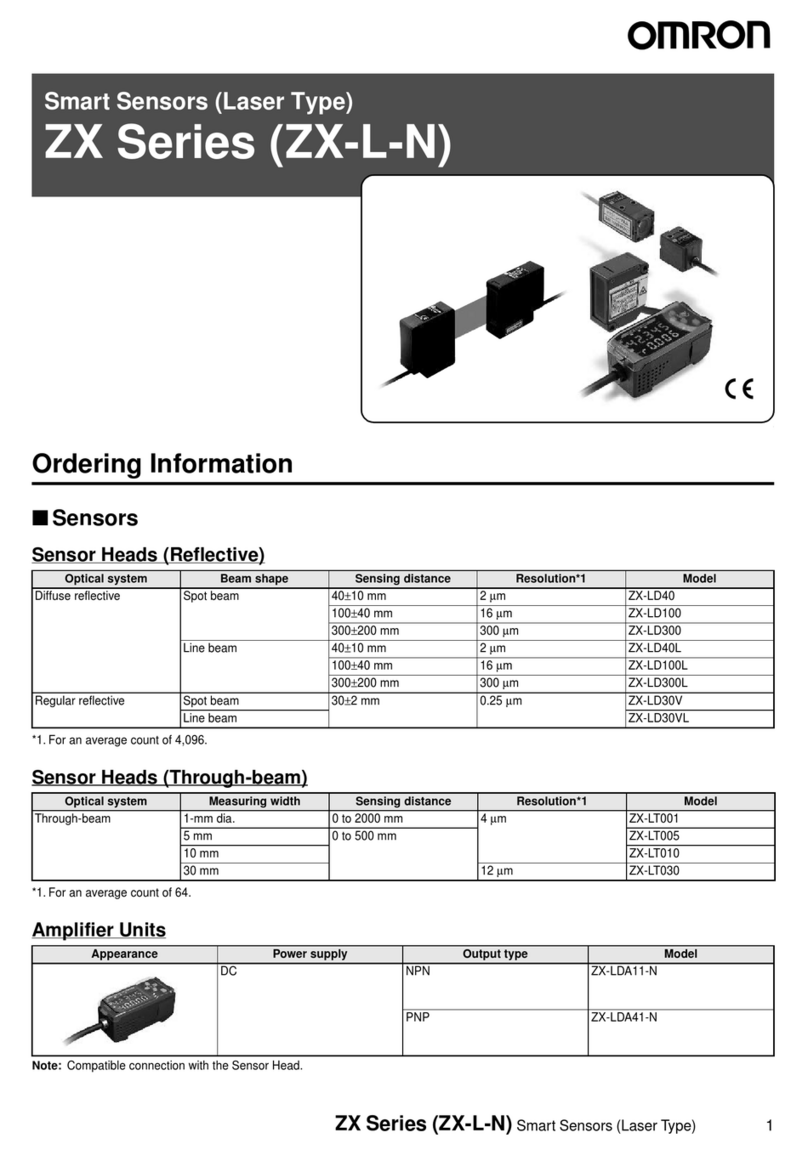

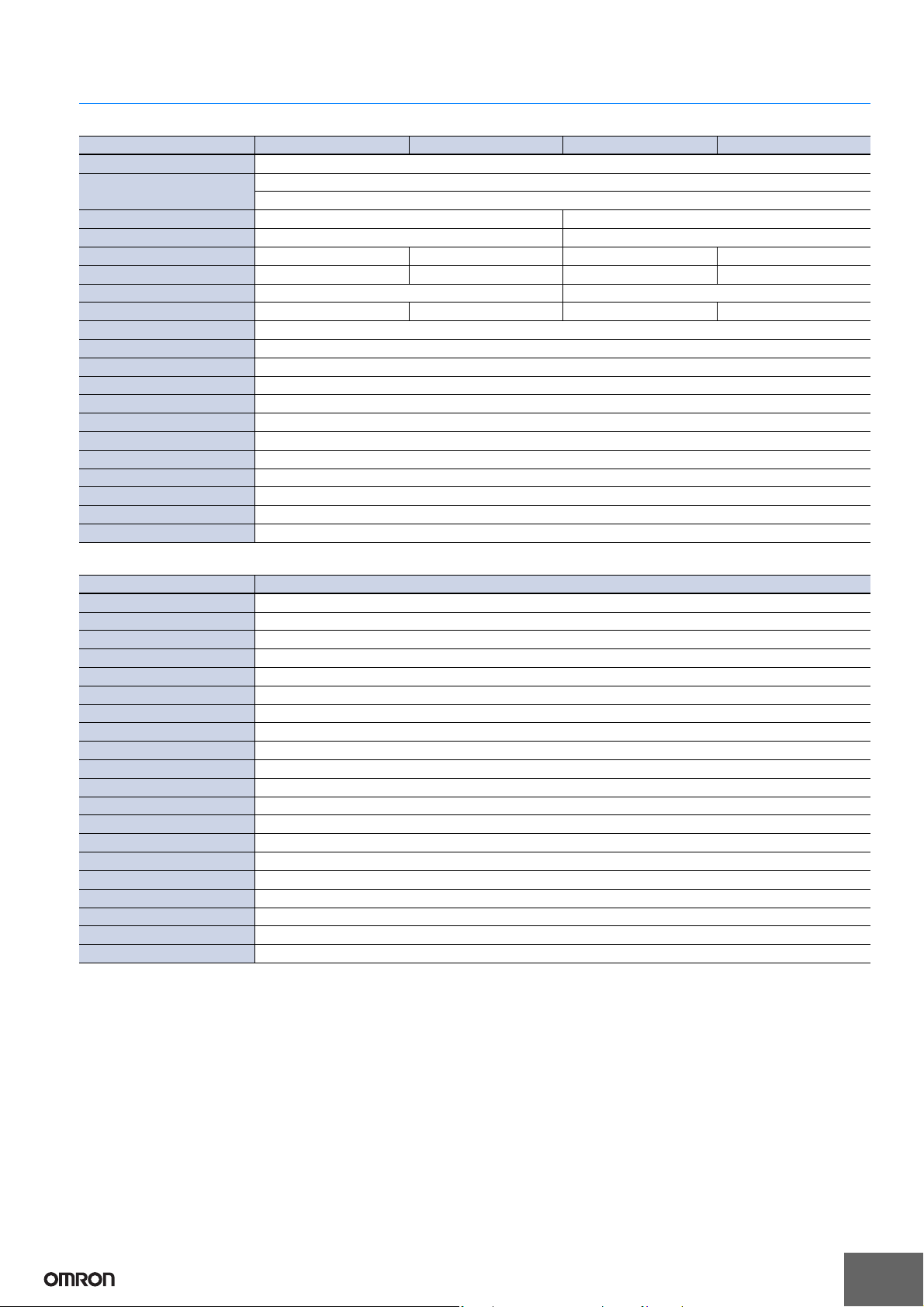

Amplifier Units

*1. In the case of Omron’s standard target object (white ceramic)

*2. Select current output (4 to 20 mA) and voltage output (±5Vor 1 to 5V) by MENU mode.

*3. Calculating unit (ZX2-CAL) is necessary. Calculations are possible for up to two amplifier units. Mutual interference prevention is possible for

up to five amplifier units.

