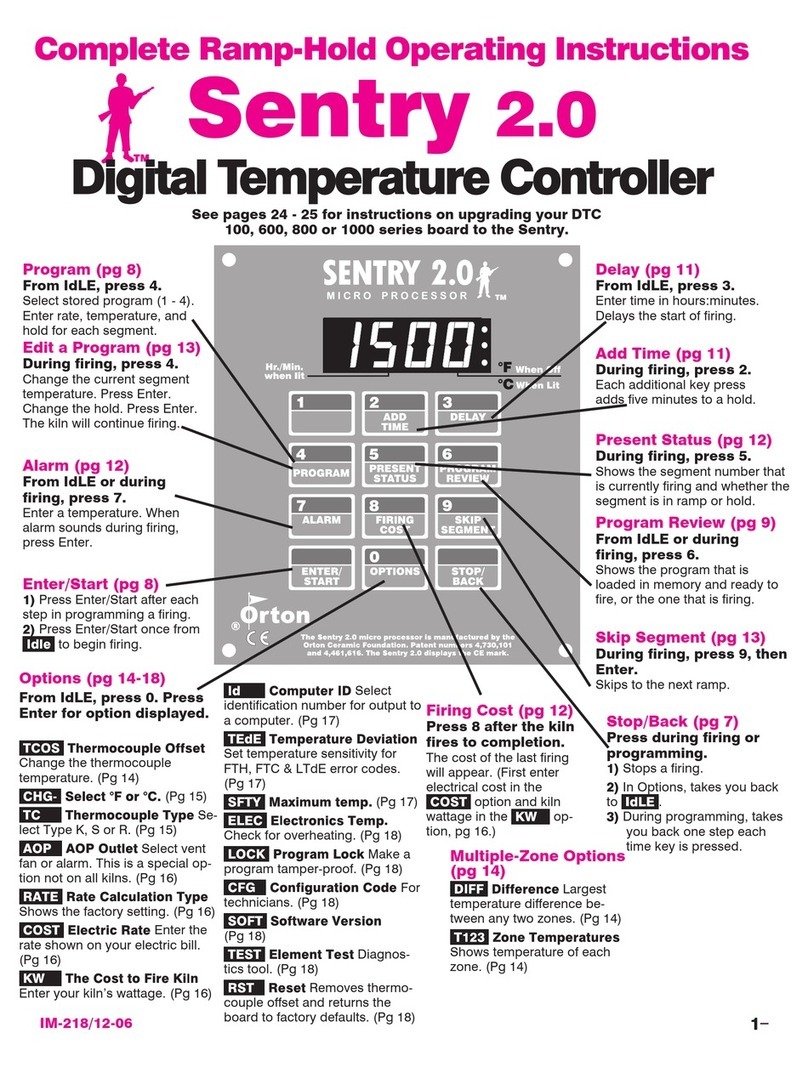

Programming Hold Time

Each step of a firing program can have an optional Hold time. Hold time is

the amount of time you want to stay at the previously determined heating or

cooling temperature. Hold time is also referred to as Soak or Dwell time.

