FoamPRO Turbo Stream S108-4008 User manual

INSTALLATION AND

OPERATION MANUAL

Unit

Serial

Number

Form 925

Rev. 6/20

All quality FoamPro products are ruggedly designed, accurately machined, carefully assembled, thoroughly inspected

and tested. In order to maintain the high quality of your unit, and to keep it in a ready condition, it is important to follow

the instructions on care and operation. Proper use and good preventive maintenance will lengthen the life of your unit.

ALWAYS INCLUDE THE UNIT SERIAL NUMBER IN CORRESPONDENCE.

Turbo Stream®

Models S108-4008 and S108-4008H

FoamPro • 26 Southern Blvd. • Nesconset, NY 11767 USA • 800-533-9511 • FAX 816-892-3178

2

Installation and Operation Manual

TABLE OF CONTENTS

Section Page

1 SAFETY ............................................................................................................................3

2 INTRODUCTION...............................................................................................................4

3 SYSTEM COMPONENT DESCRIPTION..........................................................................5

4 INSTALLER SUPPLIED PARTS .......................................................................................6

5 INSTALLATION PLANNING .............................................................................................7

6 PLUMBING COMPONENT INSTALLATION.....................................................................7

7 ELECTRICAL EQUIPMENT INSTALLATION ...................................................................8

8 MAKING SURE EVERYTHING IS WORKING RIGHT......................................................8

9 CALIBRATION AND SETUP.............................................................................................9

10 ENGINE OPERATING INSTRUCTIONS ........................................................................10

11 MAINTENANCE ..............................................................................................................11

12 TROUBLESHOOTING ....................................................................................................11

13 PARTS IDENTIFICATION...............................................................................................12

14 INSTALLATION DRAWINGS ..........................................................................................13

15 WARRANTY..................................................................................................... Back Cover

NOTE TO SYSTEM INSTALLERS

IMPORTANT: Please provide a copy of the FoamPro manual to the end user of the equipment.

For additional FoamPro manuals, contact by FAX 816-892-3178, web site www.foampro.com,

or call 800-533-9511. Request Form No. 925.

3

Installation and Operation Manual

Turbo Stream

1 Safety

1. WARNING: Use pressure relief device on the

discharge side of the pump to prevent damage

from pressure buildup when the pump discharge

is blocked or otherwise closed and the power

source is still running. For trigger gun operation,

or where discharge is frequently shut off,

pressure unloader valves are recommended. The

Turbo Stream system is equipped with a pressure

relief device and should not be removed.

FAILURE TO FOLLOW THIS WARNING MAY

RESULT IN PERSONAL INJURY AND/OR

PROPERTY DAMAGE AND WILL VOID THE

PRODUCTION WARRANTY.

2. WARNING: Do not pump flammable or explosive

fluids such as gasoline, fuel oil, kerosene, etc.

Do not use in explosive atmospheres. The

pump should be used only with liquids that are

compatible with the pump component materials.

Failure to fallow this warning may result in

personal injury and/or damage and will void the

product warranty.

3. Do not pump at a pressure higher than the maximum

recommended pressure. [1450 psi (100 BAR)].

4. Do not run the system at greater than

recommended capacity.

5. Do not permanently remove or alter any guarding

devices or attempt to operate the system when these

guards are removed.

6. Always disconnect the power source before

attempting to service any part of the system.

7. Release all pressure within the system before

servicing any of its components.

8. Drain all concentrate and water from the discharge

system before servicing any of its component parts.

9. Periodically inspect all hoses for wear or worn

conditions. Make sure all connections and fittings are

tight and secure.

10. Use pipe, hose and fittings that are rated at or

above the maximum pressure rating at which the

water pump system may operate.

11. Use pipe, hose and fittings from the hydraulic

oil pump to the foam pump hydraulic motor, which

are rated at 3000 PSI (207 BAR) minimum working

pressure or better and are approved for mobile

hydraulic system use.

12. The components and fittings used in this system

must be compatible with the foam concentrates used

and pressures at which the pump system operates.

13. CAUTION: ENSURE THAT THE ELECTRICAL

SOURCE OF POWER FOR THE UNIT IS THE

APPROPRIATE 12 VOLT NEGATIVE-GROUND

DC SYSTEM.

14. Secure all discharge lines before starting the pump.

An insecure line may whip, causing personal injury

and/or property damage.

15. Any electrical system has the potential to cause

sparks during service. Take care to eliminate

explosive or hazardous environments during service

and repair.

16. CAUTION: Do not attempt to operate the system at

or above a temperature of 130°F (55°C).

17. CAUTION: Periodically inspect the pump and

the system components. Perform routine

maintenance as required. Failure to perform routine

maintenance may cause damage to individual

system components; pump, motor, and gearbox

assemblies. See the maintenance section of this

manual for recommended maintenance procedures

and intervals between maintenance work.

18. CAUTION: Read and understand “Operating

Instructions” section before attempting to operate

the unit.

19. CAUTION: The components shipped with each

FoamPro unit are tested at the factory. Improper

handling and forcing connections can damage the

components which could result in other

system damage.

20. CAUTION: Ensure the fuel source for the gas

engine is in the “OFF” position while in transport

or storage mode. This will prevent engine flooding

and fuel leakage.

