7

Operation

TheVari-E-Plateisaself-containedunit,whichcontrolsuptotwoprimaryandtwosecondarypumps,

togetherwithatwo-portvalvetoprovidehotwater.Whenthesystemisttedwithtwoprimary

pumps,theyareoperatedonasharedduty-standbycyclewithautomaticchangeoveronpumpfailure.

a) Remote Switch or Building Management System Control

TheVari-E-PlatewillbeturnedonwhencontactsconnectedtotheRemoteEnableterminals are

closed.Thisallowstheusertocontrolthetimeofdaywhenhotwaterwillbeavailable.

When the contact is open the system is turned off.

b) Internal Time Clock Control

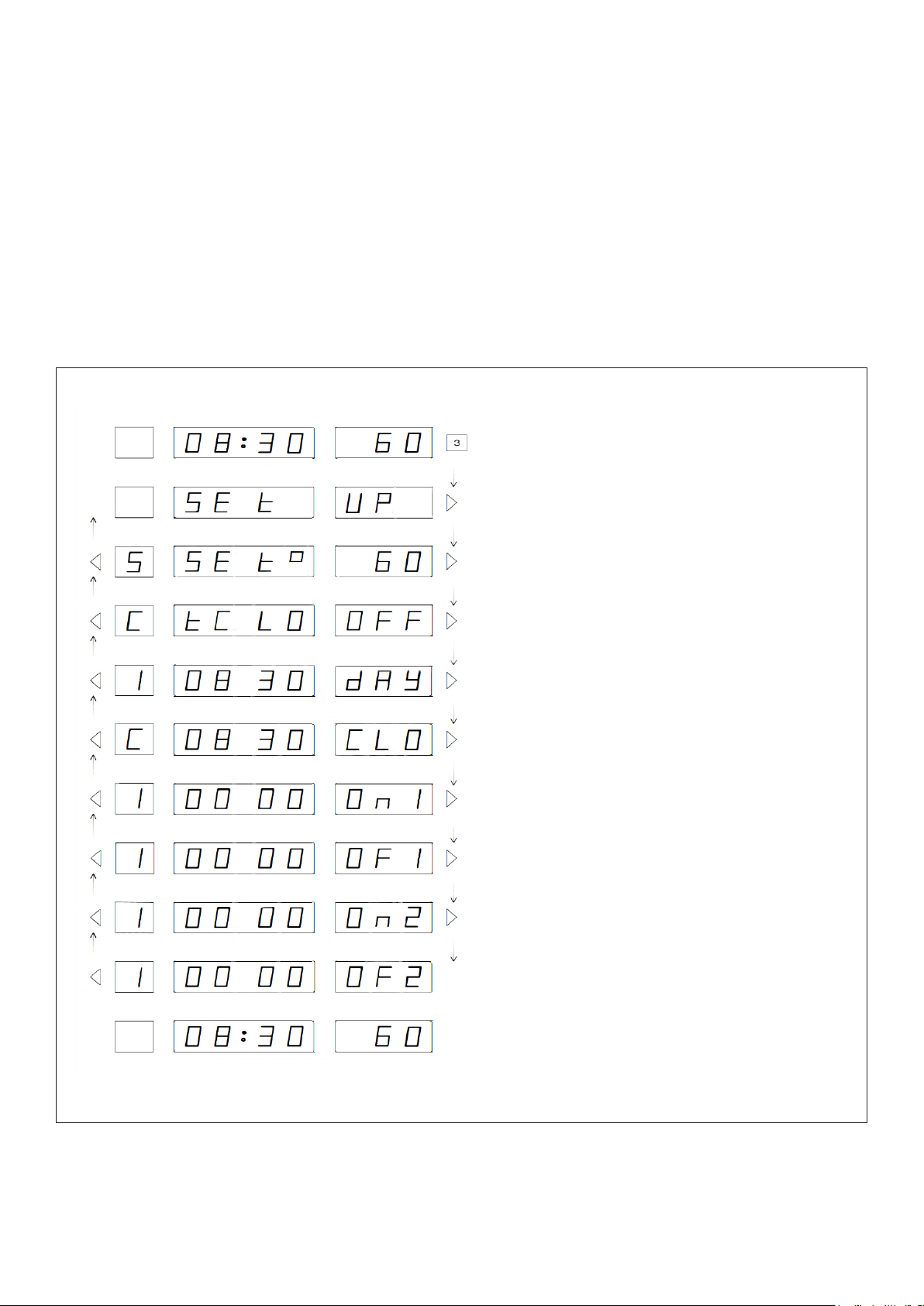

Forthisfunctiontowork,theTimeclockfunctionshouldbeturnedon(seeSetUp)andthe

RemoteEnableterminals should be linked.

UnderTimeclockcontrol,theVari-E-Platewillbeturnedonandoffatpresettimesoftheday.

Uptotwoonandtwoofftimescanbeprogrammedforeachdayoftheweek.

Thesystemcanbere-activatedafterithasautomaticallyswitchedoffbypressingthe

ValueIncrease(7)pushbutton.Eachpressofthispushbuttonwilladd30-minuteincrementsto

atotal,whichisshownintheTime/Alarmwindow.PressingtheValueDecrease(9) push button

willsubtract30-minuteincrementsfromthetotaltime.

Thetimevaluecountsdownandwhenthetimeshownhaselapsed,theunitwillrevertto

normal time clock operation.

c) Remote Switch and Internal Time Clock Control

Forthisfunctiontowork,theTimeclockfunctionshouldbeturnedon(seeSetUp)anda

remoteControlswitchshouldbeconnectedtotheRemoteEnableterminals.

