6

Introduction

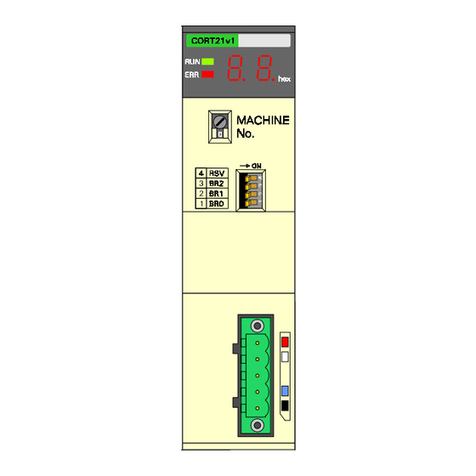

E3NW-CRT

User’s Manual

Introduction

Safety Precautions

Do not touch the terminals or disassemble the Unit and touch any internal compo-

nents while power is being supplied. Do not supply power while the cover is open.

Doing so may result in electric shock.

Do not attempt to disassemble, repair, or modify any Units. Any attempt to do so

may result in electric shock.

Provide safety measures in external circuits, i.e., not in the Sensor Communications

Unit, in order to ensure safety in the system if an abnormality occurs due to malfunc-

tion of the PLC or another external factor affecting the PLC operation. Not doing so

may result in serious accidents.

(1) Emergency stop circuits, interlock circuits, limit circuits, and similar safety mea-

sures must be provided in external control circuits.

(2) The PLC will turn OFF all outputs when its self-diagnosis function detects any

error or when a severe failure alarm (FALS) instruction is executed. As a coun-

termeasure for such errors, external safety measures must be provided to

ensure safety in the system.

(3) The outputs from the Sensor Communications Unit may remain ON or OFF due

to deposition or burning of the output relays or destruction of the output transis-

tors. As a countermeasure for such problems, external safetymeasures must be

provided to ensure safety in the system.

(4) When the 24-VDC output (service power supply to the PLC) is overloaded or

shortcircuited, the voltage may drop and result in the outputs being turned OFF.

As a countermeasure for such problems, external safety measures must be

provided to ensure safety in the system.

The CPU Unit will refresh I/O even in an operation-stopped state (PROGRAM

mode). Therefore, confirm safety when changing output bits allocated to the Sensor

Communications Unit, or words allocated to Special I/O Units or CPU Bus Units in

the CIO Area. Unexpected operation may occur in the loads connected to the Sen-

sor Communications Unit, Special I/O Units, or CPU Bus Units.

• Transferring the contents of the I/O memory areas to the CPU Unit with a Pro-

gramming Device

• Changing the present values with a Programming Device

• Force-setting/force-resetting any bit in memory with a Programming Device

• Transferring the contents of the I/O memory areas to the CPU Unit with a Memory

Card or EM File Memory

• Transferring the contents of I/O memory from another PLC or a host computer on

the network