Calculating Unit ZX2-series Communications Interface Unit

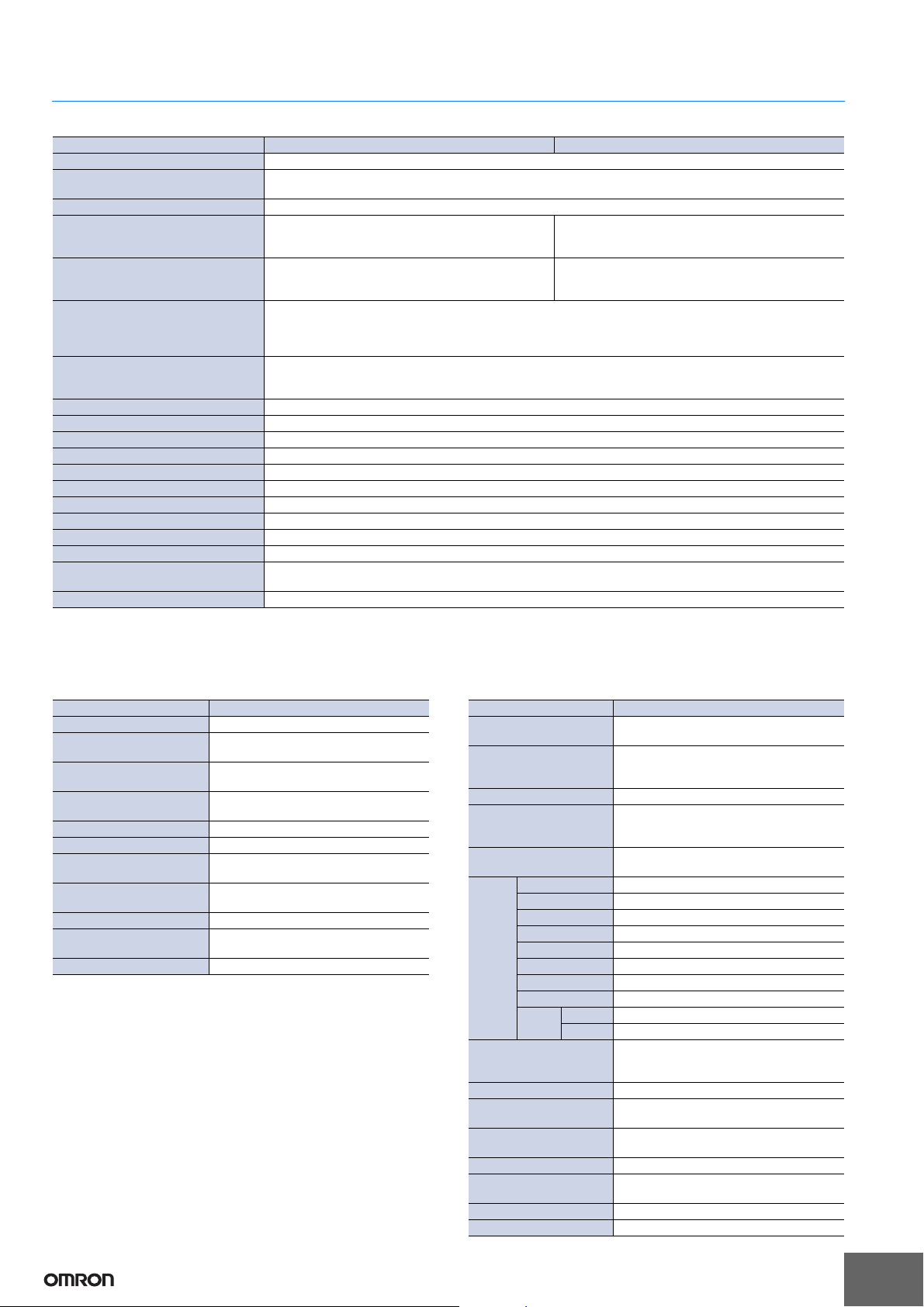

Item Model ZX2-LDA11 ZX2-LDA41

Measurement period *1Min. 30 μs

Response time 60 μs, 120 μs, 240 μs, 500 μs, 1 ms, 2 ms, 4 ms, 8ms, 12 ms, 20 ms, 36 ms, 66 ms, 128ms, 250 ms,

500ms

Analog output *24 to 20 mA, Max. load resistance: 300Ω/±5 VDC or 1 to 5 VDC, Output impedance: 100Ω

Judgement outputs

(HIGH/PASS/LOW: 3 outputs),

error output

NPN open-collector outputs, 30 VDC, 50 mA max.

(residual voltage: 1 Vmax. for load current 10 mA

max., 2Vmax. for load current above 10 mA)

PNP open-collector outputs, 30 VDC, 50 mA max.

(residual voltage: 1 Vmax. for load current 10 mA

max., 2 Vmax. for load current above 10 mA)

Laser OFF input, zero reset input,

timing input, reset input,

bank input ON: Short-circuited with 0-Vterminal or 1.2 Vor less

OFF: Open (leakage current: 0.1 mA max.) ON:Supplyvoltageshort-circuitedorsupplyvoltage

within -1.2 V

OFF: Open (leakage current: 0.1 mA max.)

