MAINTENANCE SCHEDULE

SOTR MASK MAINTENANCE SCHEDULE

SOTR FILTER MAINTENANCE SCHEDULE

9

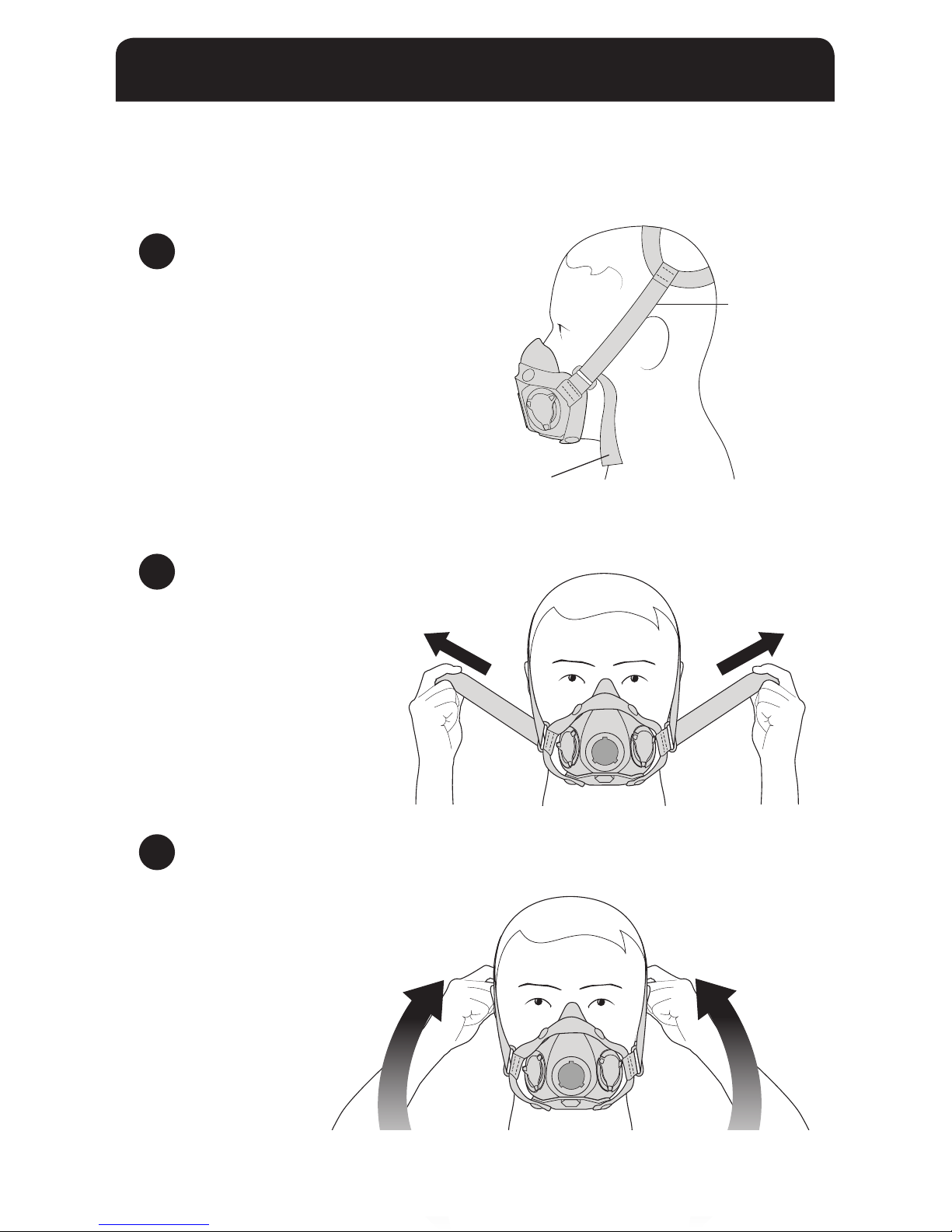

1Clean the mask with 70% isopropyl alcohol and let dry.

