• Pulse sensor type

MD625B-12S, MD625B-24S, MD825B-12S, MD825B-24S,

MD925A-12S, MD925A-24S

• Low-speed alarm, electronic alarm type

MDS1225-12M, MDS1225-24M

• Long life models (Stall alarm, electronic alarm type)

MDE625-24L, MDE825-24L, MDE925-24L, MDE1225-12L,

MDE1225-24L, MDE1238-24L

Installation

Location for installation

The fan is designed and manufactured for installation in equipment.

Install it in a well-ventilated location that provides easy access for

inspection. The location must also satisfy the following conditions:

• Inside an enclosure that is installed indoors (provide vent holes)

• Operating ambient temperature

−10 to +60 °C (+14 to +140 °F) (non-freezing)

• Operating ambient humidity 85% or less (non-condensing)

• Area that is free of explosive atmosphere or toxic gas (such as

sulfuric gas) or liquid

• Area not exposed to direct sun

• Area free of excessive amount of dust, iron particles or the like

• Area not subject to splashing water (rains, water droplets), oil (oil

droplets) or other liquids

• Area not subject to continuous vibration or excessive shocks

• Area free of radioactive materials, magnetic fields or vacuum

• Area free of excessive electromagnetic noise (from welders,

power machinery, etc.)

When using near a switching circuit or high-frequency power

supply, the induced current may flow inside the fan due to

electromagnetic noise (conductive noise, radiative noise). If the

induced current flows, the electric corrosion is caused in the

bearings of the fan. As a result, it may generate the noise or

shorten the service life of the products. Use the fan in the

environment that the electromagnetic noise does not cause.

