(2/2)

Type

Connection method

Supply voltage

Power consumption

Control output

Timer

Timer time

Differential detection mode

Fine positioning

Mutual interference

prevention

I/O settings

Response time

Advanced, twin-output models

Prewired

E2C-EDA11

E2C-EDA41

Separate

connector

*

1

E2C-EDA6

E2C-EDA8

Advanced, external-input models

Communication unit

connection model *3

E2C-EDA0

ー

ー

Output setting (channel 2 output,

area output, self diagnosis output,

or disconnection output)

External input setting (teaching

method, fine positioning, zero reset,

or synchronous detection)

Output setting

(2CH output)/area output

/self-diagnosis output)

Prewired

E2C-EDA21

E2C-EDA51

Separate

connector

*

1

E2C-EDA7

E2C-EDA9

12 to 24 VDC±10% ripple(p-p) 10%max.

NPN

PNP

1,080mW max. (45mA max. at 24 VDC)

Open collector (26.4 VDC max.);

Load current: 50mA max.; residual voltage: 1 V max.

OFF, OFF-delay, or one-shot

1 ms to 5 s

Supported

Supported

Supported (intermittent oscillation system)

*2

response time = (number of Amplifier Units + 1)×15 ms

The number of setting : 2 to 5

Power supply

connector

Protector seal

Setting the Mode

Key Operations

Reading Displays

SET

Mode Main display (red) Sub-display (green)

RUN

(See note.)

SET Select to set detection conditions, to teach the threshold value, to set initializing, etc.

Mode Description

RUN

Note: The information that appears on the displays can be set using the display switch

function. Refer to 5. Detailed Settings.

Note: Refer to 4.Basic settings for the setting method.

UP key Increases the threshold. Depends on the setting.

・Executes teaching.

・Changes the setting forward.

Depends on the setting.

・Executes teaching.

・Changes the setting in reverse.

Decreases the threshold.

Depends in the MODE key setting (See note.)

・

Executes positioning teaching(default setting).

・

Teaching with and without a workpiece.

・Executes fine positioning.

・Executes a zero reset.

Switches the function to be set on the

display.

DOWN key

MODE key

Key Function

RUN mode SET mode

NO NC

Adjusting the sensitivity (as Required)

1

2

Setting the Operation Mode

●The setting method depends on the type of Amplifier Unit.

Twin-output model

Type Setting method

External-input model

NO(normally-open)

(default)

Selection Description

NC(normally-close)

RUNSET

Switch to RUN mode.

Tuning completed and previous display returns.

Main Display

Press the MODE key for at

least 3 seconds.

Fine positioning target value

FP

During fine

positioning

Progress bar

FP Display alternates

at a fixed interval.

①Lit when the output is ON.

Twin-output Models: Lit when the output for channel 1 is ON.

②Displays the detection level or the function name.

③Twin-output Models: Lit when the output for channel 2 is ON.

External-input Models: Lit when fine positioning is set.

④Displays supplemental detection information, the setting of a function, etc.

⑤Used to switch the mode.

⑥Twin-output Models: Used to select the channel to display or set.

External-input Models: Used to select normally-open or normally-close operation

⑦Used to change the display, set functions, etc.

●

Setting Errors

An error has occurred if one of the following display appears the progress bar is displayed.

Over Error

FP OVER

Switch to RUN mode

Bottom Error

FP BOTM

FP OFF

RUNSET

Flashes twice

Flashes twice

Timeout Error

FP TOUT

Flashes twice

+

Threshold

value

NEAR

TECH ----

Setting Thresholds

●Setting Errors

Switch to SET mode.

NEAR OVER

RUNSET

The sub-display will flash.

Teaching completed and previous display returns.

③No-workpiece Teaching

The threshold value that was set will flash twice.

Do one of the following and then repeat the operation

・Adjust the Head to decrease the detection level.

・Execute fine positioning.

Press the UP or DOWN key.

Press the UP or DOWN key for at least 3 seconds.

A detection level and a detection margin value are displayed.

3

5

When the UP or DOWN key is pressed to change the threshold value, the threshold

value will be displayed on the sub-display regardless of the display switch setting.

The information set for the display switch setting will return approximately 5 seconds

after the threshold is changed.

