2155411-6E

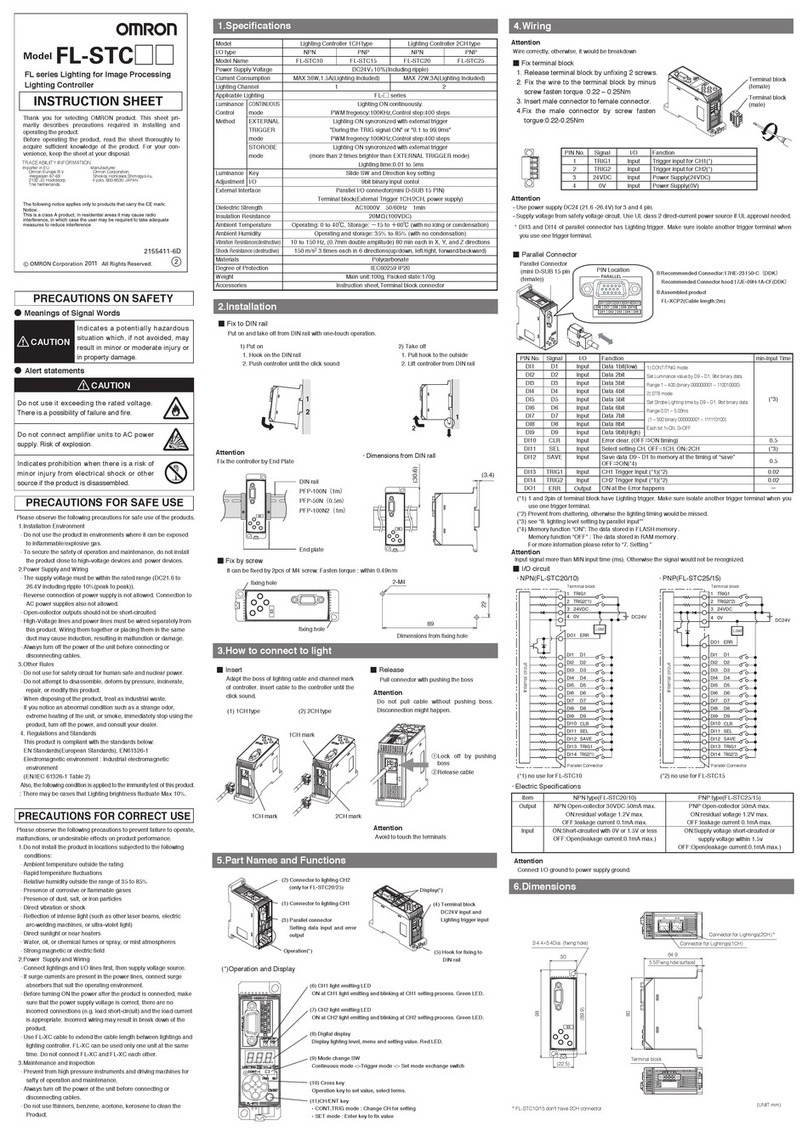

PIN No.

1

2

3

4

Signal

TRIG1

TRIG2

24VDC

0V

I/O

Input

Input

Input

Input

Fanction

Trigger input for CH1(*)

Trigger input for CH2(*)

Power Supply(24VDC)

Power Supply(0V)

