HM-40040-4

OPERATING MANUAL

Connector-terminal block

conversion unit

CC20T1, CC36T1, CC50T1

Thank you for purchasing an Oriental Motor product.

This Operating Manual describes product handling procedures and safety

precautions.

• Please read it thoroughly to ensure safe operation.

• Always keep the manual where it is readily available

Introduction

Before using this product

Only qualified personnel should work with the product.

Use the product correctly after thoroughly reading the section “Safety precautions”.

The product described in this manual has been designed and manufactured for use in

general industrial machinery, and must not be used for any other purpose. Oriental Motor

Co., Ltd. is not responsible for any damage caused through failure to observe this warning.

Hazardous substances

RoHS (Directive 2002/95/EC 27Jan.2003) compliant

Safety precautions

The precautions described below are intended to prevent danger or injury to the user and

other personnel through safe, correct use of the product. Use the product only after

carefully reading and fully understanding these instructions.

Handling the product without observing the instructions

that accompany a “Warning” symbol may result in serious

injury or death.

Handling the product without observing the instructions

that accompany a “Caution” symbol may result in injury or

property damage.

Note The items under this heading contain important handling

instructions that the user should observe to ensure safe

use of the product.

• Do not use the product in explosive or corrosive environments, in the

presence of flammable gases, locations subjected to splashing water, or near

combustibles. Doing so may result in fire or injury.

• Assign qualified personnel the task of installing, wiring, operating/controlling,

inspecting and troubleshooting the product. Failure to do so may result in fire

or injury.

• Do not transport, install the product, perform connections or inspections when

the power is on. Always turn off the power to a connected device before

carrying out these operations. Failure to do so may result in electric shock.

• Install the connector-terminal block conversion unit in an enclosure in order to

prevent injury.

• For the power supply of connector-terminal block conversion unit, use a DC

power supply with reinforced insulation on its primary and secondary sides.

Failure to do so may result in electric shock.

• Connect the cables securely by referring to “Installation and wiring”, in order

to prevent fire and electric shock.

• Do not forcibly bend, pull or pinch the cables. Doing so may result in fire.

• Do not disassemble or modify the connector-terminal block conversion unit.

This may cause injury. Should you require the inspection or repair of internal

parts, contact the Oriental Motor office where you purchased the product.

• Do not use the connector-terminal block conversion unit beyond its

specifications, or injury or damage to equipment may result.

• To dispose of the terminal block or cable, disassemble it into parts and

components as much as possible and dispose of individual parts/components

as industrial waste.

Checking the product

Upon opening the package, verify that the items listed below are included. Report any

missing or damaged items to the branch or sales office from which you purchased the

product.

• Terminal block ...................... 1 pc. • Signal name plate

• Cable [1 m (3.3 ft.)]...............1 pc. • Operating manual.................. 1 copy