4

Installation and Operation Manual

2 Introduction

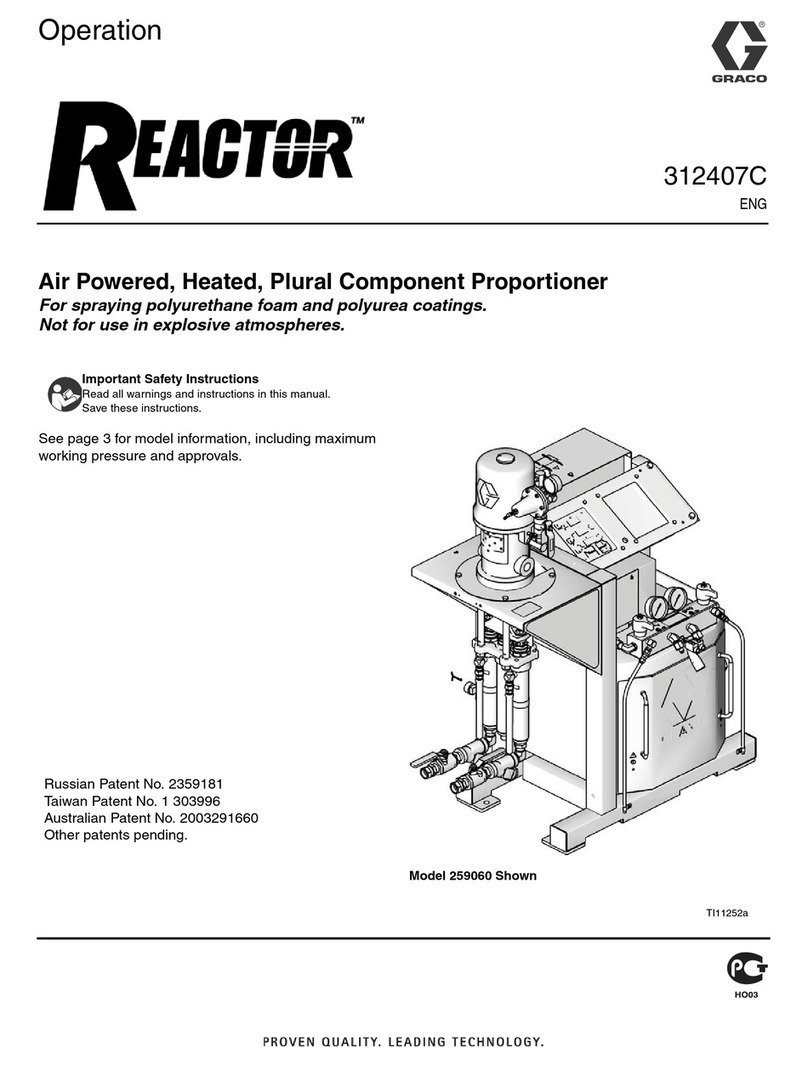

The FoamPro High Pressure System is a hydraulic or

gas engine-driven, flow-based proportioning system that

injects foam concentrate at a desired percentage at a

fixed water flow rate. The basic FoamPro High Pressure

System is shown in Figure 1. The system will accurately

deliver from 0.3% to 3.0% foam concentrate at the rated

system pressure and flow rate. The system will accurately

inject foam concentrate while the system is running at

recommended operating speed and pressure. Foam

percentage indication is instantaneously given on the

foam monitoring panel supplied.

The foam concentrate is directly injected into the

system at the head of the pump. It is then fed as foam

solution into the adjustable foam spray gun.

The pump inlet is equipped with a check valve to

prevent contamination of the water supply.

The FoamPro High Pressure Foam System is designed

for use with most foam concentrate applications with

foam viscosities less than 60 CPS. This includes Class

A and low viscosity Class B foam concentrates. High

viscosity foams, such as AR-AFFF, are not acceptable.

Flushing of the system, especially when using Class B

foams or switching foam concentrates, is required.

21. CAUTION: Use only approved petroleum-based

hydraulic fluids meeting the specifications as

noted in Section 4. Never mix fluid types. Ensure

all hoses and seals are compatible with fluids

used. Do not use water or glycol-based fluids. Do

not use phosphate ester-type fluids.

22. CAUTION: Dirt and contaminants are the primary

causes of premature wear and failure in any

hydraulic system. Use extreme care during assembly

and service to keep contaminants out of the system.

23. CAUTION: All DOT, SAE or other applicable standards

must be followed when installing the hydraulic

supply system. Pay close attention to engine and

transmission manufacturer’s drive limitations.

24. CAUTION: To ensure the integrity of fitting

connections in the hydraulic system, use only SAE

JIC 37º flare or equal-type hose connections.