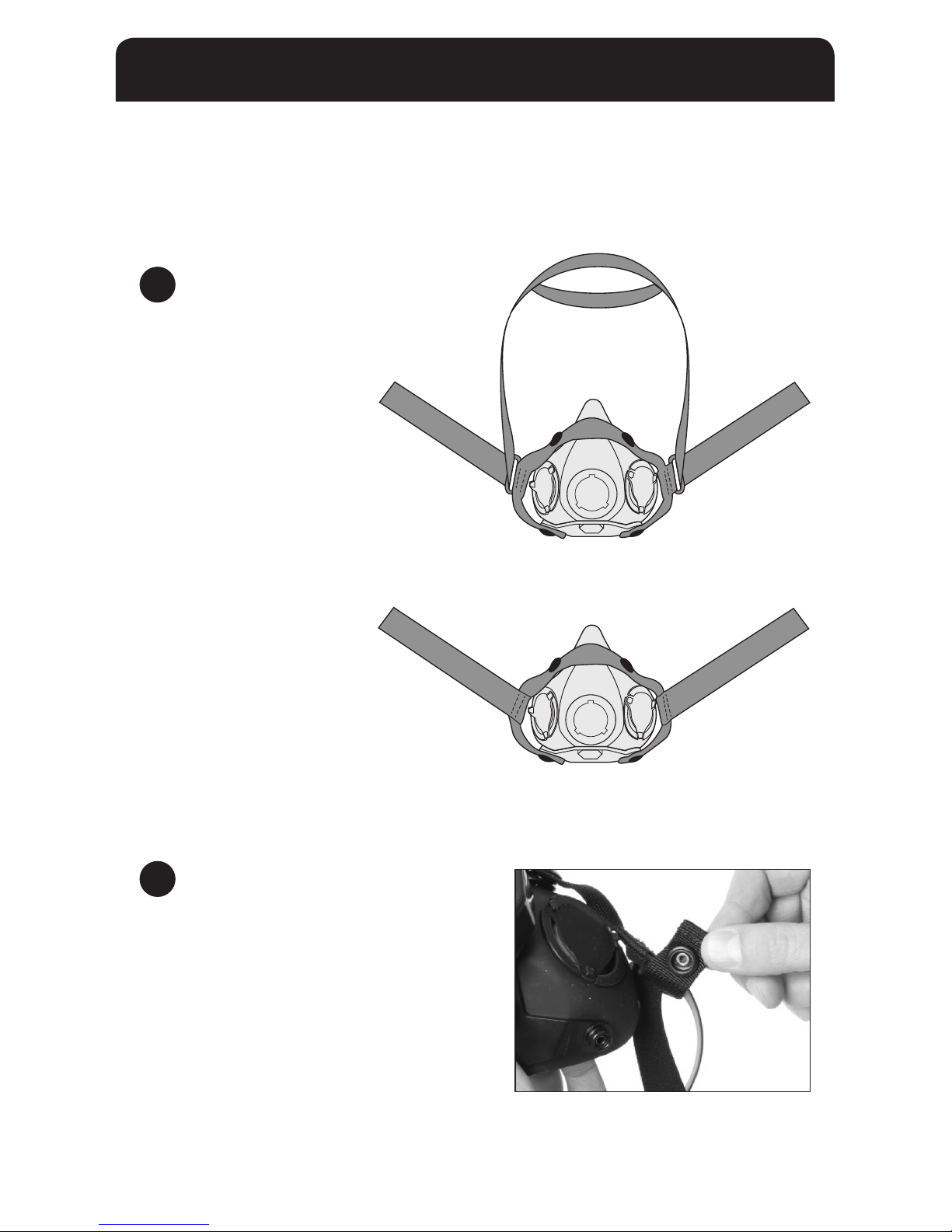

2Check that the snaps are in working condition.

3Clean the Velcro of dust and dirt by using pressurized air.

4Visually check the snaps, exhalation valves, inhalation valve, and lter gasket for signs of damage.