UnderTimeclockcontrol,theVari-E-platewillbeautomaticallyturnedonandoffatpreset

timesoftheday.Uptotwoonandtwoofftimescanbeprogrammedforeachdayoftheweek.

When contacts connected to the RemoteEnableterminalsareopenedtheVari-E-Platewillbe

turned off.

When remotely enabled and the system has turned off under time clock control, it can be

re-activatedbypressingtheValueIncrease(7)pushbutton.Eachpressofthispushbuttonwill

add30-minuteincrementstoatotal,whichisshownintheTime/Alarmwindow.Pressingthe

ValueDecrease(9)pushbuttonwillsubtract30-minuteincrementsfromthetotaltime.

Thetimevaluecountsdownandwhenthetimeshownhaselapsed,theunitwillswitchoffand

reverttonormaltimeclockoperation.However,whenthesystemhasbeenturnedoffunder

remotecontrol,itcannotbere-activatedbypressingtheValueIncrease(7) push button.

Switchonviaswitch(16)

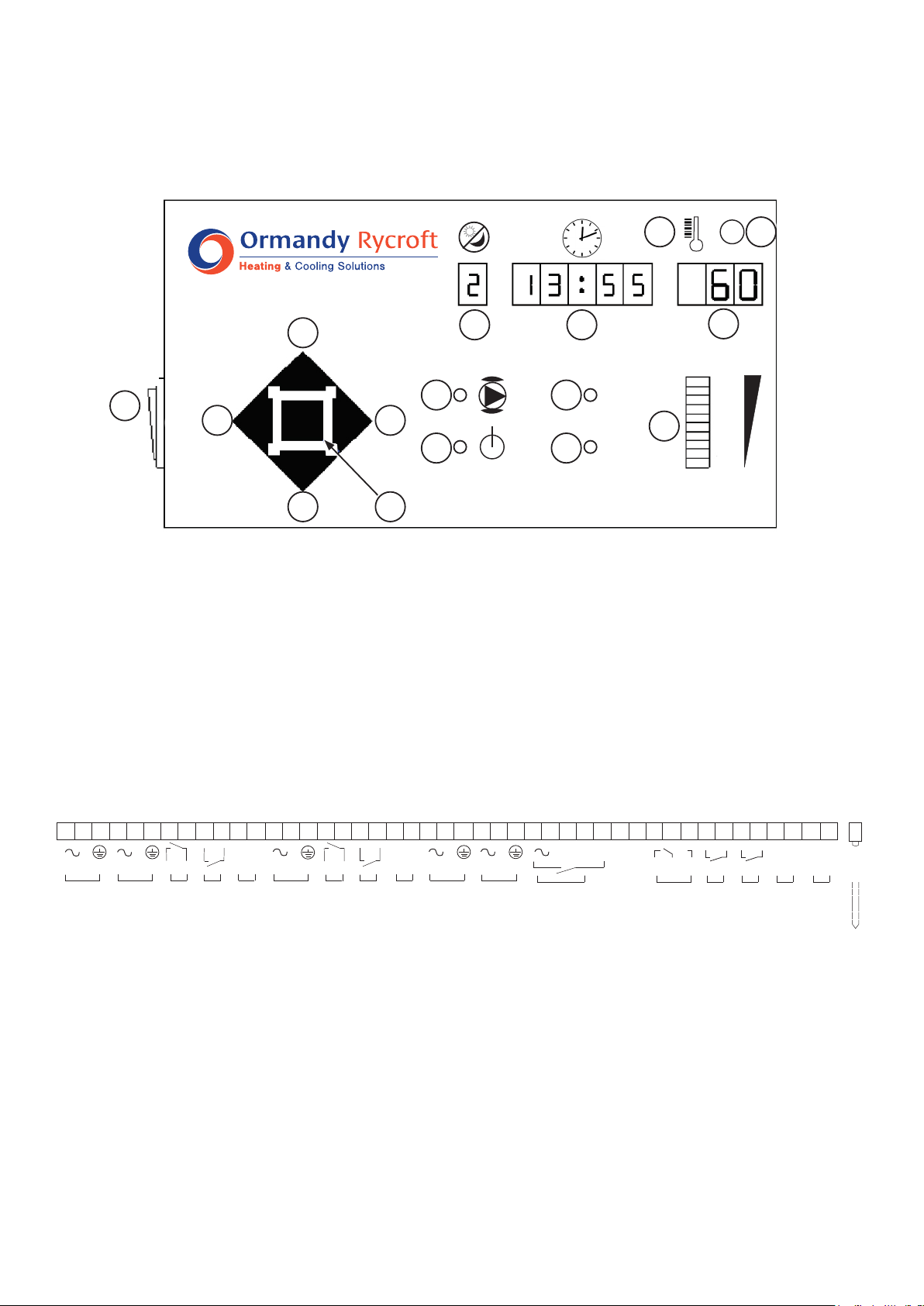

Thefrontpanelwillilluminate.Afterafewsecondsofselfchecks,thedisplayswillsettletotheDay (1)

(Time-clockonly),Time (2) and Temperature (3).Thepumpswillstart(11),thevalvewillopen(15)

and the system healthy indicator (13)willilluminate.

Thestandardtemperaturesettingis60°Candtheunitwillruncontinuously.(24houroperation).

To change any of the default settings, refer to Figure 3

TheVari-E-Platecanbeenergisedbyitsowninternaltimeclockfunction,byaremoteswitchor

BuildingManagementSystemorbyacombinationofthetwo.