Foam

Tank

Water

Tank

Water Inlet Strainer

Water Shut-Off

Valve

Foam Spray Gun

Pump/Gearbox Assy

Gas Engine

Foam Inlet Strainer

Foam

Adjustment &

Flowmeter

Figure 1. FoamPro Turbo Stream

5

Installation and Operation Manual

Turbo Stream

3 System Component Description

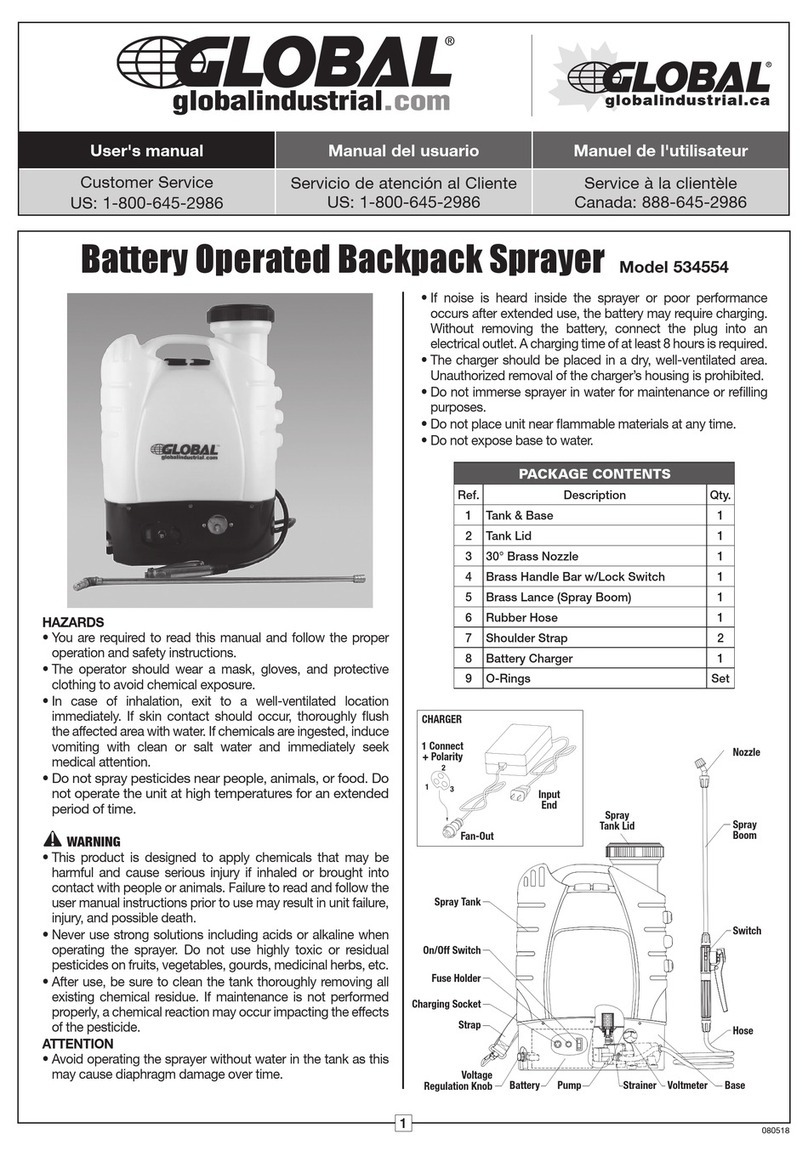

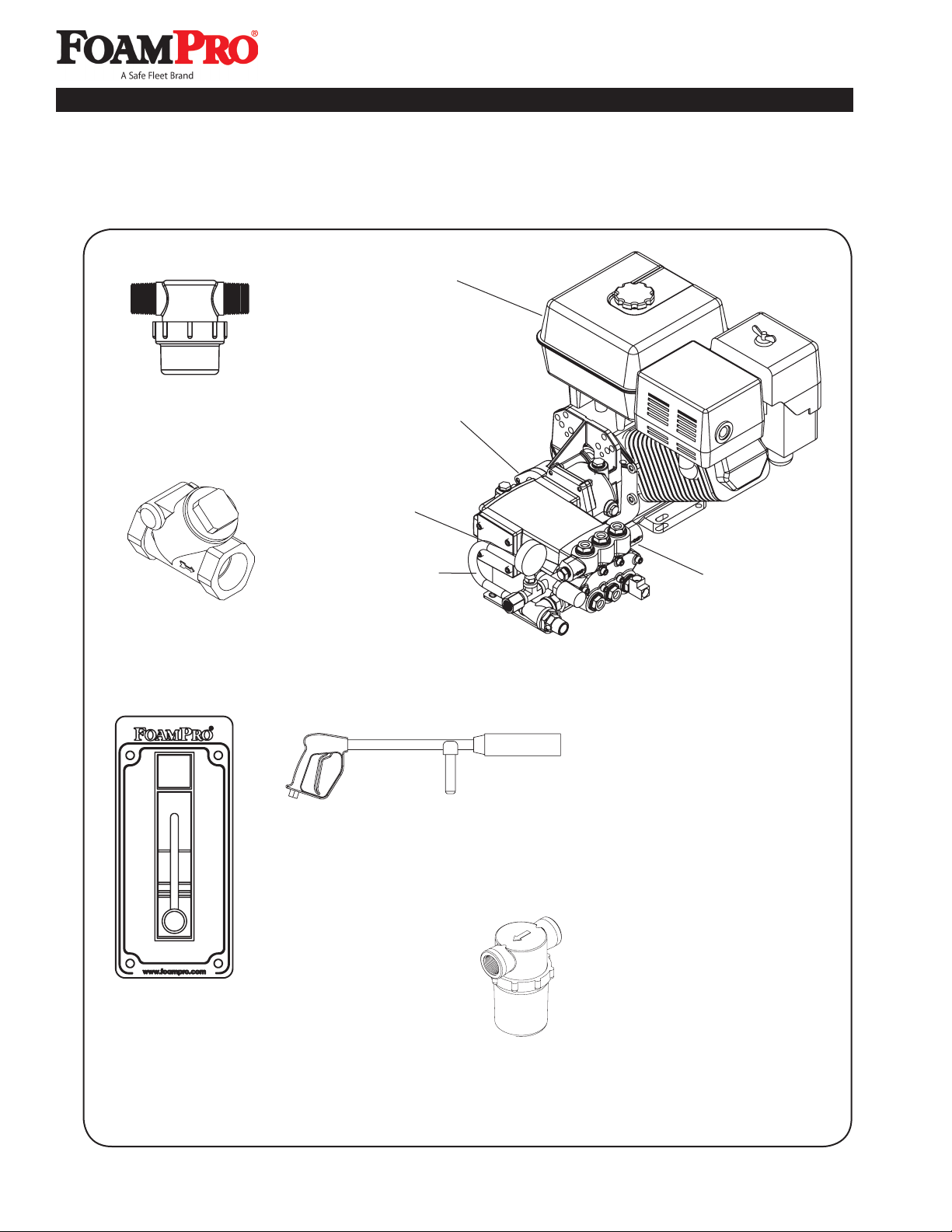

The following components are packaged with the FoamPro High Pressure System:

Control Panel

Foam Concentrate Strainer

Pump/Gas Engine Assembly

Foam Spray Gun/Wand

Thermal Relief Valve

Water Inlet Check Valve

Inlet Water Strainer

6

Installation and Operation Manual

4 Installer Supplied Parts

The FoamPro High Pressure System is provided with

the major components and accessories required for

installation. Due to differences in chassis and apparatus

configurations, the installer must provide plumbing to

satisfy individual installation requirements. The following

paragraphs list the specifications for selection of these

components. Before beginning system installation,

read this section thoroughly to make sure the proper

components are selected. For detailed system

installation instructions, refer to Sections 5, 6, and 7.