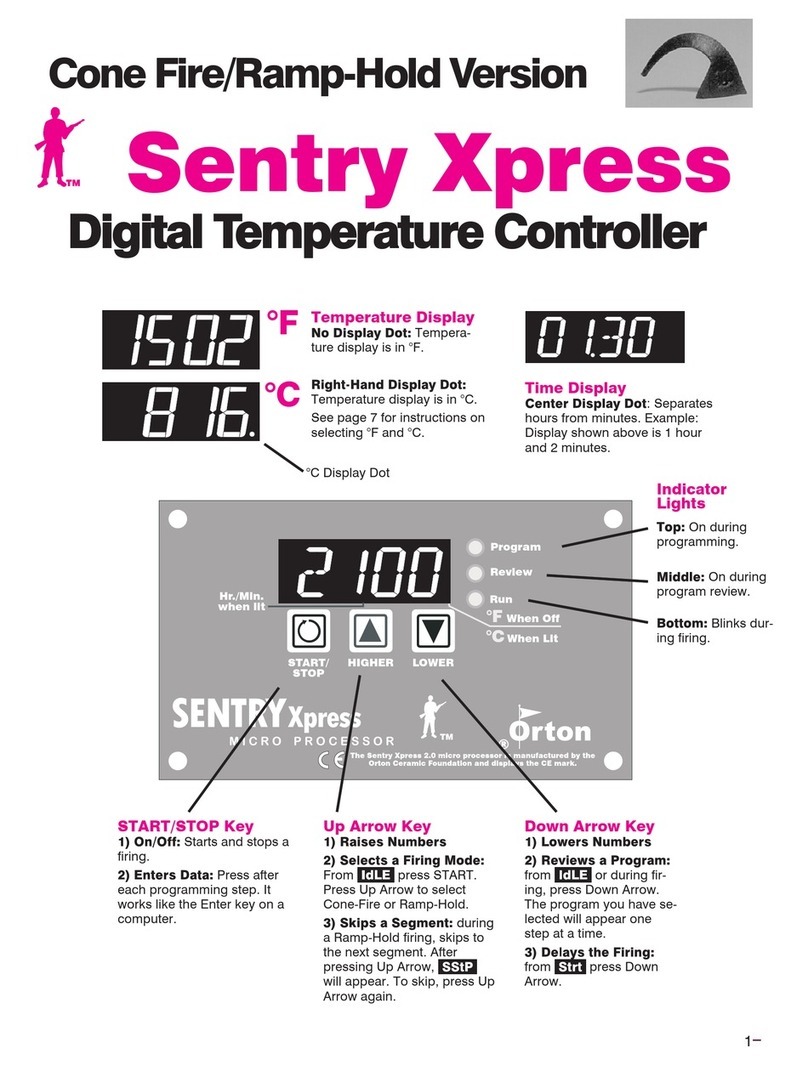

Hold Time is entered in Hours & Minutes format. The middle decimal point

light on the controller display is used to separate Hours from Minutes. For

Example, A 1 hour hold time should be set like [01.00], while a 1 hour and

30 minute hold time would be [01.30]. If no hold time is desired, the setting

should be [00.00]

A special Hold time is available for indefinite Hold periods. If it is desired to

hold the program temperature until someone manual stops the firing or

manually advances the program, a hold time of [99.59] represents

indefinite Hold.

The value range available for setting Hold time is 00.00 to 99.58.

During a firing, the hold time begins as soon as the temperature reaches the

heating or cooling temperature. As the hold time progresses, the controller

display will count-down the remaining time until the hold time has expired.

During programming the display prompts for all Hold settings is HLd

followed by the step number like HLd1, HLd2, HLd3, etc…

Other Programming Notes

After a firing program is set in the controller, the values will not change or

be lost when the controller is turned off.

It is not possible to back-up in the programming mode. If a mistake is made

while programming a previous step, you must start over from the IdLE mode

to make corrections.

If no buttons are pressed for 1 full minute during programming, the controller

will automatically exit the program mode and return to the IdLE display.

During a firing, if the options menu is activated for programming, the controller

will return to the active display if no buttons are pressed for 1 full minute.

Delay Start Option

Prior to the active start of any firing, the controller display will show a Start

prompt of Strt. This appears after the firing program selection and

programming. If a delay start time is desired, press the Decrease/Review

button to activate a delay start prompt. The display will show dELA

alternating with the adjustable delay time in Hours & Minutes format. Use the

Increase/Decrease buttons to set the Delay time and then press the Program

button to return to the Strt prompt. When you are ready to begin the delay

period, press the Program button again.

Delay time counts-down on the controller display before the actual start of the

firing. When the delay time expires, the actual firing program begins

automatically. The Delay time has a setting range of 00.00 (no delay) to

99.59 (99 hours. 59Minutes)

4

the wiring for the thermocouple and the physical condition of the probe

inside the firing chamber.

FtL -This alarm indicates that the firing was taking too much time to complete

and the firing was terminated. The controller monitors the deviation from the

desired firing schedule as compared with the actual firing results. There are 2

conditions for the FTL alarm.

1. The heating or cooling rate is slower than 27°F (15°C) per Hour

2. The current program step has lasted 2 hours longer

than anticipated.

In most cases, the FTL alarm occurs during heating if the heating rate is set

to a fast speed that cannot be maintained by the kiln. If the heating rate is

within the systems capability, a component failure has probably occurred with

the heating elements or the heater relays.

During cool-down, a well insulated system will have cooling limitation and

rapid cooling rates may set off this alarm if the cooling speed cannot be

maintained. Increasing the final cool-down temperature or slowing the

programmed cooling rate can avoid this alarm.

tCL -This alarm indicates that the thermocouple signal is not responding to the

demand for more system power during heat-up. There are 3 conditions for the tCL

alarm.

1. The heating rate is slower than 9°F (5°C) per Hour

2. The actual kiln temperature is lagging behind the desired

setpoint temperature by more than 100ºF (56ºC).

3. The actual temperature is less than 500ºF (260ºC)

In all cases, the tCL alarm occurs during heating when little temperature rise

is detected. This can be the result of a component failure; most likely a failed

heating elements or a heater relay. Another possible problem is with the

thermocouple sensor signal; if the thermocouple probe is not properly

positioned in the firing chamber or if the wiring from the thermocouple has

short -circuited the controller will not detect actual temperature changes in

the firing chamber.

EtH -This alarm indicates that the Electronics temperature is too hot for

controller operation. The controller temperature must be below176ºF (80ºC) to

prevent damage to the electronic components. The ETH alarm cannot be cleared

unless the board temperature has cooled. If the ETH occurs frequently, check the

kiln for heat loss near the controller. Proper venting and heat-shielding should be

inspected.

HtdE -The High Temperature deviation alarm sounds an audible alarm and

terminates the firing if the actual kiln temperature is above the controller set-point

by 56ºC (100ºF). This alarm is active only when the actual kiln temperature is

above 500ºF (260ºC)

9