WARNINGS

Please read the following instructions carefully.

The warnings in this manual must be observed in conjunction with the USER

MANUAL. Read and keep this manual in its entirety for the life of the product,

including proof of purchase and warranty (USER MANUAL).

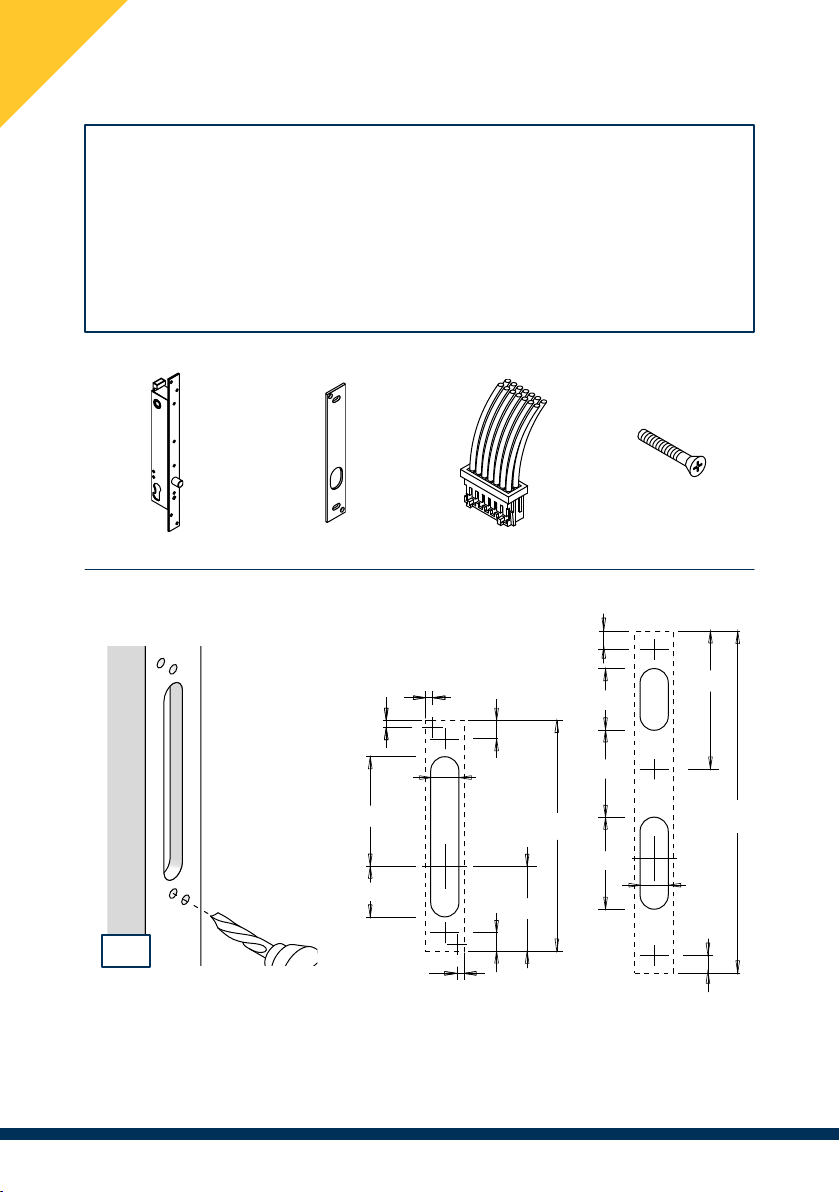

Use only supplied or recommended products.

Thoroughly clean the work area of dust and shavings before installation.

Do not expose the product to water, weather, high temperatures or strong

electromagnetic �elds. Do not install in explosive environments or in the

presence of flammable vapours: safety hazard.

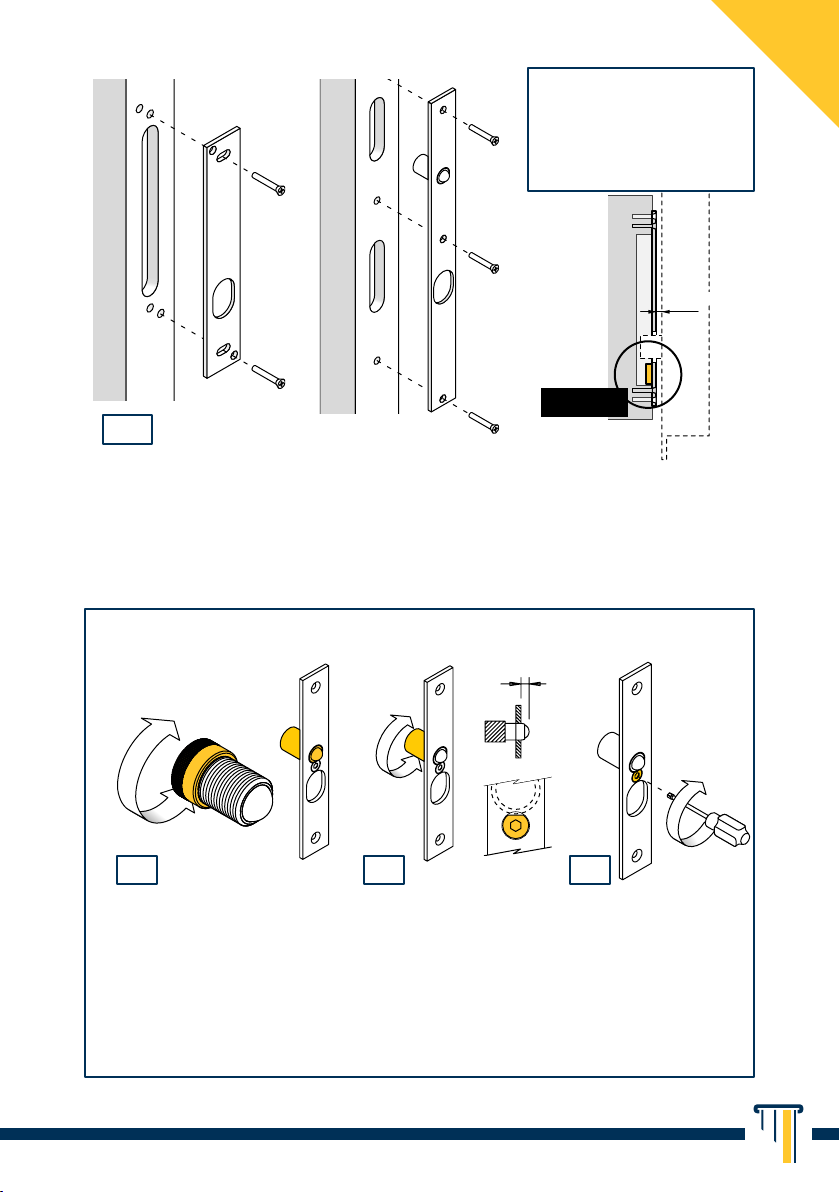

Entrust the installation of the electrical part to experienced personnel.

Do not make modi�cations or repair to the electrical or electronic components.

Check for proper grounding when connecting to the power supply.

Disposal of packaging in the appropriate containers is recommended.

For further information:

www.opera-italy.com

Tel: +39 059 451708