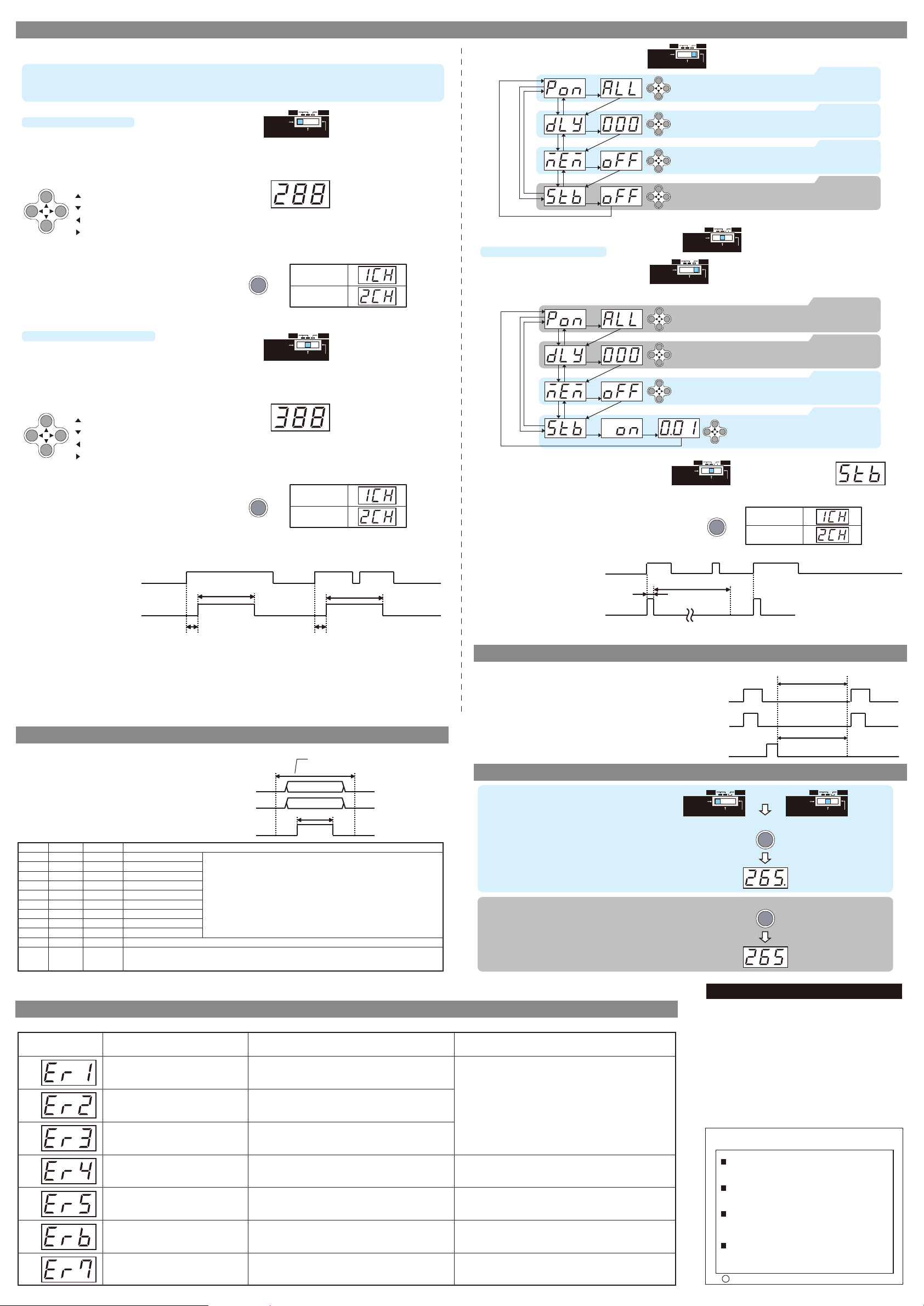

1) Put on

1. Hook on the DIN rail

2. Push controller until the click sound

2) Take off

1. Pull hook to the outside

2. Lift controller from DIN rail

■Fix by screw

It can be fixed by 2pcs of M4 screw. Fasten torque : within 0.49n/m

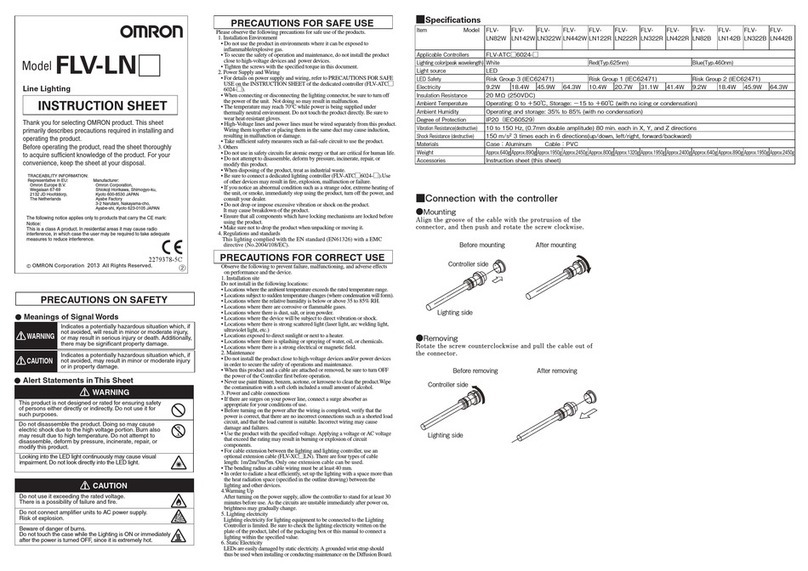

■Insert

Adapt the boss of lighting cable and channel mark

of controller. Insert cable to the controller until the

click sound.

■Release

Pull connector with pushing the boss

■Fix to DIN rail

Put on and take off from DIN rail with one-touch operation.

