Model

V680-HAM42-PRT

PROFIBUSIDSlave

Observe the following precautions to ensure safe usage of the product.

1.

Installation and Storage Environment

・Do not use the Products in environments subject to oil.

2.

Installation and Removing

・Do not connect the power supply in reverse.

・Do not never use theAC power supply.

・Do not perform wiring incorrectly or short-circuit the load. Doing so may

result in rupture or damage from burning.

・Do not install the Products near any equipment that generates a large

amount of heat (such as heaters,transformers, and large-capacity

resistors).

・Make sure that all cable connectors with locking mechanisms are locked

before using the cable.

・If multipleAntennas are mounted near each other, communications

performance may decrease due tomutual interference. Refer to Reference

Data in Section 7 Appendices of User’s Manual and check to make sure

there is no mutual interference.

・To remove the Unit from DIN rail, catch a tool on the hook and gently

PRECAUTION FOR SAFE USE

1.

Installation and Storage Environment

Do not use or store the Product in the following locations.

・Locations subject to corrosive gases, dust, dirt, metal powder, or salt.

・Locations where the specified ambient temperature and ambient humidity

range is exceeded.

・Locations subject to extreme temperature changes that may result in

condensation.

・Locations where the product would be directly subjected to vibration or

shock exceeding specifications.

・Locations where liquid and foreign body might invade in this product

such as outside boards.

・Locationssubjecttocontactwithwater,oil,orchemicals.

2.

Installation

・The Products communicate with Tags using the 13.56-MHz frequency

band. Some transceivers, motors, inverters, and switching power

supplies generate noise that can affect communications with the Tags

and cause errors. If such devices are located near the Tags, always test

operation in advance to confirm whether the system will be affected.

・

Observe the following precautions to minimize the effects of normal noise.

(1)Ground all metal objects in the vicinity of the Products to 100Ωor

less.

(2)Do not use the Products near high-voltage or high-current lines.

・Always bundle the cables connected to the power supply terminals and

the ground terminal and connect the enclosed ferrite core

(ZCAT2032-0930 manufactured by TDK).

・Do not pull on the cables with excessive strength.

・Make sure that the ID Slave is provided with sufficient ventilation space.

・Please do not connect with the PROFIBUS connector excluding a

PROFIBUS cable.

・Turn OFF the Controller power supply before mounting or removing a

connector.

3.

Using

・Make sure the power supplied by the DC power supply unit is within the

rated power supply voltage (24 VDC +10%/−15%) before using the

Product.

