Osaka B4U User manual

OSAKA - USER MANUAL - B4U - v2 - PAG. 1

B4U

Display + Power Unit

INTUITIVE CONTROL PANEL

FOR REFRIGERATION

USER MANUAL - v1

INTRODUCTION

This manual contains the information necessary

for the correct installation and instruction for

use and maintenance of the product, it is

recommended that you read it carefully and

keep it.

This publication is the exclusive property of OSAKA

SOLUTIONS, which prohibits reproduction and disclosure, even

partial, unless expressly authorized.

OSAKA SOLUTIONS reserves the right to make aesthetic and

functional changes at any time and without prior notice.

In order to avoid that an irregular operation of the B4U or

malfunction can create dangerous situations or damage to

people or things or animals, it is recalled that the installation

must comply with and take into account the attached security

systems, necessary to guarantee said security.

OSAKA SOLUTIONS and its legal representatives do not

assume any responsibility for damages to people, things or

animals derived from improper handling, improper use,

incorrect use or, in any case, non-compliance with the

characteristics of the B4U.

INDEX

1

DESCRIPTION B4U

1.1

GENERAL DESCRIPTION

1.2

DESCRIPTION DISPLAY B4U + POWER UNIT B4U

2

PROGRAMMING

2.1

QUICK CONFIGURATION OF THE SET POINT

“NORMAL”

2.2

STANDARD PARAMETER PROGRAMMING

2.3

PARAMETER PROTECTION THROUGH PASSWORD.

2.4

PARAMETER PROGRAMMING LEVELS

2.5

RESET THE FACTORY SETTINGS OF THE

PARAMETERS

2.6

KEYBOARD LOCK FUNCTION

2.7

VISUALIZATION OF THE VARIABLES

3

USE WARNINGS

3.1

PERMITTED USE

4

INSTALLATION WARNINGS

4.1

MECHANICAL ASSEMBLY

4.2

ELECTRICAL CONNECTION

5

FUNCTIONING

5.1

ON / STAND-BY FUNCTION

5.2

“NORMAL”, “ECONOMIC” AND “TURBO” OPERATING

MODES

5.3

PROBE INPUTS AND DISPLAY CONFIGURATION

5.4

DIGITAL INPUTS CONFIGURATION

5.5

CONFIGURATION OF THE OUTPUTS AND BUZZER

5.6

TEMPERATURE REGULATION

5.7

COMPRESSOR PROTECTION AND START DELAY

FUNCTION

5.8

DEFROST CONTROL

5.8.1

AUTOMATIC DEFROST

5.8.2

MANUAL DEFROST

5.8.3

DEFROST END

5.8.4

INTERVAL AND DURATION OF DEFROST IN CASE OF

EVAPORATOR PROBE ERROR

5.8.5

DISPLAY LOCK IN DEFROST

5.9

EVAPORATOR FAN CONTROL

5.10

ALARM FUNCTIONS

5.10.1

TEMPERATURE ALARM

5.10.2

DIGITAL INPUT ALARM

5.10.3

DOOR OPEN ALARM

5.10.4

VOLTAGE CONTROL ALARM

5.11

KEYBOARD OPERATION “ON / OFF” AND “LIGHT”

5.12

ACCESSORIES

5.12.1

PARAMETER CONFIGURATION BY “KEY USB” ”

5.12.2

VIEWING THROUGH X2

5.12.3

RS485 COMMUNICATION WITH “KEY TTL”

6

PROGRAMMABLE PARAMETERS TABLE

7

PROBLEMS, MAINTENANCE AND WARRANTY

7.1

SIGNALING

7.2

CLEANING

7.3

WARRANTY AND REPAIR

7.4

DISPOSAL

8

TECHNICAL DATA

8.1

FEATURES ELECTRICAL

8.2

FEATURESMECHANICAL

8.3

FEATURESFUNCTIONAL

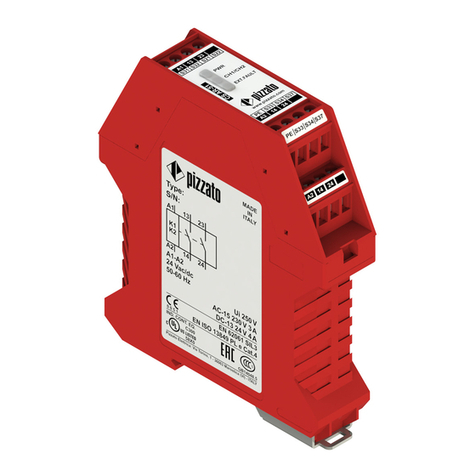

1 - DESCRIPTION B4U

1.1 - GENERAL DESCRIPTION

The B4U model is an intuitive control panel that combines the Display

B4U (Display) plus the Power Unit B4U (power unit). It has a digital

microprocessor that can be used for temperature control in

refrigeration applications. It is prepared for the ON / OFF control and

defrost control, at intervals of time, to reach the temperature or for

the continuous operation of the compressor through the compressor

stop, electrical resistance or gas inversion / hot cycle.

The B4U has special functions to optimize defrost and functions that

can be used to achieve energy savings in the system.

The B4U has up to 4 relay outputs and 5 configurable inputs, of which

3 are for NTC temperature probes and 2 are digital for voltage-free

contacts.

OSAKA - USER MANUAL - B4U - v2 - PAG. 2

The 4 outputs can be used to control the compressor or temperature

control device, the anti-fog heater, the evaporator fans and a

configurable auxiliary device (light, alarm, etc.)

The 3 temperature probe inputs can be used for cell temperature

regulation, for evaporator temperature measurement, for auxiliary

temperature measurement (Product temperature, condenser

temperature, etc.).