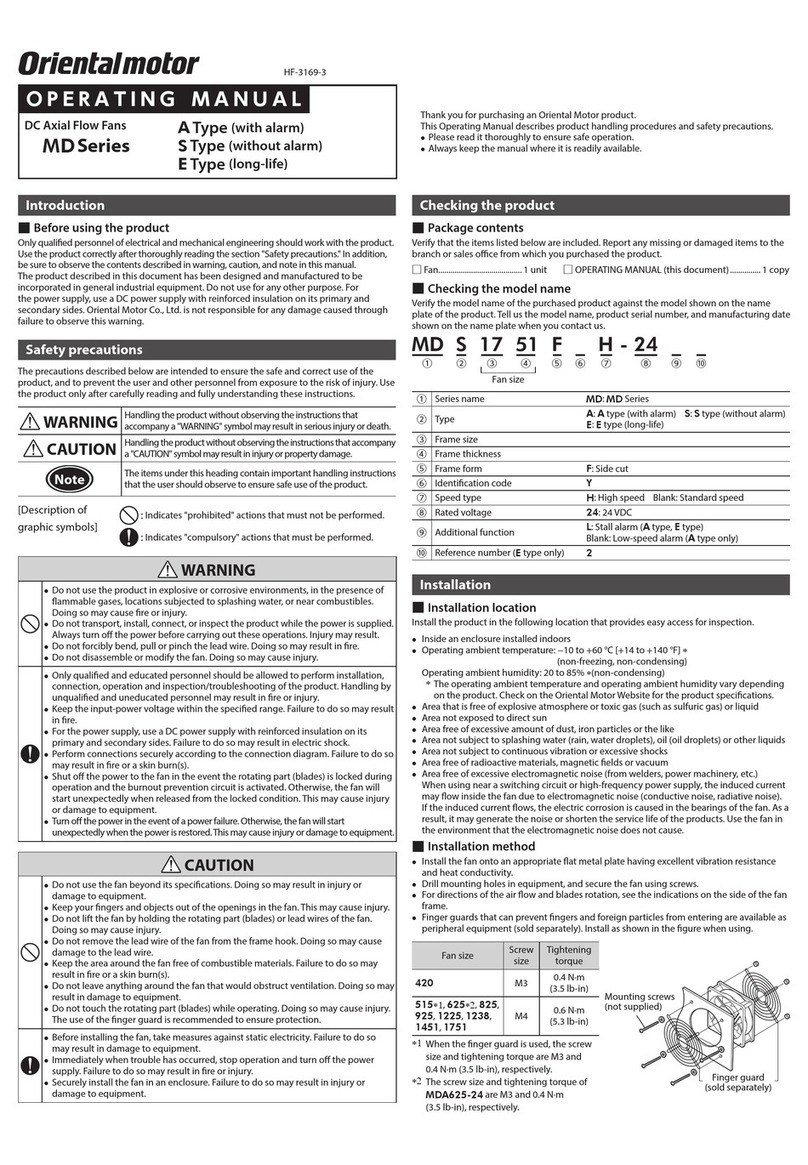

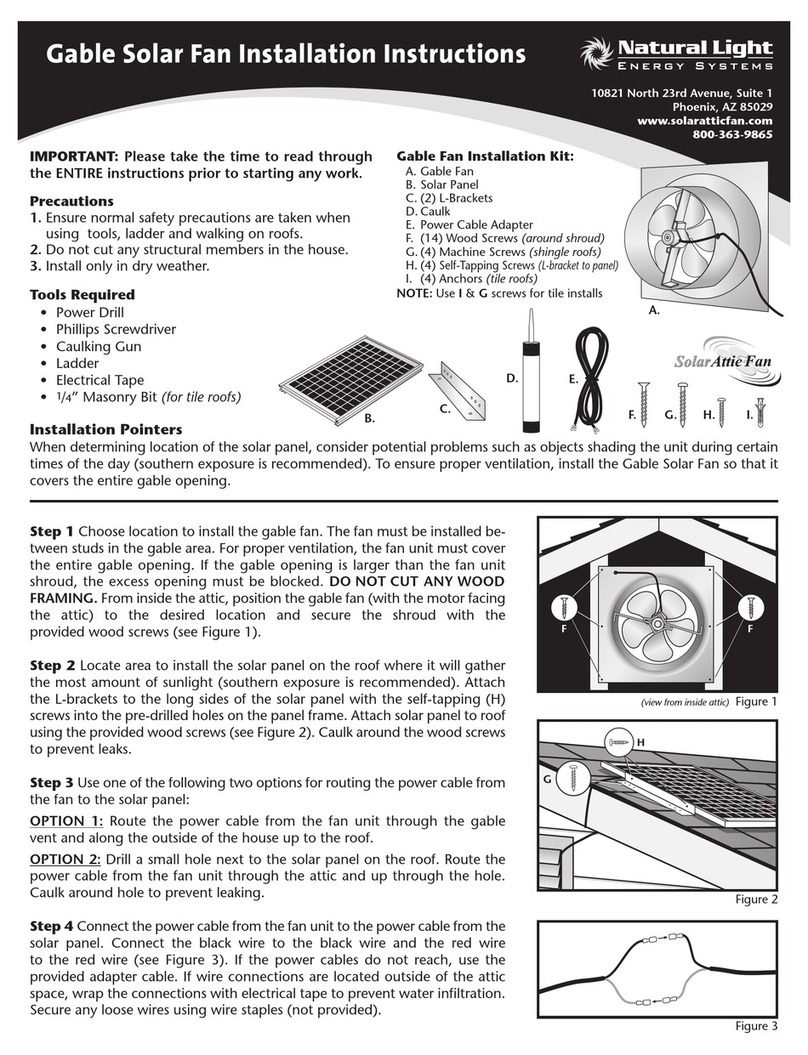

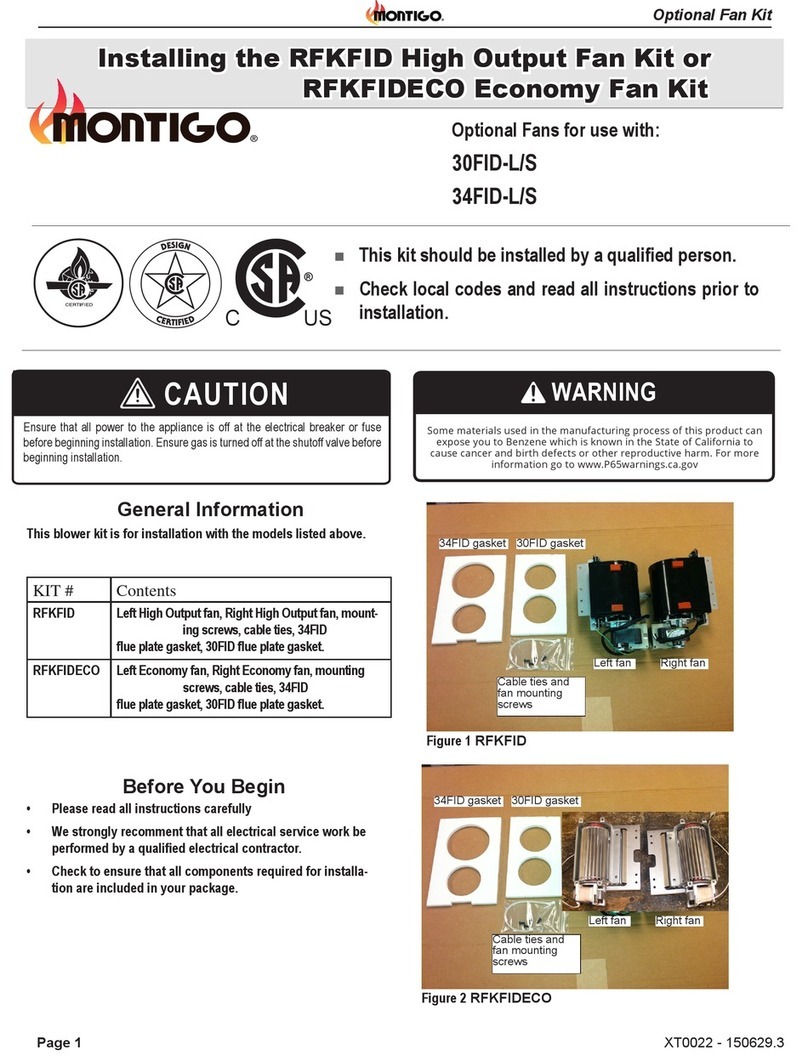

How to install the fan

Install the fan onto an appropriate flat metal plate having excellent

vibration resistance and heat conductivity. Drill holes on the

mounting plate and fix the fun on the plate using screws (not

supplied). For air orientation and rotational direction, see the

indications shown on the fan’s side frame.

Model Screw

size

Tightening

torque

MDS625, MDE625, MDS825, MD825,

MDE825, MDS925, MD925, MDE925,

MD1225, MDS1225, MDE1225, MDS1238,

MDE1238

M4 0.6 N·m

(5.3 lb-in)

MDS410, MDS510, MD625 M3 0.4 N·m

(3.5 lb-in)

