STR−NCS32100−GEVK

www.onsemi.com

6

Sensor Error

The ‘Sensor Error’ indicator will turn red if an open circuit

in the sensor coils is detected. Open coil detection is

continuously monitored. If a coil becomes damaged or is not

connected properly, then the system will be notified through

the sensor error bit. It is not recommended that the user

intentionally attempts to cause this error on the evaluation

board because it would involve damaging the PCB sensor.

Turn Count Overflow

The ‘Turn Count Overflow’ indicator turns red if the turns

count crosses 0. For example, if the current turns count is 4,

and the rotor is turned counter clockwise 5 full rotations,

then the turns count overflow error will signal. This is an

indicator to the system master that a multi turn count rollover

needs to be handled properly.

Low Battery

The ‘Low Battery’ indicator turns red if the backup

battery voltage falls below 2.7 V. The low battery error is

different than the low battery threshold that is configurable

by the user. The recommended battery voltage is 3.3 V, and

2.7 V is an indicator that the battery needs to be replaced.

No Power

The ‘No Power‘ indicator turns red if the 5 V VCC supply

is removed from the NCS32100. The user can exercise this

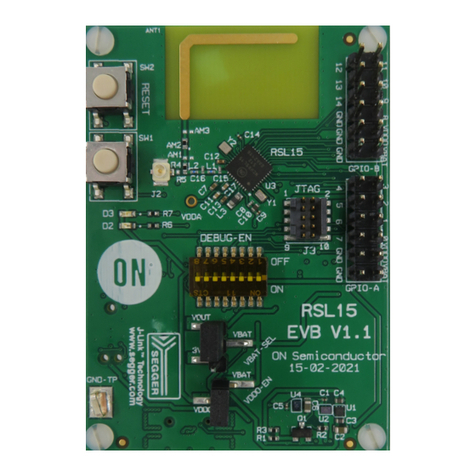

error by switching the red SW1 switch on the board to

disconnect the VCC supply. On a revA board, pulling the

J300 jumper will do the same.

Battery Alarm Threshold

The ‘Battery Alarm Threshold’ indicator will turn red if

the backup battery voltage falls below the user defined

battery threshold.

Over Temperature

The ‘over temperature’ indicator turns red if the user

defined temperature threshold is exceeded.

Any error indicators that have been tripped can be reset

from red to green by pushing the ‘Reset Error’ button on the

right side of the Strata GUI.

Diagnostics

The right side of the NCS32100 Strata GUI displays

encoder diagnostics for the user.

Turns Count

The turns count displays how many full revolutions have

occurred since the board was powered up. The turns count

can be reset back to 0 by pushing the ‘Reset Turns’ button.

Backup Battery Voltage

The ‘Backup Battery Voltage’ output gives the current

backup battery voltage as measured by the NCS32100. This

will change if the user dials around the R350 potentiometer

between 5 V and 1 V. The recommended battery voltage is

3.3 V.

Low Battery Threshold

The ‘Low Battery Threshold’ is the user specified battery

threshold as it is read out from the NCS32100. This output

will update to a new value if the user changes the battery

threshold.

Temperature

The ‘Temperature’ output is the internal temperature of

the NCS32100. The NCS32100 has an integrated

temperature sensor. The NCS32100 evaluation board does

not have a standard grounding plane connected to the back

paddle of the NCS32100 device, allowing it to be closer to

the PCB inductive sensor coils. Because there is not a heat

spreader, the internal temperature will be higher than

ambient room temperature.

Max Temp.

The ‘Max Temp’ output is the NCS32100 readout of the

user specified over temperature threshold. This will update

every time the user changes the over temperature threshold.

Version #

Indicates the firmware version number currently running

on the NCS32100.