■Fix terminal block

1. Release terminal block by unfixing 2 screws.

2. Fix the wire to the terminal block by minus

screw fasten torque :0.22 – 0.25Nm

3. Insert male connector to female connector.

4.Fix the male connector by screw fasten

torgue:0.22-0.25Nm

■Parallel Connector

■I/O circuit

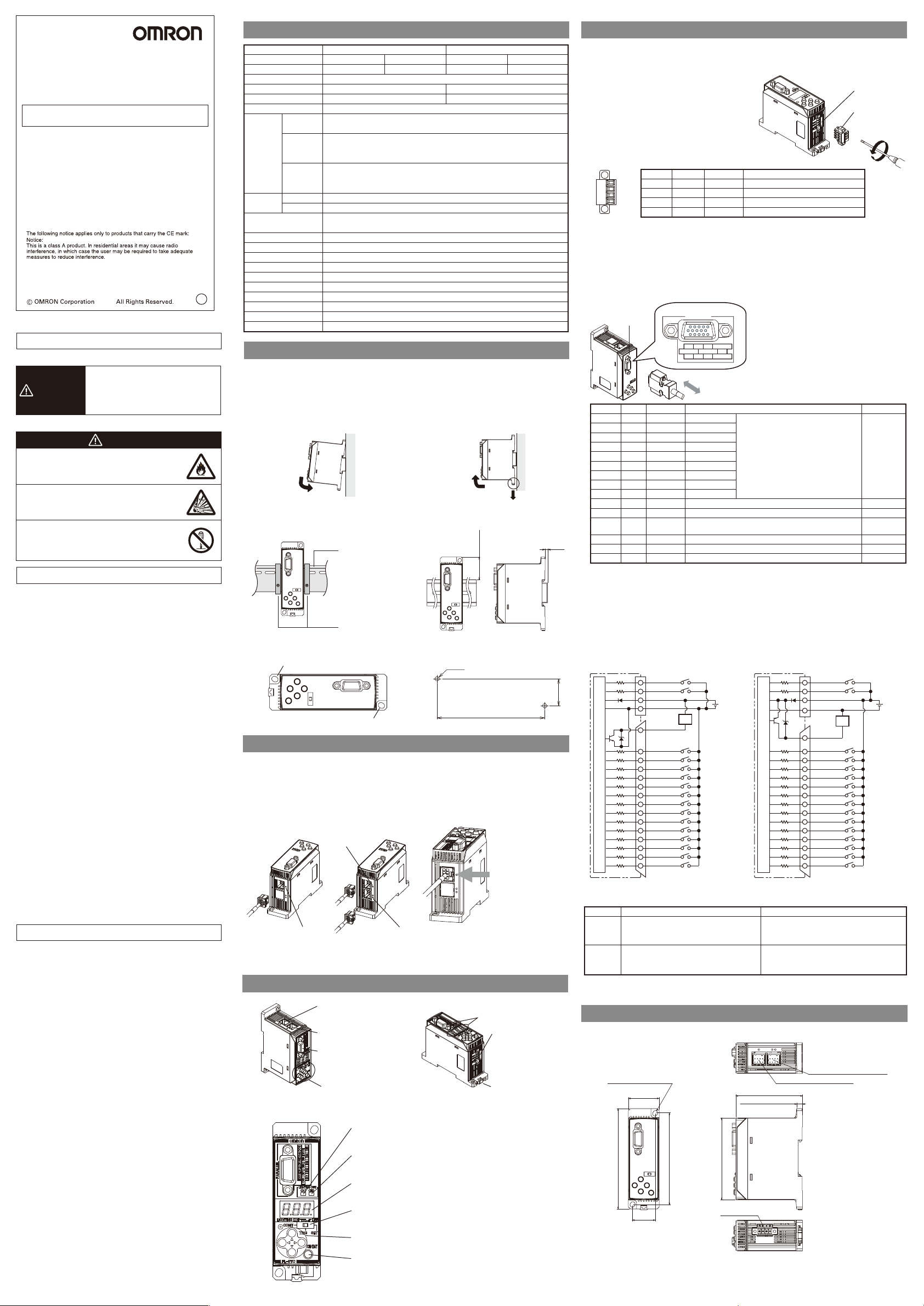

2.Installation

3.How to connect to light

6.Dimensions

4.Wiring

5.Part Names and Functions

Model

I/O type

Model Name

Power Supply Voltage

Currant Consumption

Lighting Channel

Applicable Lighting

Luminance

Control

Method

Luminance

Adjustment

External Interface

Dielectric Strength

Insulation Resistance

Ambient Temperature

Ambient Humidity

Vibration Resistance(destructive)

Shock Resistance (destructive)

Materials

Degree of Protection

Weight

Accessories

CONTINUOUS

mode

EXTERNAL

TRIGGER

mode

STOROBE

mode

Key

I/O

FL-STC10 FL-STC15 FL-STC20 FL-STC25

NPN PNP NPN PNP

DC24V±10%(Including ripple)

FL-□series

Lighting ON continuously.

PWM fregency:100KHz,Control step:400 steps

Lighting ON syncronized with external trigger

