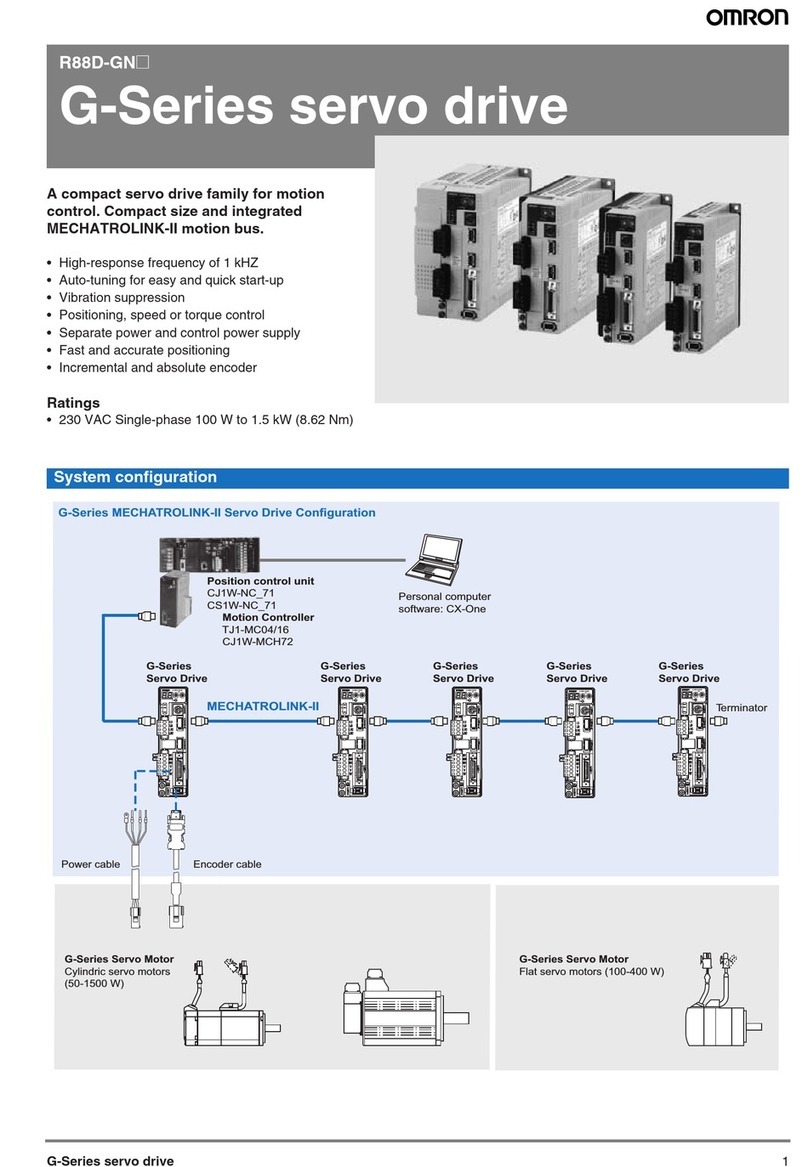

G-Series servo drive 3

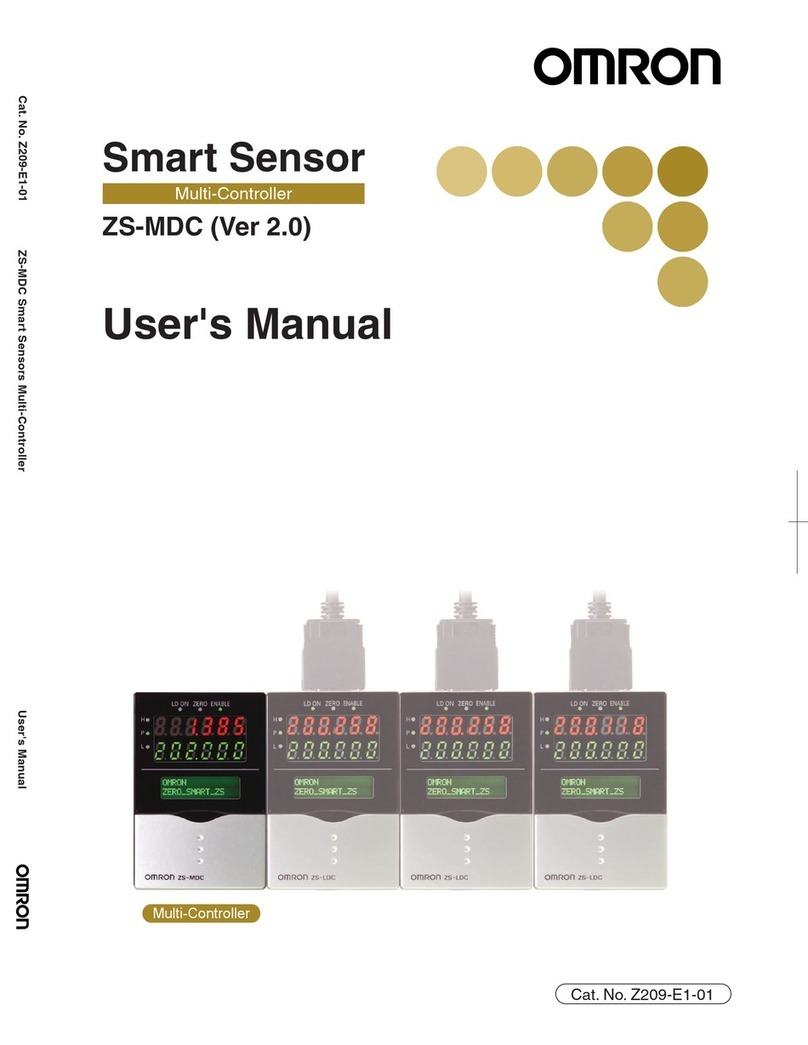

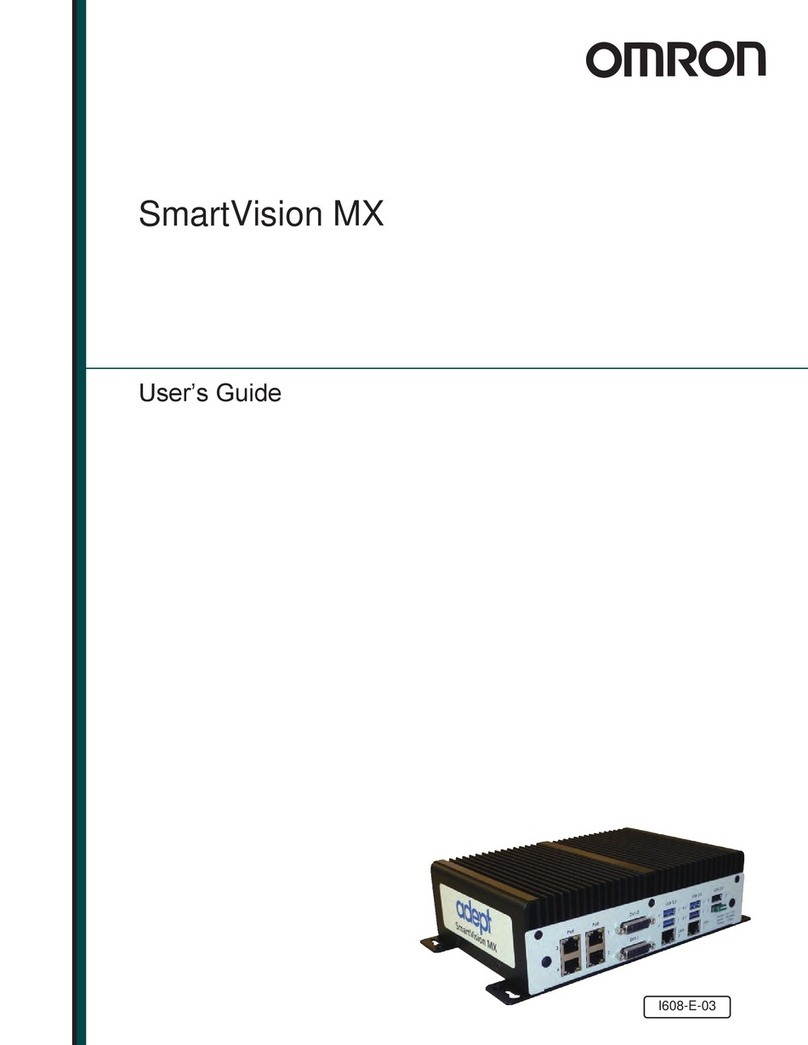

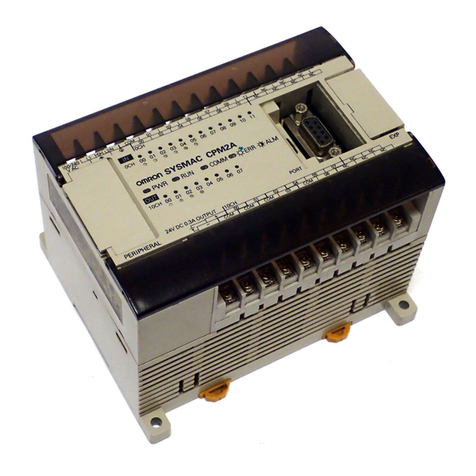

Servo drive part names

I/O signal

Sequence input signal Emergency stop, 3 external latch signals, forward/reverse torque limit, forward/reverse run prohibit, origin prox-

imity, 3 general-purpose inputs

Sequence output signal It is possible to output three types of signals: positioning completed, speed coincidence, rotation speed detection,

servo ready, current limit, speed limit, brake release and warning signal

Integrated functions

Communications

RS-232

communications

Interface Personal computer

Transmission rate From 2400 to 57600 bps

Functions Parameter setting, status display, alarm display (monitor, clear, history), servo drive data tracing function, test

run/autotuning operations, real time trace, absolute encoder setting, default values function

MECHATROLINK

communications

Communications protocol MECHATROLINK-II

Transmission rate 10 Mbps

Data length 17 bytes and 32 bytes

Functions Parameter setting, status display, alarm display (monitor, clear, history), default values function

Automatic load inertia detection Horizontal and vertical axis mode. One parameter rigidity setting.

