3

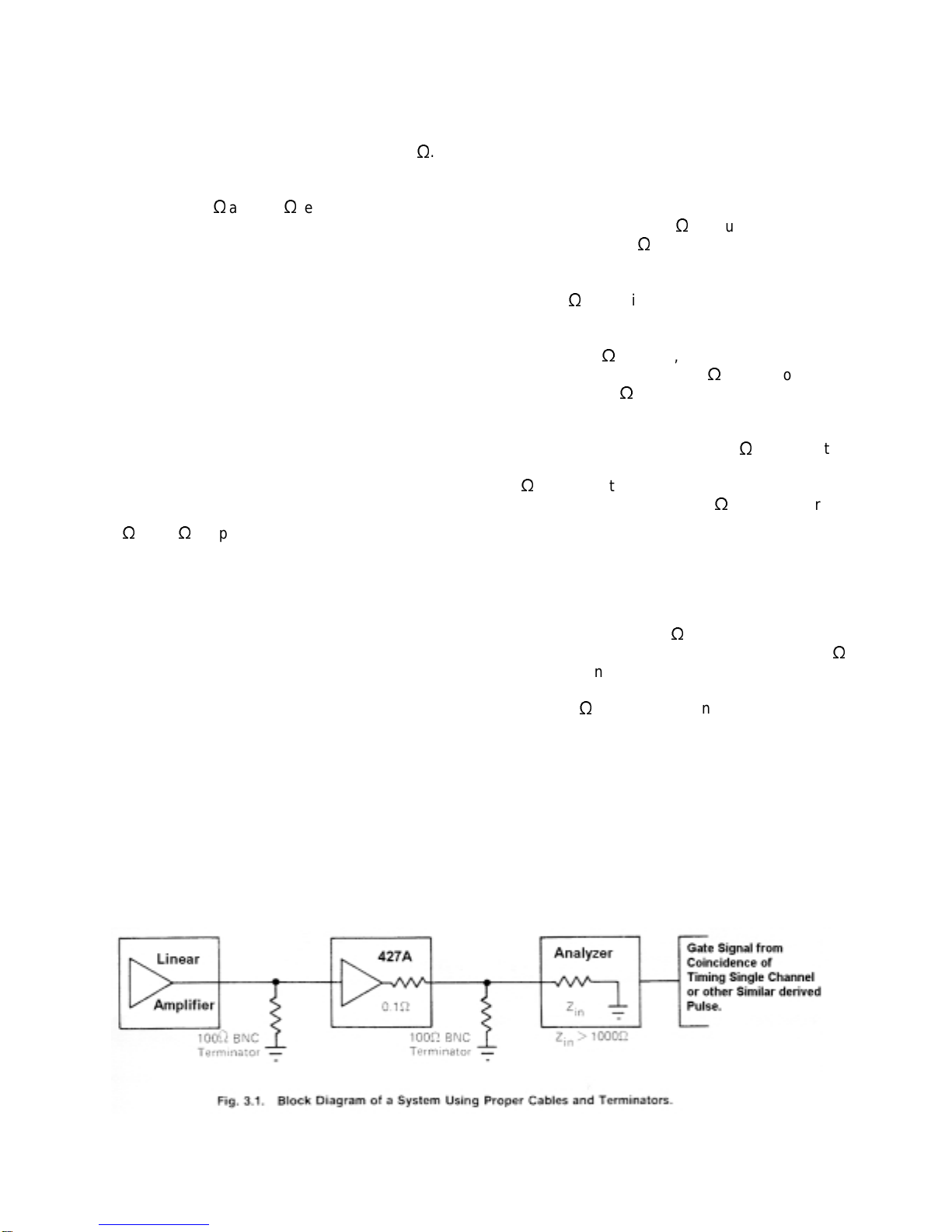

approximately 4 ft (see Fig. 3.1). The input

impedance of the 427A is approximately 1100

S

. It

is recommended that RG-62/U or RG-63/U coaxial

cable be used because of their relatively high

impedanceof 93

S

and125

S

respectively.Baseline

restoration will normally be accomplished in the

linear amplifier. The input dc level furnished into

the 427A should be zero with no signal present, and

thiswill normally be adjusted in the linear amplifier

output. The 427A has a dc-coupled output with a

dc-level adjustment for a range of ±1 V. This

permits the input to the analyzer to be normalized

in order to establish its zero-energy crossover

calibration.

3.4. LINEAR OUTPUT SIGNAL

CONNECTIONS AND TERMINATING

IMPEDANCE

The source impedance of the 0- to 10-V standard

linear outputs of most ORTEC instruments is

furnished through a series impedance of either

0.1

S

or 93

S

, depending on the connector that is

used for the connection to the next module. When

the interconnecting cable is short, such as

maximum of 4 ft, this will not usually result in any

interference problems even though impedance

matching is disregarded. However, if acablelonger

than approximately 4 ft. is necessary in a linear

output, it should be terminated in a resistive load

equal to the impedance in order to prevent

oscillations.

Therearethreegeneral methodsof terminationthat

are used. The simplest of these is shunt termination

at the receiving end of the cable. A second method

is series termination at the sending end. Thethirdis

a combination of series and shunt termination,

where the cable impedance is matched both in

series at the sending end and in shunt at the

receiving end. The most effective method is the

combination, but termination by this method

reduces the amount of signal strength at the

receiving end to 50% of that which is available in

the sending instrument.

To use shunt termination at the receiving end of

the cable, connect the 1

S

output of the sending

device through 93

S

cable to the input of the

receiving instrument. Then use a BNC tee

connector accept both the interconnecting cable

and 100

S

resistive terminator at the input

connector of the receiving instrument. Since the

input impedance of the receiving instrument is

normally 1000

S

or more, the effective instrument

input impedance with the 100

S

terminator will be

of the order of 93

S

, and this correctly matches the

cable impedance.

For series termination, use the 93

S

output of the

sending instrument for the cable connection. Use

93

S

cable to interconnect thisinto the input of the

receivinginstrument. The1000

S

(or more) normal

input impedance at the input connector represents

an essentially open circuit, and the series

impedance inthesendinginstrumentnowprovides

the proper termination for the cable.

For the combination of series and shunt

termination, use the 93

S

output of the sending

instrument for the cable connection and use 93

S

cable. Attheinput for thereceivinginstrument,use

a BNCtee to accept both the interconnecting cable

and a 100

S

resistive terminator. Note that the

signal span at the receiving end of this type of

receiving circuit will always be reduced to 50% of

the signal span furnished by the sending

instrument.

For your convenience, ORTEC stocks the proper

terminators and BNC tees, or you can obtain them

from a variety of commercial sources.