"During the TRIG signal ON" or "0.1to99.9ms"

PWM fregency:100KHz,Control step:400 steps

Lighting ON syncronized with external trigger

(more than 2 times brighter than EXTERNAL TRIGGER mode)

Lighting time:0.01to5ms

Slide SW and Direction key setting

9bit binary input contol

Parallel I/O connector(mini D-SUB 15 PIN)

Terminal block(External Trigger 1CH/2CH, power supply)

AC1000V 50/60Hz 1min

20MΩ(100VDC)

Operating: 0to40℃, Storage: −15 to +60℃(with no icing or condensation)

Operating and storage: 35%to85% (with no condensation)

10to150 Hz, (0.7mm double amplitude) 80 min each in X, Y, and Z directions

150 m/s23 times each in 6 directions(up/down, left/right, forward/backward)

Polycarbonate

IEC60259 IP20

Main unit:100g, Packed state:170g

Instruction sheet,Terminal block connector

Lighting Controller 1CH type

MAX 36W,1.5A(Lighting Included)

1

Lighting Controller 2CH type

MAX 72W,3A(Lighting Included)

2

FL-STC

□□

Attention

Fix the controller by End Plate

Attention

Wire correctly, otherwise, it would be breakdown

Attention

- Use power supply DC24 (21.6 -26.4V) for 3 and 4 pin.

