N03.0

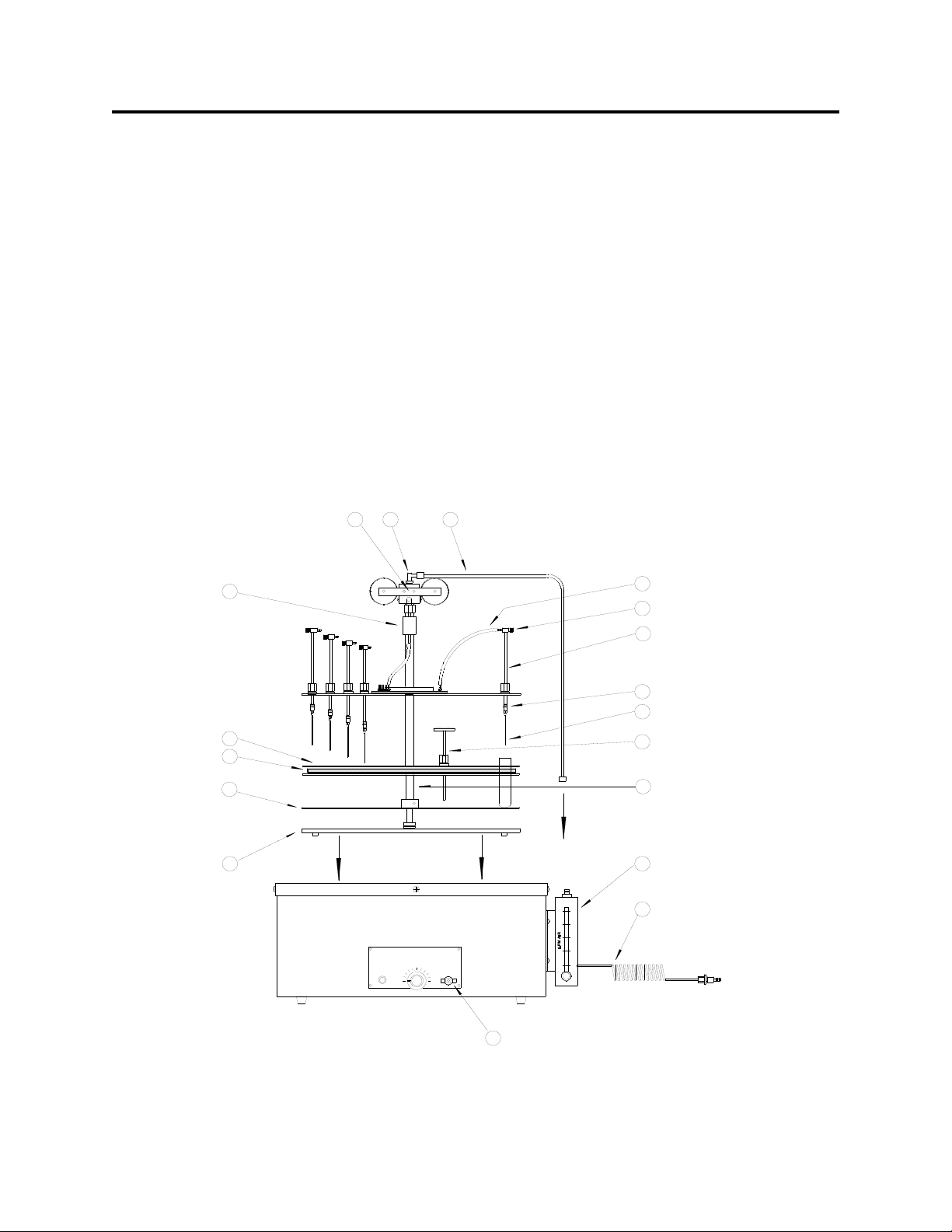

INSTALLATION

N-EVAP ™

Location

The N-EVAP Evaporator System should be located on a bench top or in a chemical

fume hood if hazardous or flammable materials and solvents are to be used. The location

should provide the necessary support services for the instrument. These include electrical

power (required for water bath) and a clean inert gas source (Air or Nitrogen). Please review

the Specifications Section for further information.

Bath Setup

1. Position the bath on a stable flat surface such as a lab bench or in a chemical fume hood.

2. Turn the bath toggle switch to the “OFF” position.

3. Turn the bath thermostat knob to its lowest position.

4. Plug the bath electrical cord into a 3 wire grounded electrical outlet rated for 110-120

VAC, 50-60 Hz, single phase, 15 amps.

Optional 220 VAC baths are clearly marked and should be plugged into a 3 wire

grounded electrical outlet rated for 220-240 VAC, 50-60 Hz, single phase, 15 amps.

5. GFCI (Ground Fault Circuit Interrupter) is an optional safety device which may be

installed on the N-EVAP power cord. For 110-120 VAC baths, this item replaces the

plug at the end of the power cord. For 220-240 VAC baths, this item is located inline

on the power cord approximately 12 inches behind the plug. Please proceed to to the

next step if your bath does not have this item installed.

A. After the power cord has been plugged in. Depress the “RESET” button on the

GFCI to activate the unit.

NOTE: Any time the electrical power to the outlet is disrupted, the GFCI must

be reset.

B. The GFCI may be tested by simulating a “fault” condition. Depress the “TEST’

button, the GFCI will detect the failure and trip off. Depress the “RESET”

button to re-energize the GFCI.

C. If you encounter difficulty using the GFCI or the GFCI continually trips off

during bath use, please review the troubleshooting section or call

Organomation Technical Department for assistance.

6. Fill the bath with water to within 0.5 inch of the bath rim. The use of de-ionized water

will reduce mineral build up and extend bath operational life and is recommended.

- 5 -