SUCTION LINES

Corrosion-resistant fittings and hoses from the foam

tank to the foam concentrate inlet of the pump must be

used. Use 5/16-inch to 3/8-inch inside diameter hose

for the foam inlet. Corrosion-resistant fittings and hoses

from the water source to the inlet of the pump must be

used. Use only 3/4-inch minimum inside diameter hose

for the water inlet. Use components that are rated for 23

in [584.2 mm] Hg vacuum and 50 psi [3 bar] pressure

or greater for all suction line inlets. The components

used must be compatible with all foam concentrates to

be used. All fittings used must be made of brass, 300

series stainless or other corrosion-resistant materials.

Before selection of components, check for compatibility

with foam concentrate. The use of clear suction hose

is recommended to allow viewing of foam and water

priming operations.

DISCHARGE LINES

Fittings and hoses from the foam solution discharge of

the pump to the foam spray nozzle must be supplied by

the installer. Hoses and fittings of 1/2-inch [12.7 mm]

minimum INSIDE diameter, rated for 1800 psi [124.1

BAR] minimum working pressure, must be supplied by

the installer. Fittings are required to be 1/2-inch male

NPT on hose ends.

The following guidelines should be followed in choosing

hose length and hose diameters.

Approximate Pressure Recommended

Hose ID Drop Per 1 ft. of Hose Max. Hose Length

1/2" 1.15 50'

5/8" .47 100'

3/4" .23 200'

1" .07 400'

Fittings and hoses must be compatible with all foam

concentrates to be used. Use fittings of brass, 300

series stainless or other corrosion-resistant material

that is compatible with foam concentrates to be used.

Thermal relief valve must be plumbed to discharge away

from operator.

CHECK VALVES

Check valves have been included with the system at the

water inlet to help prevent back flow of foam concentrate

or foam solution. The system should be disconnected

from exterior water supplies when not in use. A complete

system flush should be performed before storage to prevent

component failure due to evaporation of foam and water

within the system.

FOAM CONCENTRATE TANK

A foam concentrate tank must be supplied to suit the capacity

required for the apparatus application. The tank should

meet NFPA minimum standards for the design capacity,

including filler size, venting and drain facility. A shut-off valve

is recommended to allow cleaning of the strainer.

ELECTRICAL REQUIREMENTS

Electrical wiring must be supplied to the engine starter switch.

Use AWG No. 4 cable for power and ground connection, not

to exceed 5 ft. SEE ENGINE MANUAL for detailed electrical

hook-up specifications.

CAUTION: Always disconnect ground before electrical arc

welding on any FoamPro equipment. Failure to do so will

result in a power surge through the system that could case

irreparable damage to the electronic components.

7

Installation and Operation Manual

Turbo Stream

6 Plumbing Component Installation

5 Installation Planning

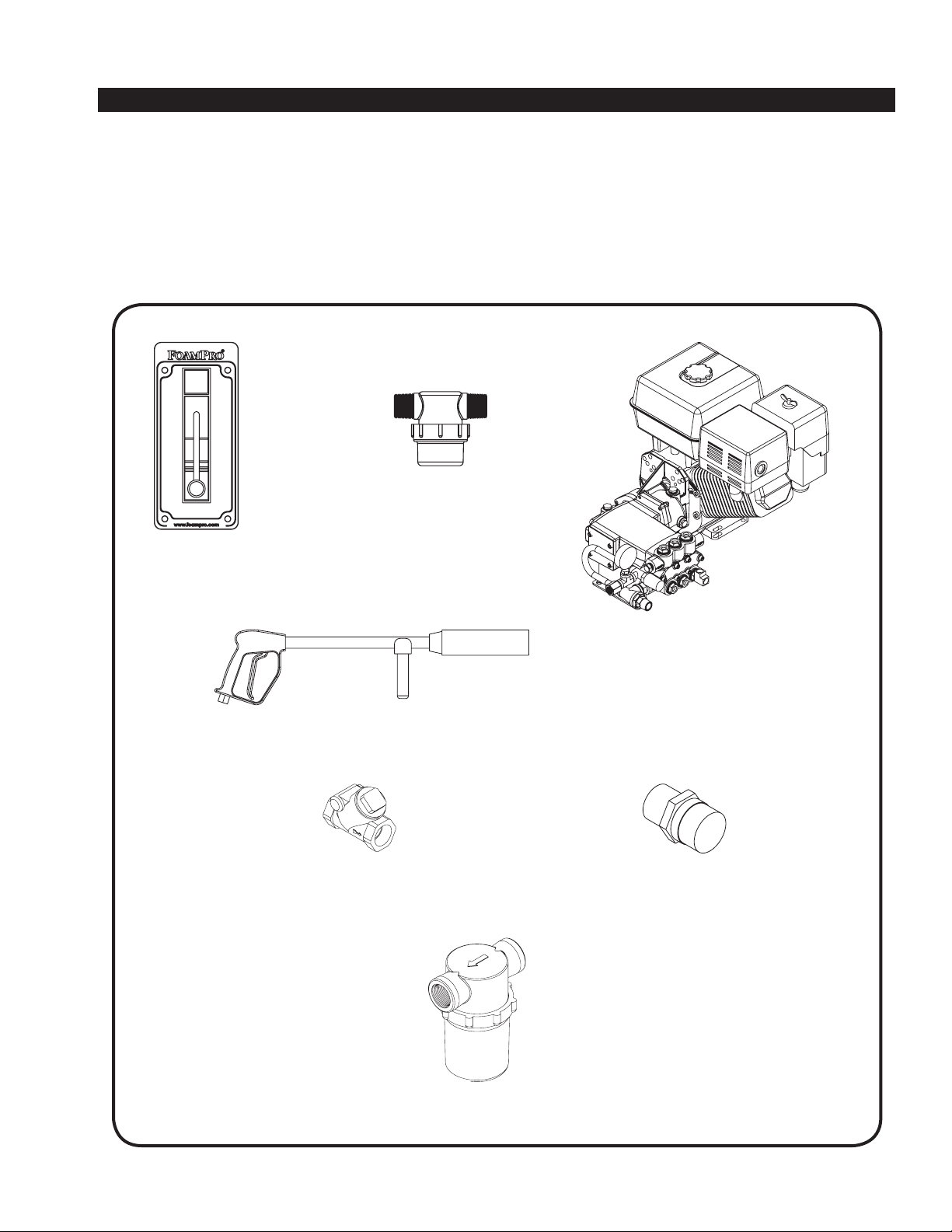

The following diagram (Figure 2) provides recommended guidelines for the location of the system components that

handle foam concentrate, water, and foam solution.