-

Supply voltage from safety voltage circuit. Use UL class 2 direct-current power source if UL approval needed.

Attention

Input signal more than MIN input time (ms). Otherwise the signal would not be recognized.

Attention

Do not pull cable without pushing boss.

Disconnection might happen.

Attention

Connect I/O ground to power supply ground.

Attention

Avoid to touch the terminals

* DI13 and DI14 of parallel connector has Lighting trigger. Make sure isolate another trigger terminal when

you use one trigger terminal.

(*1) 1 and 2pin of terminal block have Lighting trigger. Make sure isolate another trigger terminal when you

use one trigger terminal.

(*2) Prevent from chattering, otherwise the lighting timing would be missed.

(*3) see “8. lighting level setting by parallel input””

(*4) Memory function “ON”: The data stored in FLASH memory .

Memory function “OFF” : The data stored in RAM memory .

For more information please refer to “7. Setting ”

1

21

2

End plate

fixing hole

fixing hole

· Dimensions from DIN rall

DIN rail

PFP-100N(1m)

PFP-50N(0.5m)

PFP-100N2(1m)

(30.6)

(3.4)

89

2-M4

22

Parallel Connector

(mini D-SUB 15 pin

(female))

· NPN(FL-STC20/10)

· Electric Specifications

· PNP(FL-STC25/15)

PARALLEL

DI11 DI12 DI13 DO1DI14

DI6 DI7 DI8 DI10DI9

DI1 DI2 DI3 DI4 DI5

(2) Connector to lighting CH2

(only for FL-STC20/25)

(1) Connector to lighting CH1

(3) Parallel connector

Setting data input and error

output

(4) Terminal block

DC24V input and

Lighting trigger input

(5) Hook for fixing to

DIN rail

Operation(*)

(*)Operation and Display

Display(*)

(6) CH1 light emitting LED

ON at CH1 light emitting and blinking at CH1 setting process. Green LED.

(7) CH2 light emitting LED

ON at CH2 light emitting and blinking at CH2 setting process. Green LED.

(8) Digital display

Display lighting level, menu and setting value. Red LED.

(9) Mode change SW

Continuous mode <>Trigger mode <> Set mode exchange switch

(10) Cross key

Operation key to set value, select terms.

(11)CH/ENT key

- CONT,TRIG mode : Change CH for setting

- SET mode : Enter key to fix value

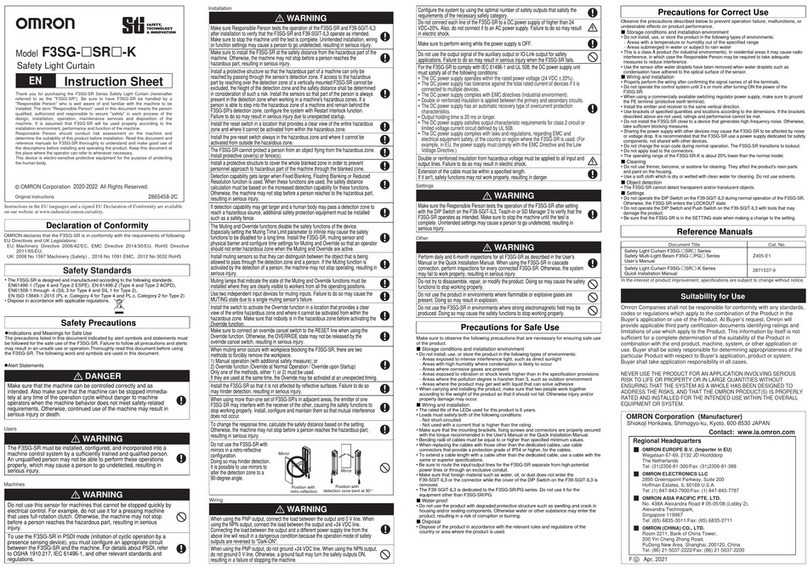

Please observe the following precautions for safe use of the products.

