Light reception authorization LED: Red

(Upper/Lower)

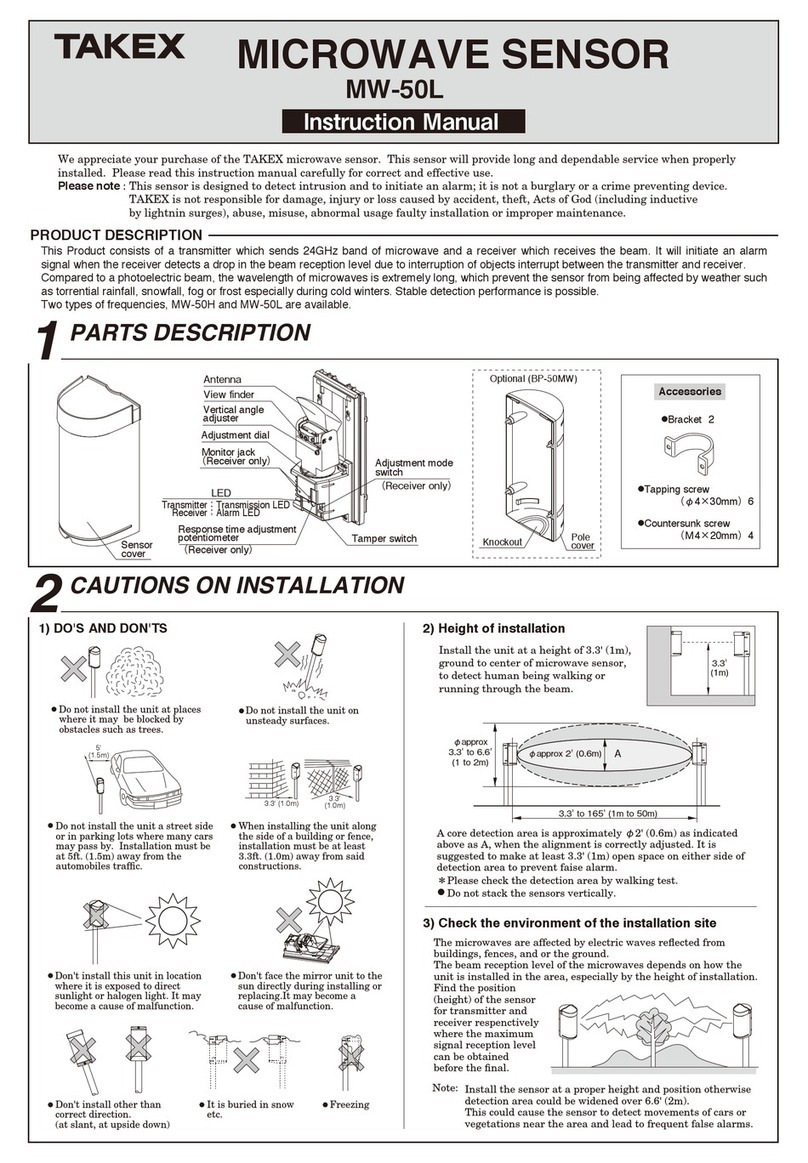

Monitor jack

Sound check switch (Factory setting: OFF)

Transmitter power changeover switch

(Factory setting: H)

Transmitter LED switch

Transmitter channel changeover switch

(Factory setting: 1CH)

Detection response time adjustment volume

Upper/lower changeover switch

Upper/lower changeover switch

[Transmitter]

[Receiver]

Not used

“8 EXPLANATION OF FUNCTIONS

(8-1 MODULATION FREQUENCY

CHANGEOVER FUNCTION)”

“8 EXPLANATION OF FUNCTIONS

(8-2 TRANSMITTER POWER

SELECTION FUNCTION)”

“8 EXPLANATION OF FUNCTIONS

(8-6 UPPER/LOWER CHANGEOVER FUNCTION)”

(Factory setting: Standard position [0.05 secs])

“8 EXPLANATION OF FUNCTIONS

(8-6 UPPER/LOWER CHANGEOVER

FUNCTION)”

“8 EXPLANATION OF FUNCTIONS

(8-5 DETECTION RESPONSE TIME

ADJUSTMENT FUNCTION)”

“8 EXPLANATION OF FUNCTIONS

(8-3 ALARM MEMORY DISPLAY FUNCTION)”