Dynamic brake (DB) Operates when main power OFF, servo alarm, overtravel or servo OFF

Regenerative processing Built-in regeneration resistor in models from 750 W to 1.5 kW. External regeneration resistor optionally.

Overtravel (OT) prevention function Dynamic brake, disables torque or emergency stop torque during POT and NOT operation

Emergency stop (STOP) Emergency stop input

Encoder divider function Optional division pulses possible

Electronic gearing 0,01<Numerator/Denominator<100

Internal speed setting function 8 internal speeds

Protective functions Overvoltage, undervoltage, overcurrent, overload, regeneration overload, servo drive overheat

Analog monitor Ouput The actual servomotor speed, command speed, torque and number of accumulated pulses can be measured u-

sing an oscilloscope or other device.

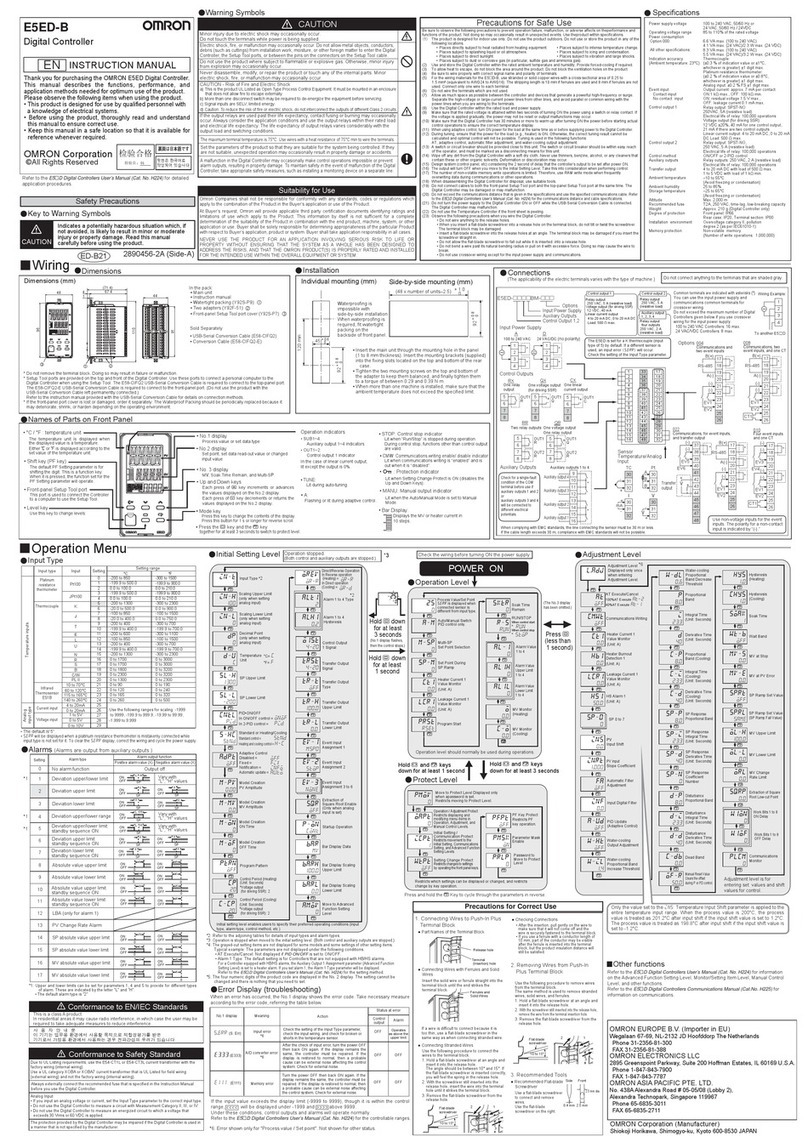

Panel operator Display functions A 2-digit 7-segment LED display shows the servo drive status, alarm codes, parameters, etc.

MECHATROLINK-II communications status LED indicator (COM)

Switches Rotary switch for setting the MECHATROLINK-II node address

Servo drive type R88D-GN@01H-ML2 02H-ML2 04H-ML2 08H-ML2 10H-ML2 15H-ML2

Applicable

servomotor

R88M-G@05030@/10030@20030@40030@75030@G1K020T@90010T@/ 1K030T@/

1K5@0T@

R88M-GP@10030@20030@40030@- - -

Control I/O connector (CN1)

Encoder connector (CN2)

G

IM

SP

COM

X10

3

2

1

0

ADR

AC SERVO DRIVE

X1

6

7

8

9

0

1

2

3

4

5

Display area

Rotary switches

for ML-II node address

ML-II comms

status LED indicator

RS-232 comms connector (CN3)

ML-II comms connector

(CN6A, CN6B)

Analog monitor check pins

(SP, IM, G)

Main-circuit power terminals

(L1, L2, L3)

Control-circuit power terminals

(L1C, L2C)

External regenerative resistor

connection terminals (B1, B2, B3)

Servomotor connection terminals

(U, V, W)

Protective ground terminals