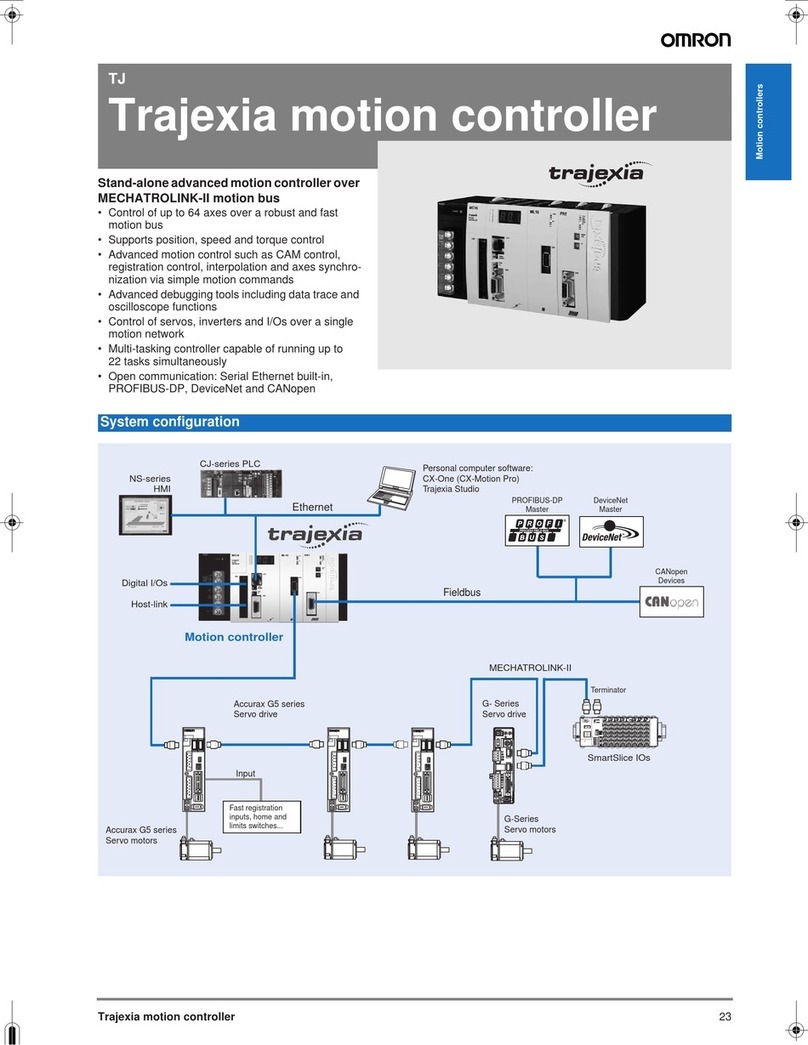

PC motion controller 81

MECHATROLINK-II, analog output module (AN2910)

MECHATROLINK-II repeater

MECHATROLINK-II servo drive interface unit

MECHATROLINK-II, frequency inverter interface units

Items Specifications Appearance

Model JEPMC-AN2910

Number of output

channels 2

Output voltage range -10Vto+10V

Max. allowable

load current ± 5 mA (2 kΩ)

Data format Binary, -32000 to +32000

Output delay time 1ms

Error ± 0.2% F.S. (at 25 °C), ± 0.5% F.S. (at 0 °C to 60 °C)

External power supply 24 VDC (20.4 VDC to 26.4 VDC), 120 mA max.

Weight 300 g

Items Specifications Appearance

Model JEPMC-REP2000

Communication type MECHATROLINK-II

Cable length Between controller and repeater: 50 m, after repeater: 50 m

Max. connected

stations Total stations on both sides of repeater: 30

(limited to the max. number of connectable stations of the controller (e.g., 21 stations for the MP2300 series)

Restrictions Between controller and repeater

- Total cable length ≤30 m: 15 stations max. including I/O and servo, etc.

- 30 m < total cable length ≤ 50 m: 14 stations max. including I/O and servo, etc.

After repeater:

- Total cable length ≤30 m: 16 stations max. including I/O and servo, etc.

- 30 m < total cable length ≤ 50 m: 15 stations max. including I/O and servo, etc.

Power supply 24 VDC, 100 mA

Weight 340 g

Dimensions (mm) 30x160x77 (HxWxD)

Item Details

Type JUSP-NS115

Applicable servo drive SGDH-@@@E models (version 38 or later)

Installation method Mounted on the SGDH servo drive side: CN10.

Basic

specifications Power supply method Supplied from the servo drive control power supply.

Power consumption 2 W

MECHATROLINK -II

communications Baud rate/transmission cycle 10 Mbps / 1 ms or more. MECHATROLINK-II communications

Command format Operation specification Positioning using MECHATROLINK-I/II communications.

