www.multispanindia.com

Page - 1

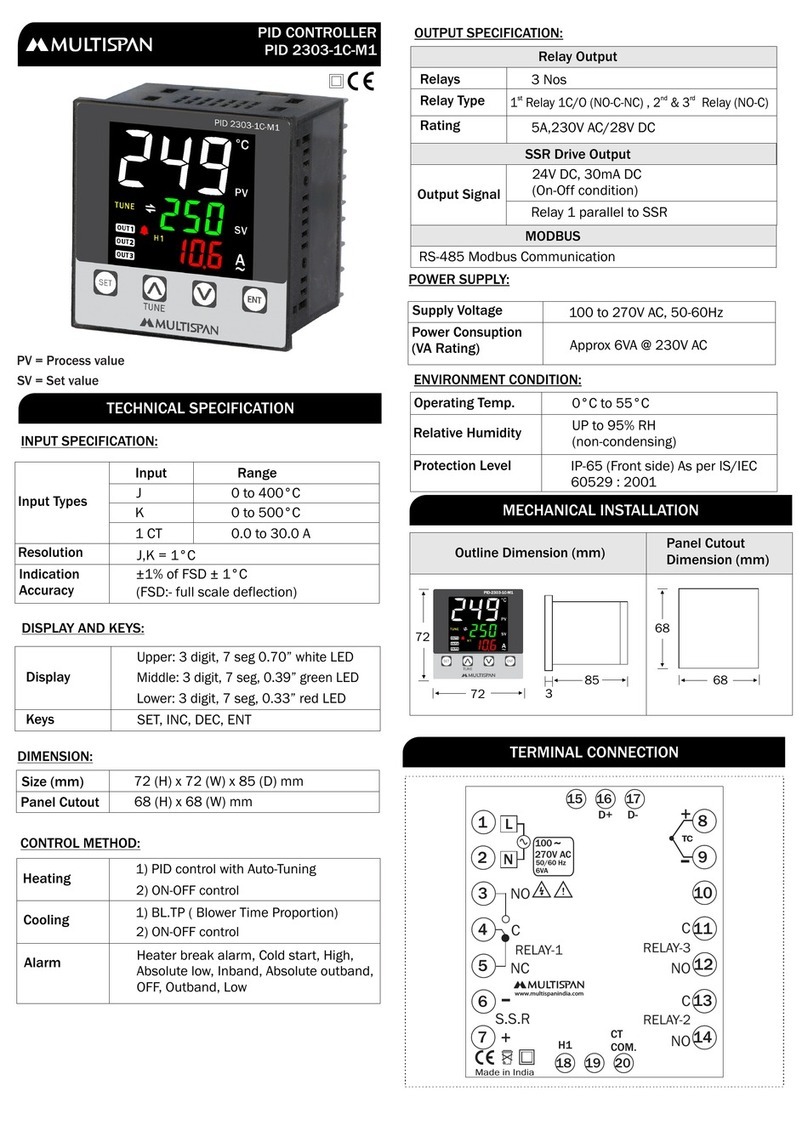

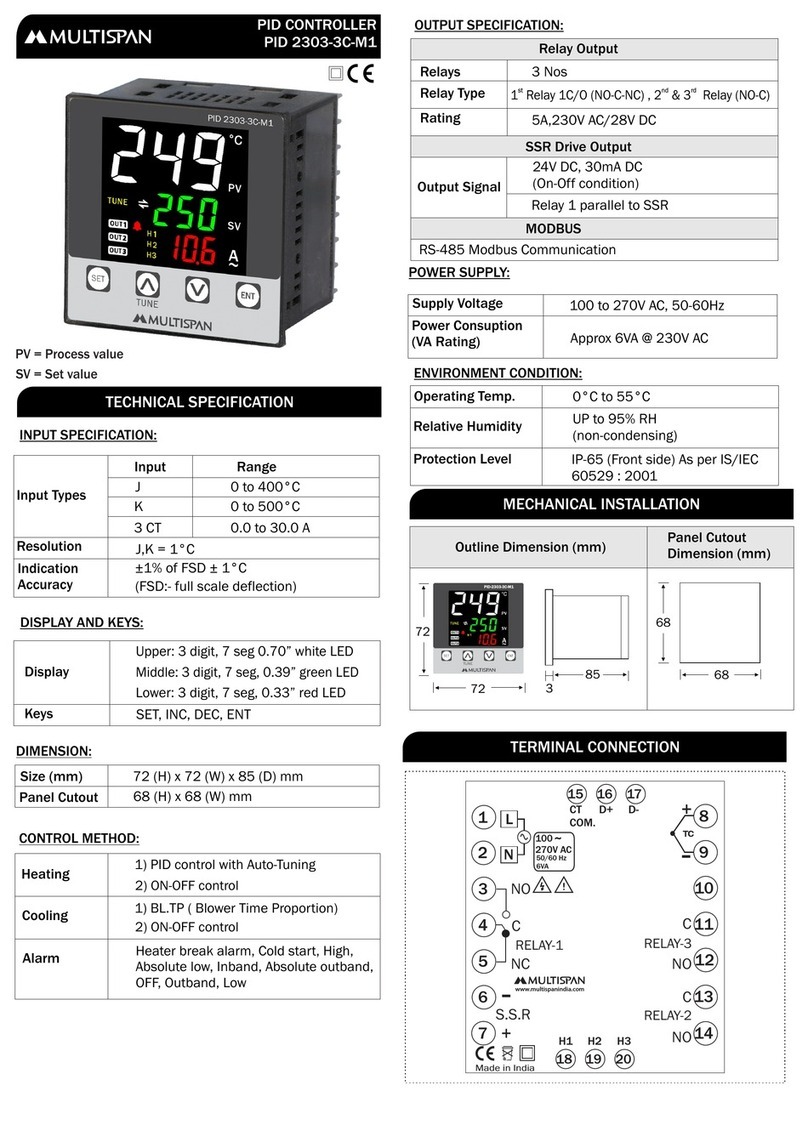

PID-2303-1C

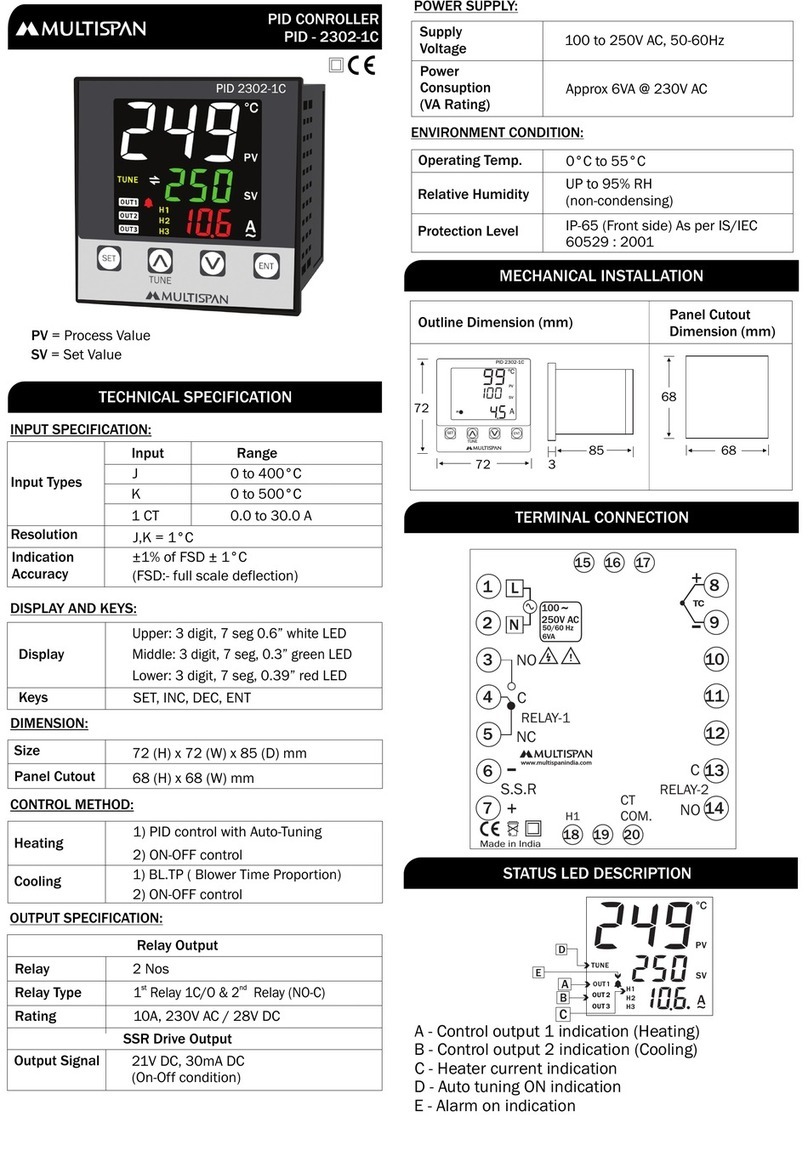

Technical Specification

UPPER : 4 Digit 7 seg 0.56”,White LED Display

MIDDLE : 4 Digit 7 seg 0.31”,GREEN LED Display

LOWER : 3 Digit 7 seg 0.39”,RED LED Display

PID/ ON-OFF (selectable)

