1

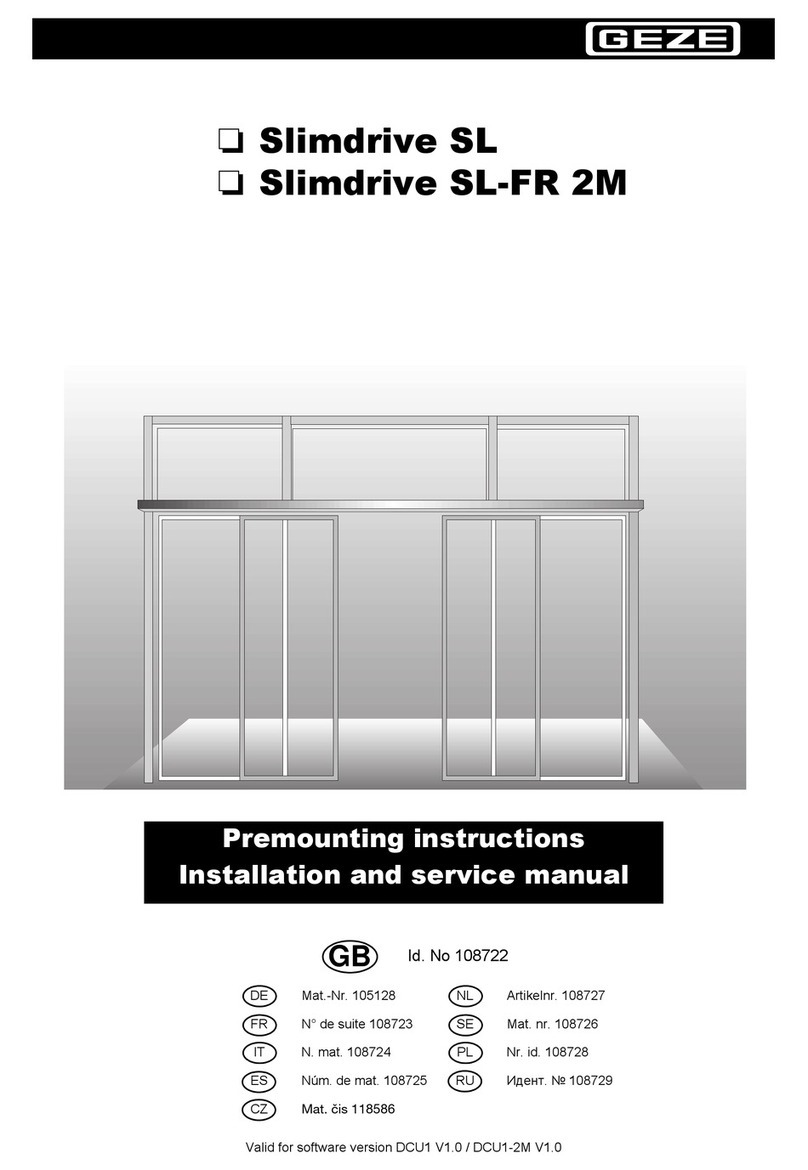

GEZE TS4000EFS Electrohydraulic

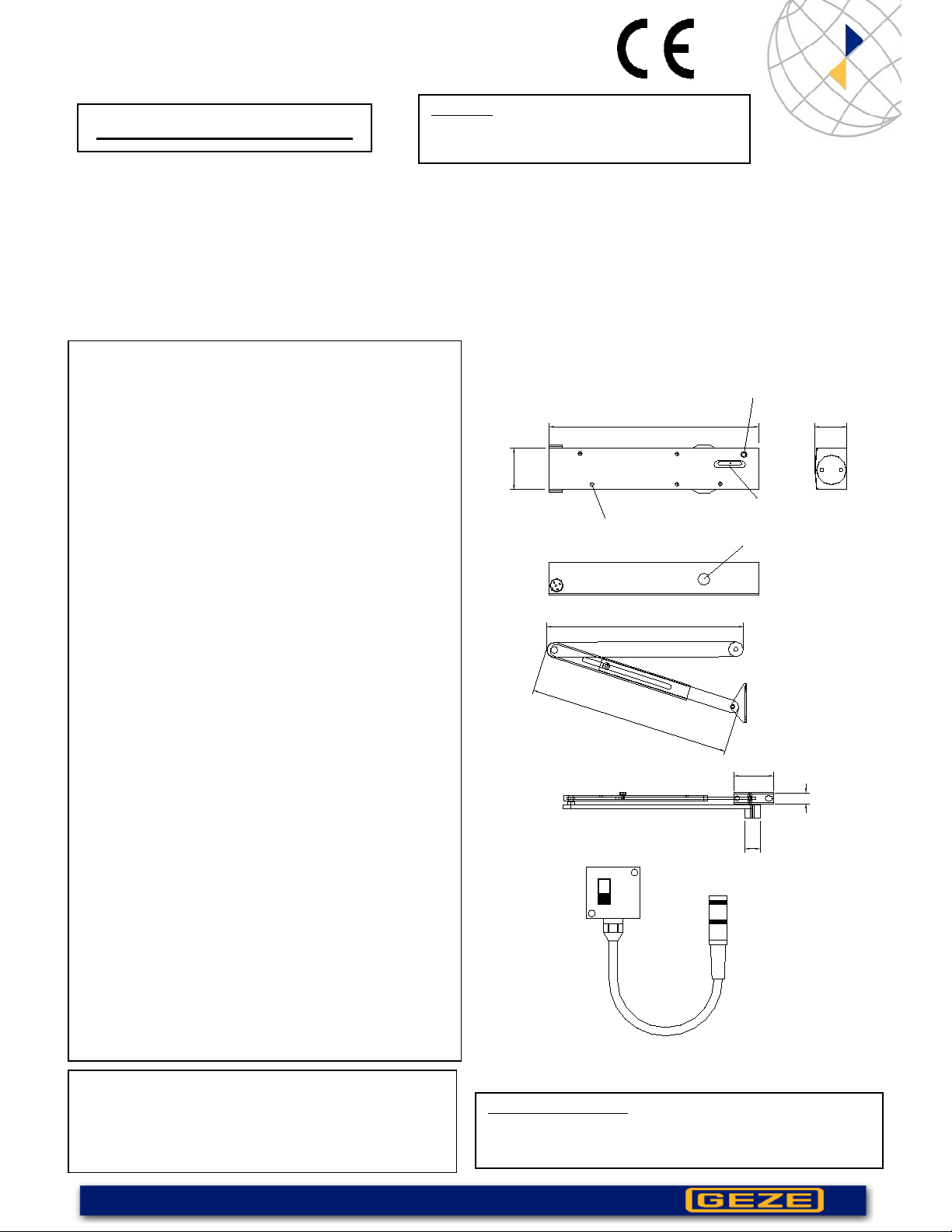

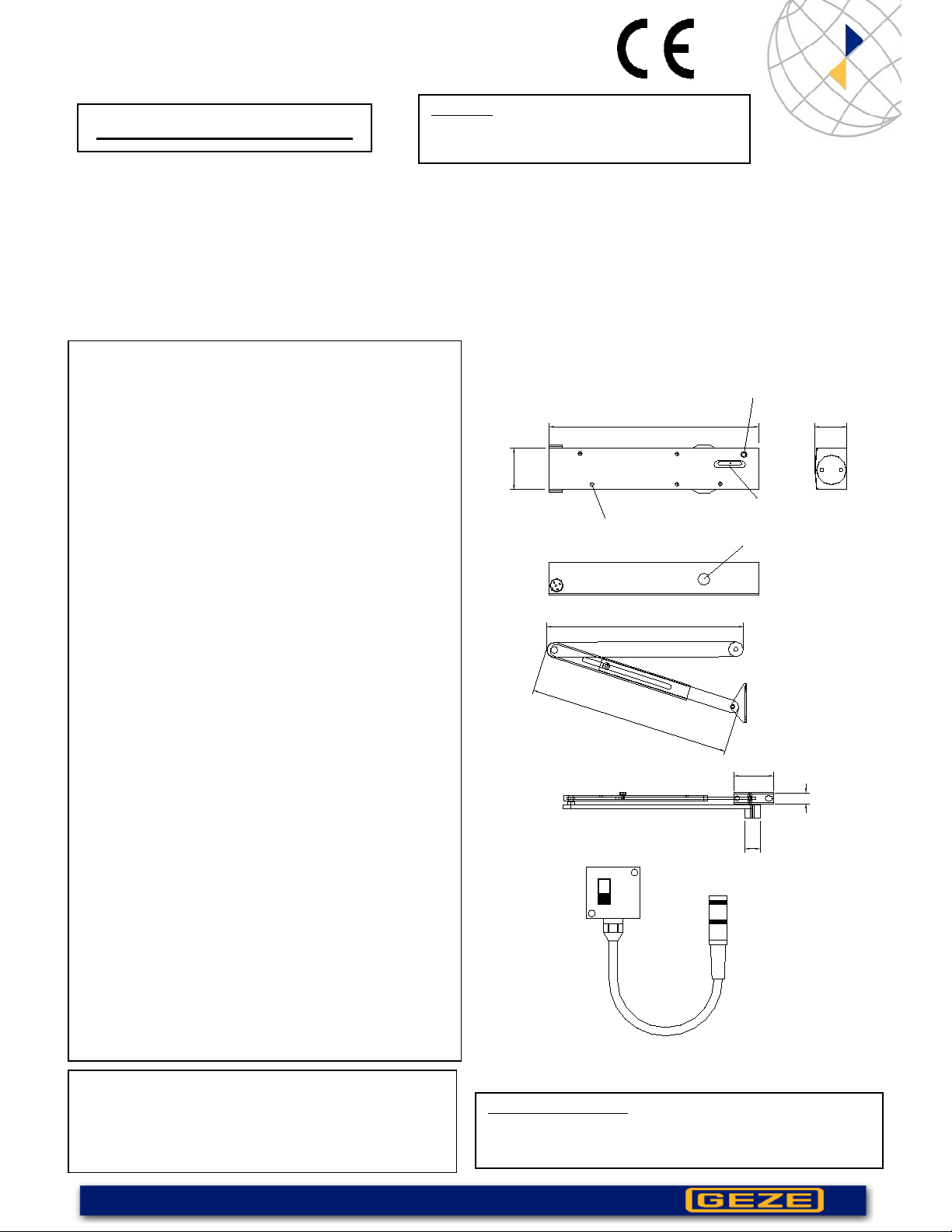

Figure 1 Overhead Door Closer

WARNING: DOOR CLOSERS WITH A POWER

RATING LOWER THAN 3 OR WITH MECHANICAL

HOLD OPEN DEVICES ARE NOT SUITABLE FOR

USE WITH FIRE DOORS.

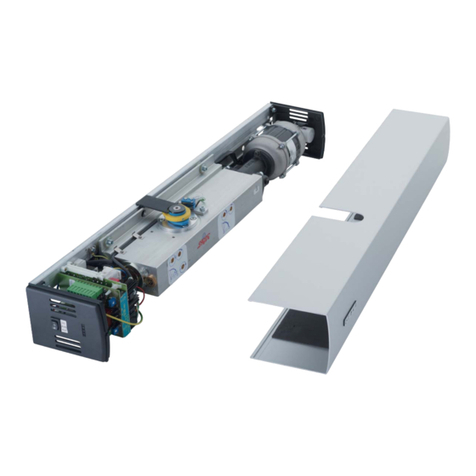

Components Checklist:

1x Closer body & cover

1x Guide Rail Assembly

2x M6 Allen Bolts

2x Plastic end caps

1x Plastic spindle cover

4x 5x55mm Self-tapping countersunk screws

2x M5x40mm Countersunk screws

4x M5x55mm Countersunk screws

2x 5x50 Self-tapping countersunk screws

Tools Required For Installation:

Flat head screwdriver

Posidrive screwdriver

Power drill

4.2mm drill bit

Template (supplied)

Pencil

10mm Spanner

5mm Allen key (supplied)

M5 Tap and Tap wrench

(steel door mounting)

User Information for Door Closers

This information must be observed. Non compliance