“8 EXPLANATION OF FUNCTIONS

(8-4 SOUND CHECK FUNCTION)”

Alarm memory changeover switch (Factory setting: Remote)

Light reception channel changeover switch (Factory setting: 1CH)

“8 EXPLANATION OF FUNCTIONS

(8-1 MODULATION FREQUENCY CHANGEOVER FUNCTION)”

2

NAMES OF OPERATION SECTION

1-3

Transmitter LED: Red

(Upper/Lower)

Alarm LED

: Red

Auto gain

lock switch

Sensitivity

attenuation LED

: Red

Memory LED

: Red

Do not use the sensors powered with a voltage level other

than the indicated power supply voltage specied (between

10 to 30V DC). Doing so may cause a re or electrical shock.

Do not connect a device that exceeds the capacity shown to

the output contact of this device. Doing so may cause a re or

electrical shock.

Do not touch the terminal section with wet hands.

Doing so may cause an electrical shock.

Do not disassemble or modify this device. Doing so may cause

a re, electrical shock, or malfunction of the device.

If smoke or an abnormal odor or sound is found, leaving it

unattended may cause a re or electrical shock. Immediately

turn off the power to the device and conrm that the abnormal

state has been corrected, and then ask the place of purchase for

repair.

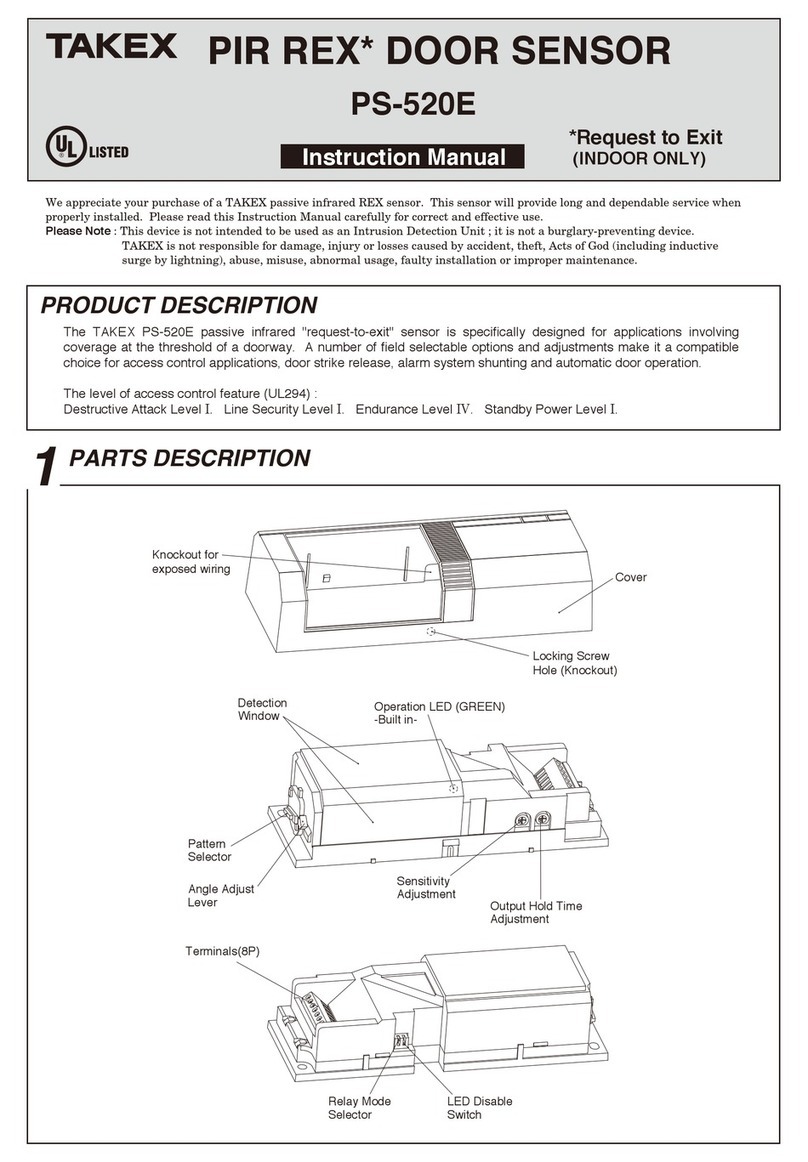

EXAMPLE OF INCORRECT INSTALLATION

2-1 DON'TS Do not install as shown below. This will cause

erroneous detection or detection failure.