1.Installation Environment

· Do not use the product in environments where it can be exposed

to inflammable/explosive gas.

· To secure the safety of operation and maintenance, do not install

the product close to high-voltage devices and power devices.

2.Power Supply and Wiring

· The supply voltage must be within the rated range (DC21.6 to

26.4V including ripple 10%(peak to peak)).

· Reverse connection of power supply is not allowed. Connection to

AC power supplies also not allowed.

· Open-collector outputs should not be short-circuited.

· High-Voltage lines and power lines must be wired separately from

this product. Wiring them together or placing them in the same

duct may cause induction, resulting in malfunction or damage.

· Always turn off the power of the unit before connecting or

disconnecting cables.

3.Other Rules

· Do not use for safety circuit for human safe and nuclear power.

· Do not attempt to disassemble, deform by pressure, incinerate,

repair, or modify this product.

· When disposing of the product, treat as industrial waste.

· If you notice an abnormal condition such as a strange odor,

extreme heating of the unit, or smoke, immediately stop using the

product, turn off the power, and consult your dealer.

4. Regulations and Standards

This product is compliant with the standards below:

EN Standards(European Standards), EN61326-1

Electromagnetic environment : Industrial electromagnetic

environment

(EN/IEC 61326-1 Table 2)

Also, the following condition is applied to the immunity test of this product.

: There may be cases that Lighting brightness fluctuate Max 10%.

Please observe the following precautions to prevent failure to operate,

malfunctions, or undesirable effects on product performance.

1.Do not install the product in locations subjected to the following

conditions:

· Ambient temperature outside the rating

· Rapid temperature fluctuations

· Relative humidity outside the range of 35 to 85%

· Presence of corrosive or flammable gases

· Presence of dust, salt, or iron particles

· Direct vibration or shock

· Reflection of intense light (such as other laser beams, electric

arc-welding machines, or ultra-violet light)

· Direct sunlight or near heaters

· Water, oil, or chemical fumes or spray, or mist atmospheres

· Strong magnetic or electric field

2.Power Supply and Wiring

· Connect lightings and I/O lines first, then supply voltage source.

· If surge currents are present in the power lines, connect surge

absorbers that suit the operating environment.

· Before turning ON the power after the product is connected, make

sure that the power supply voltage is correct, there are no

incorrect connections (e.g. load short-circuit) and the load current

is appropriate. Incorrect wiring may result in break down of the

product.

· Use FL-XC cable to extend the cable length between lightings and

lighting controller. FL-XC can be used only one unit at the same

time. Do not connect FL-XC and FL-XC each other.

3.Maintenance and inspection

· Prevent from high pressure instruments and driving machines for

safty of operation and maintenance.

· Always turn off the power of the unit before connecting or

disconnecting cables.

· Do not use thinners, benzene, acetone, kerosene to clean the

Product.

●Meanings of Signal Words

●Alert statements

PRECAUTIONS ON SAFETY

PRECAUTIONS FOR SAFE USE

PRECAUTIONS FOR CORRECT USE

Indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury or

in property damage.

CAUTION

CAUTION

Model

FL series Lighting for Image Processing

Lighting Controller

Do not use it exceeding the rated voltage.

There is a possibility of failure and fire.

Do not connect amplifier units to AC power

supply. Risk of explosion.

Indicates prohibition when there is a risk of

minor injury from electrical shock or other

source if the product is disassembled.

