ORTEC 451

SPECTROSCOPY AMPLIFIER

1-1

1. DESCRIPTION

1.1 General Description

The ORTEC 451 Spectroscopy Amplifier is a single width NIM module with a versatile combination

of switch selectable pulse shaping and output characteristics. It features extremely low noise, wide gain

range, and excellent overload response for universal application in high resolution spectroscopy. It

accepts input pulses of either polarity which originate in germanium or silicon semiconductor detectors.

scintillation detectors with either fast or slow scintillaton, proportional counters. pulsed ionization

chambers, electron multiplixs, etc.

The 451 has a dc input impedance for approximately 1000 ohms and accepts either positive or negative

input pulses with rise times < 650 nsec and fall times > 25!~sec. Three integrate and differentiate time

constants are separately switch selectable to provide optimum shape for resolution and count rate. The

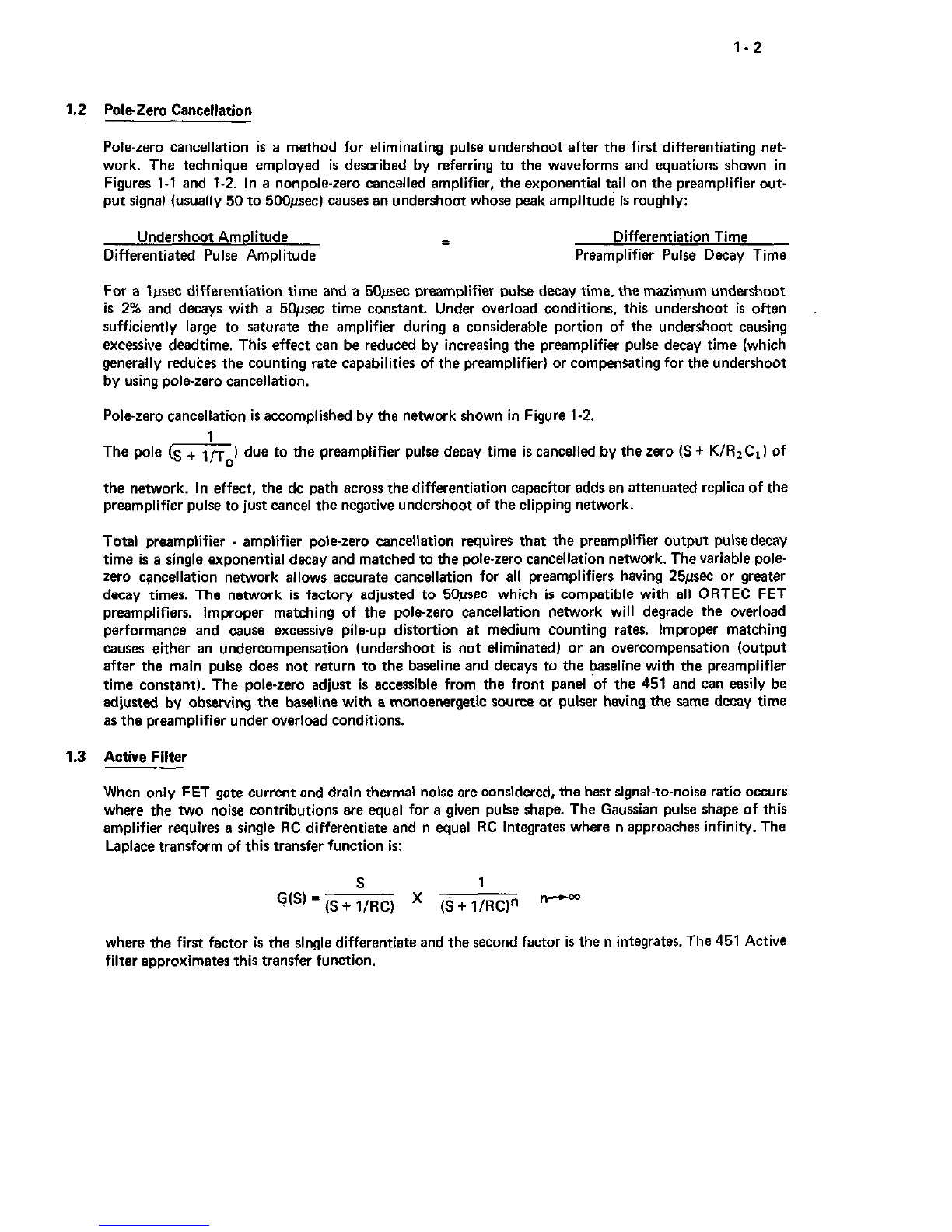

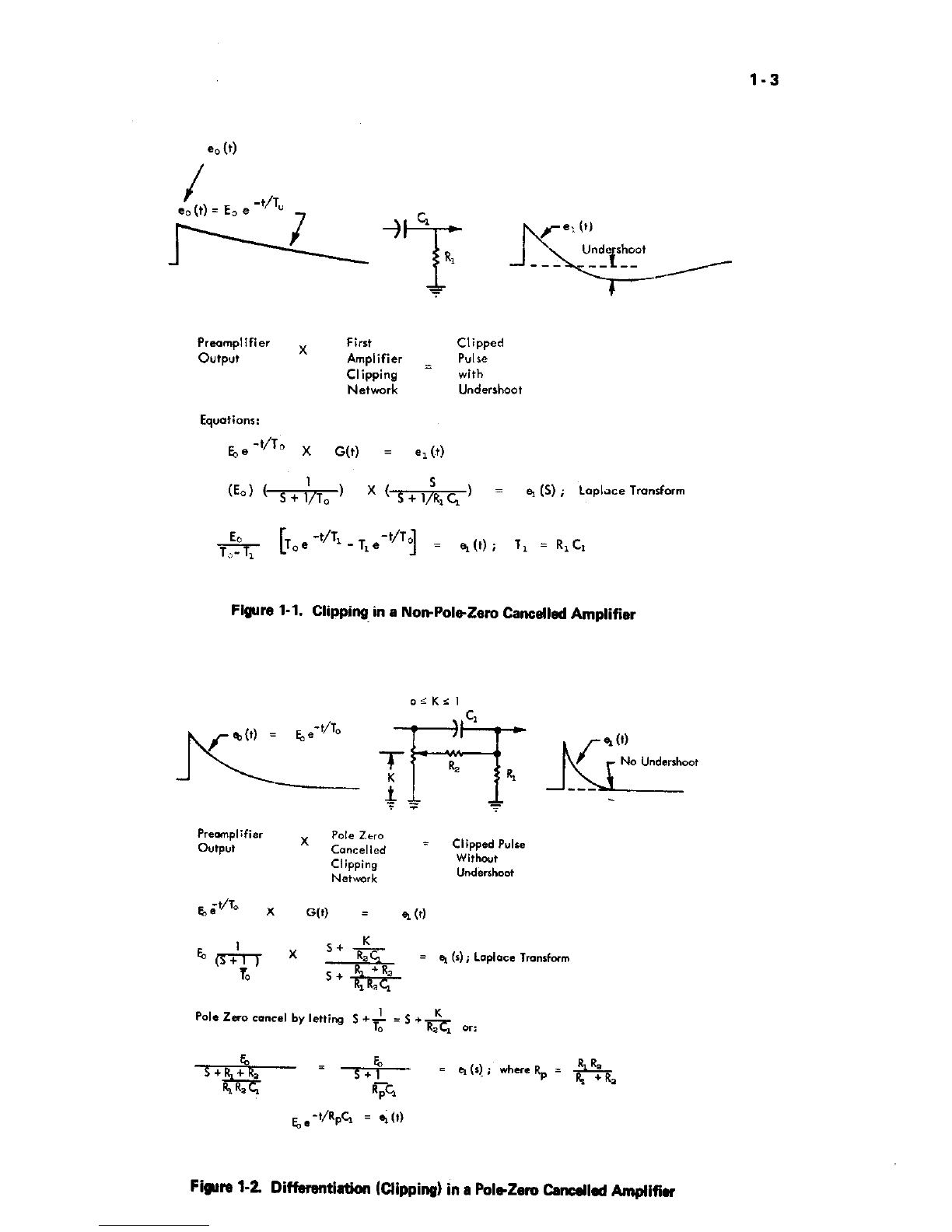

first differentiation network has variable pole-zero cancellation which can be adjusted to match

preamplifiers with > 25psec decay time. The pole-zero cancellation drastically reduces the undershoot

