T 8394 EN 3

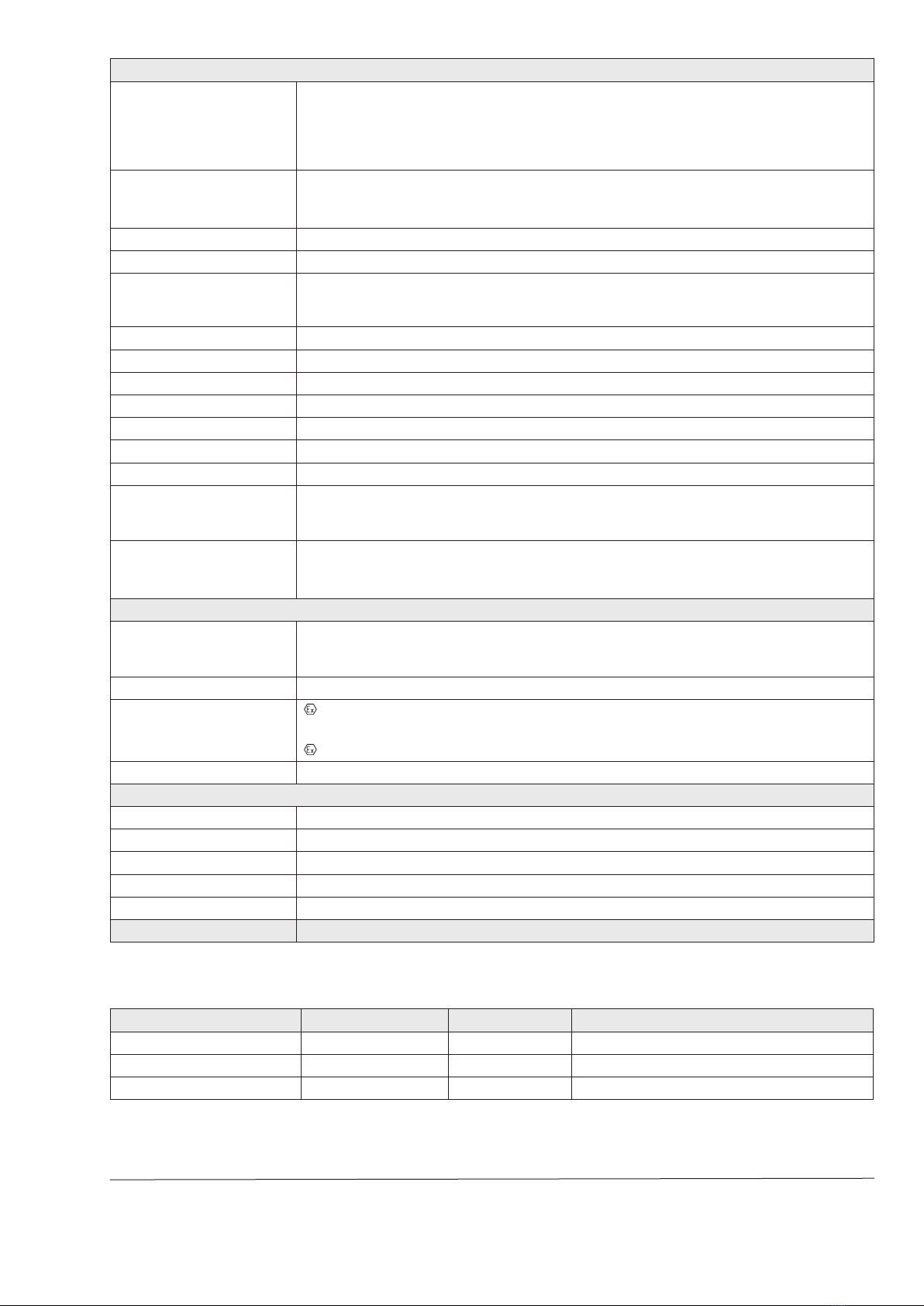

Table1: Technical data

Type3725Positioner

Travel (adjustable) Direct attachment to Type 3277 Actuator: 3.75 to 30 mm

Direct attachment to Type 2780-2 Actuator: 6/12/15 mm

Attachment to Type 3372 Actuator: 15/30 mm

Attachment according to IEC 60534-6 (NAMUR): 3.75 to 50 mm

Attachment to rotary actuators: 24 to 100°

Reference variable w

(reverse polarity protection)

Static destruction limit

4 to 20mA signal range · Two-wire device · Split-range operation 4 to 11.9 mA and 12.1 to 20 mA

±33 V

Minimum current 3.8 mA

Load impedance Max. 6.3V

Supply air

Air quality acc. to ISO8573-1

Supply air: 1.4 to 7bar (20 to 105psi)

Max. particle size and density: Class 4 · Oil content: Class 3 · Pressure dew point: Class 3 or at least 10K

below the lowest ambient temperature to be expected

Signal pressure (output) 0 bar up to the capacity of the supply pressure · Can be limited to approx. 2.3bar by software

Characteristic 3 characteristics for globe valves · 9 characteristics for rotary valves

Hysteresis ≤ 0.3 %

Sensitivity ≤ 0.1 %

Transit time Only for actuators with initialization time > 0.5 s 1)

Direction of action w/x reversible

Air consumption ≤ 100 ln/h with a supply pressure up to 6bar and a signal pressure of 0.6bar

Air output capacity

Actuator lled with air At Δp = 6 bar: 8.5mn3/h, At Δp = 1.4 bar: 3.0mn3/h KVmax(20 °C) = 0.09

Actuator vented At Δp = 6 bar: 14.0mn3/h, At Δp = 1.4 bar: 4.5mn3/h KVmax(20 °C) = 0.15

Permissible ambient temperature –20 to +80 °C

–25 to +80 °C with metal cable gland

The limits in the test certicates additionally apply for explosion-protected versions

Safety

Inuences Temperature: ≤ 0.15 %/10 K

Inuence of vibrations: ≤ 0.25 % up to 2000 Hz and 4 g according to IEC 770

Supply air: None

Electromagnetic compatibility Complying with EN 61000-6-2, EN 61000-6-3 and NAMUR Recommendation NE 21

Explosion protection II 2G Ex ia IIC T4 according to ATEX

Intrinsically safe, Ex ia IIC T4 according to CSA Group

1Ex ia IIC T4 Gb X according to GOST

Degree of protection IP 66

Materials

Housing Polyphthalamide (PPA)

Cover Polycarbonate (PC)

External parts Stainless steel 1.4571 and 1.4301

Cable gland M20 x 1.5, black polyamide (PA)

Venting High-density polyethylene (PE-HD)

Weight Approx. 0.5 kg

1) For faster actuators, a volume restriction must be used. Otherwise, the initialization cannot be performed successfully.

Table2: Explosion protection certicates

Type of approval Certicatenumber Date Comments

EC Type Examination Certicate PTB 11 ATEX 2020 X 2011-08-25 II 2G Ex ia IIC T4

GOST certication RU C-DE.GB08.B.00697 2014-12-15 1Ex ia IIC T4 Gb X

CSA certication 2703735 2014-06-03 Ex ia IIC T4