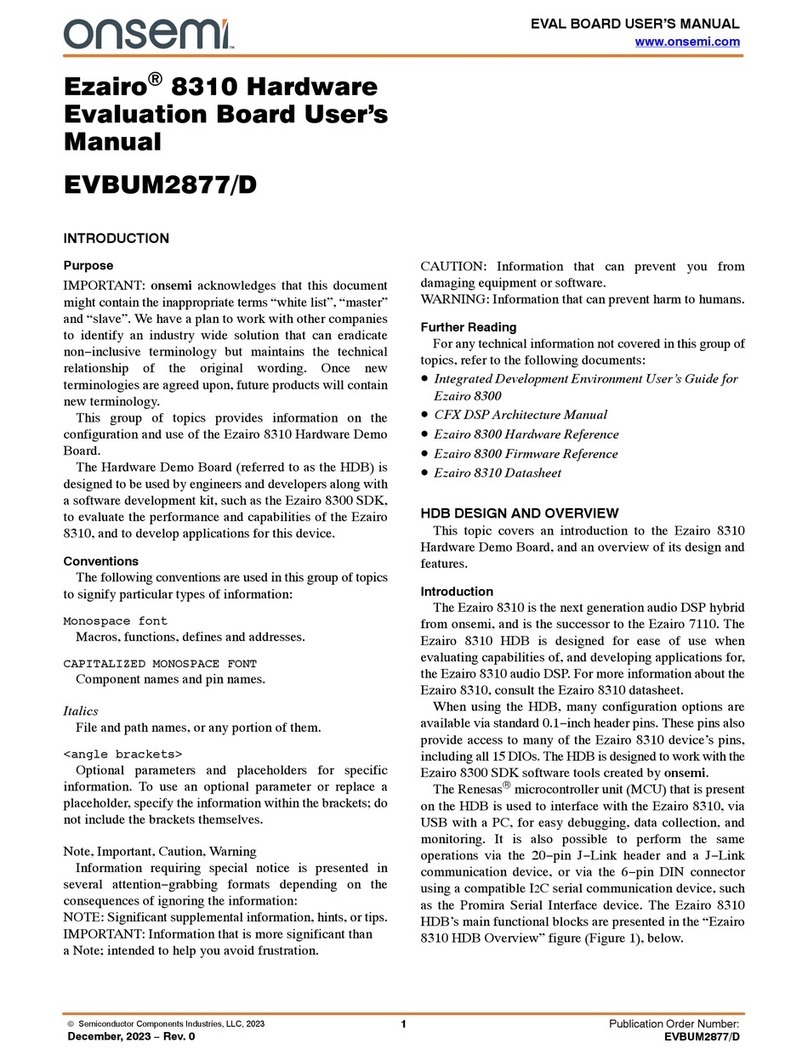

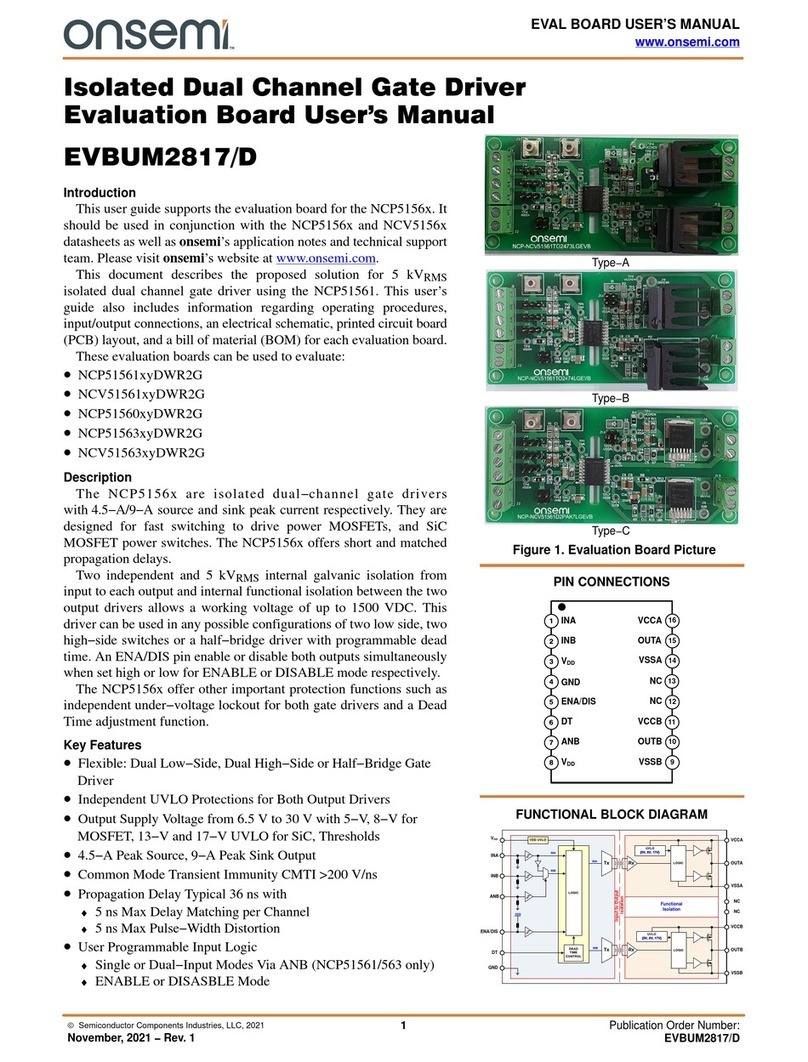

Calibration

The NCS32100 Strata UI allows the user to run the

self−calibration routine with 2 different options. The options

can be selected using the pull−down menu underneath the

“Calibration” button, as shown below.

Figure 8. Calibration Options

The “Master” option in the pull down will run the

calibration routine via the master (STM32), while the

“NCS32100” will run the calibration routine in the

NCS32100 internal MCU. Calibration through the master is

faster due to the higher capability of the STM32 processor.

Calibration through the master is expected to take less than

5 seconds, while calibration through the NCS32100 takes

around 10 seconds to complete, but has the added advantage

that no supporting code is needed from the master for the

calibration to run. For the calibration routine to run, the rotor

must be turning at a speed less than 500 rpm. While the rotor

is spinning, click the “Calibrate” button, and the UI will

freeze while the calibration routine runs. Once the calibration

routine has completed, the UI will return to normal operation.