Line Processing Instructions

and Quality History Management

●

Processes where processing is performed without stopping

● Production lines with a short tact time

●

Lines performing high-mix, high-volume production

Line Processing Instructions

and Quality History Management

●

Processes where processing is performed without stopping

● Production lines with a short tact time

●

Lines performing high-mix, high-volume production

Machine Control

●

Control of installations performing high-speed processing

● Control of conveyance installations

Machine Control

●

Control of installations performing high-speed processing

● Control of conveyance installations

Applications

and narrow-pitch mounting. Greater flexibility with mounting location and operating conditions allows use in a much wider range of applications.

High-speed Processing Comparable to ON/OFF-sensor Operation

●Auto Repeat Function

Communications are performed whenever a Tag

enters the communications range. Communications

are performed only once with the same Tag.

Antenna

Tag

●Tag Specification

The V670 communicates only with the Tags that

it communicated with previously or with the other

Tags, depending on the specification.

Antenna

If the Tag specification is for different Tags, the system will wait for

the Tag not yet communicated with before performing communications.

Tag previously

communicated with

Tag not yet

communicated with

●Repeat Input Trigger

Each time the rising edge of the input signal is detected, the

existence of a Tag is confirmed and communications are per-

formed. If there is no Tag, an error is generated.

Antenna

Tag

Photoelectric sensor, etc.

Controller's trigger input signal

High-speed movement

Tag

Antenna

Controller

(Synchronous sensor)

Trigger input

Coincidence output

Error output

Self-execution System

Previous System

Total processing time

Total processing time

Host communications

(command)

Tag

communications

Host communications

(response)

Discrimination

and instructions

Tag

communications

Discrimination

and instructions

Flow Control of Moving Objects

¥ RGV

¥ OHT

¥ Carts

¥ Sorters

*FeRAM: Ferroelectric RAM

The V670 Series performs high-speed data

communications with battery-free Tags. Reading

and writing of Tag data can be performed at speeds

allowing operation that seems like ON/OFF-sensor

operation. Even in production lines for small items

with short processing times for each process, the

communications time does not affect the tact time. It

is also now possible to handle more data in

processes where, until now, the amount of data has

been limited to reduce processing time.

Reliable Reading and Writing during Operation

A short communications processing time means that

data is read and written reliably without stopping the

Tags. This means that

reading and writing can be

performed while Tags and

Antennas are moving.

Even in cases where Tags

are mounted to moving

pallets, changes to con-

veyance control to allow

access are unnecessary.

Simplified conveyance

control contributes to cost

reductions in installations.

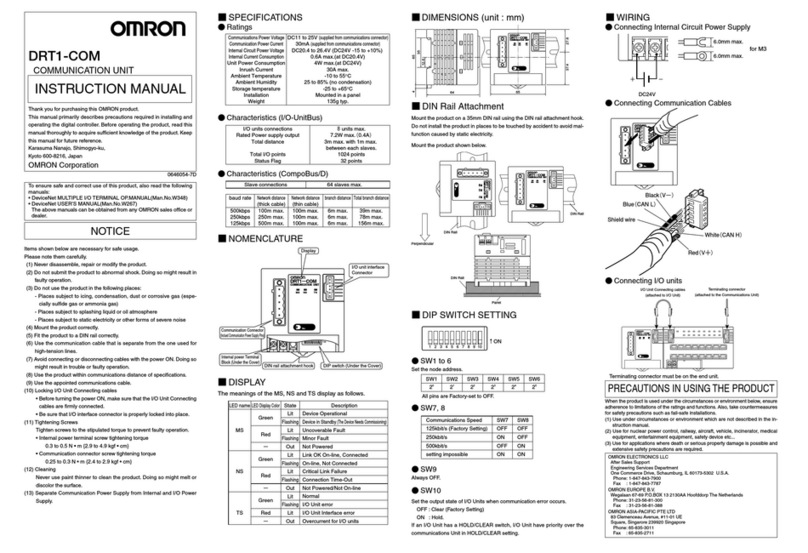

Communications Control with a Broad Range of Functions

V670-series products are equipped with a wide variety of communica-

tions functions that allow host devices to easily perform communica-

tions control for the Tags. Using the auto repeat and repeat input trig-

ger functions, repeated communications with several Tags can be per-

formed automatically with a single command. Using the tag specifica-

tion function, in cases where data

is written to individual Tags or

where more complex commands

are used, such as applications

where writing is performed after

reading, consideration of the tim-

ing with which Tags enter the

communications range is not re-

quired.

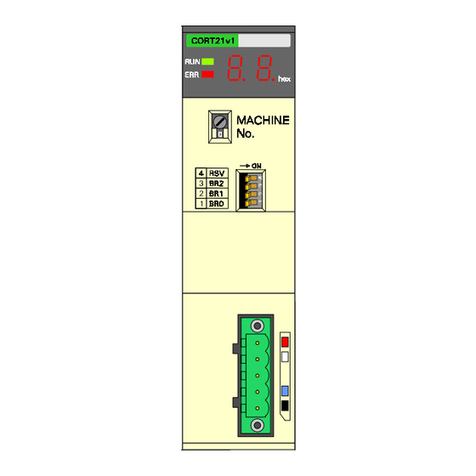

Simple Control and High-speed Response

Achieved with Self-execution Mode

In self-execution mode, the V670 repeats communications according

to previously set conditions, discriminates data, and turns ON output

accordingly. Control for simple sorting

can be performed just using the Control-

ler, without connecting a host device. The

time required for exchanging commands

and responses is eliminated, enabling the

time from communications to result out-

put to be significantly reduced. This

makes it possible to perform control for

lines and installations requiring high-

speed responsiveness.

