Radio & Esc setup

Transmitter Settings:

Throttle Travel Maximum / 100%

Brake Travel Maximum / 100%

Throttle Exponential Start with 0%

Throttle Neutral Trim Center / 0

Bind your receiver and transmitter first if your radio requires

you to do so.

Initial set-up of the throttle end-points of the ESC: (1 or 2)

1) : Automatically

When you follow the “Operation” to connect the electronic,

you can switch on the ESC and then start to run.

2) : Manually (When the manual function is started, the

automatic function will permanently canceled.)

a)Turn on the transmitter and hold the throttle at full

brake position.

b)Turn on ESC and listen for 2 beep.

c)After you hear the 2 beep, apply full throttle and listen for

another 2 beep.

d)Once you hear the 2 beep, release the throttle to neutral

position.

e)A beep will then sound, signifying that the ESC endpoint

have been successfully set.

If the car direction is reverse, please check the ESC +ve and -

ve are right connect to the motor, is this is right you can

change your transmitter throttle direction setup to Reverse

your car direction.

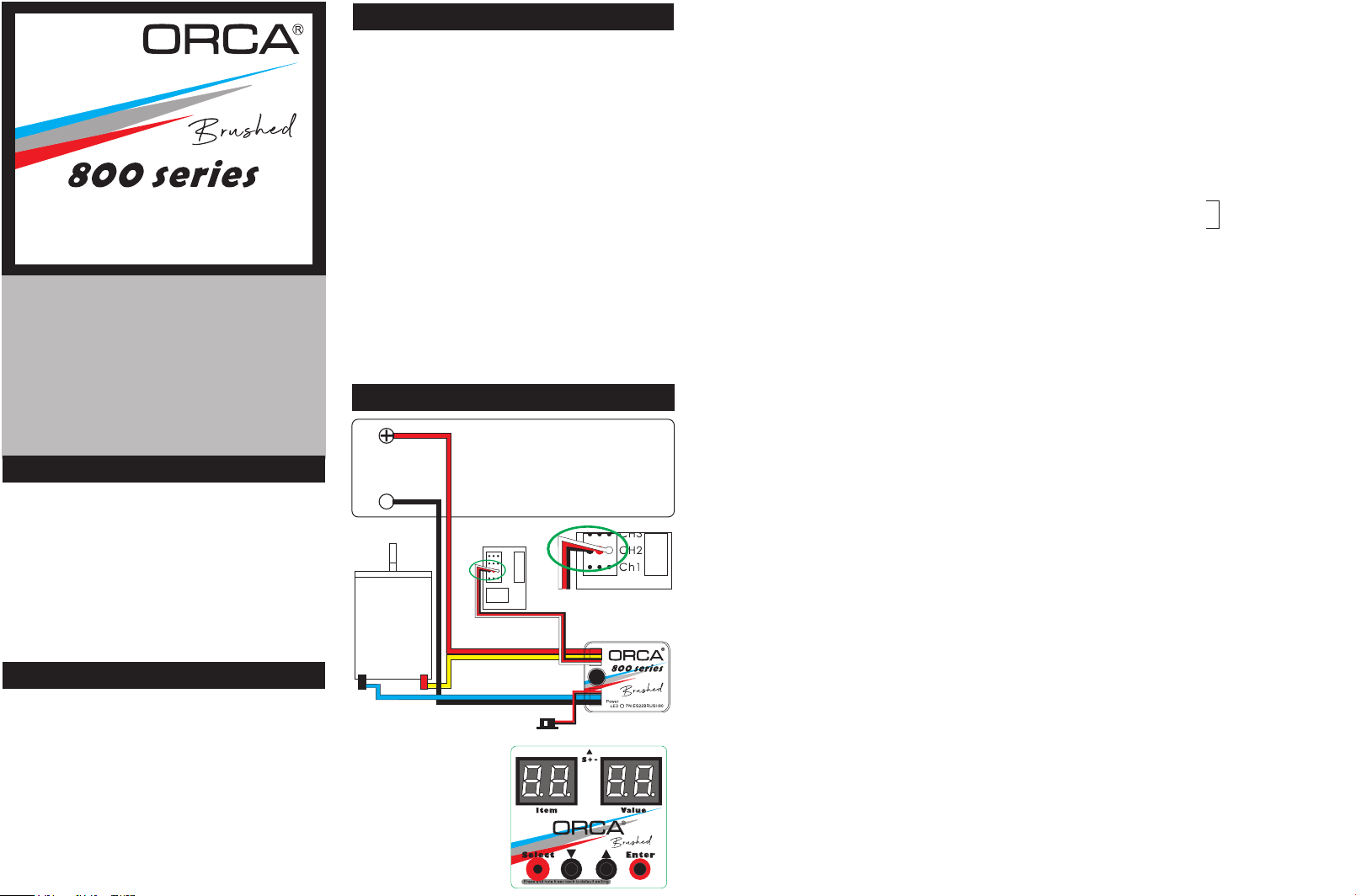

Operation

* Used ESC porvide XT60 connector to the battery,

Red to +ve and Black to -ve.