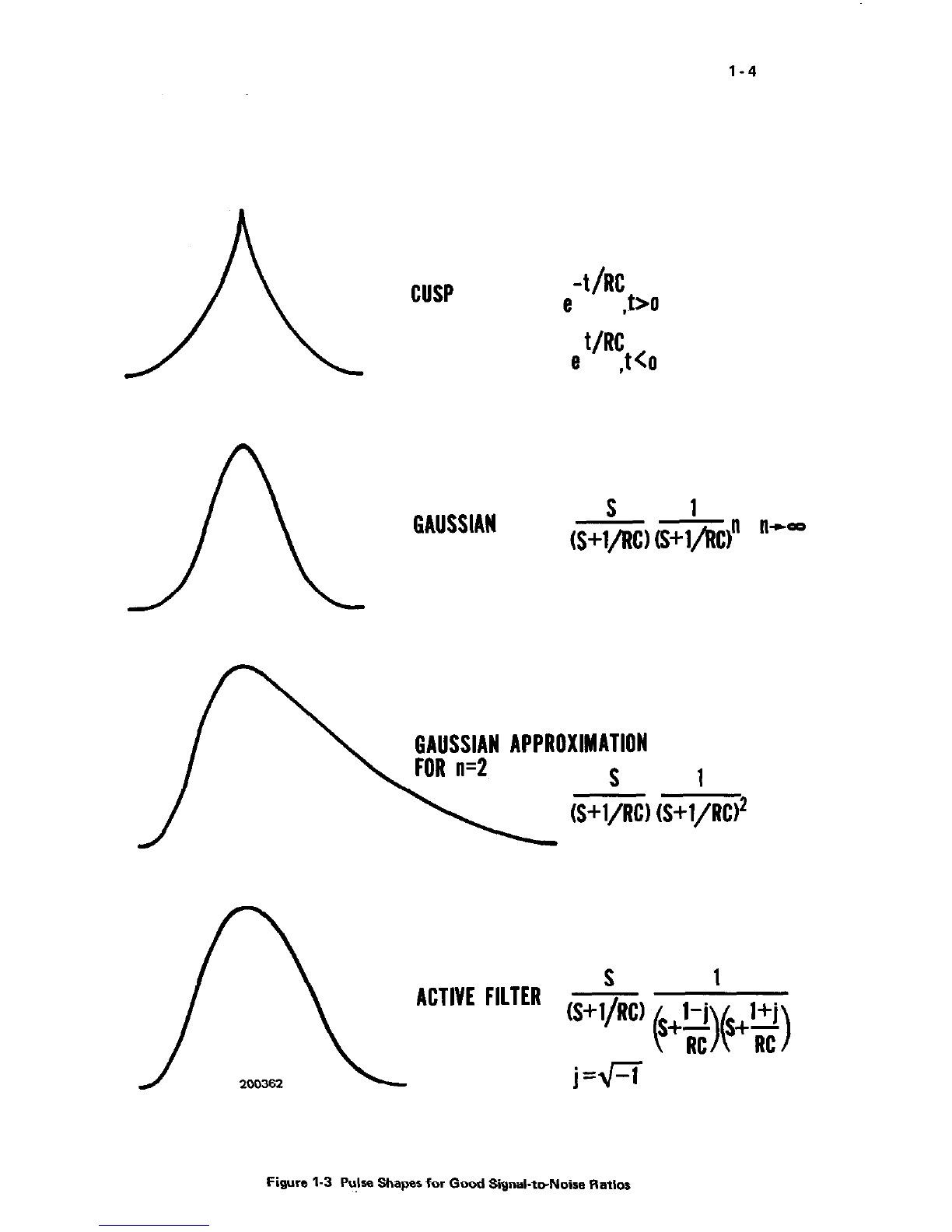

after the first clip and greatly improves overload characteristics. In addition, the amplifier contains an

active filter shaping network which optimizes the signal to noise ratio and minimizes the overall