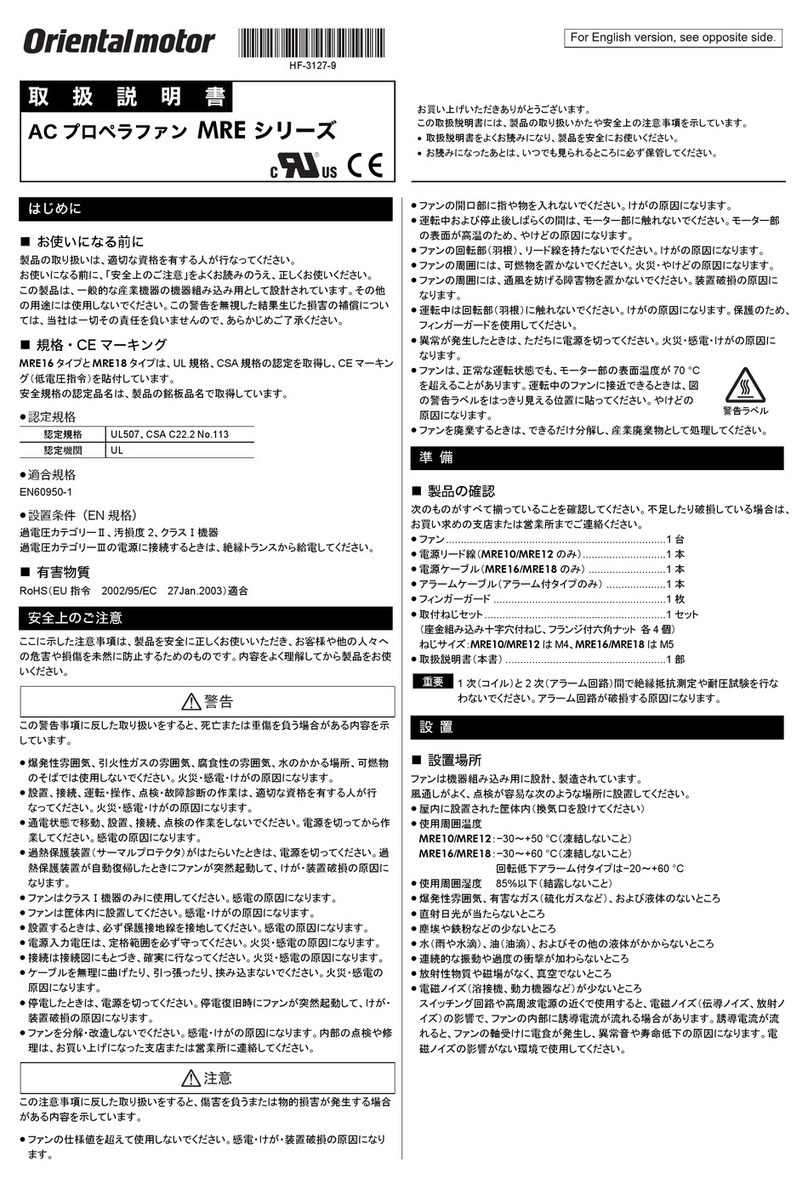

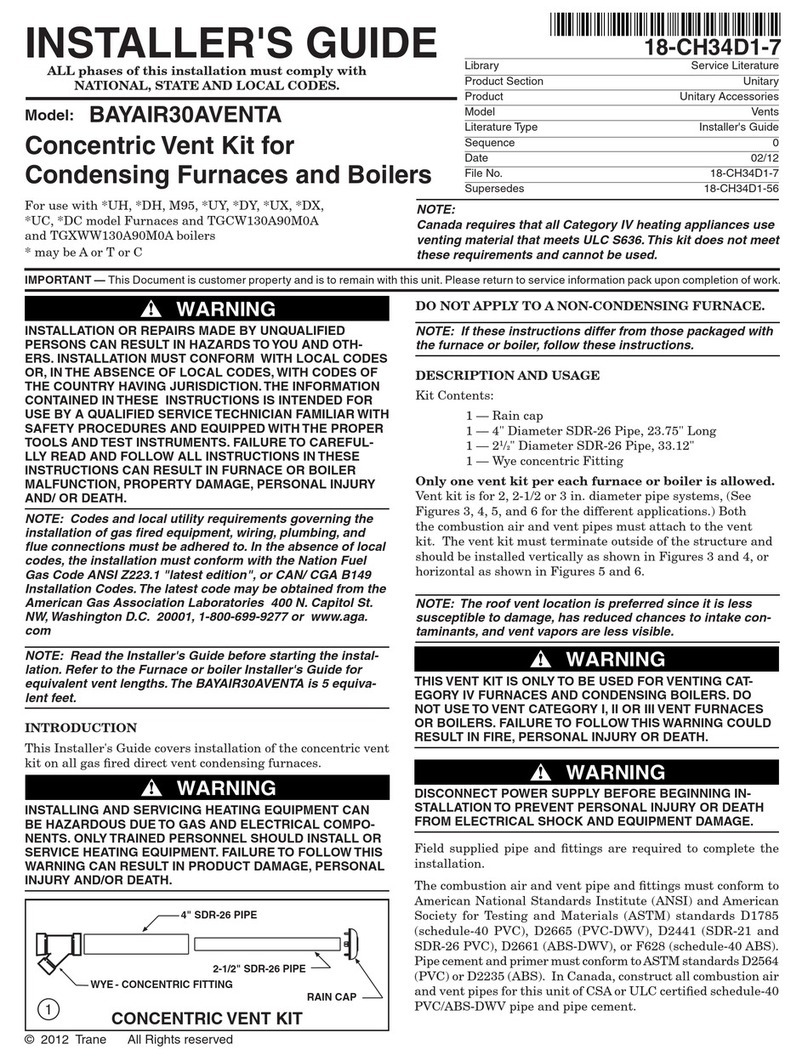

Connecting the power supply

Connect the red wire to the

positive (+) power supply and

the black wire to the ground

connection.