Output

Power Supply

Operating

Temperature

Relative

Humidity

100 to 250V AC,50/60 Hz, Approx 6VA

0°C To 55°C

Up to 95% RH Non Condensing

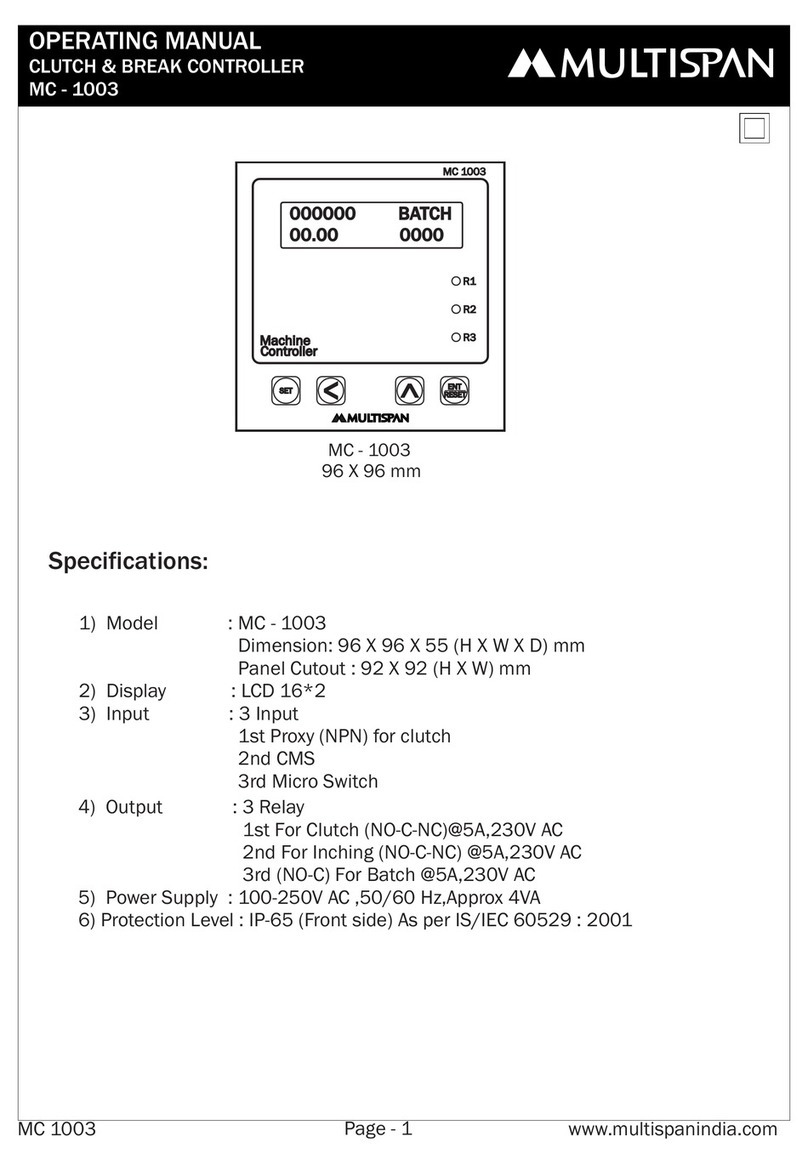

Model

Display

Size (mm)

Panel Cutout

Input

Control Action

72 (H) X 72 (W) X 85 (D) mm

68 X 68 mm

PID-2303-1C

J TYPE/ K TYPE, 1CT

3Relay, 1C/O Contact,5A, 230V AC S.S.R,

12V DC approx,30mA DC

1Relay-For Heating PID/ON-OFF Selection//S.S.R.

2Relay-For Blower TP/ON-OFF Selection

3Relay- For Alarm

Protection

Level

(As per request)

IP-65 (Front side) As per IS/IEC 60529 : 2001

OPERATING MANUAL

PID CONTROLLER

PID 2303-1C

PID-2303-1C

www.multispanindia.com

Page - 2

Temperature:J type: 0 to 400°C/ K type: 0 to 500°C

Ampere : 0.0 to 30.0 A (1 CT)

