Safety warnings (warning notes)

OPTIMUM

MASCHINEN - GERMANY

30 / 11 / 2007Page 8 Safety warnings (warning notes) Add-on kit D240/D280 ; Version 1.3.3

© 2007 GB

3.2 Proper use

WARNING!

In the event of improper use of the add-on pieces

• will endanger personnel,

• will endanger the machine and other material property of the operator,

• may affect proper operation of the machine.

The add-on pieces as conversion kit are provided for the computer-aided - CNC, Computerised

Numerical Control - milling operations of your machine.

The drive of the step motors may also be performed manually with a control unit (potentiome-

ter).

Improper

use! The milling machine with the adapter kit must only be placed and operated in dry and ventilated

rooms.

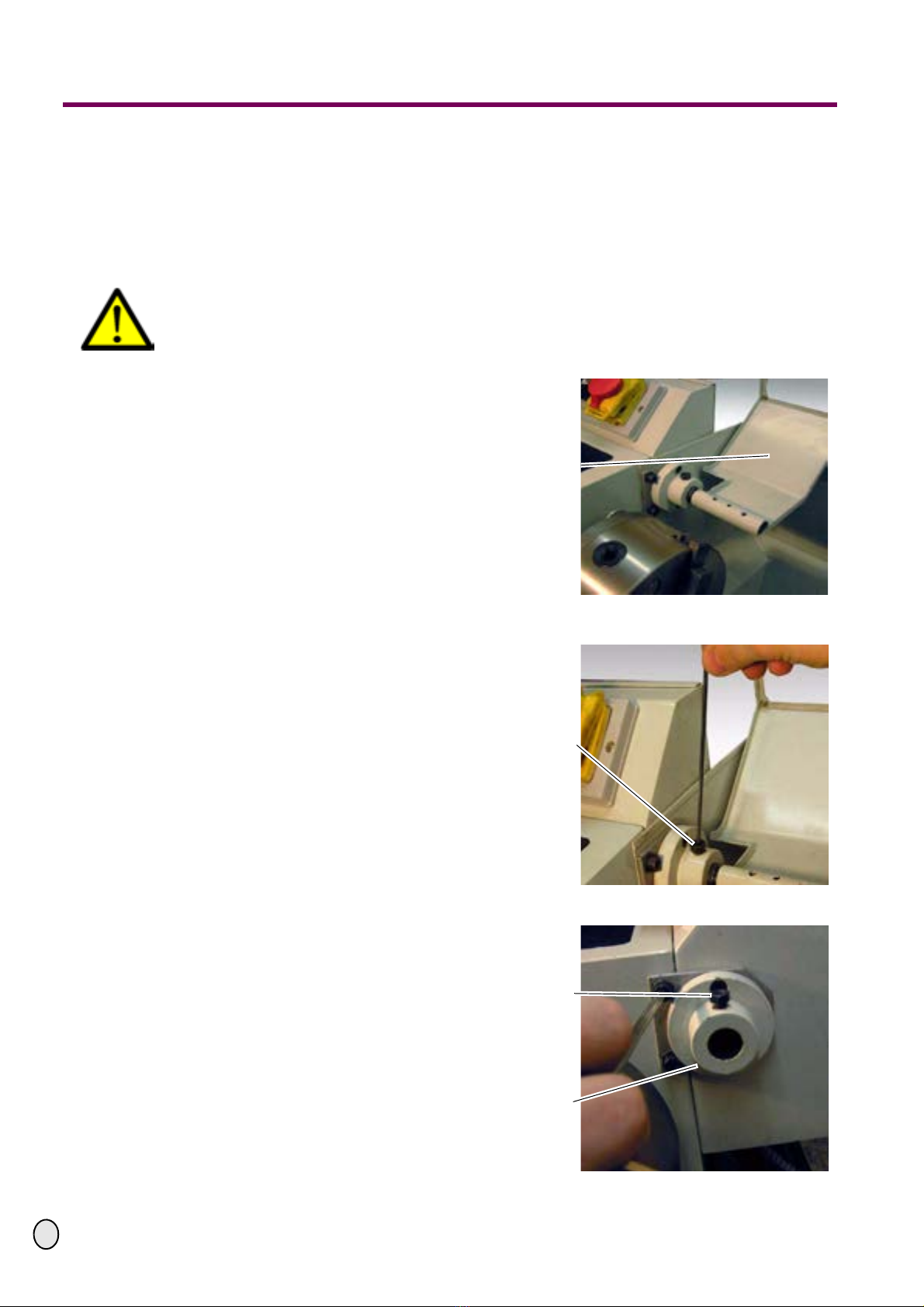

The handwheels need to be disassembled.

If the adapter kit is used in any way other than described above, modified without the authorisa-

tion of Optimum Maschinen Germany GmbH or operated with different process data, then it is

being used improperly.

We do not take any liability for damages caused by improper use.

We would like to stress that any modifications to the construction, or technical or technological

modifications that have not been authorised by Optimum Maschinen Germany GmbH will also

render the guarantee null and void.

3.3 Required auxiliary material

• Means of shaft lock-down device "Loctite 601, join the shaft"

• The designation of parts in the assembly description corresponds to the numbering of the

packing list.

• In order to degrease the shaft, a cleaner for brakes or a corresponding cleaning agent is

required.

• A tenacious grease e.g. Mobilux 2 or a corresponding lubrication grease serves to grease the

bearings.

• Lubricating oil for threading.

• Required tools: reamers 6 H7; twist drill 5mm, 5,8mm and 6,5mm;

• Countersink; plastic tip hammer; prick punch and scriber;

• A set of Allan keys; fork wrench; screw driver;

• Tongs and stripping tongs; cutter; screw tap M6;

• Manual drilling machine; shifting square; box wrench 13mm; chipping spanner

• Soldering iron; small chisel ; abrasive cloth; metal cutting saw