Check the voltage specification

on the product identification

Red

Black

DC power supply

+

GND

plate and input the correct voltage.

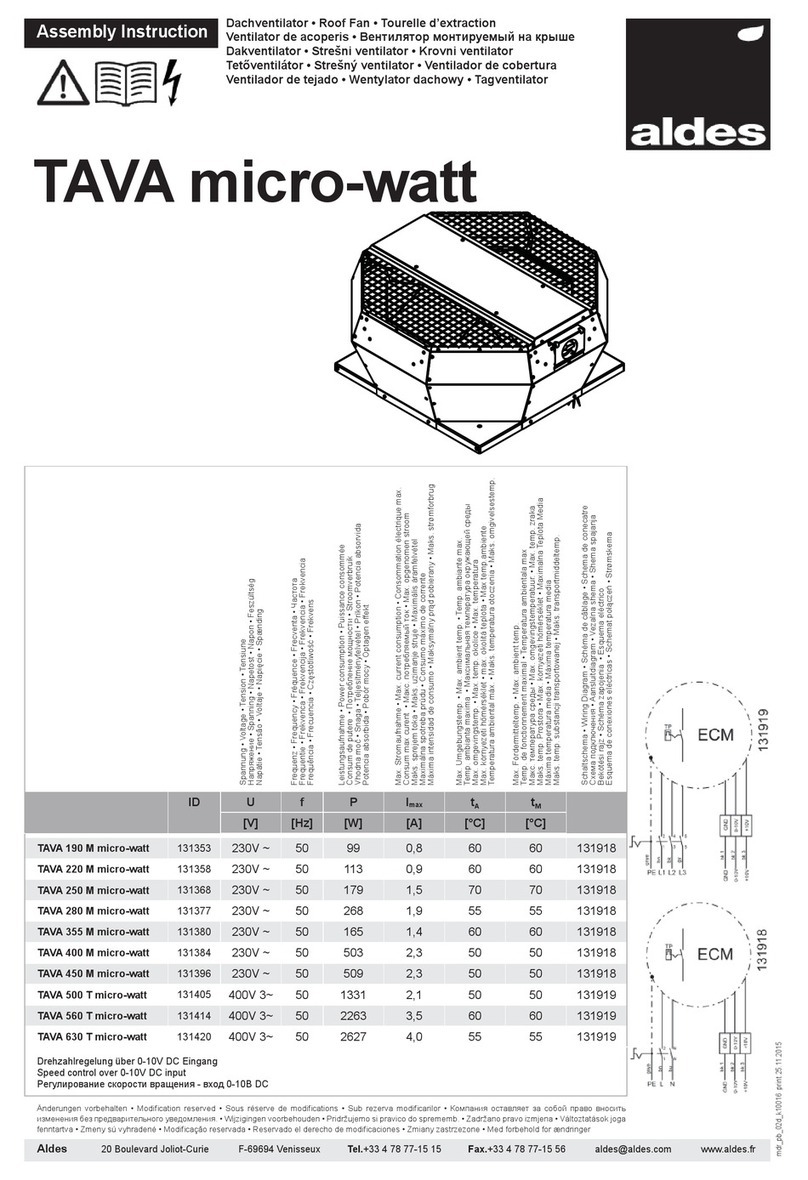

Connection and specifications of the alarm

Pulse sensor type

The yellow wire is lead wire for

the pulse output. GND is

common to the sensor and

power supply.

Two cycles of rectangular waves

are output per rotation.