Range

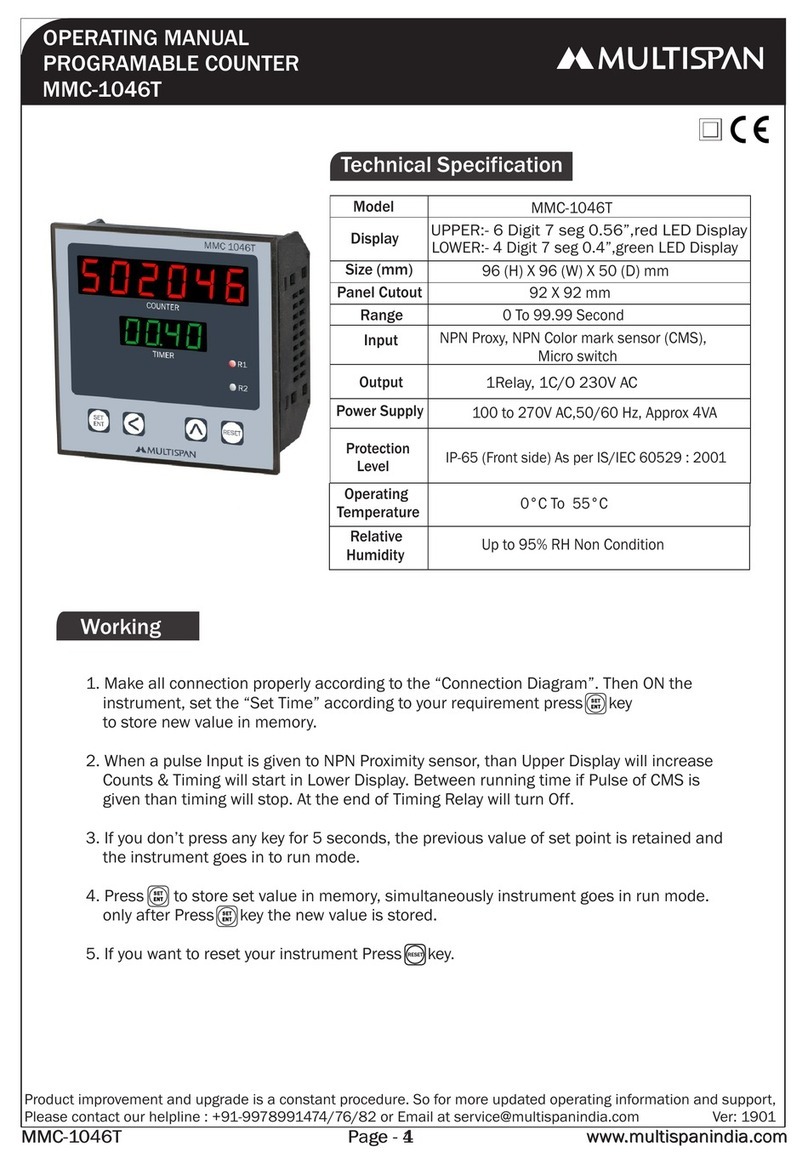

Working

Do all connection according to circuit diagram.

-Relay will be working as per following modes.

1) Control Mode PID: Relay turning ON/OFF according to heat requirement of the

machine.

2) Control Mode ON/OFF: Relay turns ON (and remains ON) when PV < SV. Relay turns

OFF when PV > SV. After this there may be overshoot depending on the thermal

inertia of the machine. When the PV < SV Minus HYS, Relay turns ON and heating

is resumed.

1) Cooling Time proportional Control action: Relay turns ON/OFF as per set Cycle time

and difference between PV and cooling SV.

2) Cooling ON/OFF control action: Relay is initially OFF. When PV > SV, Relay turns ON

and when PV < SV Minus HYS relay turns OFF.

1) Heater Break alarm: - If the current of the Heater < AMP SV (unhealthy condition)

then Relay turns ON and Upper Display will show , middle display will blinkhbr

showing . To manually turn off Relay, press ENT key 4 sec. Display will continue h

showing till the fault is rectified.hbr

2) Cold start (CS) alarm: Relay is initially OFF. When PV > Alarm SV, Relay turns ON.

When PV < Alarm SV MINUS HYS, Relay turns OFF.

3) High Alarm: Relay is initially OFF. When PV > Alarm SV, Relay turns ON , And remains

ON up to set Alarm time. Alarm is reset when temp. of PV < Alarm SV MINUS HYS.

