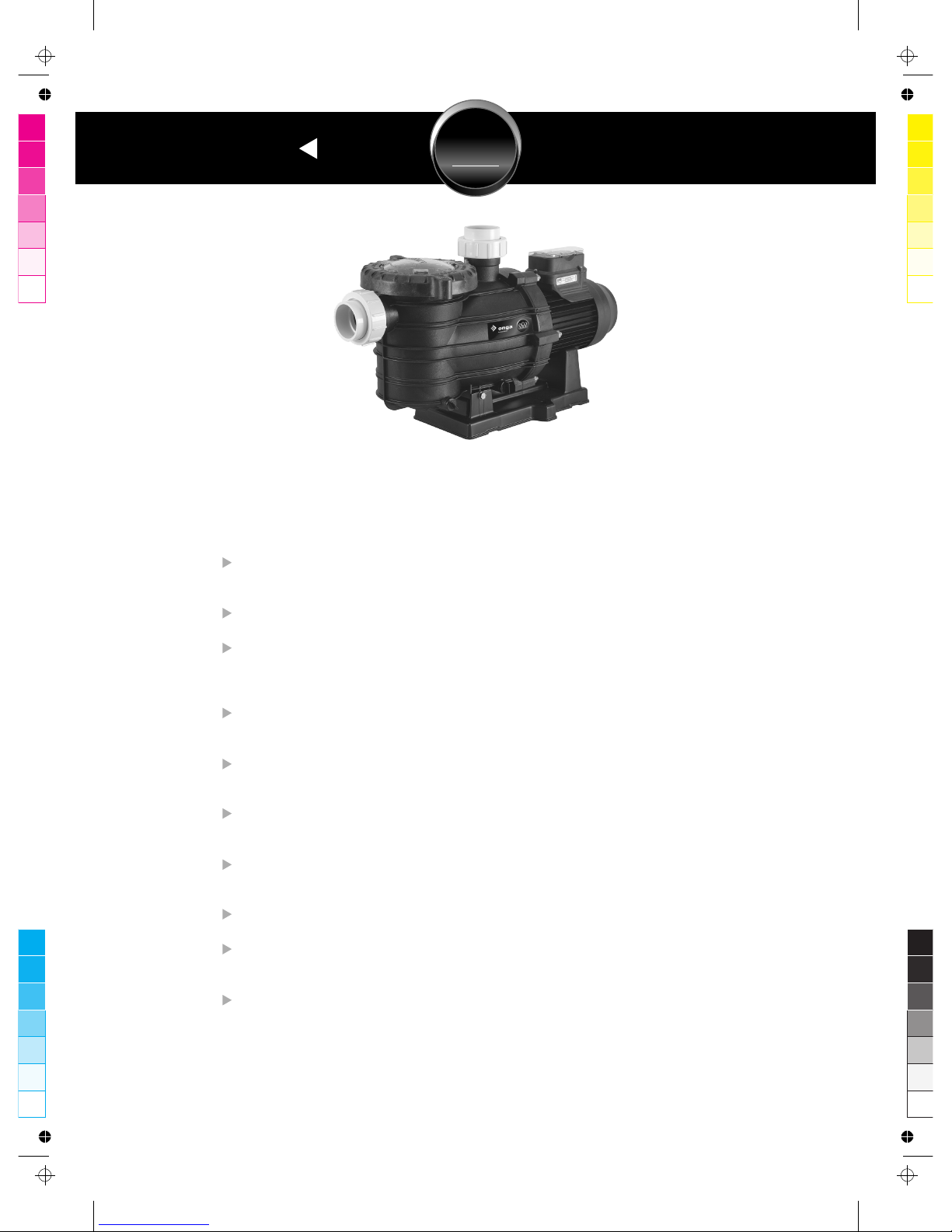

Installation eco

8 0 0

The pump must be installed and serviced by a suitably qualified person in order to avoid

hazard. Incorrectly installed or tested equipment may fail, causing severe injury or property

damage.

These instructions are a guide only. Should you the installer or owner of the product be

unfamiliar with the correct installation or operation of this product you should contact a

suitably qualified person for advice.

Do not connect system to high pressure or mains water system.

This pump is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety.

Children should be supervised to ensure that they do not play with the pump.

The Eco800 is electrically connected. Ensure that it is isolated from electrical supply during

installation and any subsequent service work.

