Sensors PG1 | Data sheet No. 13252 | Version 09-2019 | 1| 6

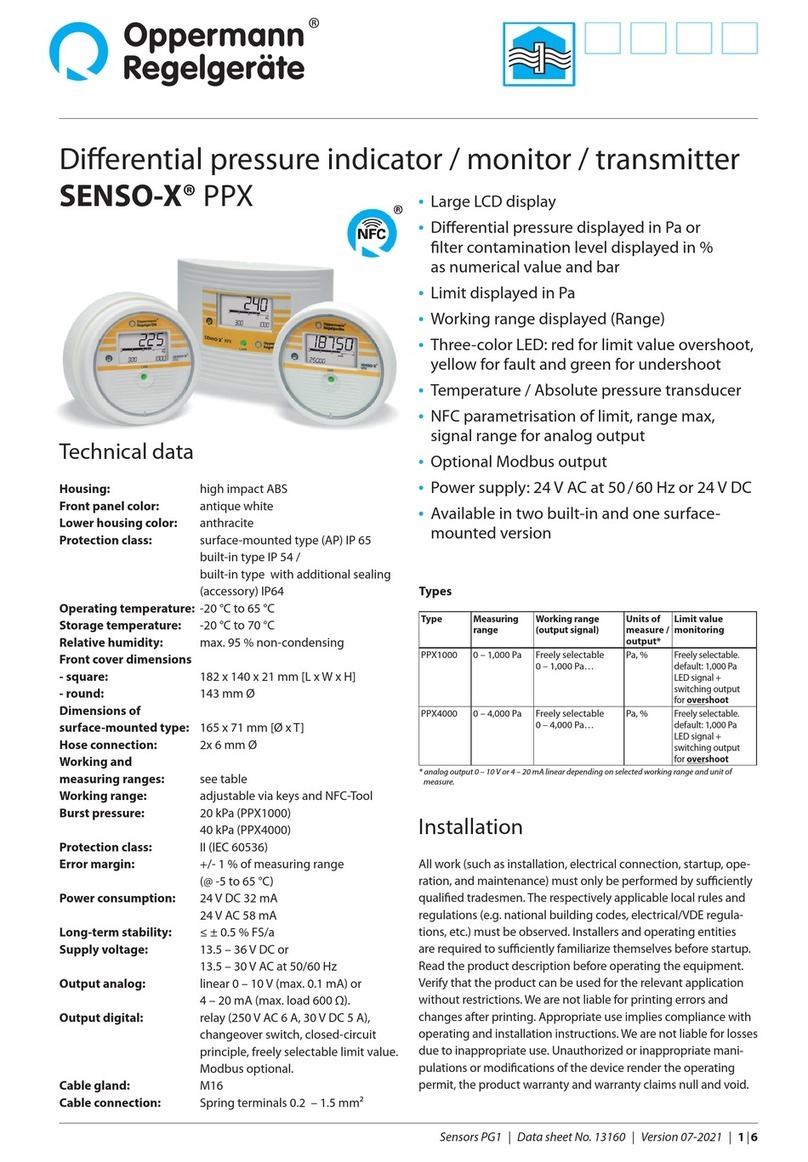

Pressure dierential

transmitter DDS-AR984...

DDS-QR984...

• Automatic zero point setting

• Up to 8 sensor ranges

• Metric cable glands

• Arbitrary installation orientation

• Output can be toggled between square root

extraction/lin.

Technical Data

Compressed medium: Air and non-aggressive media

Power supply: 22 – 30 V AC/DC

Output signal: 0 – 10 V or 4 – 20 mA

Maximum current draw:

• Without display 160 mA

• With LED display 210 mA

Admissible ambient

conditions: -10 - 50 °C, 0 - 95 % RH

(non-condensing)

Long-term stability, type:

n. a.