If DIFF (differential operation) is set for the detection method, the threshold value

will be set to half of the difference between the two measured values.

Threshold

value Threshold

value

2PNT

TECH

Detection

level Detection

level

----

Detection

margin value Detection

margin value

4

The information set for the display switch will be displayed.

(The default setting is for the detection level and the threshold value.)

Sensor head

ON point

Sensor head

Without a workpiece

Detection

level

Threshold

value

Adjust the threshold value with the UP and DOWN keys.

Increases the threshold value.

Decreases the threshold value.

Switch to SET

mode.

RUNSET

The sub-display

will flash.

②Teaching With and Without a Workpiece

①Positioning Teaching

Position a workpiece

and press the

UP or DOWN key.

Switch to RUN mode.

RUNSET

Manually Setting Threshold Values

PPT Threshold

value

Switch to SET

mode.

RUNSET

The threshold

value that was set

will flash twice.

Teaching completed and

previous display returns.

Press the UP or DOWN

key for at least 3 seconds.

Please observe the following precautions for safe use of the product.

1) Do not use the Amplifier Unit in environments subject to flammable or explosive gases.

2) Do not use the Amplifier Unit in environments subject to exposure to water, oil, chemicals, etc.

3)

Do not attempt to disassemble, repair, or modify the Amplifier Unit in any way.

4) Do not apply voltages or currents that exceed the rated ranges.

5) Wire the Amplifier Unit correctly, e.g., do not reverse the polarity of the power supply.

6) Connect the load correctly.

7) Do not short both ends of the load.

8) Do not use the Amplifier Unit if the case is damaged.

9) When disposing of the Amplifier Unit, treat it as industrial waste.

1. Ratings and Specifications

3. Basic Operating Information

Please observe the following precautions to prevent failure to operate, malfunction, or undesirable

effects on product performance.

1) Wire the Amplifier Unit separately from power supply or high-voltage lines. If the Amplifier Unit

wiring is wired together with or placed in the same duct as high-power lines, inductive noise may

cause operating errors or damage the Amplifier Unit.

2)

Do not extend the cable to more than 30 m, and use a wire size of 0.3 mm2or larger for the extension cable.

3)

The Amplifier Unit is ready to operate 200 ms after the power supply is turned ON. If the Amplifier Unit and load are

connected to power supplies separately, turn ON the power supply to the Amplifier Unit first.

Please turn on the power supply at the same time when you connecting use the Amplifier Units with cables.

Mutual interference prevention might not operate normally or mobile console might not be able to be used

when the difference between connected Amplifiers at the power supply turning or time is 30ms or more.

4) Always keep the protective cover in place when using the Amplifier Unit.

5)

When using a connector model, place a protective label (provided with the E3X-CN series connectors) on

the power supply connecting terminals that are not used, to prevent electric shock or short circuit.

6)

When using a communication unit connection model, place a protective cap

(provided with the E3X-ECT/CRT communication unit ) on the connecting

terminals that are not used, to prevent electric shock or short circuit.

7) When connecting or removing the communication unit connection

model, make sure that the connecting part is not slanted.

8)

Always turn OFF the power supply before connecting or disconnecting Sensor

Heads, joining or separating Amplifier Units, or adding Amplifier Units.

9)

If the data is not written to the EEPROM correctly due to a power failure or

static-electric noise, initialize the settings using the keys on the Amplifier Unit.

10) Using a Mobile Console(The communication unit connection

model cannot use a mobile console.)

Use the E3X-MC11-SV2 Mobile Console for the E2C-EDA-series Amplifier Units. Other Mobile

Consoles, such as the E3X-MC11,E3X-MC11-S, cannot be used.

11) Optical communications are not possible with an E3X-DA-N Amplifier Unit.

12)

Depending on the application environment, time may be required for the detection level to stabilize after the power supply is turned ON.

13) Output pulses may occur when the power is interrupted and so turn OFF the power to the load or

load line before turning OFF the power to the Sensor.

14) The Sensor Head of E3C-LDA cannot be used. It may damage, if it connects.

15)

When mutual interference prevention is confirmed, the execution time of fine positioning becomes long.

16) Do not use thinners, benzine, acetone, or kerosene for cleaning the Amplifier Unit.

