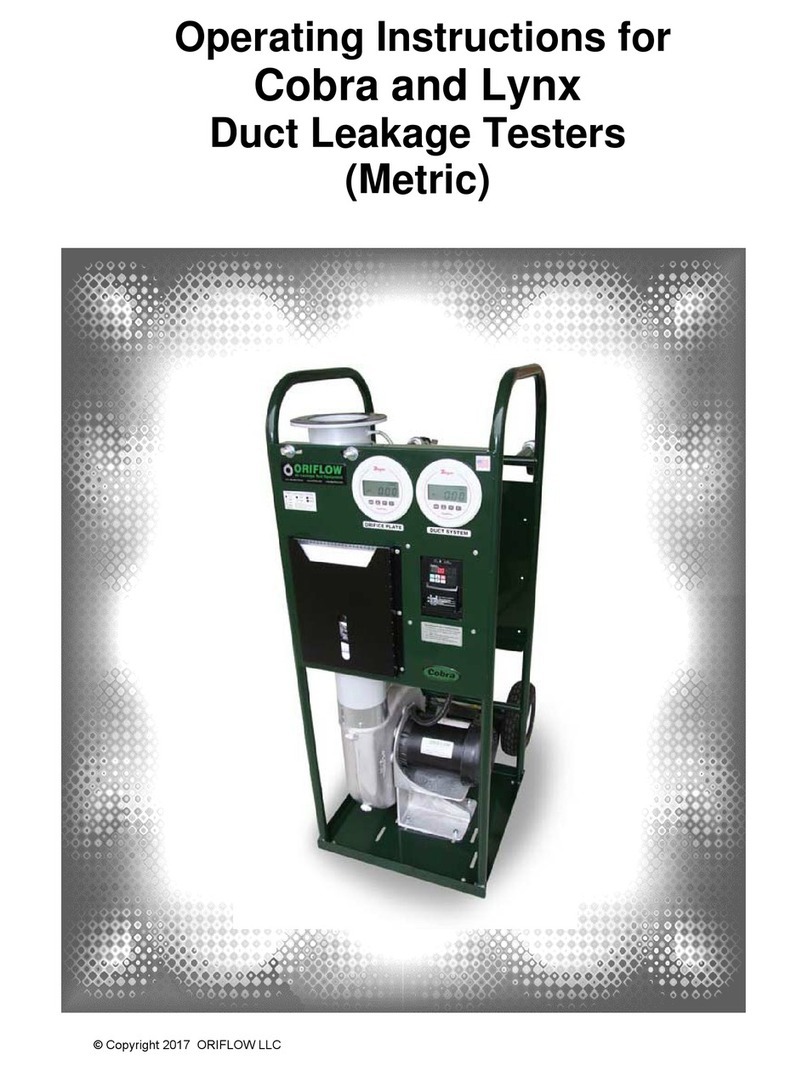

Operating Instructions for Cobra © Copyright 2018

and Lynx Duct Leakage Testers Rev: 01/2018

3

Introduction

These operating instructions are for ORIFLOW models COBRA and LYNX air leakage testers. Take

pride in knowing that you have purchased the best air leakage tester on the market. It is no secret that

Oriflow manufactures the highest quality testers, and has unparalleled customer service and technical

support.

The orifice plates available for your duct leakage tester are constructed from laser-cut 0.063-inch

stainless steel and do not require recalibration for 5 years. Note the authority having jurisdiction may

override this requirement, and if so, Oriflow has reasonable rates for re-calibrating orifice plates

manufactured by Oriflow.

Safety Precautions

Before operating your tester, read the following safety precautions:

DO NOT operate the tester in the rain,

DO NOT operate the tester while it is near or in water,

DO NOT operate the tester with a damaged electrical cord or plug,

DO NOT remove the inlet safety screen,

DO NOT touch the blower wheel when the unit is plugged in,

DO NOT look into the discharge end of the tester when the unit is plugged in,

DO NOT use the tester as a ladder or step stool,

DO NOT allow children near the tester,

DO use an extension cord of the proper gauge (see Table 2),

DO use the proper voltage and line frequency listed on the motor nameplate,

DO lock the caster when the tester is positioned horizontally,

DO use the tester on level ground,

DO secure the tester when transporting it,

DO wear proper hearing protection, safety glasses and work gloves,

DO seek assistance when lifting the tester (e.g., loading onto truck, going up or down stairs).