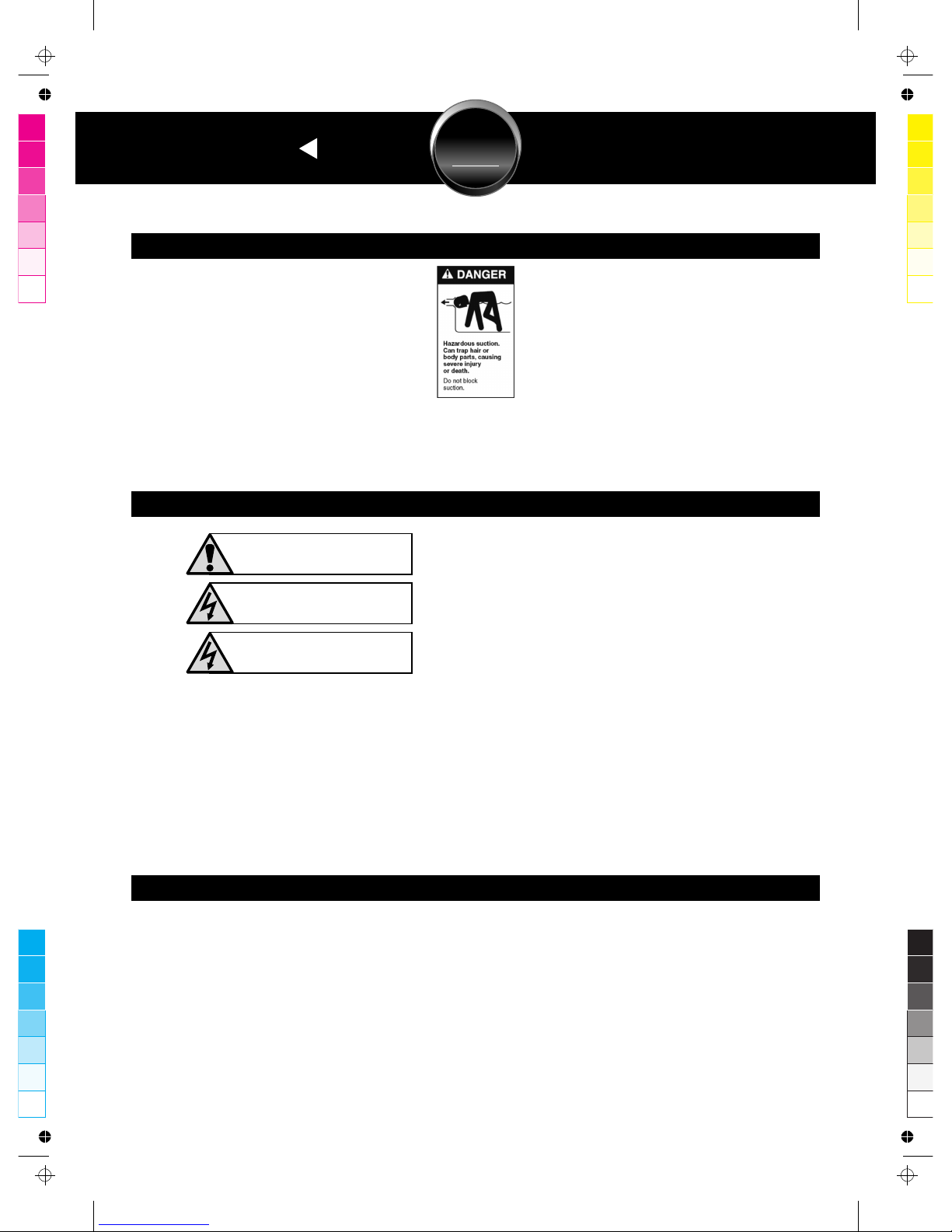

For best performance, allow pump

suction inlet height to be as far

below water level as possible and

allow the use of short, direct suction

pipe with minimum bends (to reduce

friction losses).