5Visually check the SOTR facepiece for any signs of damage.

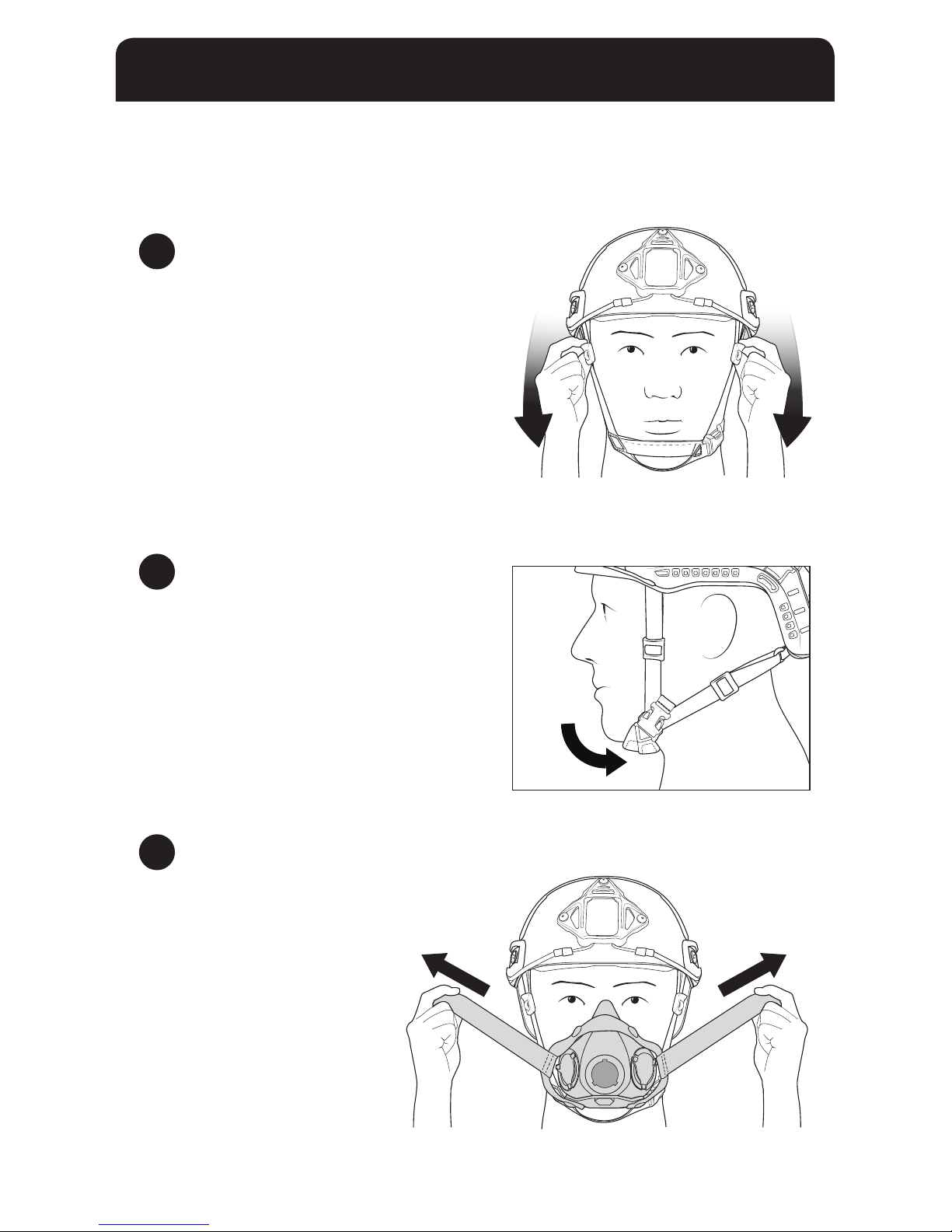

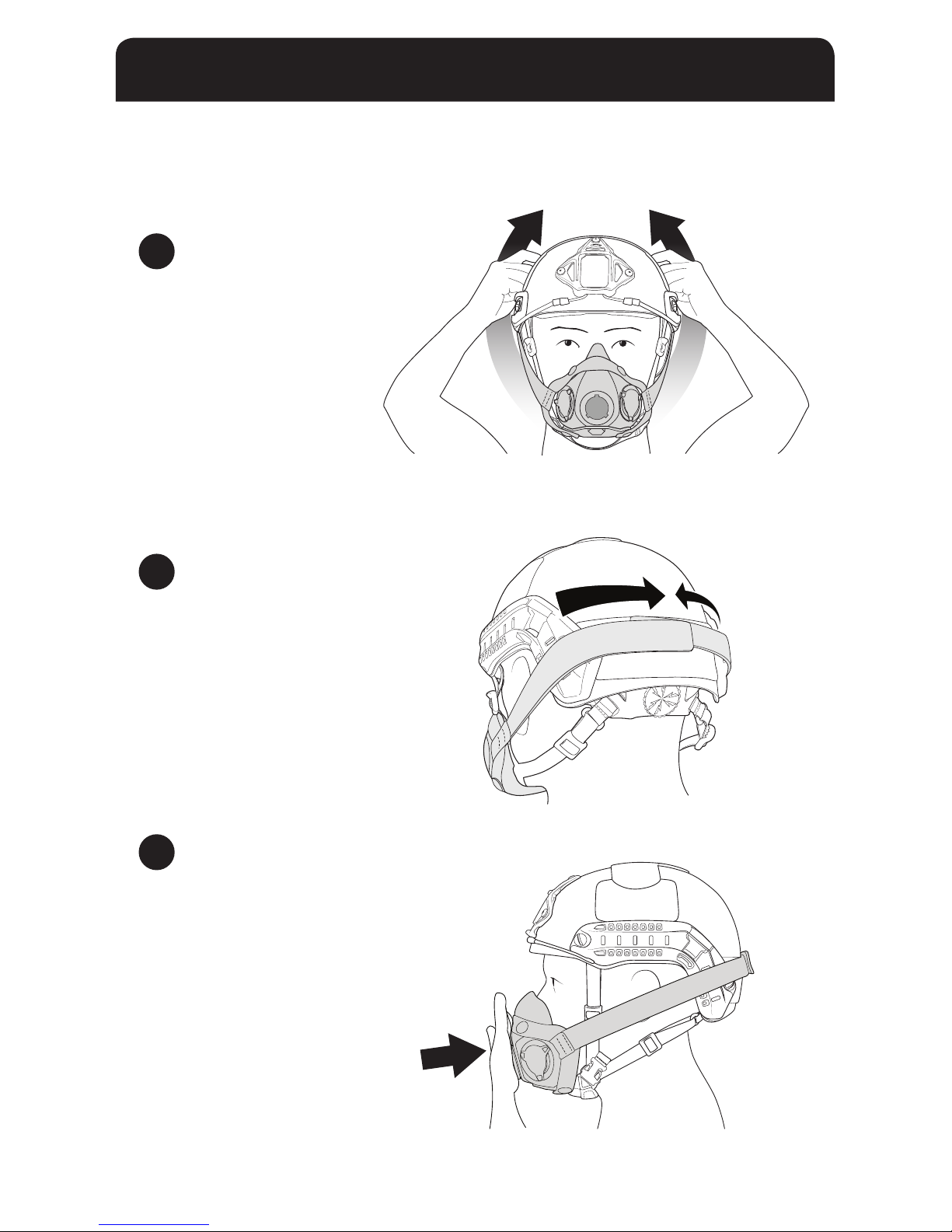

6Check that both harnesses work properly and do not have any damage.

7Visually check the microphone and conduct operational checks of the microphone.

NOTE: If any defects are found, the damaged components should be replaced before use.