Functions Smart tuning, scaling, sample hold, peak hold, bottom hold, peak-to-peak hold, self-peak hold,

self-bottom hold, average hold, zero reset, On-delay timer, OFF-delay timer, keep/clamp switch,

(A-B) calculations *3, thickness calculation *3, mutual interference prevention *3,

laser deterioration detection, bank function (4 banks), differential function

Indications Judgement indicators: HIGH (orange), PASS (green), LOW(orange), 11-segment main display (red),

11-segment sub-display (orange), laser ON (green), zero reset (green), enable (green), menu (green),

HIGH threshold (orange), LOWthreshold (orange)

Power supply voltage 10 to 30 VDC, including 10%ripple (p-p)

Power consumption 3,000 mWmax. (at 24 VDC: 125 mA max., at 12 VDC: 250 mA max.)

Ambient temperature Operating: 0 to 50 °C, Storage: −15 to 70 °C (with no icing or condensation)

Ambient humidity Operating and storage: 35%to 85%(with no condensation)

Dielectric strength 1,000 VAC, 50/60 Hz for 1 min.

Vibration resistance (destruction) 10 to 150 Hz, 0.7-mm double amplitude, 80 min. each in X, Y, and Z directions

Shock resistance (destruction) 300 m/s

2

3 times each in six directions (up/down, left/right, forward/backward)

Degree of protection IEC60529, IP40

Connection method Prewired (standard cable length: 2 m)

Weight (packed state) Approx. 200 g (main unit only: Approx. 135 g)

Materials Case: PBT (polybutylene terephtahalate), Cover: Polycarbonate, Display: Methacrylic resin,

