Do not operate the gate unless it is completely necessary. Typically the plant (i.e.: waste water treatment plant) has

not been finished when the commissioning occurs. Therefore, dust and dirt tends to accumulate on the seals and

stems. Do not apply extra grease on the seal and/or stem until the construction of the plant has been completely

finished as it forms a sticky paste with the dust. If the equipment needs to be operated previously wet the seals.

Clean the unit with clear water and make sure there are no foreign deposits or materials on the seals, guides or

sealing area. Use plastic tools to remove any foreign material in order not to contaminate the stainless steel

equipment.

Visual Inspection

Verify that all installation instructions defined in the GAD and the IOM manual have been followed.

Verify that the seal is in compression against the logs. Use a 0.5mm (1/32”) gauge.

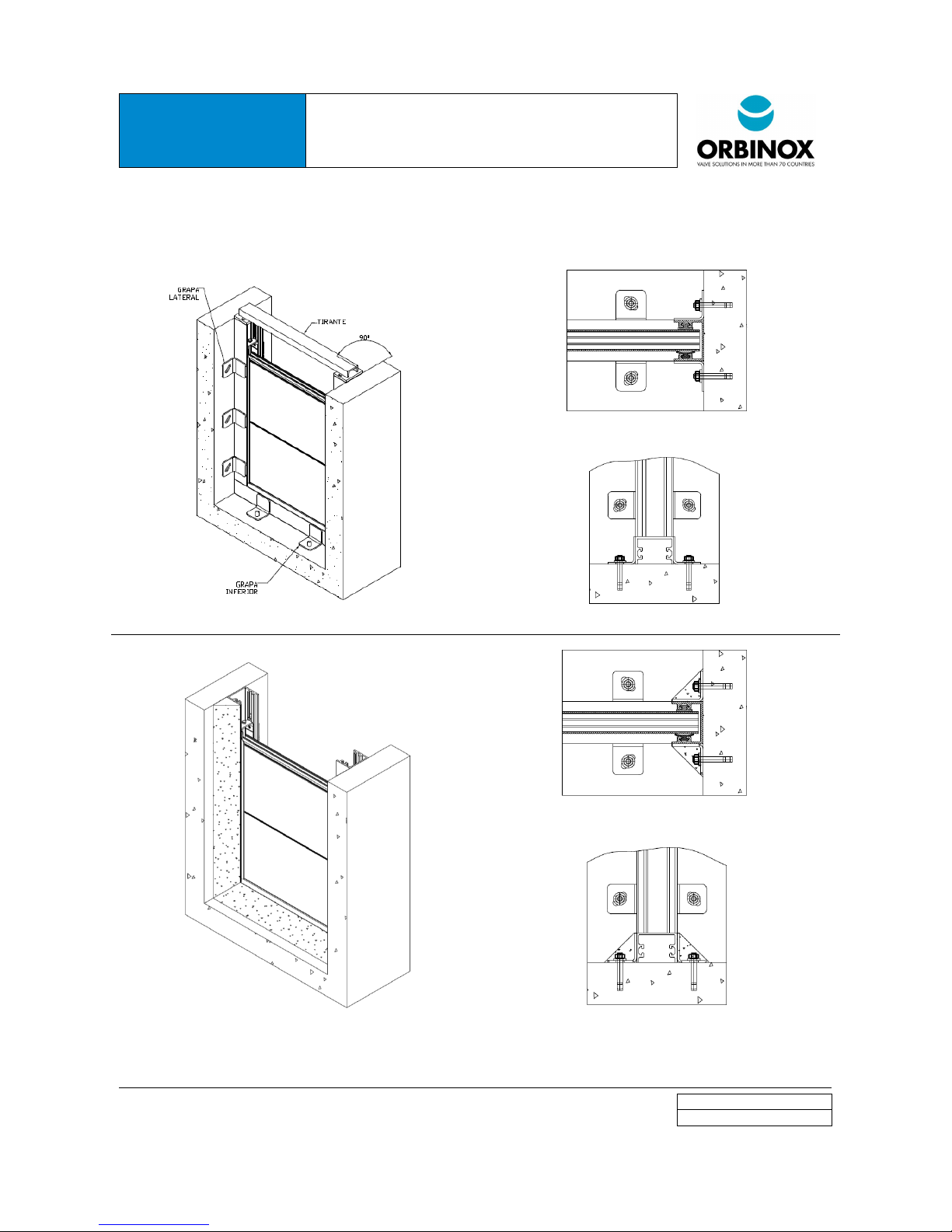

Embedded In concrete installation:

oCheck that the frame (or other embedded parts) has not been distorted during installation. Measure the

opening width every 1 meter. The maximum deviation should be +-width/1000.

oVerify that the frame invert has been embedded in concrete.

Wall mounted at the end of the channel installation. Verify that there are no voids between the concrete wall and

the back of the frame (open the gate and look on the sides). No light must go through the frame and the wall. Clean

water can also be used to verify water tightness between the concrete wall and frame.

Face mounted in existing channel installation:

oCheck that the frame has not been distorted during installation. Measure the opening width every 1 meter.

The maximum deviation should be +-width/1000.

oCheck that the frame has been grouted as indicated in the GAD

Field Operational Test:

Before cycling the unit, make sure there are no foreign deposits or materials on the seals, guides or sealing area.

Clean the unit with clear water. Gate seals could be damaged if the area is not cleaned and coated with grease.

Please refer to Section 7.1 for detailed information.

Seals shall be wetted with clear water before operating the slide gate, and stems and stem nuts shall be greased.

Field Leakage Test

Close the slide and pressurize the unit at the design water head.

Collect the leaked water during a period of time of 10 minutes (LT10)

Calculate the leakage rate: LR(L/min and m) = LT10/(10*P), where P is the sealing perimeter in meters.