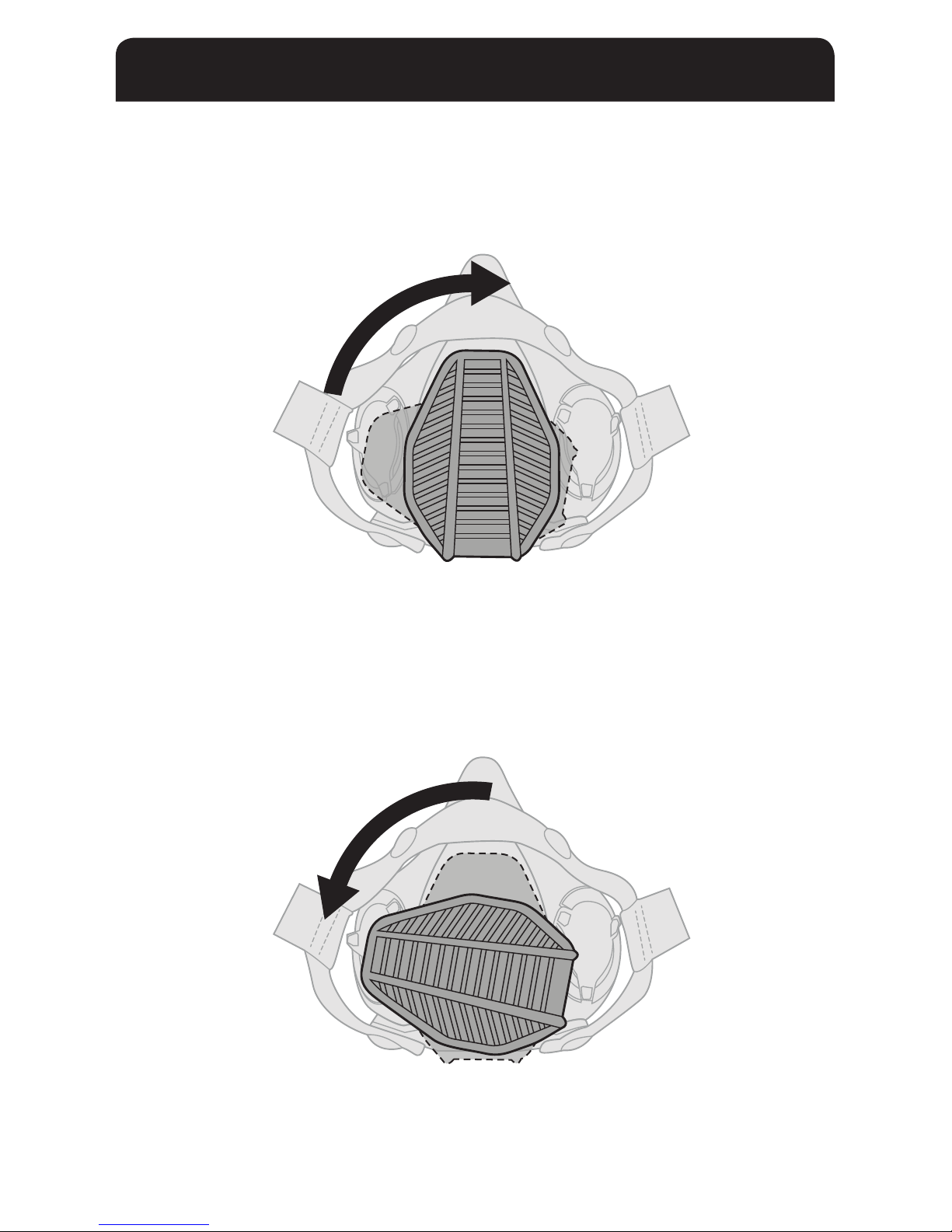

1Always start your training or operation with a new lter.

2Once the lter becomes difcult to breathe through, discard the lter* and replace with a new one.

3Visually check the lter gasket on the front of the yoke for any signs of damage.

4Replace the lter gasket after 50 lter changes (or earlier if damage is observed).

NOTE: *Dispose of the lter according to your unit’s recommendation. The lter will contain

hazardous elements and must be disposed of accordingly. Local, state, and/or federal disposal

regulations may apply.