1.Specifications

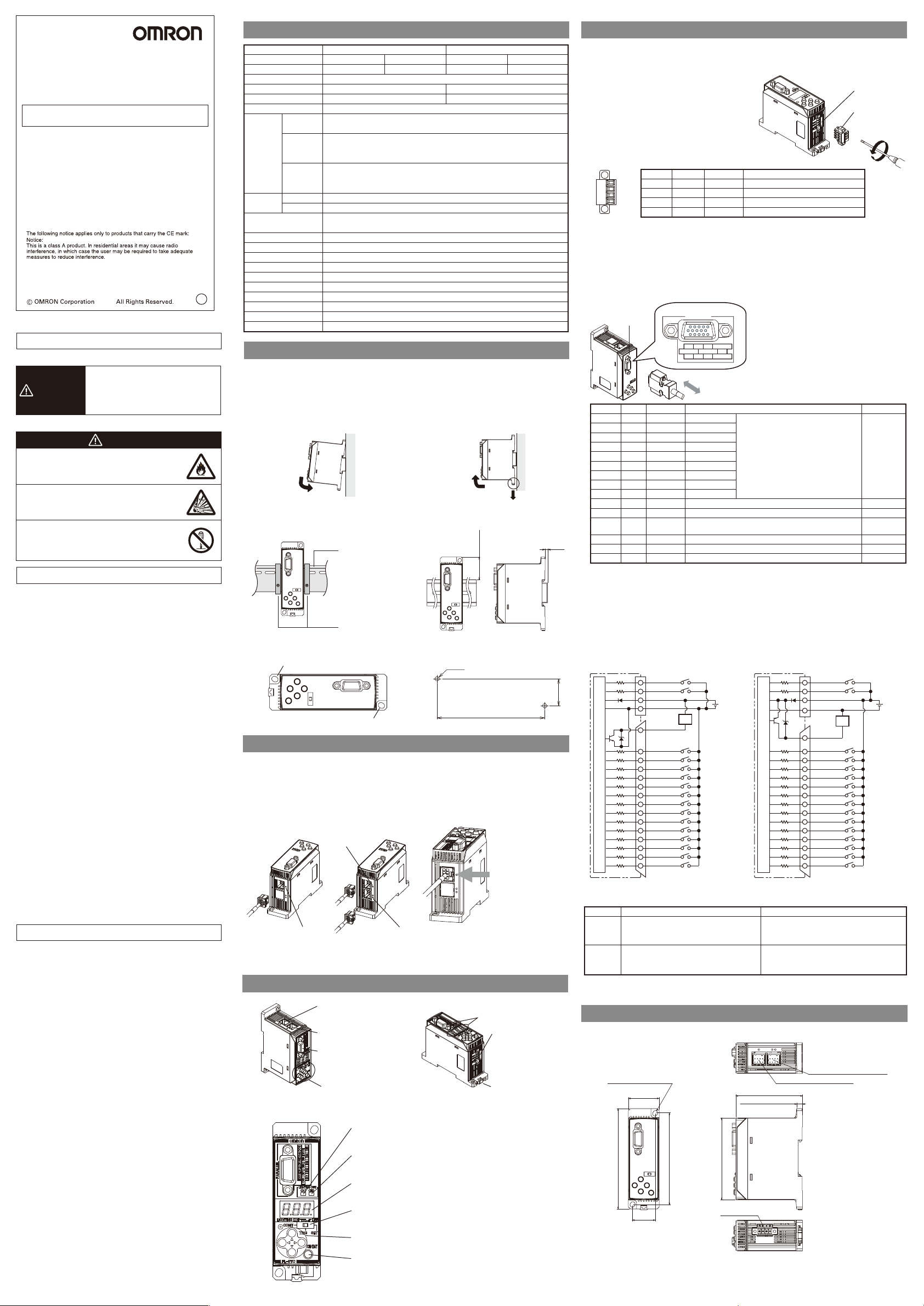

PIN No.