17)

A disconnection output may be rarely outputted under the large installation conditions of a detection level also except disconnection.

■Confirming the Package Contents

・Amplifier Unit: 1 ・Instruction Sheet (this sheet): 1

Refer to 5.Detailed Settings Detection Method

Operation/Storage: 35 to 85 %RH (with no condensation)

10 to 55 Hz, 1.5mm double amplitude 2 hours each in X, Y, and Z directions

The mode is set using the SET/RUN switch. Set this switch according to the operation to be performed.

Teaching is performed in the state where a workpiece is in an ON

point. A detection level is set up as a threshold value.

Teaching is performed in the state where there is no workpiece.

It sets up about +6% of a detection level as a threshold value. It is stabilized and a very small

difference can be detected.

If DIFF(differential operation) is set for the detection method, the threshold value will be set

to the minimum value above the detection level without a workpiece that will enable stable

detection.

Teaching can be performed twice, once with and once without a workpiece, and the value between

the two measured values is set as the threshold.

In the case of a 【Method 2】, please check that a setup of a "MODE key setting" function is

[2PNT](teaching with and without a workpiece) in advance. Refer to 5.Detailed Settings.

The operation keys are used to switch the displays and set detection conditions. The functions of the

keys depend on the current mode.

The information displayed on the main display and sub-display depends on the current mode. For the

default settings, the RUN mode displays will appear when the power supply is turned ON for the first time.

Select either normally-open or normally-close operation.

Fine positioning can be used to adjust the detection level that is currently being received to the fine

positioning target value (1,500). Before executes fine positioning, always secure the workpiece and

Sensor Head and be sure that the detection level is stable.

Confirm that the MODE key setting is FP(fine positioning) in advance.

The default is "PPT" (positioning teaching). Refer to 5. Detailed Settings.

Teaching cannot be performed when DIFF(differential operation) is set as the detection

method.

4. Basic Settings

The output will turn ON when the detection level is above the threshold.

If DIFF (differential operation) is set for the detection method, the output will turn

ON when an edge is detected.

Set as the operation mode in SET mode.

Refer to 5. Detailed Settings.

Set using the operation mode selector.

The output will turn ON when the detection level is below the threshold.

If DIFF (differential operation) is set for the detection method, the output will turn

OFF when an edge is detected.

●

Clearing method

【Method 1】 【Method 2】

【Method 1】 【Method 2】

PPT Threshold

value

Switch to RUN

mode.

RUNSET

The threshold

value that was set

will flash twice.

Teaching completed and

previous display returns.

Press the MODE key for

at least 3 seconds.

●

Setting method

●

Setting method

●

Setting method

●

Setting method

In the case of a【Method 2】, please check that a setup of a "MODE key setting" function is

[PPT](positioning teaching) in advance. Refer to 5.Detailed Settings.

Workpiece Workpiece

TECH ----

Switch to RUN

mode

RUNSET

2PNT

●

Setting method

A threshold value can be set manually.

A detection margin

level can check the

margin of the present

detection level to the

variation in a detection

level with a workpiece.

A detection margin

level can check the

margin of the present

detection level to the

variation in a detection

level with a workpiece.

Remove the

workpipece and

press the UP or

DOWN key.

The threshold

value that was set

will flash twice.

The threshold

value that was set

will flash twice.

Remove the

workpiece and

press the MODE

key for at least 3

seconds.

The sub-display will

flash.

Position a workpiece

and press the MODE

key for at least 3

seconds.

Teaching completed and

previous display returns.

Teaching completed and

previous display returns.

Display alternates

at a fixed interval.

Display alternates

at a fixed interval.

Groups of 1 to 2 Amplifiers: -10

℃

to 55

℃

Groups of 3 to 5 Amplifiers: -10

℃

to 50

℃

Groups of 6 to 16 Amplifiers: -10

℃

to 45

℃

Groups of 17 to 30 Amplifiers: −10°C to 40°C

Combination with EDR6-□

Groups of 3 to 4 Amplifiers: -10

℃

to 50

℃

Groups of 5 to 8 Amplifiers: -10

℃

to 45

℃

Groups of 9 to 16 Amplifiers: -10

℃

to 40

℃

Groups of 17 to 30 Amplifiers: −10°C to 35°C

●

Setting Errors

An error has occurred if any of the following is display when the UP or DOWN key is pressed

without a workpiece.