PRECAUTION FOR CORRECT USE

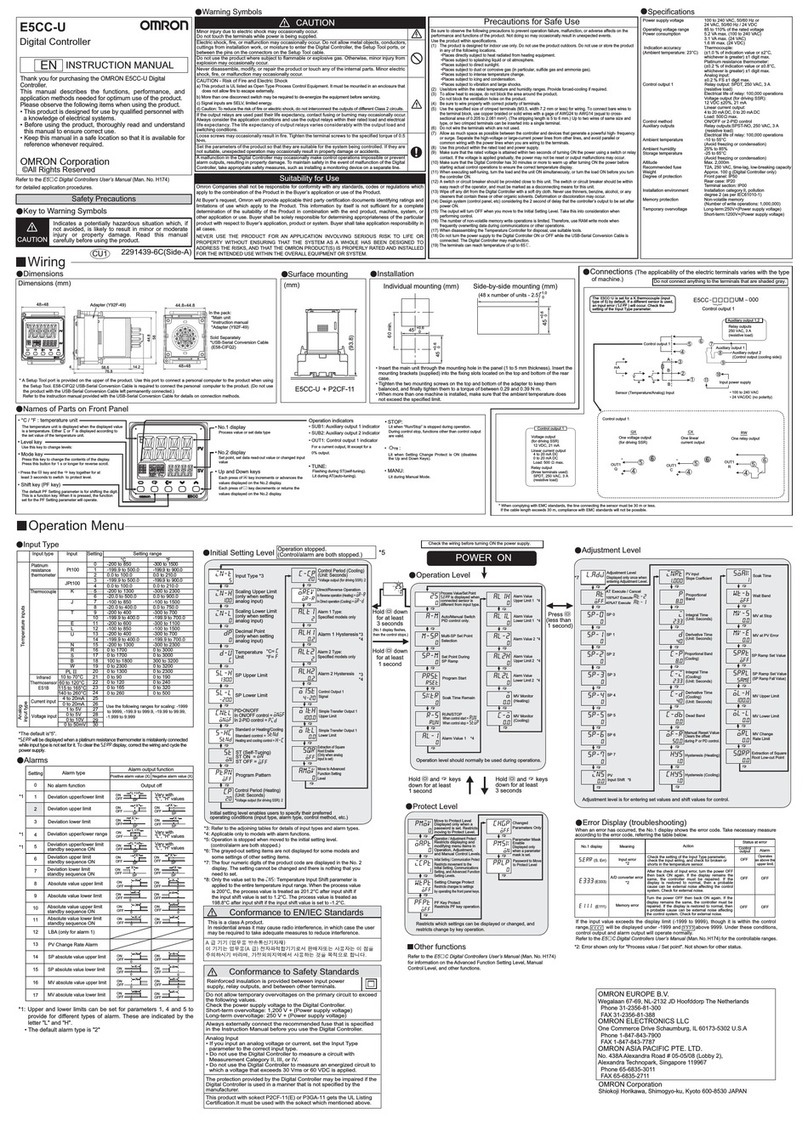

(Unit:mm)

・Node Address Switch

remove the Unit.

3.

Using

・Donotattempttodisassemble,repair,ormodifyanyProduct.

・Donotallowwaterorpiecesofwiretoenterfromopeningsinthe

case.Doingsomaycausefireorelectricshock.

・TurnOFFtheControllerpowersupplybeforemountingor

removinganAntenna.

・IfanerrorisdetectedinanyProduct,immediatelystopoperation

andturnOFFthepowersupply.ConsultwithanOMRON

representative.

4.

Cleaning

・DonotcleantheProductswithpaintthinner,benzene,acetone,or

kerosene.

5.

Disposing

・DisposeoftheProductsasindustrialwaste.

Specifications

Supply voltage 24 VDC (-15% to +10%)ripple(p−p)10% is contained.

Power consumption

4W max

Ambient operating

temperature

At operation:-10 to 55℃

(No freezing.There is no dew formation.)

At preservation:-25 to 65℃

(No freezing.There is no dew formation.)

At operation,At preservation:25 to 85%RH

(No freezing.There is no dew formation.

The ambient temperature of 85%RH is 40℃or less.)

Insulation resistans 20MΩmin.(with 500VDC megohmmeter)

Between power supply terminals (except for grand) and casing

Between power supply terminals (except for grand) and grand

Withstand voltage 1000VAC,50/60Hz,1min

Between power supply terminals (except for grand) and casing

500VAC,50/60Hz,1min

Between power supply terminals (except for grand) and grand

Vibration resistanse

10 to 150 Hz, double amplitude: 0.2 mm,Acceleration: 150m/s2,

with 10 sweep of 8 min each in 3 directions

Shock resistance

Mechanical durability: 150m/s2, 3times each in 6 directions

Dimensions 65 × 65 ×65 mm (excluding protruding parts)

Degree of protection

IEC60529Standard IP20 (Panel-mounting)

Material PC/ABS resin

Weight Approx. 150 g

Mounting method DIN rail

Ambient operating

humidity

Accessory

Ferrite core (TDK:ZCAT2032-0930) 1 pcs

Connector (PHOENIX CONTACT:FKC2.5/5-ST-5.08-RFAUM) 1 pcs

Instruction Sheet 1 sheet

Description of Regulations and Standard 1 sheet

Description

Setting method

Characteristic

Setting range

Setting method

Left rotary switch is a grider of ten.

Right rotary switch is a grider of one.

00〜63

The setting in the factory when shipping it is 00.