Yellow

Black

Fan Client's circuit

GND

R

0 V

30 VDC

or less

15 mA

or

less

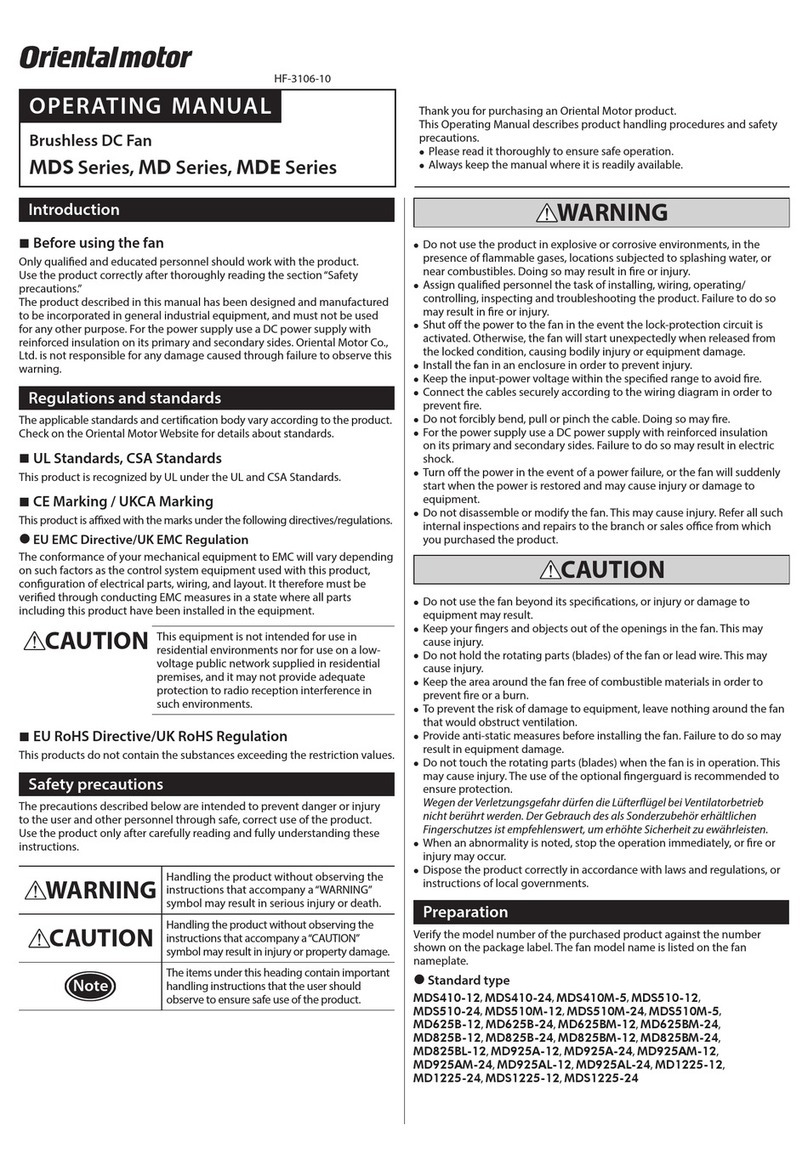

Stall alarm, electronic alarm type

The orange or yellow wire is lead

wire for the alarm circut. GND is

common to the sensor and

power supply.

If the fan stalls while the power is

on, an alarm signal is output.

Vo

Orange

or

Yellow

Black

Fan Client's circuit

GND

R

0 V

I

Model Vo: Maximum applied voltage I: Maximum current

MDE series 27.6 VDC or less ∗15 mA or less

MDS series 30 VDC or less ∗25 mA or less

MD series 30 VDC or less 15 mA or less

∗1 MDE1225 type = 30 VDC or less

∗2 MDS1238-24L = 27.6 VDC or less

Note The stall alarm type of fan is not equipped with a delayed

trip-point alarm circuit. Therefore, an external delay

function is necessary to avoid the detection of fan start.

The set time of the delay function should be at least one

second.