Figure 2. FoamPro High Pressure System Plumbing

Foam

Tank

Water

Tank

Water Inlet Strainer

Water Shut-Off

Valve

Foam Spray Gun

Pump/Gearbox Assy

Gas Engine

Foam Inlet Strainer

Foam

Adjustment &

Flowmeter

Because of the potential differences in apparatus

plumbing and foam system configuration, it is not

practical to depict exactly how each FoamPro unit can

best be installed onto a particular apparatus. Most of

the information contained in the following sections,

however, will apply to any situation.

It is recommended that you read the following sections

thoroughly before beginning installation of the FoamPro

system. It is also recommended that you spend time

planning and designing where and how you intend to

install this unit in the apparatus before beginning the

actual installation.

Determine the location of the components to be

installed such as: foam tank, water tank, foam system,

and display panel. Try to position the components to

minimize fittings and hose lengths. Position the system

in an accessible area.

For best performance, the foam system should be

positioned below the foam tank discharge to allow

gravity feed to the pump. The foam system will draft up

to three feet. Place the foam tank where refilling with 5

gallon [19 liter] containers and other methods is suitable

for the end user.

Determine a location for the display panel on the

unit that is visually accessible while the system is in

operation. The display panel should be located on the

same horizontal plane as the system and foam tank for

best possible performance.

Determine a safe place for the thermal relief valve drain

hose, and be sure it drains in a safe location away

from operator.

8

Installation and Operation Manual

7 Electrical Equipment Installation

8 Making Sure Everything is Working Right

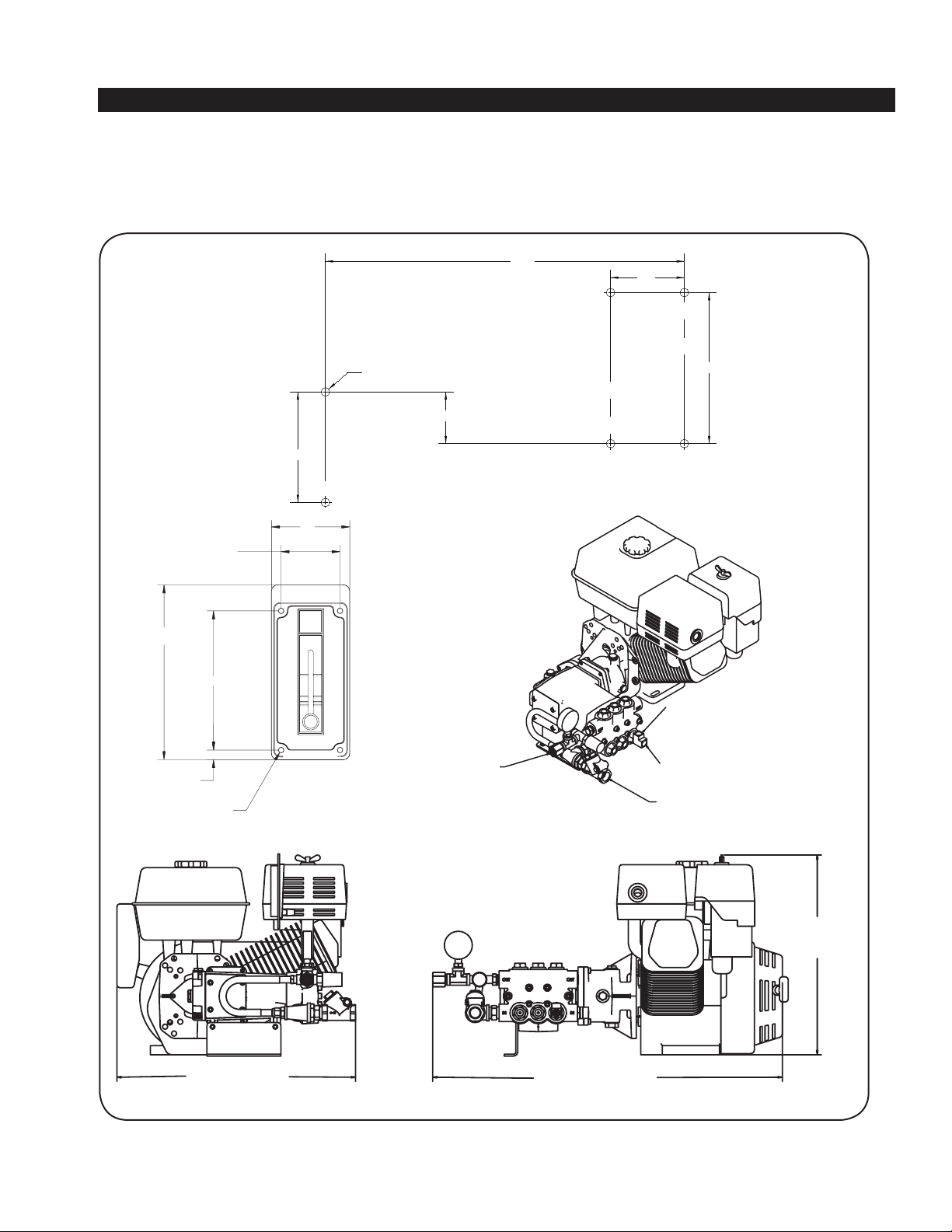

PUMP/MOTOR BASE ASSEMBLY

The pump/motor base assembly must be mounted in

the horizontal position. The system can be run at 15

degrees on any plane to the horizontal and may be

run intermittently at 30 degrees to the horizontal plane.