DI1

DI2

DI3

DI4

DI5

DI6

DI7

DI8

DI9

DI10

DI11

DI12

DI13

DI14

DO1

Signal

D1

D2

D3

D4

D5

D6

D7

D8

D9

CLR

SEL

SAVE

TRIG1

TRIG2

ERR

I/O

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Output

min-Input Time

0.5

(*3)

0.02

0.02

−

Fanction

Data 1bit(low)

Data 2bit

Data 3bit

Data 4bit

Data 5bit

Data 6bit

Data 7bit

Data 8bit

Data 9bit(High)

Error clear. (OFF⇒ON timing)

Select setting CH. OFF=1CH, ON=2CH

Save data D9 - D1 to memory at the timing of “save”

OFF⇒ON(*4)

CH1 Trigger Input (*1)(*2)

CH2 Trigger Input (*1)(*2)

ON at the Error happens

Item

Output

Input

NPN type(FL-STC20/10)

NPN Open-collector 30VDC 50mA max.

ON:residual voltage 1.2V max.

OFF:leakage current 0.1mA max.

ON:Short-circuited with 0V or 1.5V or less

OFF:Open(leakage current:0.1mA max.)

PNP type(FL-STC25/15)

PNP Open-collector 50mA max.

ON:residual voltage 1.2V max.

OFF:leakage current 0.1mA max.

ON:Supply voltage short-circuited or

supply voltage within 1.5v

OFF:Open(leakage current:0.1mA max.)

1) CONT/TRIG mode

Set Luminance value by D9 – D1, 9bit binary data.

Range 1 – 400 (binary 000000001 – 110010000)

2) STB mode

Set Strobe Lighting time by D9 – D1, 9bit binary data.

Range 0.01 – 5.00ms

(1 – 500 binary 000000001 – 111110100)

Each bit 1=ON, 0=OFF

①Lock off by pushing

boss

②Release cable

DI1

DI2

DI3

DI4

DI5

DI6

DI7

DI8

DI9

DI10

DI11

DI12

DI13

DI14

D1

D2

D3

D4

D5

D6

D7

D8

D9

CLR

SEL

SAVE

TRIG1

TRIG2(*2)

DO1 ERR

1

2

3

TRIG1

TRIG2(*2)

24VDC

4 0V DC24V

DI1

DI2

DI3

DI4

DI5

DI6

DI7

DI8

DI9

DI10

DI11

DI12

DI13

DI14

D1

D2

D3

D4

D5

D6

D7

D8

D9

CLR

SEL

SAVE

TRIG1

TRIG2(*1)

DO1 ERR

1

2

3

TRIG1

TRIG2(*1)

24VDC

4 0V DC24V

Parallel Connector

(*1) no use for FL-STC10 (*2) no use for FL-STC15

Parallel Connector

Terminal block

Internal circuit

Internal circuit

Terminal block

30 64.9

* FL-STC10/15 don’t have 2CH connector. (UNIT:mm)

2-4.4×5.4Dia. (fixing hole)

Connector for Lightings(2CH) *

Connector for Lightings(1CH)

Terminal block

5.5(Fixing hole surface)

(22.5)

98

80

(89.9)

(*3)

0.5

Dimensions from fixing hole

Terminal block

(female)

Terminal block

(male)

PIN Location

(1) 1CH type

1CH mark

1CH mark 2CH mark

(2) 2CH type

Load Load

INSTRUCTION SHEET

Thank you for selecting OMRON product. This sheet pri-

marily describes precautions required in installing and

operating the product.

Before operating the product, read the sheet thoroughly to

acquire sufficient knowledge of the product. For your con-

venience, keep the sheet at your disposal.

TRACEABILITY INFORMATION:

Importer in EU

Omron Europe B.V.

Wegalaan 67-69

2132 JD Hoofddorp,

The Netherlands

Manufacturer

Omron Corporation,

Shiokoji Horikawa,Shimogyo-ku,

Kyoto, 600-8530 JAPAN

2 011 2

※Assembled product

FL-XCP2(Cable length:2m)