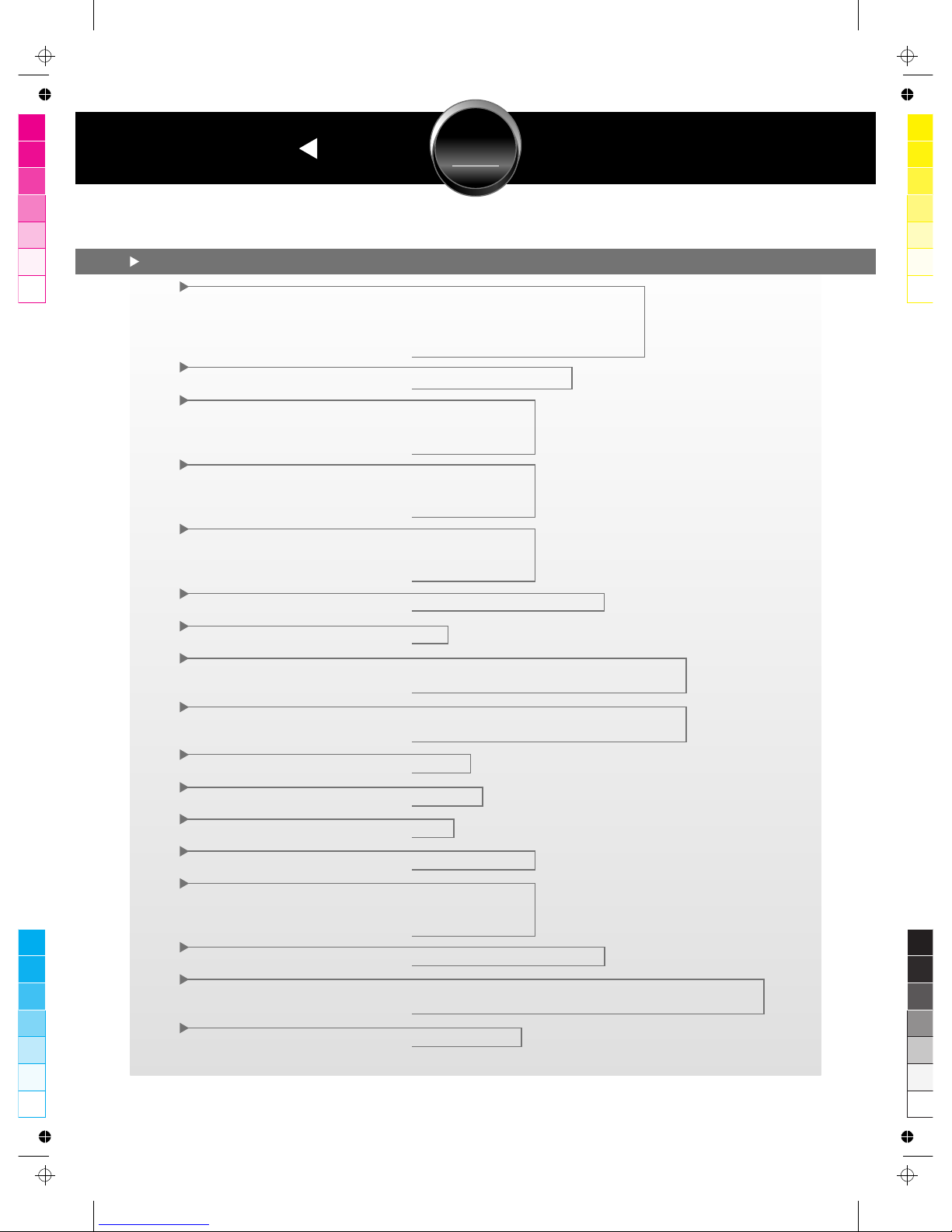

1. Plan the position of the pump

a) Have enough ventilation to keep ambient temperature below the motor's rated ambient temperature whenever the pump

is running. If installed in an enclosure/pump house, the enclosure must have adequate ventilation (200sq.cm min, inlet &

outlet) and air circulation Allow 200mm to keep rear of motor clear.

b) Have adequate floor drainage to prevent flooding and be protected from excess moisture.

c) Be solid, level, rigid and vibration free.

d) To reduce vibration and pipe stress, bolt pump to mount. Fixing holes accept 12mm fasteners.

e) Be within 2m of a power outlet for electrical connection (refer to AS/NZS 3000 for rules regarding connection of

electrical equipment in pool zones).

f) Allow adequate access for servicing pump and piping.

2. Piping

For best performance, allow pump

suction inlet height to be as far

below water level as possible and

allow the use of short, direct suction

pipe with minimum bends (to reduce

friction losses).

a) Use only Australian Standard PVC pressure pipe. For best performance use at least 50mm diameter pipe for all

connections to the pump. Never use a suction pipe smaller than pump suction connections (50mm) and use larger pipe

for long suction distances.

b) To avoid stress on the pump, support both suction and discharge pipes independently. Place these supports as close to

the pump as possible.

c) To avoid a strain left by a gap at the last connection, start all piping at the pump and run pipe away from the pump.

6