The base of the system must be anchored to a surface

or structure that is ridged and of adequate strength to

withstand the vibration and stresses of apparatus

operation. The main pump has a water drafting capability

not to exceed six feet of vertical lift and should not be

subjected to an inlet pressure of more than 3 PSI to

ensure proper operation of the foam injection system.

The drawings on pages 14 and 15 provide the mounting

dimensions for the FoamPro High Pressure pump/motor

base assembly. Flexible hose is required to make the hose

connections to the FoamPro High Pressure System. DO

NOT hard pipe the system.

Protect the hoses and wiring to prevent chafing and

abrasion during operation of the foam system. Protect

the foam pump base unit from excessive spray

and debris. See engine manual for allowed engine

operating conditions.

LINE STRAINERS

There are two line strainers provided with the FoamPro

unit. The pump inlet line strainer has 3/4-inch NPT

female threaded ports and is to be installed on the

water inlet of the foam pump. The water supply hose

should have adequate wall stiffness to withstand

the vacuum of the pump while it is in operation [23 in.

(584 mm) Hg and 50 PSI (3 BAR)].

The second strainer has 1/2-inch NPT male and 1/4-inch

NPT female-threaded ports and is to be installed in the

foam inlet before the flow meter. The foam supply hose

should be 1/4 to 3/8- inch and able to withstand 23 in/

Hg of vacuum and 50 psi. Clear foam supply hose is

recommended so that the operator can see the flow of

foam concentrate in the hose.

NOTE: If a pressurized water flush is incorporated, the

pressure should be limited to 100 PSI (7 BAR).

CHECK VALVES

A 3/4-inch check valve is included at pump inlet. A foam

injection check valve is incorporated in the design.

FLUSHING SYSTEM

Depending on the corrosiveness of the foam concentrates

to be used, a flushing system may be required in the

foam concentrate injection system. Most Class A foam

concentrates (per NFPA 1150) are less corrosive and

therefore may not require flushing. It is important to flush

and drain the entire system before long periods of storage

to prevent component malfunction.

THERMAL RELIEF VALVE

A thermal relief valve is included with the system to prevent

pump overheating during unloading.

SYSTEM CHECK

Check fuel level and oil level per engine manual prior to

running system. Check pump and gear case oil level prior

to running system. Pump and gear case should be filled

with oil per manual instructions.

Check the function of all components before using the

system. Also check that all plumbing and components are

tight and functional.

Check to see that water supply lines, strainers and foam

tank lines are free of debris and plumbed correctly. Any

leaks in the system will cause poor system performance

and operation.

ELECTRICAL CONNECTIONS

See engine manual for detailed electrical connections only if engine is equipped with electric start.

9

Installation and Operation Manual

Turbo Stream

9 Calibration & Setup

CALIBRATION

The FoamPro High Pressure System has been

calibrated at the factory. To check calibration of the

system, the following procedure should be used:

1) Start the system. Run the engine to an RPM that

produces 8 GPM (3345 Engine RPM) of pump

water inlet flow. Tools needed for the test are

a Pitot tube or other calibrated flowmeter to test

the system inlet water flow, a graduated bucket

to remove and calibrate foam concentrate, and a

stop watch to measure volume unit/time of foam

concentrate and water flow.

2) Open the control knob of the display panel to start

foam injection, while holding the spray gun in the

on position, run the system for a few minutes. The

system will not inject foam concentrate while the

system is unloading.

3) Turn the injection control knob to the desired foam

injection calibration point. Start the stop watch

and record the necessary volumes or flow rates of

foam concentrate and water.

4) Measure the amount of foam concentrate in the

container and compare that to the calculated

amount. (Main flow rate X injection rate X minutes

flowed [8.00 GPM X 0.005 (0.5%) injection rate X

5 minutes = 0.20 gallons]).

5) CAUTION: Long periods of pump deadheading

may result in pump damage due to overheating of

water in the system. The system is equipped with

a thermal relief valve to eliminate damage to the

pump during unloading. It is recommended to idle

down the system during unloading if the system

must stay running during transportation.

6) CAUTION: System may only be calibrated with

foams with a viscosity from 60 CPS. Use of other

higher viscosity foams will create an error in

calibration and setup. Use only quality

foam concentrate.

7) Measure the amount of concentrate injected

over time and compare to the level indicated on

the display panel during this time. The output

of the FoamPro High Pressure System must be

set at a constant 8 GPM + 0.20 GPM/-0.5 GPM.

Injection rate is easily changed by turning the

foam % control knob on the display panel. The

foam percentage is indicated on the display panel

and is read using the largest diameter of the foam

percent float. Repeat at each indicated %

if desired.

8) The water inlet flow rate may be adjusted by

changing the engine RPM. Increasing the engine

RPM will increase the flow rate. Decreasing the

engine RPM will decrease the water inlet flow rate.

Varying engine RPM will change calibration settings.

NOTE: The viscosity of different foam concentrates

may have an effect on the amount of foam concentrate

that is injected into the water stream. When checking

the calibration of the system, use the foam concentrate

that will be used most frequently during normal

operations. When different viscosity foam concentrates

are used, the actual concentrate injection may vary as

much as 100%.

PRESSURE RELIEF-UNLOADER

VALVE ADJUSTMENT

The pressure relief-unloader valve is factory tested

and preset. Adjustment is only required if the

relief-unloader valve is replaced. After setting

the valve properly, no other adjustments will be

required. The following procedure is provided for

proper adjustment.

1) Start the system and run the pump to maximum

RPM with the foam spray gun in the open position.

2) Turn the adjustment nut (lower) slowly so the

pressure on the gauge is at 1450 PSI (100 BAR).