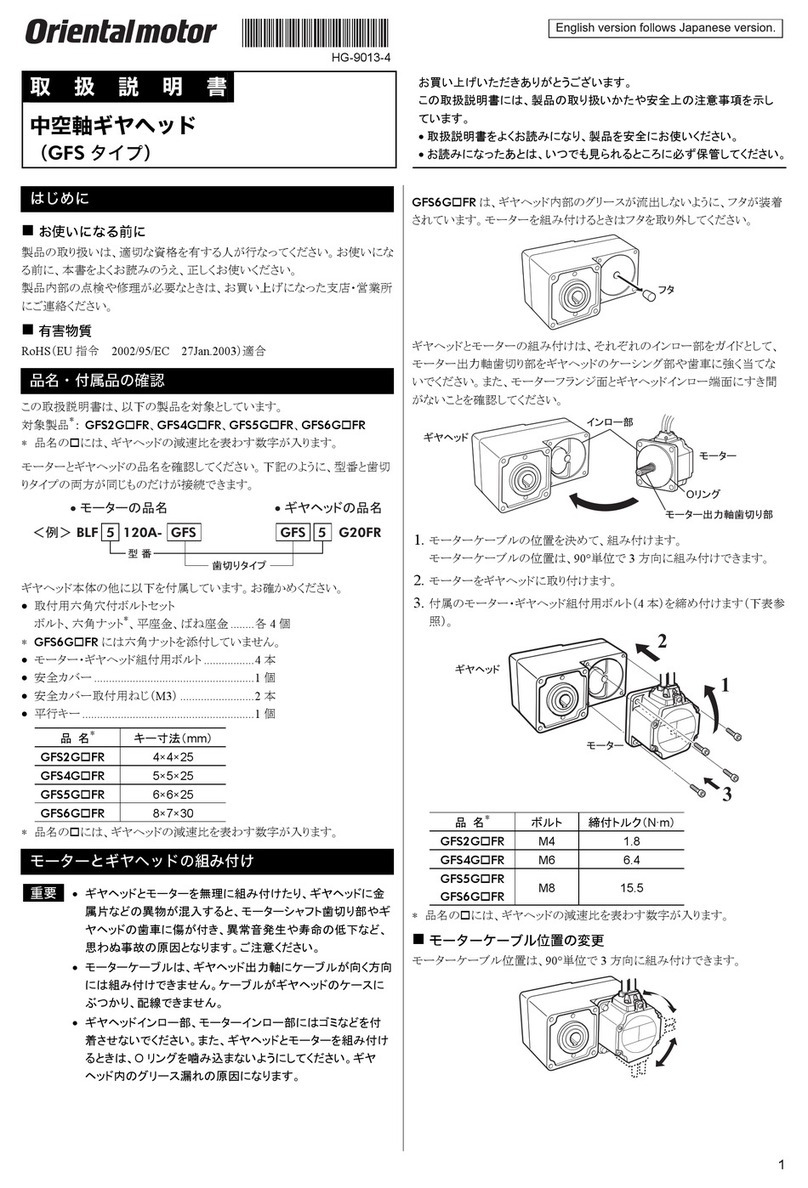

Names of parts

Illustration shows CC36T1.

Rail attachment/detachment

lever switch

Input/Output

signal connector

Rail attachment/detachment

lever switch

LOCK LOCK

Mounting hole (for M4 screw)

Terminal block

Mounting hole (for M4 screw)

Installation and wiring

Installation

Illustration shows CC36T1.

Tightening torque: 1 to 1.3 N·m (142 to 185 oz-in)

Tightening torque: 0.2 N·m (28 oz-in)

LOCK LOCK

• Mounting to a DIN rail

1. Turn the rail attachment/detachment lever switch from “LOCK” to “RELEASE.”

2. Position the terminal block along the rail.

3. Set the rail attachment/detachment lever switch to “LOCK” to affix the terminal block.

• Mounting to a plate or panel

Be sure to set the rail attachment/detachment lever switch to “LOCK,” and then screw

the terminal block using two mounting holes (Ø4).

Wiring

Use an appropriate crimp terminal for connecting the terminal block.

Appropriate crimp terminal

Screw size: M3

Tightening torque: 1.2 N·m (170 oz-in)

Applicable minimum lead wire size:

AWG22 (0.3 mm2)

3.2 (0.13) or more

6.2 (0.24) or less

5.8 (0.23) or more

4.2 (0.165) or less

[Unit: mm (in.)]

Note • The pin assignments on the terminal block correspond to the pin

numbers on a half-pitch connector.

• The function assignments vary depending on the connected

product. Wire the terminal block after checking the model name

of the connected product. (Alternatively, refer to the supplied

signal name plate.) Align the inserting direction of the plate with

the shape of the terminal block.

• The maximum transmissible pulse frequency drops as the pulse

line becomes longer. Keep the wiring length to no more than 1 m

(3.3 ft.) from the terminal block.

• Do not process or modify the cable. It may result in damage or

malfunction of the controller, driver or sensors.

Inspection

It is recommended that the following items be checked regularly after operation.

• Are there any loose terminal block screws?

• Are there any loose cable-mounting screws?

Printed on Recycled Pape

• Please contact your nearest Oriental Motor office for further information.

Headquarters Tokyo, Japan

Tel:(03)3835-0684 Fax:(03)3835-1890

Tel:01 47 86 97 50 Fax:01 47 82 45 16

Tel:(02)8228-0707 Fax:(02)8228-0708

Technical Support Tel:(800)468-3982

8:30 a.m. to 5:00 p.m., P.S.T. (M-F)

7:30 a.m. to 5:00 p.m., C.S.T. (M-F)

E-mail: techsupport@orientalmotor.com

www.orientalmotor.com

Headquarters and Düsseldorf Office Tel:0211-5206700 Fax:0211-52067099

Munich Office Tel:08131-59880 Fax:08131-598888

Hamburg Office Tel:040-76910443 Fax:040-76910445

Tel:01256-347090 Fax:01256-347099

Tel:02-93906346 Fax:02-93906348

Tel:(6745)7344 Fax:(6745)9405

KOREA

Tel:(032)822-2042~3 Fax:(032)819-8745

Tel:(03)22875778 Fax:(03)22875528

Tel:66-2-254-6113 Fax:66-2-254-6114