Load (at 4 – 20 mA): 20 – 500 Ω

Linearity (incl. hysteresis

and reproducibility):

≤ ± 0,5% of full scale, min ± 1 Pa

Uncertainty (total error

excluding long-term and

temperature inuence): ± 1% of full scale, min ± 1 Pa

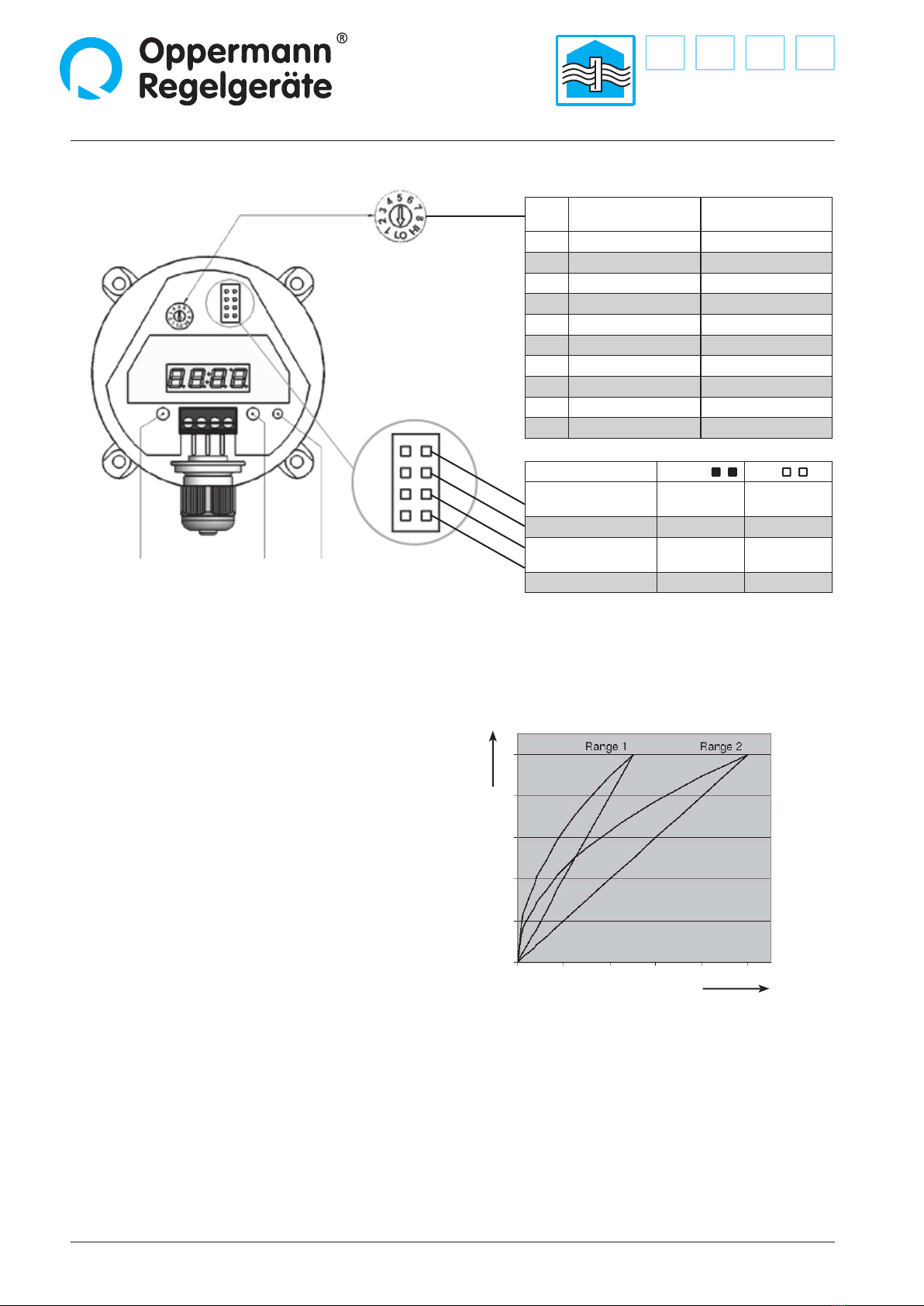

Switching output (npn): max. 30 V DC/100 mA

Output signal toggle: Linear/square root extraction

Zero setting adjustment: Automatic

Response time settings: Short, 200 ms

Long, 1 s (default state)