Do one of the following and then repeat the operation

・Adjust the Head to decrease the detection level.

・Execute fine positioning.

Do one of the following and then repeat the operation

・Adjust the Head to increase the detection level.

・Execute fine positioning.

2PNT OVER

2PNT LO

Flashes twice

Flashes twice

Flashes twice

A zero point is registered. (zero reset)

Switch to RUN mode.

This level difference

is judged.

This level difference

is judged.

Zero reset execution Zero reset execution

Switch to RUN mode.

Zero reset is

cleared.

RUNSET RUNSET

+

Detection

level

Threshold

value

Detection

level

Threshold

value

Zero reset cannot be performed when DIFF(differential operation) is set as the

detection method.

The standard position of a workpiece is registered as "detection level =0", and it judges to the amount of

change of a detection level.When there is change of the standard position of a workpiece or change of

the detection level by the operating condition, detection stabilized when performing zero reset can be

performed.

Execution of zero reset shifts to "0" the detection level currently displayed on the main display. The

threshold value currently displayed on the sub display is not shifted.

Please set "a MODE key settings" as "0RST" in advance.The default is "PPT" (positioning teaching).

Refer to 5.Detailed Settings.

●

Setting method

●

Clearing method

Workpiece Next workpiece

© OMRON Corporation 2004 All Rights Reserved.