Reference input MECHATROLINK-I/II communications

Commands: position, speed, torque, parameter read/write, monitor output

Position control

functions Acceleration/deceleration method Linear first/second-step, asymmetric, exponential, S-curve

Fully closed control Position control with fully closed feedback is possible.

Fully closed

system

specifications

Encoder pulse output in the

servo drive 5 V differential line-driver output (complies with EIA Standard RS-422A)

Fully closed encoder pulse signal A quad B line-driver

Maximum receivable frequency

for servo drive 1 Mpps

Power supply for fully closed

encoder To be prepared by customer.

Input signals in the

servo drive Signal allocation

changes possible Forward/reverse run prohibited, zero point return deceleration LS

External latch signals 1, 2, 3

Forward/reverse torque control

Internal functions Position data latch function Position data latching is possible using phase C, and external signals 1, 2, 3

Protection Parameters damage, parameter setting errors, communications errors,

WDT errors, fully closed encoder detecting disconnection

LED indicators A: Alarm, R: MECHATROLINK-I/II communicating

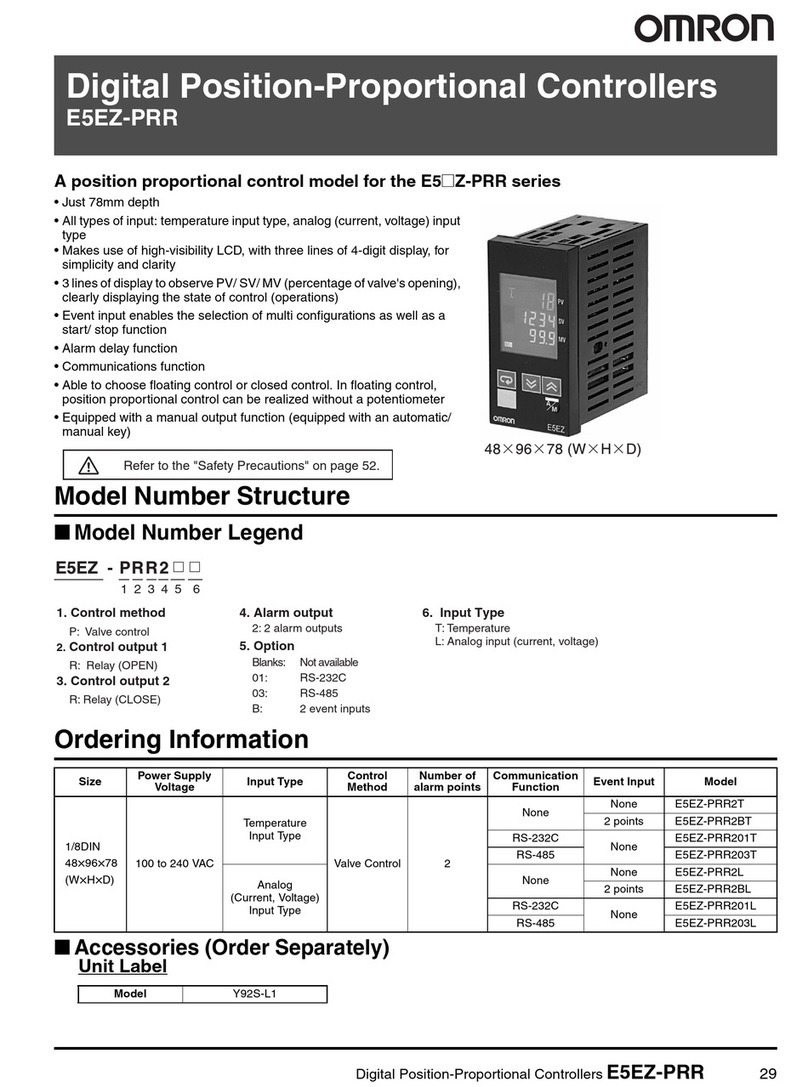

Item Details

Type SI-T/V7 SI-T

Applicable inverter CIMR-V7 / 3G3-MV

(firmware 5740 or newer) CIMR-G7 / CIMR-F7

(firmware 656x/for G7 / 4011 or newer for F7)

Contact your OMRON sales office for information about firmware compatibility

Installation method Mounted on the inverter

Power supply Supplied from the inverter

MECHATROLINK-II communications 10 MHz, 0.5 ms to 8 ms for MECHATROLINK-II

Operation Read and write registers, read monitors, inverter operation, speed reference, torque reference

(G7/F7 only).

Inputs and outputs The inputs and outputs in the inverter can be read and set by the MLII master

Connectors ML-II bus connector. DPRAM connector for the inverter

Switches Rotary switch for ML-II address (low byte)

Dip switch for: ML-II address (high bit). ML-II/ML-I selection. 17 byte/32 byte data length selection.

NS115

Y203-EN2-02-Katalog.book Seite 81 Mittwoch, 24. Mai 2006 2:22 14