The node address of PROFIBUS is set.

・

Mode Switch

The operation mode is set.

Name

The setting is prohibited.(It becomes a mode setting error.)

No.

0

1

2

3

4

5

6

7

8

9

Run mode

The setting is prohibited.(It becomes a mode setting error.)

ー

ー

ー

ー

NOISE

TEST

RUN

ー

ー

ー

ー

ー

ー

The setting is prohibited.(It becomes a mode setting error.)

Normal operation.

Test lead execution on page 1 of 4 bytes

The environment measurement of the noise in the antenna surroundings .

Abbreviation Description

Communication Test

Noise measurement

ー

The setting is prohibited.(It becomes a mode setting error.)

The setting is prohibited.(It becomes a mode setting error.)

The setting is prohibited.(It becomes a mode setting error.)

ー

ー

ー

The setting is prohibited.(It becomes a mode setting error.)

SAFRTY PRECATIONS

5

1

9

6

1

2

3

4

5

−

CNTR-P

RxD/TxD-P

−

DGND

Name

PINNo.

6

7

8

9

VP

RxD/TxD-N

−

−

−

Control signal for repeaters (direction control)

Receive/Transmit data - plus (B wire)

−

Data ground (reference potentia for VP)

Description

Supply voltage of the terminator resistance (5Vdc)

Receive/Transmit data - minus (Awire)

−

−

1.5

16

20 10

6 18

21.5

42

18.25

32.5

5.1

22.6

3-SWITCH

CONNECTOR

12-OPERATION

INDICATOR

65 55 5

65

4

12

CONNECTOR

CONNECTOR

65

28.5

(3.7)

(12)

35.2

5

4.8

9.5 dia.

(6.1)

Meaning of Signal Words

Warning

WARNING

TheseProductsarenotdesignedtobeusedeitherdirectly

orindirectlyinapplicationsthatdetecthumanpresencefor

thepurposeofmaintainingsafety.Donotusethese

Productsasasensingmeansforprotectinghumanlives.

InIndicatesapotentiallyhazardoussituation

which,ifnotavoided,willresultinminoror

moderateinjury,ormayresultinseriousinjury

ordeath.Additionally,theremaybesignificant

propertydamage.

WARNING

Meaning of Alert Symbols

Indicatesgeneralprohibitionsforwhichthereisno

specificsymbol.

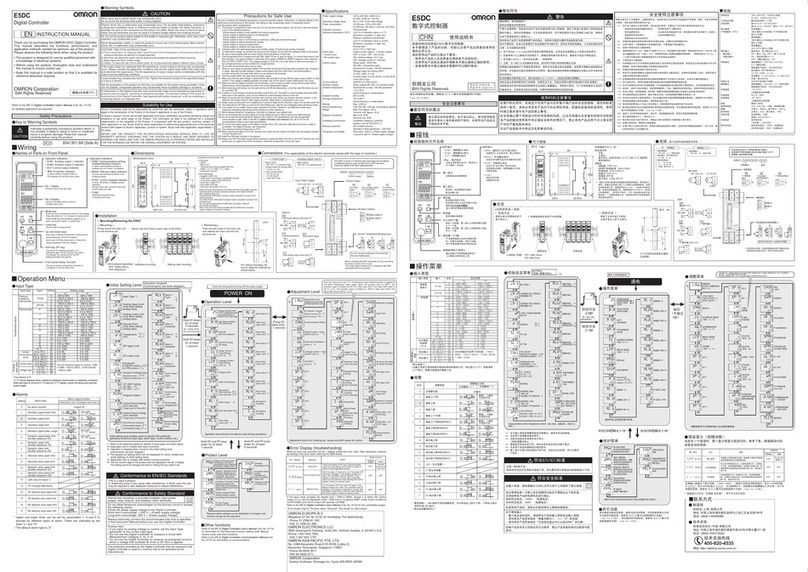

1. Rating performance

2. Installation

3. Name and functions

4. Dimensions

Recommended DIN Track

OMRON PFP-100N2

(track length: 1m)

1. First hook the ID Slave on part A, then press the ID Slave in direction B to

mount it to the DIN Track.