This action will repeat whenever temp goes beyond Alarm SV.

4) Absolute -Low alarm: Relay is initially OFF. Now for once PV will go above SV, then

when PV < alarm SV, then alarm relay turns ON and remains ON up to alarm time.

Alarm is reset when temp. of PV > Alarm SV+HYS. This action will repeat

whenever temp. goes beyond Alarm SV.

5) In band alarm:- Two Alarm SV has to be defined . Between these two values, Relay

turns ON up to set Alarm time. Below the band & above the band relay turns OFF.

6) Absolute outband alarm:- Two Alarm SV has to be defined. Relay is initially OFF.

Once PV goes in between band value, after this if it goes below the band or above

the band, relay remains ON until alarm time.

HYS= Hysteresis

R1-Heating

R2-Cooling

R3-Alarms

Note:

1) If Sensor Connection is reverse, Display will show message.SRE

2) If Sensor is not connected, Display will show message.Open

3) Set 2 is relative to Set 1. (e.g. Set1=100°C and Set 2 = 15°C then Set 2 is

becomes “115”)

4) For Heater Break Indication, if any phase Heater breaks down than upper display will

indicate and middle display will show blinkingHBR h

P.V = Process value

S.V = Set value

Power On

All digit segment will be turned ON for 3 sec

Previous or default sensor input will be displayed for 2 sec

Process Value

Set Value