3) Turn off the foam spray gun and open it again to

ensure the pressure is the same as it was set.

4) Turn off the spray gun and shut off the engine.

Lock the adjustment nut (lower) into place with the

nut (upper).

10

Installation and Operation Manual

10 Engine Operating Instructions

PREPARATIONS BEFORE STARTING

THE SYSTEM

1) Fuel: Check fuel level in tank. Do not overfill tank.

Use fresh, clean automotive fuel. NOTE: DO NOT

FILL FUEL TANK WHEN ENGINE IS RUNNING.

2) Engine Oil: Before checking or refilling with engine

oil, make sure the engine is stopped and placed on

a stable, level surface. Use oil recommended for

ambient air temperatures at which the engine will

be running. Change oil according to manufacturer’s

recommendation. (At least once after the first 20

hours and every 100 hours thereafter.)

3) Pump Oil: Before checking or refilling with pump

oil, make sure the engine is stopped and placed on

a stable, level surface. Use oil recommended for

ambient air temperatures at which the pump will be

running. Change oil according to manufacturer’s

recommendation, using SAE 30 weight non-

detergent oil. Check oil level before running the

system using the oil level dip stick on the pump.

4) Gear Case Oil: Before checking or refilling with

gear case oil, make sure the gear case and engine

are stopped and placed on a stable level surface.

Use oil recommended for ambient air temperatures

at which the gear case will be running at. Change

oil according to manufacturer’s recommendation,

using SAE 90 weight non-detergent oil. Check oil

level before running the system using the oil level

hole on the side of the gear case.

5) Check to see that water supply lines, strainers and

foam tank lines are free of debris and plumbed

correctly. Any leaks in the system will cause poor

system performance and operation.

STARTING THE SYSTEM

IMPORTANT: Before starting engine, be sure

discharge hose is secure.

1) Turn the engine switch located by the recoil starter

to the ON position.

2) Turn the fuel cock to the ON position.

3) Push the throttle lever to a slightly open position.

4) Operation of the choke lever

a) When engine is cold:

i) In cold weather, start engine with choke in

the fully-closed position.

ii) In warm weather, start engine with choke in

half-closed position.

b) When engine is warm:

i) Start engine with choke in fully open position.

5) Open the gun by pulling the trigger. This will allow

easier starting of the engine.

6) Start the engine with electric start key or recoil starter.

OPERATION OF THE SYSTEM

1) Idle the engine for 3 to 5 minutes or until operating

temperature is achieved.

2) CAUTION: Do not run the FoamPro High Pressure

System for long periods during unloading. Long

periods of pump deadheading may result in pump

damage due to overheating of water in the system.

3) Open the throttle lever to the upper zone after

engine has reached operating temperature.

4) Once the system is primed, you will note a load on

the engine; adjust RPM to proper speed for your

pumping application.

5) Adjust the foam concentrate injection percentage

with the display panel to the desired percentage

while the system is running at full capacity (8 GPM).

STOPPING THE SYSTEM

1) Stop pump for a short time:

a) Run throttle all the way down (fully to the right).

b) Turn engine switch to OFF position.

c) Turn the fuel cock to the OFF position. This

valve should be closed for transporting the

unit also.

2) Stopping pump for storage:

a) Turn fuel cock to OFF position instead of

turning the engine off.

b) Let the engine idle for 2 to 3 minutes until fuel

in the carburetor is depleted and engine stops.

c) Drain the pump and flush pump after use.

d) Drain all fuel from engine.

e) Store system in clean, dry environment.

11

Installation and Operation Manual

Turbo Stream

11 Maintenance

12 Troubleshooting

1. Daily: Inspect wiring, hoses, pump, gear case,

engine and connectors for tightness, corrosion,

leaks and/or damage.

2. Daily: Check hydraulic/engine oil level and refill

as necessary.

3. Monthly: Remove and clean the foam and pump

inlet strainer screens. Flush as required.

4. Monthly: Check pump gear case oil level and refill

as necessary.

5. Monthly: Check gear case oil level and refill

as necessary.

6. Monthly: Change engine oil every month or every

100 hours, whichever comes first. First oil change is

to be done at 20 hours.

7. Annually: Drain the pump oil and refill pump gear

case with SAE 30 weight non-detergent oil. Check for

foreign materials in the drained oil (water or debris).

8. Annually: Drain the gearbox oil and refill gearbox

with SAE 90 weight gear lube. Check for foreign

materials in drained oil.

Note: Water quality, flushing and storage

techniques, environment and usage may have an

effect on your maintenance schedule. To ensure

equipment longevity, it is recommended to adjust

your schedule accordingly.

Caution: Release all pressure and drain all

concentrate and water from the system before

servicing any of its components.

The FoamPro Turbo Stream system is designed to be easy to diagnose and service. There are several major

components (see Figure 2). Servicing the system involves isolation of the failed component and replacing it.

Following the trouble-shooting guide will allow quick diagnosis of the problem and the corrective action to take.

Symptom Probable Cause(s) Corrective Action

Pump runs but produces no flow. Pump is not primed. Pull trigger on foam sprayer gun while priming pump.

Pump loses prime, Air leak in suction hose or inlet fittings. Remove suction hose and test for leaks by pressurizing hose

chattering noise, pressure fluctuates. with water. Make sure thread sealant has been used on all

fittings.

Suction line is blocked, collapsed or Remove suction line and inspect it for a loose line or debris

too small. lodged in hose. Avoid all unnecessary bends. Do not kink hose.

Clogged suction strainer. Clean strainer.

Foam pump capacity below rating. Net Positive Suction Head required. If foam does not flow freely, modification of piping and pump

location is required.

Engine RPM Check engine RPM

Engine does not run or runs poorly. See engine manual.

12

Installation and Operation Manual

13 Parts Identification

2414B-G1P

Pump/Gearbox Assy.