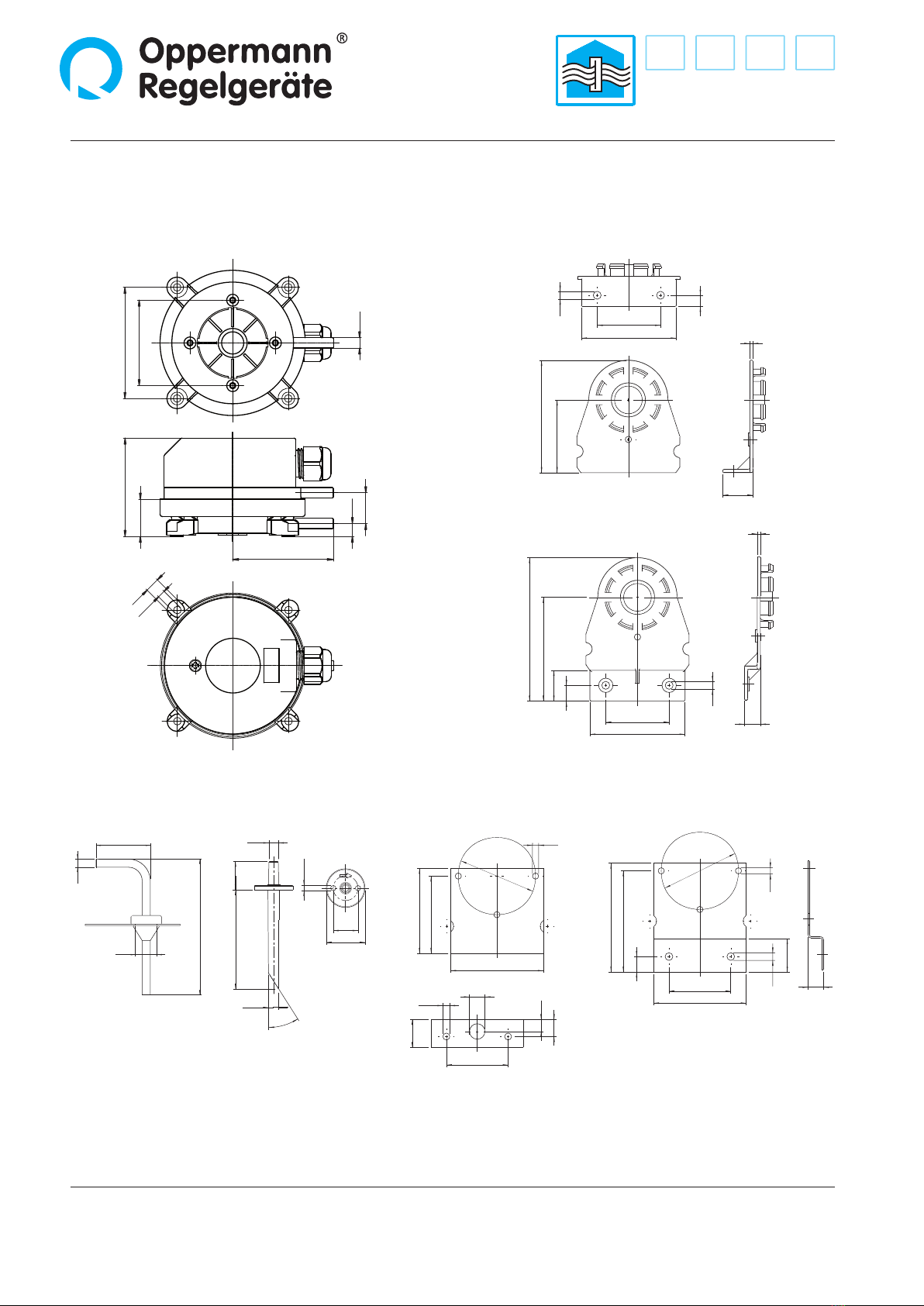

Process ports: 6 mm hose ttings

Electrical connection: Screw terminals for wires

and cores up to 1.5 mm²

Mounting: Screw mounted with

sheetmetal screws

Display, optional: Red LED display, 3.5 characters

Housing material: Switch housing with process port P2,

ABS, light-gray;

Mounting bracket with process port

P1, POM, white

Housing dimensions: approx. Ø 85 mm, H 58 mm

Weight: approx. 150 g

Protection type iaw.