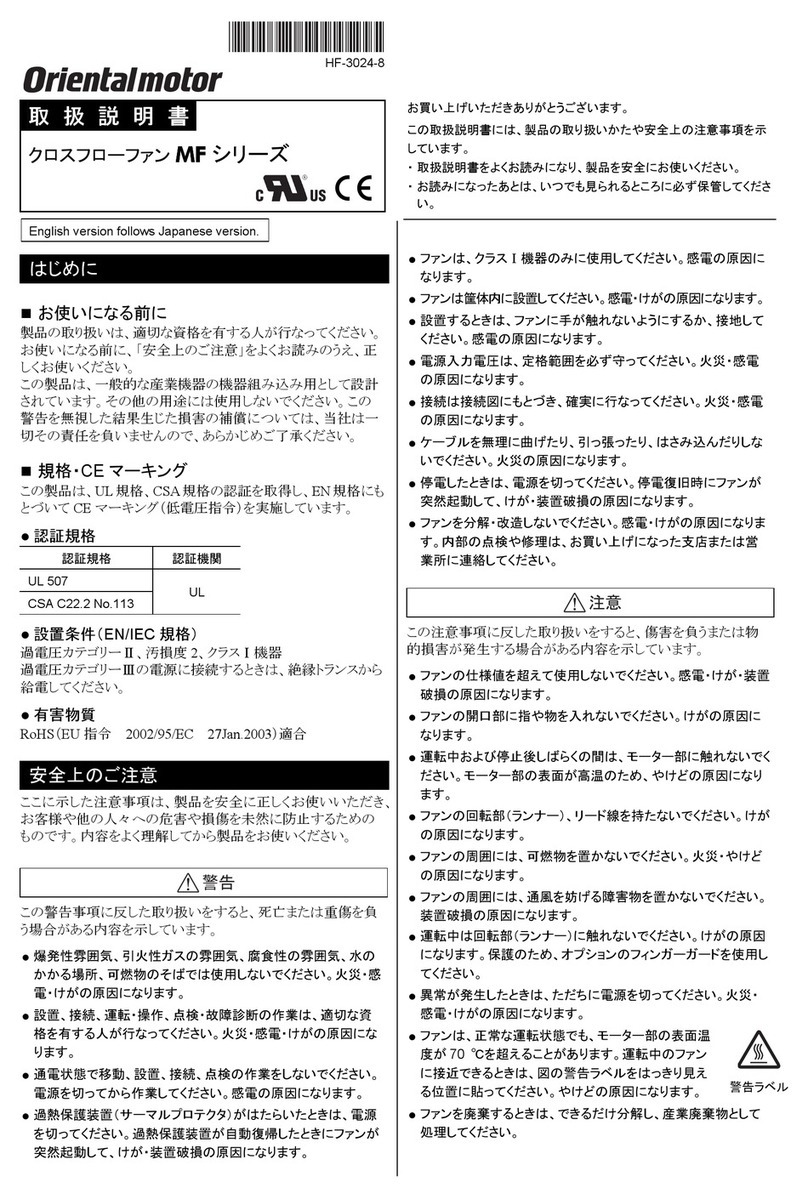

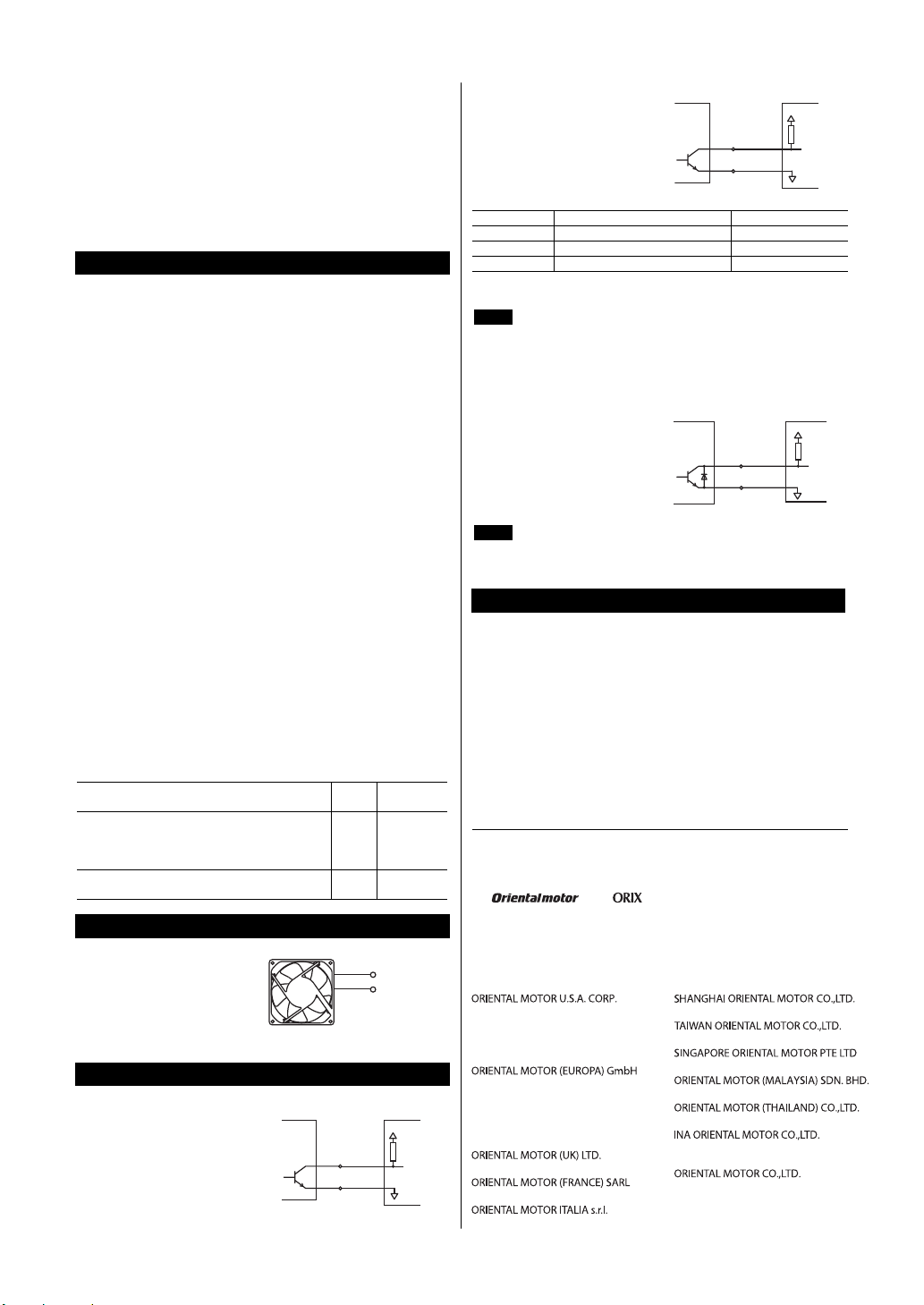

Low-speed alarm, electronic alarm type

The orange and blue wires are

lead wires for the alarm circuit.

An alarm (H level) signal is

output when the fan’s rotation

speed falls below 2100±400

r/min.

Orange

Blue

Fan Client's circuit

R

0 V

30 VDC

or less

GND

15 mA

or

less

Note The low-speed alarm type of fan is equipped with an

internal delayed-start alarm circuit. The alarm function

becomes effective within 10 seconds of the fan start.

Overheat protection

The fan is equipped with an internal protective circuit against

overheating. In the event a lock-up condition is detected, this

function automatically controls the current flow to the fan motor’s

windings, thus preventing the fan blades from locking and burning

out. The fan resumes operation automatically as soon as it is

released from the locked condition. Be sure to shut off the power to

the fan before performing an inspection.

• Unauthorized reproduction or copying of all or part of this

manual is prohibited.

