6 7

FOR SAFETY:

• Unless trained and authorized.

• Unless operator manual is read and understood.

• Unless mentally and physically capable of following machine instructions.

• Under the inuence of alcohol or drugs.

• While using a cell phone or other types of electronic devices.

• If not in proper operating condition.

• In outdoor areas. This machine is for indoor use only.

• In areas where ammable vapors/liquids or combustible dusts are present.

• With pads or accessories not supplied or approved by Tennant. The use of othe pads may impair safety.

• In areas with possible falling objects.

• In areas that are too dark to safely see the controls or operate machine.

1. Do not operate machine:

2. Before operating machine:

• Check machine for uid leaks.

• Make sure all safety devices are in place and operate properly.

3. When operating machine:

• Use only as described in this manual.

• Report machine damage or faulty operation immediately.

• Wear closed- toe, non- slip work shoes.

• Reduce speed when turning.

• Go slowly on inclines and slippery surfaces.

• Do not scrub on inclines that exceed 9% grade or transport on inclines that exceed 21% grade.

• Follow site safety guidelines concerning wet oors.

• Follow mixing, handling and disposal instructions on chemical containers.

• Do not carry passengers on machine.

• Use care when reversing machine.

• Keep children and unauthorized persons away from machine.

4. Before leaving or servicing machine:

• Stop on level surface.

• Set the parking brake, if equipped.

• Turn o machine and remove key.

5. When servicing machine:

• Disconnect battery connection and charger cord before working on machine.

• All work must be done with sucient lighting and visibility.

• All repairs must be performed by trained personnel.

• Use Tennant supplied or approved replacement parts.

• Do not modify the machine from its original design.

• Do not jack up machine.

• Avoid moving parts. Do not wear loose clothing or jewelry and secure long hair.

• Do not disconnect the o- board charger’s DC cord from the machine’s receptacle when the charger is

operating. Arcing may result. If the charger must be interrupted during charging cycle, disconnect the

AC power supply cord rst.

6. When loading/unloading machine onto/o truck or trailer:

• Drain tanks before loading machine.

• Use a ramp, truck or trailer that can support the machine weight and operator.

• Do not operate the machine on a ramp incline that exceeds a 5% grade level.

• Use a winch if ramp incline exceeds a 5% grade level.

• Lower the scrub head and squeegee before tying down machine.

• Turn machine o and remove key.

• Set parking brake (if equipped).

• Block machine wheels.

• Use tie- down straps to secure machine.

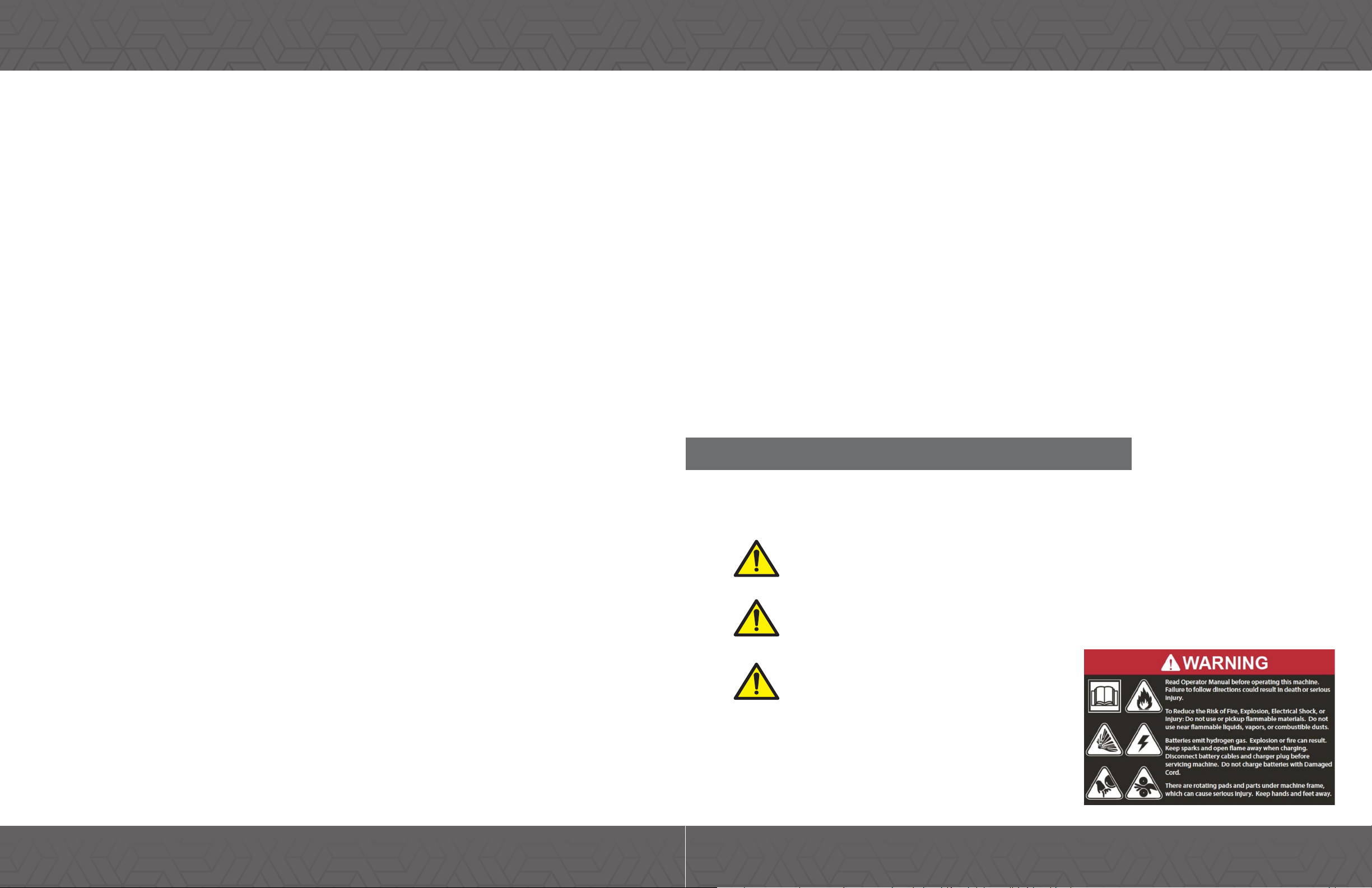

SAFETY SYMBOLS

These following safety symbols appear on the machine and in this manual to alert the operator of

potential safety hazards. Read them carefully and understand their meaning. Replace labels if they are

missing or become damaged or illegible.

• Do not use incompatible battery chargers as this may damage battery packs and potentially cause a

re hazard.

• Inspect charger cord regularly for damage.

• Keep work area well ventilated.

• Avoid contact with battery acid.

• Keep all metal objects o batteries.

• Do not power spray or hose o machine.

• Use a hoist or adequate assistance when lifting batteries.

• Battery installation must be done by trained personnel.

• Wear personal protection equipment as needed and where recommended in this manual.

DANGER: The signal word DANGER indicates a hazardous situation which, if not avoided according

to the instruction found in this Operator Manual or on your machine, will result in death or serious

bodily injury.

WARNING: The signal word WARNING indicates a hazardous situation which, if not avoided

according to the instruction found in this Operator Manual or on your machine, could result in

death or serious bodily injury.

CAUTION: The signal word CAUTION indicates a

hazardous situation which, if not avoided according

to the instruction found in this Operator Manual or

on your machine, could result in minor or moderate

injury or damage to your engine or property.

SAFETY INSTRUCTIONS SAFETY INSTRUCTIONS