Compact and Slim

The Compact Tags boast stream-

lined dimensions of 8 x 16 x t3.5 mm

(V670-D13F01). Tags both with and

without mounting holes are available

to suit the application. Also, the

mounting direction of the Tags can

be changed to allow, for example,

mounting on the top of narrow pallets

or on the side of slim pallets. Using

the V670-A81 Attachment makes it possible to mount Tags on

metal surfaces. The Compact Antenna boasts dimensions of M18

x 43 mm (V670-H51). The Antenna is mounted with the screws of

the Controller and so fine adjustment of the communications dis-

tance can be performed with ease.

Narrow-pitch Mounting

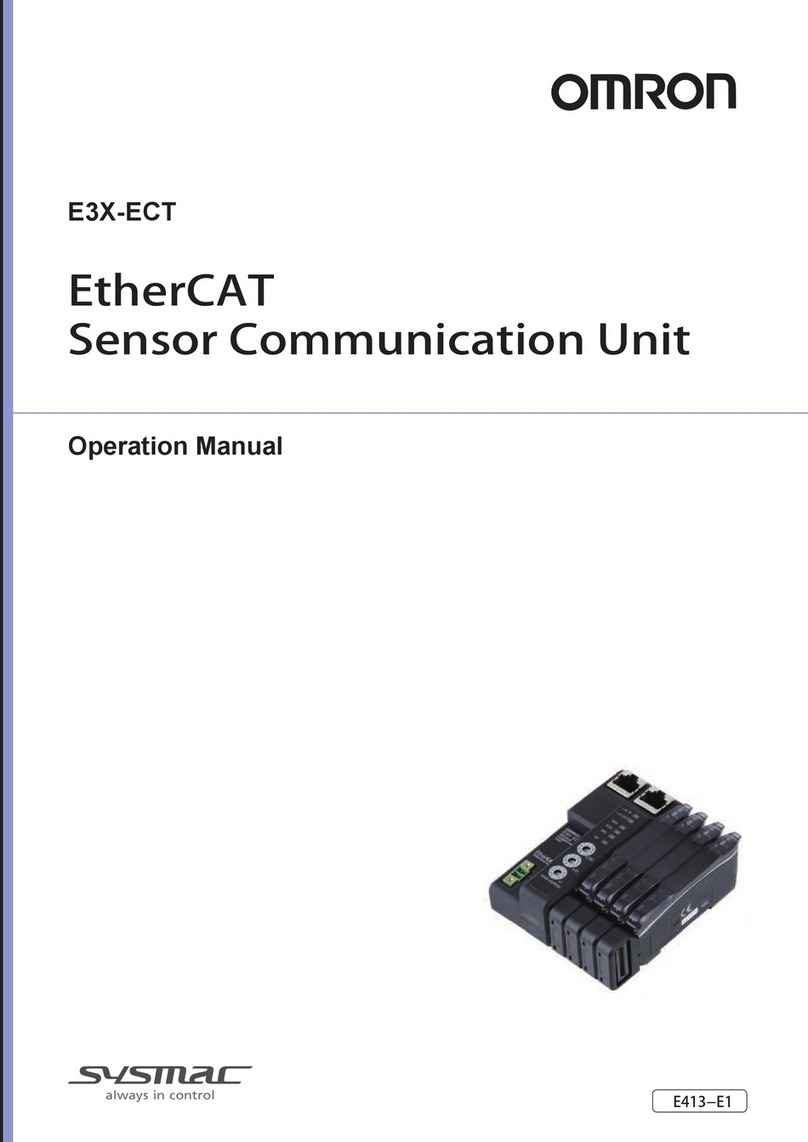

High Resistance to the Environment

The Tags and Antennas all conform to the IP67 (IEC) degree of

protection. In particular, the Compact Antenna (V670-H51Q)

uses a fluororesin case, and also conforms to IP67g (JEM; water

resistance and oil resistance). PPS resin, which is high in chemi-

cal resistance, is used in the case material for the Compact Tag

(V670-D13F01/D13F01H) enabling use in harsh environments

subject to chemicals, oils, and coolants.

Reduced Maintenance with No Battery or Tag Replacement

The V670 Series uses a FeRAM (ferroelectric RAM) with a serv-

ice life of 1,000 million times and so there is essentially no re-

striction on the memory service life. Even if the memory were ac-

cessed once a second, 24 hours a day, 365 days a year, it would

still last more than 10 years. In production lines for miniature de-

vices where pallets are reused with a high frequency, or in appli-

cations where data is frequently rewritten, maintenance such as

battery replacement or Tag replacement is unnecessary.

Tag V670-D13F03

Controller

V670-CD1D-V1

Antenna

V670-H11

OK

NG

Inspection, Selection, and Classification

of Food Products

Assembly Management for Miniature

Electronic Devices

Manufacture and Inspection of Electronic Components

and Secondary Batteries

Management of Components for Mounting Equipment

Applications

Communications Time

Approx. 5 ms (reading/writing 12 bytes)

Approx. 14 ms (reading/writing 128 bytes)

Combination of V670-H51 and V670-D13F01 (Perpendicular Mounting)

Maximum speed: 100 m/min (12 bytes)

Maximum speed: 36 m/min (128 bytes)

Combination of V670-H11 and V670-D13F03

Maximum speed: 360 m/min (12 bytes)

Maximum speed: 150 m/min (128 bytes)

16 mm

30 mm

Tag

Antenna

Water!

V670-D13F01