• Characteristics, specifications and dimensions are subject to

change without notice.

• and are registered trademarks or

trademarks of Oriental Motor Co., Ltd., in Japan and other

countries.

© Copyright ORIENTAL MOTOR CO., LTD. 2011

• Please contact your nearest Oriental Motor office for further information.

Technical Support Tel:(800)468-3982

8:30

A.M.

to 5:00

P. M .

, P.S.T. (M-F)

7:30

A.M.

to 5:00

P. M .

, C.S.T. (M-F)

E-mail: techsupport@orientalmotor.com

www.orientalmotor.com

Headquarters and Düsseldorf Office

Tel:0211-52067-00 Fax:0211-52067-099

Munich Office

Tel:089-3181225-00 Fax:089-3181225-25

Hamburg Office

Tel:040-76910443 Fax:040-76910445

Tel:01256-347090 Fax:01256-347099

Tel:01 47 86 97 50 Fax:01 47 82 45 16

Tel:02-93906346 Fax:02-93906348

Tel:(02)8228-0707 Fax:(02)8228-0708

Tel:+65-6745-7344 Fax:+65-6745-9405

Tel:(03)22875778 Fax:(03)22875528

KOREA

Tel:080-777-2042 Fax:02-2026-5495

Headquarters Tokyo, Japan

Tel:03-6744-0361 Fax:03-5826-2576

Tel:+66-2-251-1871 Fax:+66-2-251-1872

Tel:400-820-6516 Fax:021-6278-0269