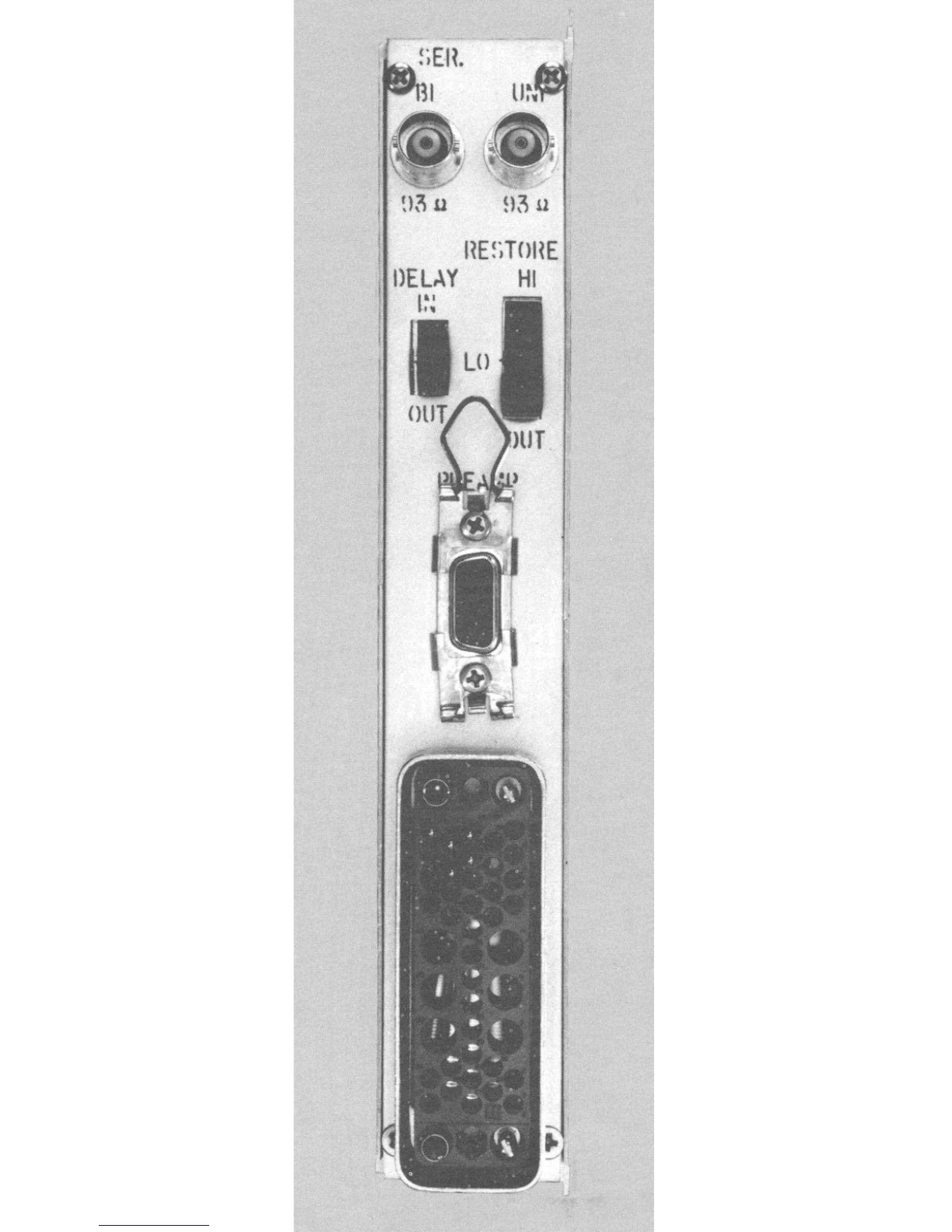

resolving time. Both unipolar and bipolar outputs are provided simultaneously on the front and rear

panels.

The unipolar output should be used for spectroscopy when dc coupling can be maintained from the 451

Amplifier to the analyzer. A BLR (Base Line Restoration) circuit is included in the 451 for improved

performance at high count rates. A switch on the rear panel permits this circuit to be switched out. set

for low count rates, or set for high count rates. When using the direct coupled input of the various

analyzers, a variety of voltage requirements exist. To meet these requirements the 451 unipolar out!

put can be selected for either positive or negative polarity and selected for full scale voltage of 3V,

6V. or 1OV. The unipolar output dc level can be adjusted from -IV to +lV. This output permits the

use of the direct coupled input of analyzers with a minimum amount of interface problems. The 451

bipolar output may be preferable for spectroscopy when operating into an x-coupled system at high

counting rates.

The 451 can be used for crossover timing when used in conjunction with an ORTEC 407 Crossover Pick-

off or a 420A Timing Single Channel Analyzer. The 420A Timing Single Channel Analyzer output has a

minimum of walk as a function of pulse amplitude and incorporates a variable delay time on the output

pulse to enable the crosswer pickoff output to be placed in time coincidence with other outputs. A

switch selectable 2psec delay is provided on the unipolar output to aid in obtaining the proper spacing

of the linear pulse in a coincidence gated system.

The 451 has complete provisions including power for operating any ORTEC solid state preamplifier

such as the 109A. 113, 118A. and 120. Preamplifier pulses should have a rise time of 0.5jJsec or less, to

properly match the amplifier filter network and a decay time > 25!.1sec for proper pole-zero cancella-

tion. The 451 input impedance is 1000 ohms. When long preamplifier cables are used, the cables can be

terminated in series at the preamplifier end or in shunt at the amplifier end with the proper resistors.

The output impedance of the 451 is about 0.1 ohm at the front panel connectors and 93 ohms at the

rear panel connectors. The front panel outputs can be connected to other equipment by single cable

going to all equipment and shunt terminated at the far end. If series termination is desired, the rear

panel connectors can be used in connecting the 451 to other modules (see Section 3).

Gain changing is accomplished by varying feedback networks. These networks are varied in such a

manner that the band width of the fedback amplifier stages remain essentially constant regardless to

gain and, therefore, rise time changes with gain switching (which cause crossover walk) are limited to

small variations.