2. To disconnect the ID Slave from the DIN Track, pull the mounting hook

downwards, and then lift the ID Slave upwards.

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

V680-HAM42-PRT

OMRON

OMRON Corporation

SOURCE : 24VDC 0.2A

MADE IN JAPAN

X10 1X10 0

MS

BF

T/R

NORM/ERR

7

3

6

2

5

1

4

0

NODE ADDRESS MODE RUN TEST

NOISE

(2)Data indicator (2colored LED)

DATA:DATA code (Green)

ERC:Error code (Red)

(3)Mode Switch

regulates function mode

(4)Node Address Switch

node address setting (00〜63)

(7)PROFIBUS connector

Connect to the PROFIBUS Master Unit

(5)Power supply terminal

24VDC power supply is supplied.

Attached connector type:FKC2.5/3-ST-5.08-RF

(PHOENIX CONTACT)

Use wire size of AWG 12-22 with strip length of

10 mm. Recommended source is S8VS-03024

(OMRON).

(6)Antenna connector

1

2

3

GND

0V

+24V

Name

1

2

PIN No.

3

Ground terminal

24 VDC input terminals

Function

(1)Status indicator

MS:Machine status

BF:Bus Failure

T/R:Transmission status

NORM/ERR:Communication status

Connectable Antennas

V680-HS63-W

V680-HS65-W

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

V680-HAM42-PRT

OMRON

OMRON Corporation

SOURCE :24VDC 0.2A

MADE IN JAPAN

X10 1X10 0

MS

BF

T/R

NORM/ERR

7

3

6

2

5

1

4

0

NODEADDRESS MODE RUN TEST

NOISE

DIN Track

End Plate End Plate

Mounting Hook

©OMRON Corporation 2 011 All Rights Reserved.

INSTRUCTION SHEET

Thank you for selecting OMRON product. This sheet pri-

marily describes precautions required in installing and

operatingtheproduct.

Beforeoperatingtheproduct,readthesheetthoroughlyto

acquiresufficientknowledgeoftheproduct.Foryourcon-

venience,keepthesheetatyourdisposal.

Cable length

Radiated magnetic

field strength

13,56MHz

maximum 20 dBμA/m at 10 meters

Suitability for Use

s

Omron Companies shall not be responsible for conformity with any standards,

codes or regulations which apply to the combination of the Product in the

Buyer’s application or use of the Product. At Buyer’s request, Omron will

provide applicable third party certification documents identifying ratings and

limitations of use which apply to the Product. This information by itself is not

sufficient for a complete determination of the suitability of the Product in

combination with the end product, machine, system, or other application or

use. Buyer shall be solely responsible for determining appropriateness of the

particular Product with respect to Buyer’s application, product or system.

Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING

SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE

SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS,

AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL

EQUIPMENT OR SYSTEM.

See also Product catalog for Warranty and Limitation of Liability.

Oct, 2014

D

OMRON Corporation Industrial Automation Company

Contact: www.ia.omron.com

Tokyo, JAPAN

OMRON ELECTRONICS LLC

2895 Greenspoint Parkway, Suite 200

Hoffman Estates, IL 60169 U.S.A.

Tel: (1) 847-843-7900/Fax: (1) 847-843-7787

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark,

Singapore 119967

Tel: (65) 6835-3011/Fax: (65) 6835-2711

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200

OMRON EUROPE B.V.

Sensor Business Unit

Carl-Benz-Str. 4, D-71154 Nufringen, Germany

Tel: (49) 7032-811-0/Fax: (49) 7032-811-199

Regional Headquarters

Manufacturer:

Omron Corporation,

Shiokoji Horikawa, Shimogyo-ku,

Kyoto 600-8530 JAPA N

TRACEABILITY INFORMATION:

Importe in EU :

Omron Europe B.V.

Wegalaan 67-69

2132 JD Hoofddorp,

The Netherlands