3

Contents

Getting Started. . . . . . . . 5

Room Temperature

and Humidity . . . . . . . . . . . . . . . . 5

Thunder Storms and

Power Surges . . . . . . . . . . . . . . . 5

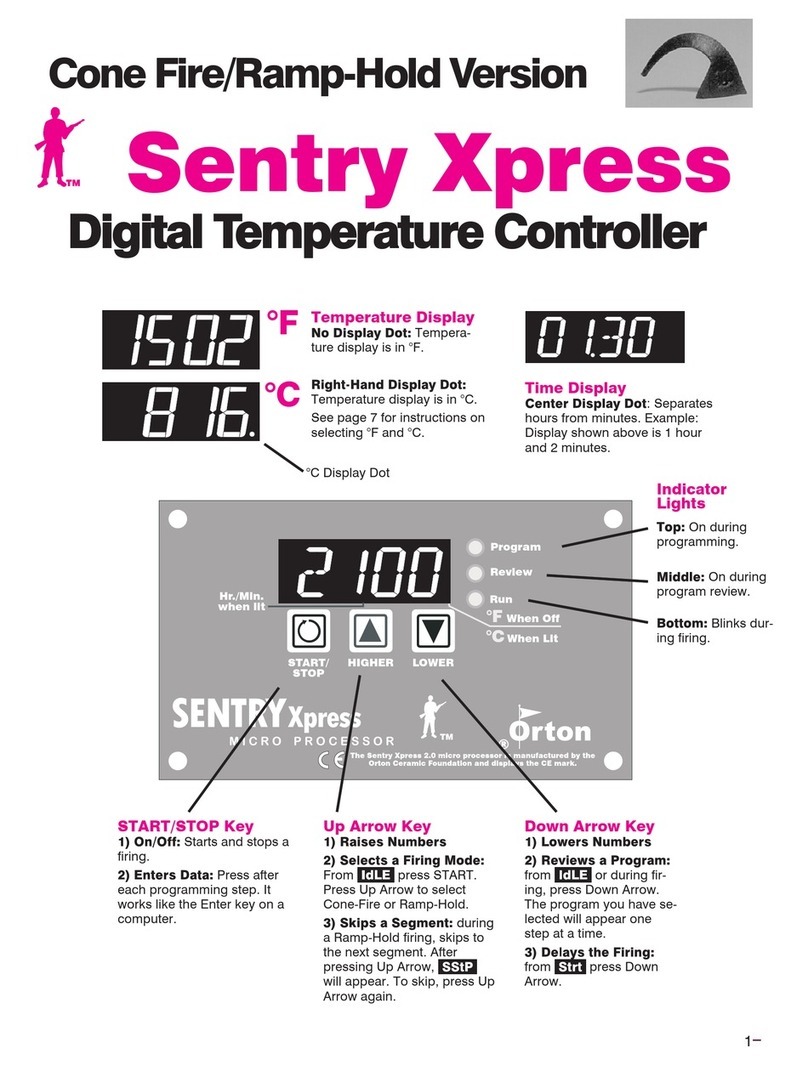

Time and Temperature Display. . 5

The IdLE Display . . . . . . . . . . . . . 5

Thermocouple Inspection. . . . . . 5

Preventing an Overfire. . . . . . . . . 6

Theory of Operation . . . . . . . . . . 6

Programming

Instructions . . . . . . . . . . 7

The Stop/Back Key . . . . . . . . . . . 7

Correcting Entries . . . . . . . . . . . . 7

Canceling a New Program . . . . . 7

Storing “User” Programs . . . . . . 7

Firing a Stored User Program. . . 7

Rate . . . . . . . . . . . . . . . . . . . . . . . 7

Hold . . . . . . . . . . . . . . . . . . . . . . . 8

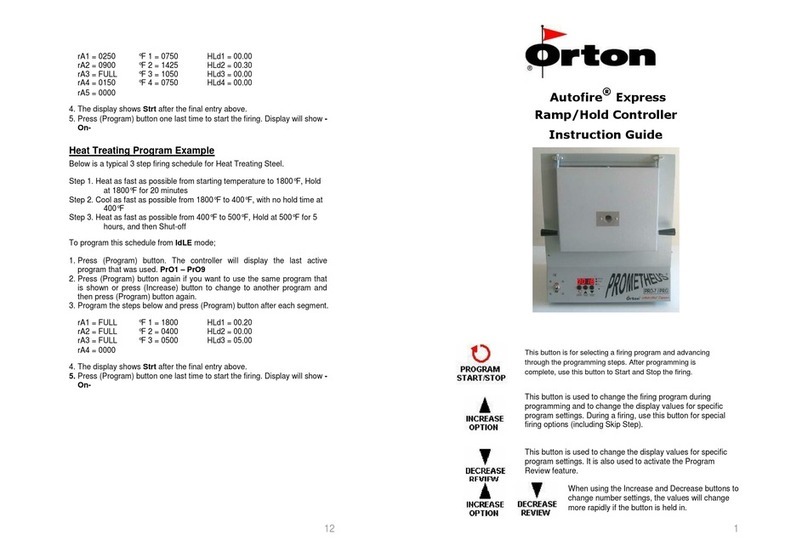

Programming Steps . . . . . . . . . . 8

Repeat Firings . . . . . . . . . . . . . . . 9

Program Review . . . . . . . . . . . . . 9

Programming a

Cooling Segment . . . . . . . . . . . . 9

CPLT Message . . . . . . . . . . . . . . 9

Temperature Overshoot . . . . . . 10

Starting a Firing in a Hot Kiln . . 10

AOP Fan . . . . . . . . . . . . . . . . . . 10

A Practice Program . . . . . . . . . . 10

Sample Firing

Programs . . . . . . . . . . . 10

Heat Treating D-2 Steel . . . . . 10

Glass Fusing Firing Schedule 10

Glass Slumping

Firing Schedule . . . . . . . . . . . 11

Other Features . . . . . . . 11

The Add Time Key. . . . . . . . . . . 11

Delay Fire . . . . . . . . . . . . . . . . . 11

Present Status . . . . . . . . . . . . . . 12

The Temperature Alarm . . . . . . 12

Estimating the Firing Cost. . . . . 12

Skip Segment . . . . . . . . . . . . . . 13

Editing the Current Segment

During Firing . . . . . . . . . . . . . . . 13

Multiple-Zone Kilns . . . 13

An Overview of Multiple-

Zone Firing . . . . . . . . . . . . . . . . 13

Thermocouple Failure

In a Multiple-Zone Kiln . . . . . . . 13

Power Output Lights . . . . . . . . . 13

Testing Multiple-Zone

Elements . . . . . . . . . . . . . . . . . . 14

DIFF / Zone Temperature

Difference . . . . . . . . . . . . . . . . 14

T123 / Zone Temperature

Display. . . . . . . . . . . . . . . . . . . . 14

The Options Key. . . . . . 14