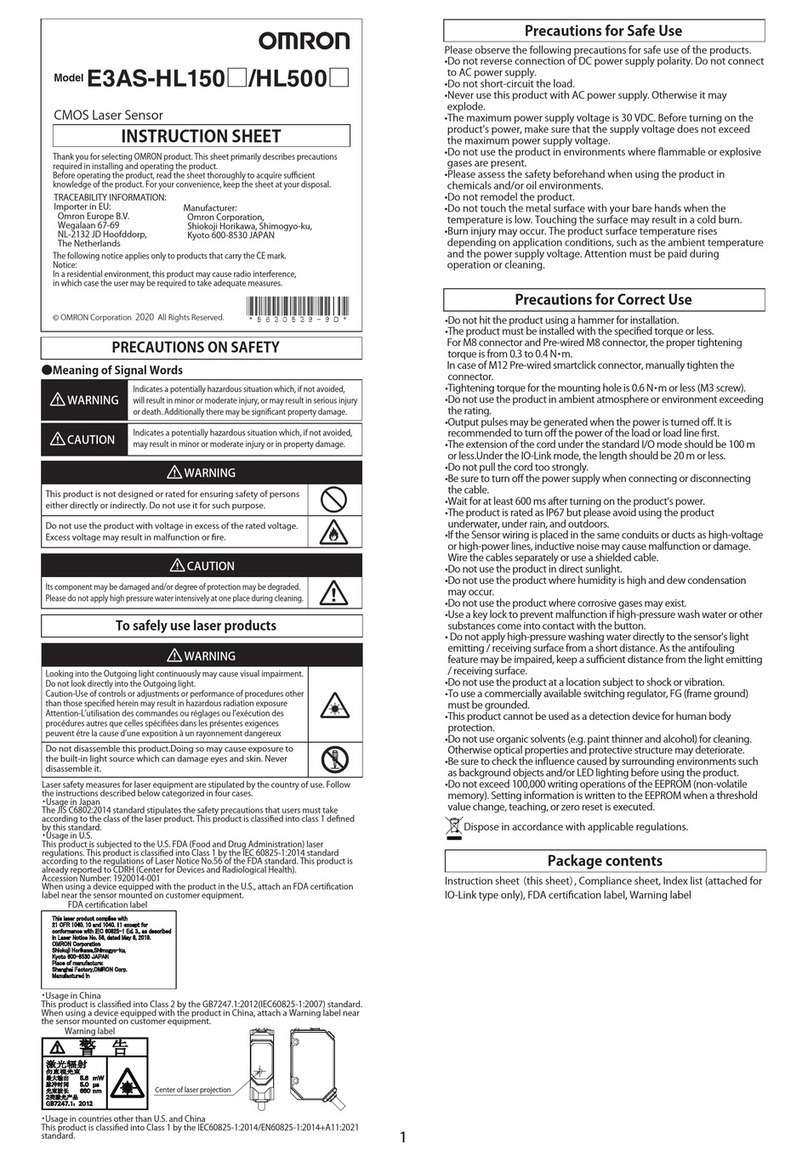

INSTRUCTION SHEET

Proximity Sensors with Separate Digital Amplifier

Amplifier Units

E2C-EDA□□

PRECAUTIONS FOR SAFE USE

PRECAUTIONS FOR CORRECT USE

Operation

Storage

Model

number

Ambient

temperature

Displays the detection level,* function name,

or other information depending on the key

operation.

*The detection level will be displayed even if

DIFF (differential operation) is set for the

detection method.

For the default setting, the current

detection level will be displayed.

The change in the detection level will be

displayed when DIFF (differential

operation) is set for the detection mode.

Displays threshold value* or the setting of the

function displayed on the main display depending

on the key operation.

*The threshold value for the change in the

detection level will be displayed if DIFF (differential

operation) is set for the detection method.

For the default setting, the current threshold

value will be displayed.

The threshold value for the change in the

detection level will be displayed if DIFF

(differential operation) is set for the detection

method.

A progress bar will appear

on the sub-display one

digit at a time.(Release the

MODE key when the

progress bar appears.)

It is the error for the present workpiece position having been too far to the

fine positioning possible range. It is adjusted by the maximum sensitivity.

The fine positioning possible range is 50 to 150% of measurement range.

It is the error for the present workpiece position having been too near to the

fine positioning possible range. It is adjusted by the minimum sensitivity. The

fine positioning possible range is 50 to 150% of measurement range.

An error occurred because the detection level was not stable during fine

positioning.

Make sure that the workpiece and Sensor Head are secured and retune

the sensitivity.

Hold down the MODE key and press the DOWN key for at least 3 seconds.

Note: Press the DOWN key right after pressing the MODE key.

The sub-display will flash twice and fine positioning will be cleared.

Press the MODE key for at

least 3 seconds.

The display of a detection

level is fixed.

The DOWN key is pushed 3

seconds or more, pushing

the MODE key. Press the

DOWN key right after

pressing the MODE key.

Zero reset is

performed and a

detection level is

shifted to "0."

UP

SET RUN

1 2

DOWN MODE

NO NC

①Operation indicator

E2C

③Twin-output Models : Operation indicator for channel 2

External-input Models : Fine positioning indicator

⑥Twin-output Models : Channel selector

External-input Models : Operation mode selector

②Main display (red)

④Sub-display (green)

⑦Operation keys

⑤SET/RUN switch

2. Nomenclature

*1: When using individually or as a master, obtain the E3X-CN21 Master Connector (4-conductor), and when

using as a slave, obtain the E3X-CN22 Slave Connector (2-conductor). Either Connector can be used.

*2: Communications are disabled if SHS is selected for the detection mode, and the communications functions

for mutual interference prevention and the Mobile Console will not function.

*3: Connectable communication units are E3X-ECT (30 units max.) and E3X-CRT (16 units max.). For details

on names of each part and settings, refer to items of the twin output model.

−

20

℃

to 70

℃(withnoicingorcondensation)

Ambient humidity

Vibration

Select for actual detection operation or set the following: Manual adjustment of

thresholds, Positioning teaching, Teaching with and without a workpiece, Fine

positioning, Zero reset, or Key lock

The following notice applies only to products that carry the CE mark:

Notice:

This is a class A product. In residential areas it may cause radio

interference, in which case the user may be required to take adequate

measures to reduce interference.

Manufacturer:

Omron Corporation,

Shiokoji Horikawa, Shimogyo-ku,

Kyoto 600-8530 JAPA N

Ayabe Factory

3-2 Narutani, Nakayama-cho,

Ayabe-shi, Kyoto 623-0105 JAPA N

TRACEABILITY INFORMATION:

Representative in EU:

Omron Europe B.V.

Wegalaan 67-69

2132 JD Hoofddorp,

The Netherlands

Protective Cap

Power Supply

Connecting Terminal

*4012133- 6A*