will absolve the manufacture from any liability. The

door closer must only be used in accordance with its

intended use; i.e. closing of side hung doors

following manual opening.

Incorrect use may cause injury

¾Obstruction of closing process (e.g. dragging

doors, sticking weather strips/sealing rubbers, rough-

running locks)

¾Incorrect installation and adjustment (e.g.

slamming doors)

¾Danger of finger trap between frame and door leaf.

¾Wrong size door closer.

¾Closer used for other purpose than to close side

hung doors.

Maintenance:

NOTE:

¾Maintenance to be carried out by a specialist only.

¾Check assembly for tolerance and undue wear.

¾Tighten any screws that may have become loose.

At least once a year:

¾Grease moveable parts.

¾Check operation of doors and adjust if necessary.

¾For door closers subject to release by Electro

Mechanical and Electro Hydraulic means ensure that

local regulation are adhered to.

Installation and adjustment by specialist only

Where necessary, an additional doorstop or buffer

must be fitted to limit the maximum opening of the

door. This is of particular relevance for slide rail

closers where the opening angle may be limited by

frame. For further explanations see catalogue

preface and product information.

Door handing - DIN left / right

Stand facing the door on the hinge side / pull side. If the hinge or

pivot is to your right hand side the door is considered to be DIN

right. If the hinge or pivot is to your left hand side the door is

considered to be DIN left.

IMPORTANT WARNING:

HIGH INTERNAL PRESSURES, UNDER NO CIRCUMSTANCES

ATTEMPT TO DISMANTLE THE CLOSER.

approx. 300

285

SECONDARY ARM

PRIMARY ARM

58

16

20

Closing speed adjuster

325

60

TS4000E BODY

48

Spindle

6

4

5

1

2

3

Size indicator

Power adjustment

TS4000E FIG1 TRANSFER LOOP

Installation Instructions