TCOS / Thermocouple Offset . . 14

Calibrating Thermocouple

Offset With a

Digital Pyrometer . . . . . . . . . . 14

Setting Thermocouple Offset . 15

Multiple-Zone

Thermocouple Offset . . . . . . . 15

CHG- / Selecting °F or °C . . . . . 15

°F/°C Temperature

Conversion Formula. . . . . . . . 15

TC / Thermocouple Type . . . . . 15

AOP / Auxiliary Outlet . . . . . . . . 16

RATE / Types of Rates . . . . . . . 16

COST / Electric Cost

Per Kilowatt-Hour . . . . . . . . . . . 16

KW / Kilowatts Used to

Calculate Firing Cost. . . . . . . . . 16

Id / Computer ID . . . . . . . . . . . . 17

TEdE / Temperature Deviation . 17

SFTY / Maximum Temperature. 17

ELEC / Electronics

Temperature . . . . . . . . . . . . . . . 18

LOCK / Program Lock. . . . . . . . 18

CFG / Configuration Code . . . . 18

SOFT / Software Version. . . . . . 18

TEST / Element Test . . . . . . . . . 18

RST / Reset . . . . . . . . . . . . . . . . 18

Error Messages . . . . . . 19

FTC / Failed to Cool . . . . . . . . . 19

FTH / Failed to Heat . . . . . . . . . 19

LTdE / Low Temperature

Deviation . . . . . . . . . . . . . . . . . . 19

PF / Power Failure. . . . . . . . . . . 19

TC with Lines / Multiple-Zone

Kiln Thermocouple Failure . . . . 19

- - - - / No Thermocouple. . . . . . 20

BAdP / Bad Programming . . . . 20

ETH / Electronics Too Hot . . . . 20

FAIL / Thermocouple Failure . . 20

FTL / Firing Too Long . . . . . . . . 20

HTdE / High Temperature

Deviation . . . . . . . . . . . . . . . . . . 20

PF1 / Power Failure. . . . . . . . . . 20

PF 2 / Power Failure . . . . . . . . . 20

PF 3 / Power Failure . . . . . . . . . 20

TC 2 / Thermocouple Failure . . 20

TCL / Thermocouple Lag . . . . . 21

LId / Missing Connector Pin . . . 21

TCdE / Uneven Multiple-Zone

Temperatures . . . . . . . . . . . . . . 21

TCR / Thermocouple

Leads Reversed. . . . . . . . . . . . . 21

Power Failures. . . . . . . . . . . . . . 21

When the Kiln Shuts

Off Too Soon. . . . . . . . . . . . . . . 21

Appendix A:

Display Messages . . . . 22

Appendix B:

Upgrading Instructions 24

Upgrading the DTC 100, 600, 800

and 1000 Series to the Sentry

Appendix C:

User Program Records 26

Appendix D:

Quick Programming. . . 28