OPERATING PRECAUTIONS This manual describes the precautions to be observed for safe operation of this

device by classifying them into the following categories. As these are important, be

sure to read and strictly observe them.

Warning

Caution

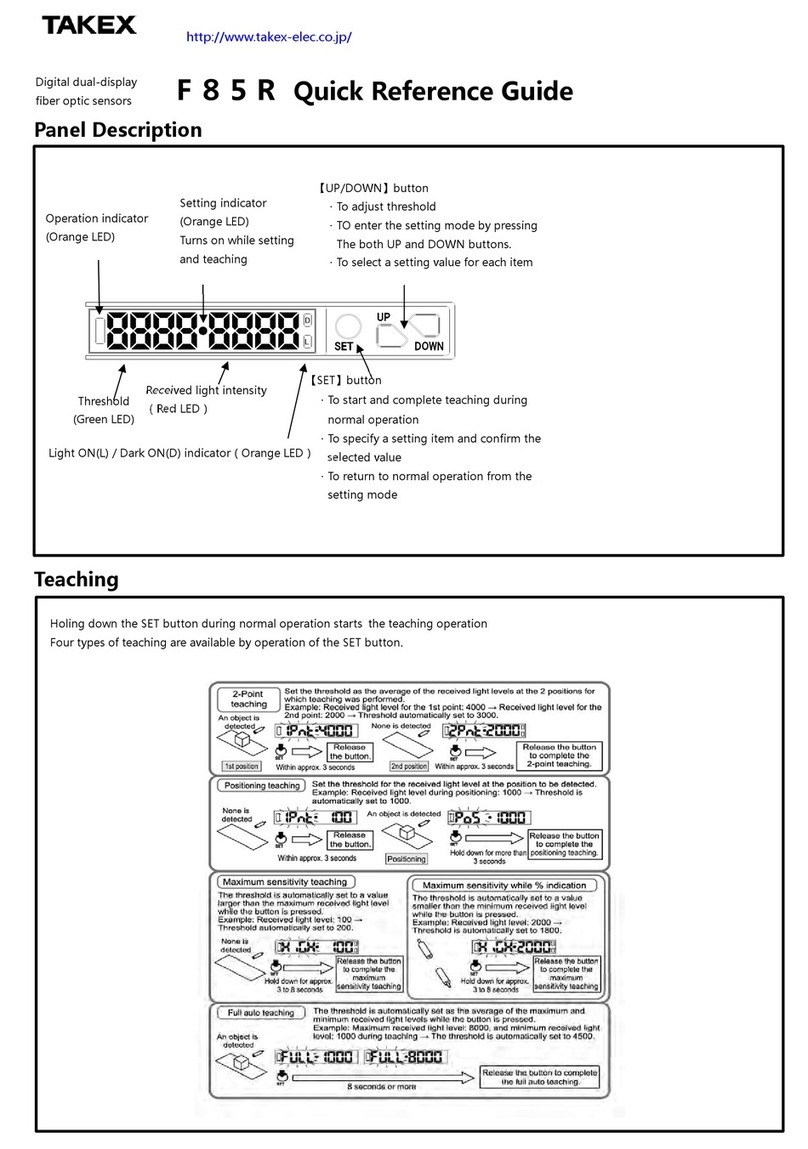

Description of the Display

Indicates information that if ignored and the device is handled incorrectly, may result in death or serious injury.

Indicates information that if ignored and the device is handled incorrectly, may result in injury or damage to property alone.

This symbol indicates a prohibited action, with the specic action shown near the symbol.

Indicates the useful information.

Example: Do not disassemble

Warning

Caution

(1) When using multi-level protection, use sensors of the same model for both upper and lower sensors, and set the

same transmission power (H/L) for all of them.

(2) Using these sensors together with sensors from a different series (e.g. PB-HF-KH) may cause interference between

the sensors.

Do not install this device in a location that cannot support its

weight. Doing so may cause the device to fall and cause an

injury or malfunction of the device.

Installation in locations

shaded by trees etc.

Installation in location where

strong light such as sunlight or

light from vehicle headlights can

directly enter the receiver

Installation in areas where

objects that move with the

wind (the laundry etc) can

obstruct the optical axis