EN60529: IP 54 with protective cover

Cable grommet for

protective cover: M 16 x 1,5 Polyamide threads

Standards / conformity: EN 60770, EN 61326

2011/65/EU (RoHS)

Sensor method: Piezo-resistive pressure transducer

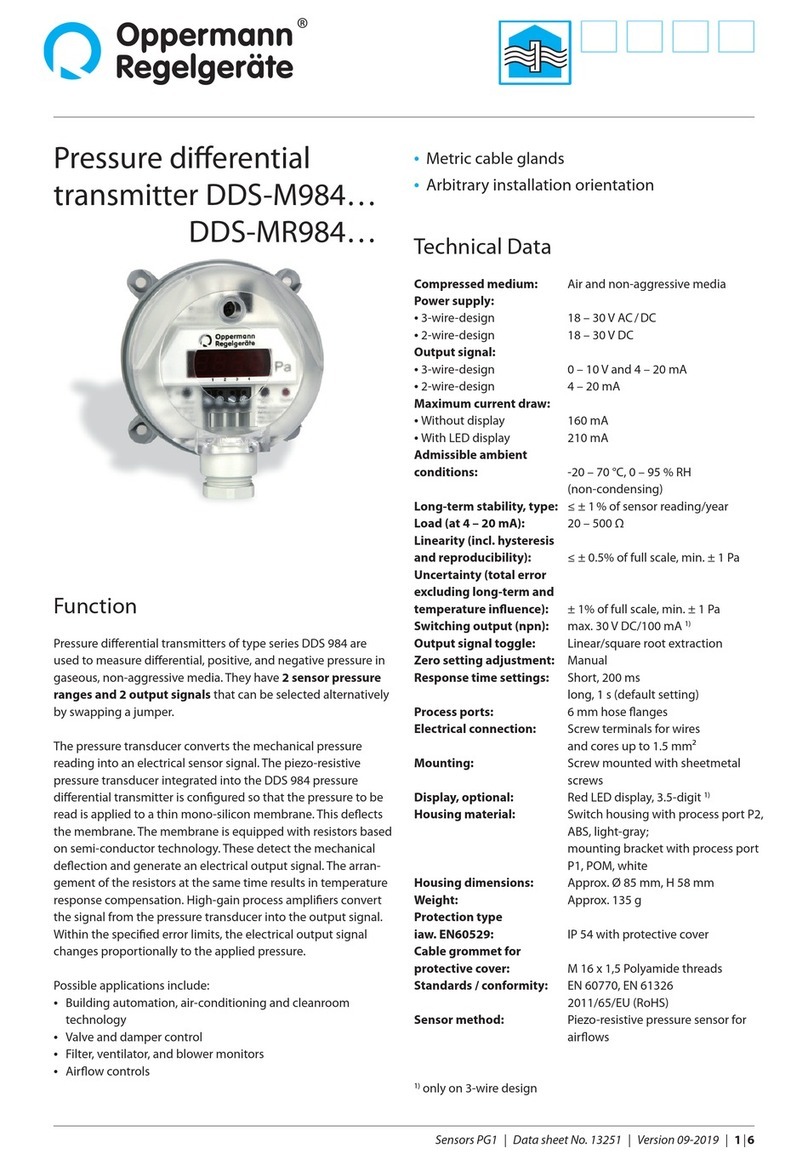

Function

Pressure dierential transmitters of type series DDS 984 are

used to measure dierential, positive, and negative pressure

in gaseous, non-aggressive media. They have up to 8 sensor

pressure ranges and 2 output signals that can be selected

alternatively by swapping a jumper.

The pressure transducer converts the mechanical pressure value

into an electrical sensor signal. The piezo-resistive pressure

transducer integrated into the DDS 984 pressure dierential

transmitter is congured so that the pressure to be read is

applied to a thin mono-silicon membrane. This deects the

membrane. The membrane is equipped with resistors based

on semi-conductor technology. These detect the mechanical

deection and generate an electrical output signal. The arran-

gement of the resistors at the same time results in temperature

response compensation. High-gain process ampliers convert

the signal from the pressure transducer into the output signal.

The electrical output signal changes proportionally to the

applied pressure within the specied error limits.

Possible applications include:

• Building automation, air-conditioning and cleanroom

technology

• Valve and damper control

• Filter, ventilator, and blower monitors

• Airow controls

DDS-AR984…: 2 sensor ranges, automatic zero point setting

DDS-QR984…: 8 sensor ranges, automatic zero point setting