(WARNING! Reversing the battery polarity will destroy

your ESC and void the warranty.)

* Connect supplied BEC wire(200mm) to 3pin port match

the (- + s) between the CH2/throttle pin of the receiver

and ESC.

* Connect the 2 motor wire(Brushed Motor) to the motor.

The connect suggest solder direct to the motor and

match the label ESC Yellow +ve and Blue -ve. Avoid

soldering each joint for longer than 5 seconds.

(WARNING! Improper wiring may damage the ESC and

void the warranty.)

Instruction Manual

Version 1.01

Thank you for choosing ORCA Products. Welcome to

join our brushed system convenience of power RC.

By purchasing the 800 Series Electronic Speed

Control ("ESC") you have choose one of the most

advanced speed controls in RC. The 800 series ESC

allow to use brushed motor to driver. The ESC attach

the LED program card let you easy to change the

setup of ESC. Please read this manual thoroughly to

familiarize yourself with the installation, setup and

operation. By operating this product, you accept the

ORCA Warranty Terms.

Specific ation

Detailed Explanation of each Function Menu items:

1) Running Mode

Forward/Brake-------This function the car will not have reverse function, Just forward and brake.

Forward/Rev--------- This function the car will reverse immediately when the throttle brake the car.

Froward/Brk/Rev--- Set this function the first touch of throttle brake the car will have brake function, and if you

release to center position after brake and continue brake again the reverse function will

appear.

2) Battery Type

Lipo, LiFe and Nixx select.

3.) Battery Cut-Off Voltage

Lipo --- Low ------ cut off at 2.9V/cell Li-Fe — Low ------ cut off at 2.2V/cell Nixx — Low

Middle -- cut off at 3.2V/cell Middle--- cut off at 2.5V/cell Middle — cut off at 4.0V/ total

High ----- cut off at 3.4V/cell High ------ cut off at 2.8V/cell High

Disable - No cut off protect Disable - No cut off protect Disable - No cut off protect

4) Punch

Allows you to change the punch of the ESC (Level 1 to Level 5). Level 1 has the most miniature punch and Level

5 has the highest punch. Adjust punch level to maximize acceleration speed with minimum wheel spin.

5) PWM(Driver Freq)

Allows you to change the forward drive frequency of the ESC (“1K to 24K From six-step)

* The 1K setup will give you good punch at the low end.

* The 24K setup will result in strong mid to top end.

* Experiment to find out what suits your driving style best.

6)Throttle Compress

Basically the effective range of throttle is 0%~100%, when the T.Compress set in 10%, the throttle effective range

will change to 0% ~ 90%, it can let the throttle respond more sensitive, specially suitable for most brush motor

when you want to make it more strong and sensitive in the bottom power.

7) Initial start force

Usually the throttle force starts from 1% to 100%; it can let you get the best linear control feeling. This function

let you choose the throttle start point at 3%, 6%, 9%, 12%, 15%, or 18% to get the throttle feeling more

aggressive.

8) Max Forward Force

Control the maximum output power of ESC, it can control the maximum speed and increase the handling of the

car, specially in Crawl racing. Lower speed more control.

9) Max Reverse Force

Control the Maximum Reverse power when you Reverse the car.

10) Max Brake Force

Control the maximum brake power, it can control the brake feeling more smooth or more aggressive.

11) Brake Punch

When you set Punch 6, the brake time will follow your throttle brake simple and direct, if you used Punch 1-5 the

brake feeling have something ABS, get more smooth.

12) Drag Brake

Set the automatic brake force applied when the throttle returns to neutral position (8 steps from 0% to 100%):

* 60%, 80% and 100% Drag Brake recommend used in Crawl only.

13) Initial Brake Froce

Usually the brake force starts from 1% to 100%; it can let you get the best linear control feeling. This function

can let you get a more aggressive brake feeling. You can choose the brake force start point at 1%, 5%, 10%,

15%, 20%, 25%, 30% or /35% to 100%.

14) Neutral Range

Set the sensitive relay to your throttle feeling, preset in 45us.

Brushed ESC

Installation & Conne ctors

Brushed

System

WARNING!

Motor +/- polar must

match the ESC initial

Setup,otherwise the

motor rotation will

reverse.

-Black

+Red

+

6V-12.6V

-

-

(B E C ca b le )

(B EC c a bl e )

Receiver

CH 4

CH 3

CH 2

Ch 1

Bec cable

Bec cable

OFF O N

Power Switc h

Brushed System

Yes

29(L) x 34.8(W) x10.2mm(H)

20g (excluding wires)

6V-12.6V (Lipo 2~3Cells)

400A

80A

540 sized brushed motor

3A / 6V

Yes

Yes

System:

Forward/Brake/Reverse:

Dimensions:

Weight:

Voltage Input:

Peak Current:

Continuous current :

Motor Type:

B.E.C.:

Multi Protection System:

Water proof :