1

SECTION 1.0

INTRODUCTION

U.S. Patent No. 6,327,081

“One of the single greatest detriments to taking truly outstanding astronomical images is the focus shift due

to changing thermal conditions. A small change in ambient temperature can cause otherwise sharp stellar

images to bloat in size ruining the final image and wasting precious observing time. Someone needs to

develop a focusing system which compensates for these temperature changes and holds the focus steady

throughout the night.”

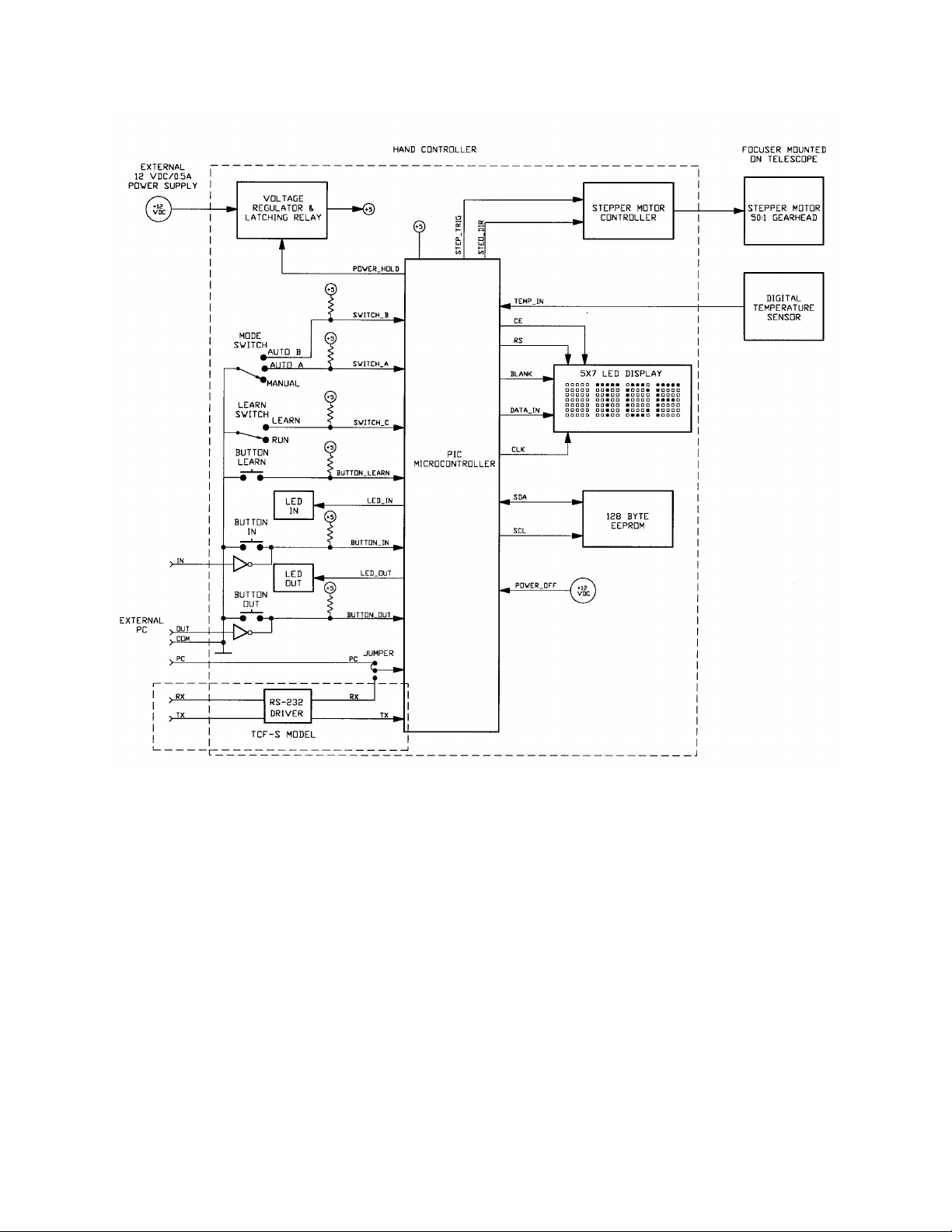

Optec has developed such a system. Mechanically, the new TCF-S (Temperature Compensating

Focuser) is a robust Crayford style motorized focuser with high repeatability. The Crayford

design allows for a solid friction roller focusing system with no play and very little backlash.

Optec’s implementation is ideal for applications that require exact focus such as CCD imaging or

film astrophotography. A geared stepper motor rotates the drive shaft with one step rotation of the

motor equal to a 0.00008-inch movement of the drawtube. A pair of pushbuttons control the

direction of focus and the DRO (digital read-out) displays the current position. The TCF-S

focuser can handle cameras and instrument packages weighing up to 10 pounds.

Unique to the TCF-S focuser, an electronic controller system monitors the telescope's tube

temperature and compensates the focus accordingly. A small temperature probe is attached to the

side of the telescope tube and monitors temperature with a resolution of 0.1°C. For a typical

Schmidt-Cassegrain of 8 to 11 inches aperture and f/10 focal ratio, the back focus will move

approximately 0.20 mm for every 1°C change in telescope temperature. It is not unusual during an

observing session for the ambient temperature to change by as much as 10°C within the time span

of a few hours. This change in focus due to temperature is a serious problem for most telescope

designs and requires frequent re-focusing during long exposures. A typical RGB exposure

sequence can last one hour making it imperative that the focus be checked and corrected after each

filter change.

A simple learning procedure is used to find the temperature coefficients specific to the user's

telescope system. The TCF-S system allows for two different coefficients (corresponding to two

different f-ratio configurations) to be calculated and stored in the EEPROM memory. Once

learned, either coefficient can be selected with a simple slide switch. A manual mode allows the

user to set the focus manually at any time.

The digital nature of the TCF-S allows opportunities for truly intelligent focusing. Using a serial

interface, a programmer can control the focuser from any PC. Exact focus can be found by

optimizing a stellar centriod’s diameter.

At the end of an observing session, the TCF-S focuser remembers the last temperature and

position. When the unit is turned back on for a new session, the TCF-S computes a new position

using the current tube temperature and moves to that position. Assuming no changes to the optical

configuration, the object will snap into sharp focus.