Button: Polyacetal, Cable: PVC

Accessories Instruction sheet

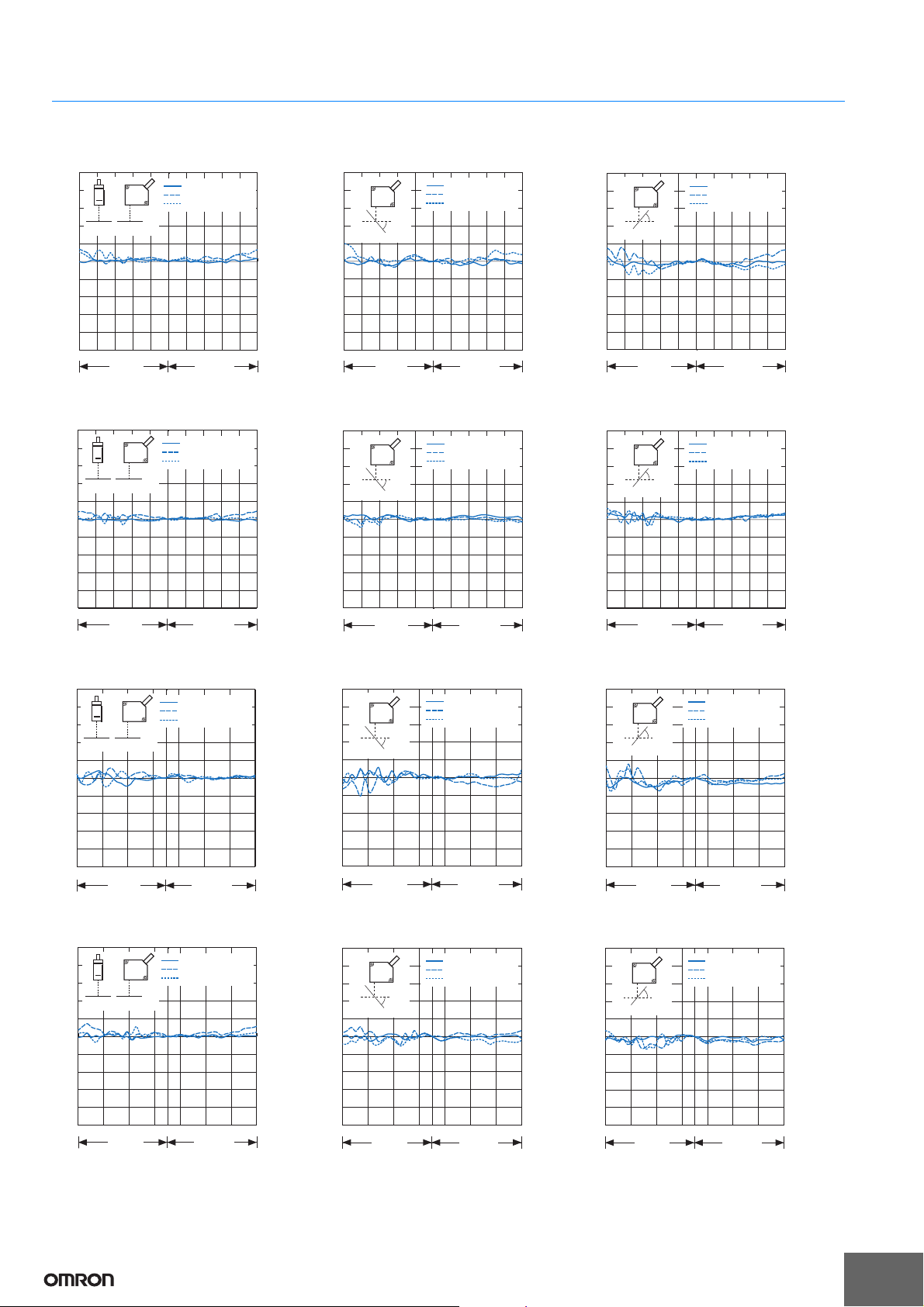

Item Model ZX2-CAL

Applicable Amplifier Units

ZX2-LDA11, ZX2-LDA41

Current consumption 12 mA max. (supplied from the Smart

Sensor Amplifier Unit)

Ambient temperature Operating: 0 to +50°C, storage: -15 to

+70°C (with no icing or condensation)

Ambient humidity Operating and storage: 35%to 85%

(with no condensation)

Connection method Connector

Dielectric strength 1,000 VAC, 50/60 Hz for 1 minute

Vibration resistance

(destruction)

10 to 150 Hz, 0.7-mm double amplitude,

80 minutes, each in X,Y,and Z directions

Shock resistance

(destruction) 300 m/s

2

3 times each in six directions

(up/down, left/right, forward/backward)

Materials Case: ABS, Display: Methacrylic resin

Weight (packed state) Approx. 50g

(Calculating Unit only: Approx. 15g)

Accessories Instruction sheet

Item Model ZX2-SF11

Power supply voltage

10 to 30 VDC ±10%(including 10%ripple (p-p))

(Supplied from Sensor Amplifier.)

Power

consumption

720 mWmax. (at 24 V: 30 mA max., at 12 V: 60 mA max.)

(Not including Sensor Amplifier current consumption or

output current

Applicable Amplifier Units

ZX2-LDA

@@

(Production after November 2013)

Applicable Amplifier

Unit versions

Sensor Amplifier Unit version: V1.330 or higher

(The Sensor Amplifier version is shown on the sub-digital

display when the power of the Sensor Amplifier is turned ON.)

Max. No. of Amplifier

Units 5

Commu-

nications

functions

Port RS-232C (9-pin, D-Sub connector)

Communications method

Full duplex

Synchronization method

Start/stop synchronization

Transmission code

ASCII

Baud rate

38,400 (at shipping)/9,600 bps switchable

Data bit length 8bits

Parity check None

Stop bit length 1 bit

Data

delimiter

Receiving

CR or CR + LF is automatically recognized.

Sending

CR + LF fixed

Indicators

Power supply: green, Sensorcommunications: green, Sensor

communicationserror:red,Externalterminalcommunications:

green, External terminal communications error: red

Protective circuits

Power supply reverse polarity protection

Ambient temperature

Operating: 0 to 50°C, storage: -15 to 60°C

(with no icing or condensation)

Ambient humidity Operating and storage: 35%to 85%

(with no condensation)

Insulation resistance 20 MΩmin. (at 500 VDC)

Dielectric strength 1,000 VAC, 50/60 Hz for 1 min,

Leakage current: 10 mA max.

Materials

Case: PBT (polybutylene terephthalate), Cover: Polycarbonate

Accessories Instruction sheet, 2 clamps