2541-0049

PowerProTM Engine

2541-0057

Honda Engine

3312-0005

Thermal Relief Valve

2640-0004

Pressure Gauge

6032-0078

Control Panel

3320-0063

Inlet Check Valve

3350-0085

Foam Inlet Strainer

3350-0044

Water Inlet Strainer

3381-0045

Gun/Wand Assembly

with Low Pressure 3385-4500 Nozzle (approx. 400 PSI)

Nozzles

High Pressure 3385-2300 (1450 PSI)

Medium Pressure 3385-3000 (750 PSI)

2900-0049

Bypass Hose

13

Installation and Operation Manual

Turbo Stream

21.44 31.31

17.94

Pulse Hose Connection

Foam Concentrate Inlet

3/8-18 NPT

Water Inlet Port

3/4-14 NPT

Solution Outlet

1/2-14 NPT

6.69

5.31

.38

.22 Dia (4)

2.25

3

14 Installation Drawings

.44 Dia (6 Holes)

5.62

2.63

7.68

3.75

18.25

14

Installation and Operation Manual

NOTES

15

Installation and Operation Manual

Turbo Stream

NOTES

Installation and Operation Manual

26 Southern Blvd. • Nesconset, NY 11767 USA

Phone 800-645-0074 • FAX 816-892-3178

www.fireresearch.com

26 Southern Blvd. • Nesconset, NY 11767 USA

Phone 800-533-9511 • FAX 816-892-3178

www.foampro.com

15 Limited Warranty

Fire Research Corp. (FRC), as supplier of FoamPro, warrants to the original purchaser, each new pump, system or other product of its

own manufacture, for a period of two years from the date of shipment from the factory, to be free from defects in material and

workmanship under normal use and service. “Normal use and service” means not in excess of recommended maximum speeds,

pressures, and temperatures, or handling fluids not compatible with components materials, as noted in applicable FoamPro

product catalogs, technical literature, and instructions. This warranty shall not apply to any pump, system or other product which

shall have been repaired or altered to adversely affect the performance or reliability of the pump, system or other product.

Neither this warranty nor any implied warranty apply to damage or harm caused by any or all of the following: (1) Freight damage;

(2) Freezing damage; (3) Damage caused by parts and/or accessories or components not obtained from or approved by FRC; (4)

ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES, OTHER THAN INJURY TO THE PERSON, ARISING FROM THE USE

OF ANY PUMP OR OTHER PRODUCT MANUFACTURED BY FRC EXCEPT in states that do not allow the exclusion or limitation

of incidental or consequential damages; (5) Damage due to misapplication and/or misuse; (6) Normal wear of moving parts or

components affected by moving parts.

The liability of FRC under the foregoing warranty is limited to the repair or replacement at FRC's option without charge for labor

or materials of any parts upon return of the entire pump, system or other product or of the particular part to the FRC factory within

the warranty period, at the sole expense of the purchaser, which part shall upon examination appear to FRC’s satisfaction to have

been defective in material and workmanship. The liability of FRC under any theory of recovery (except any express warranty where

the remedy is set forth in the above paragraph) for loss, harm or damage, shall be limited to the lesser of the actual loss, harm or

damage or the purchase price of the involved pump, system or other product when sold by FRC to its customer.

FRC expressly warrants its pumps and other products as above stated. THERE ARE NO OTHER EXPRESS WARRANTIES. ANY

IMPLIED WARRANTIES, INCLUDING IMPLIED WARRANTY OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR

PURPOSE, ARE LIMITED IN DURATION TO TWO YEARS FROM THE DATE OF PURCHASE BY THE ORIGINAL

PURCHASER EXCEPT in states that do not allow time limitations on implied warranties. THERE IS NO IMPLIED WARRANTY OF

FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY WHEN THIS PRODUCT IS PUT TO RENTAL USE.

No person including any dealer or representative of FoamPro is authorized to make any representation or warranty concerning

FRC’s FoamPro products on behalf of FRC, or to assume for FRC the obligations contained in this warranty. FRC reserves the

right to make changes in design and other changes and improvements upon its products without imposing any obligations upon

itself to install the same, upon its existing products then in process or manufacture.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

IMPORTANT NOTICE

It is imperative to package all FoamPro components properly, before shipment (with Return Goods Authorization attached) back

to FRC. The FoamPro contains electronic components that may receive damage from improper shipping procedures! All FoamPro

components shipped back to FRC will pass through Quality Control Inspection, and will be photographed after the box is opened.

Any shipping damage, such as superficial scratches, nicks, etc., to the unit makes it unusable (even after the internal warranty

problem is repaired) and thus must be refinished to “like-new” condition during the warranty process. You are responsible for any

physical damage occurring to FoamPro components at your facility and during shipment back to FRC.

Package the FoamPro, complete with all the recommended parts the Customer Service representative requires (i.e., Digital

Display control with all premolded wire cables etc.) in its original carton with the Styrofoam and other packaging materials, as it

was received at your facility. FRC appreciates your attention in this matter, as we feel it will help us to serve you in a better fashion,

while keeping the cost of the FoamPro product competitive. Thank you.

Other manuals for Turbo Stream S108-4008

1

This manual suits for next models

2

Table of contents

Popular Paint Sprayer manuals by other brands

Clas Ohlson

Clas Ohlson SJ-108 instruction manual

National Garden Wholesale

National Garden Wholesale EZ Sprayer user manual

Gilson

Gilson SS-8R operating manual

Ningbo Dino-power Machinery

Ningbo Dino-power Machinery DP6388B owner's manual

Hozelock

Hozelock PortaShower Instructions & warnings

OHAUS

OHAUS SHRC0719DG instruction manual

Reflex

Reflex Servitec Mini Original operating manual

Annovi Reverberi

Annovi Reverberi AR Spray 16 Original instructions

Husqvarna

Husqvarna BP4E Owner's/operator's manual

WAGNER

WAGNER Paint Crew 770 owner's manual

Jula

Jula 082-203 operating instructions

Milwaukee

Milwaukee HEAVY DUTY M12 BHCS3L Original instructions