There is always a digital input available on the Power Unit B4U and,

as an alternative to the temperature probe inputs Pr2 and Pr3, two

other digital inputs can be configured.

The digital inputs can be configured to perform various functions,

such as door signal, defrost commands, selection of a different set of

temperature regulation, signaling of an external alarm, activation of a

continuous cycle, activation of the auxiliary output, etc.

In addition, the B4U is equipped with a voltage alarm that turns off

the outputs when the voltage is too high or too low.

The selection of the functions and the programming of the

parameters are carried out through the 4 capacitive keys on the B4U

Display.

The connection between the Display B4U and the Power Unit B4U is

made using the LIN cable, a small three-pole cable included.

1.2 - DESCRIPTION OF THE B4U DISPLAY AND THE B4U

POWER UNIT

1 - ON / OFF key: Pressing for 1 second turns the B4U on / off

(Stand-by).

Pressing for 5 seconds together with the LIGHT key (4), allows

access to the parameter programming mode.

Pressing for 5 seconds together with the DOWN key (3), allows

access to the display mode of the temperature measured by the room

probe, the evaporator temperature (P1 and P2) and in addition to the

maximum (Ht) and minimum (Lt) temperature recorded by the team.

Inside the programming mode by pressing for 3 seconds and

releasing, we exit and return to normal operation.

2 - UP / DEFROST key: In normal operating mode, pressing and

releasing allows quick access to the Set Point selection and

modification mode.

Pressing for 5 seconds allows activating / deactivating a manual

defrost cycle.

In the programming and display modes of the temperature measured

by the room probe, the evaporator temperature (P1 and P2) and in

addition to the maximum (Ht) and minimum (Lt) temperature

registered by the equipment, is used to select the parameters and

increase the values to be configured.

3 - DOWN / AUX 2 key: In normal operating mode, pressing and

releasing allows quick access to the Set Point selection and

modification mode.

Pressing for 3 seconds allows activating / deactivating the configured

output configured as A2 (anti-fog heating elements).

In the programming and display modes of the temperature measured

by the room probe, the evaporator temperature (P1 and P2) and in

addition to the maximum (Ht) and minimum (Lt) temperature

registered by the equipment, is used to select the parameters and

decrease the values to configure.

4 - LIGHT button: Pressing for 2 seconds allows you to manually

activate / deactivate the output configured as light (Auxiliary).

Pressed for 5 seconds, together with the Stand-by key (1), it allows

access to the parameter programming mode.

In programming mode it is used to access parameter editing and to

confirm values.

In programming mode, it can be used in conjunction with the UP key

to modify the parameter programming level.

Pressed for 3 seconds when the keypad is locked, allows the keypad

to be unlocked.

5 - Led SET: In normal operation mode, lights up when a button is

pressed to indicate that it has been pressed.

In programming mode it is used to indicate the level of parameter

programming.

6 - Led OUT - COOL:Indicates the status of the regulation output

(compressor or temperature control device); output on (on), output

off (off), or output failed (flashing).

7 - Led DEF: Indicates that a defrost is being carried out (on) or in a

dripping state (intermittent).

8 - FAN Led: Indicates the status of the evaporator fan output: ON,

OFF, or failed (flashing).

9 - Led AUX2: Indicates the activation of the output configured as A2

(anti-fog heating elements).

10 - Led Stand-By / Decimal point:When the B4U is in Stand-By

mode, it is the only LED that remains lit. In normal operation it is used

as a decimal point separator.

11 - Unit of Measure Led: Indicates the temperature measurement

unit in use.

POWER UNIT B4U

1 - Led ON: When it is turned on, for a few seconds, the led shows

solid red indicating that the control is starting. Once started, the LED

starts to blink between a weak red and a more intense one, indicating

the correct operation of the control unit.

2 - TTL communication port: Used to connect to the following

devices:

USB Key: to transfer operating parameters to and from the B4U.

Key TTL-RS: for MODBUS communication via RS485.

X2: Remote display that shows the temperature measured by the Pr1

probe.

3 - LIN communication port: used to communicate the Display B4U

with the Power Unit B4U.

OSAKA - USER MANUAL - B4U - v2 - PAG. 3

2 - PROGRAMMING

2.1 - QUICK CHANGE OF THE SET POINT IN "NORMAL" MODE

To configure the Set Point in normal mode, press and releasethe UP

or DOWN keys and the screen will display "S1" and the current

setting value at that time.

By pressing the UP or DOWN keys again, we will be able to select

the new desired value within the limits established by the "SH" and

"SE" parameters.

Once the desired value has been selected, press the LIGHT button

or wait 3 seconds for the B4U to activate the new set value and return

to the normal operating screen.

2.2 - STANDARD PROGRAMMING OF PARAMETERS

To access the B4U parameter menu when the parameter protection

is not active, press the ON / OFF + LIGHT keys simultaneously for 5

seconds.

The screen will show the acronyms that identify the first group of

parameters ("-SP") and with the UP and DOWN keys we will select

the group we want.

Once the desired group of parameters has been selected, press the

LIGHT key and the acronyms that identify the first parameter of the

selected group will be displayed.

Once inside, with the UP and DOWN keys we will select the desired

parameter and press the LIGHT key, the screen will alternately show

the initials of the parameter and its value, which we will modify with

the UP or DOWN keys.

Once the desired value has been established in the parameter, we

will press the LIGHT button to memorize the new value and the

display will show only the initials of the selected parameter.

Using the UP or DOWN keys, we can select another parameter from

the group and modify it as described above.

To exit and select another group of parameters, we must press the

ON / OFF key for 1 second and the screen will show the initials of the

parameter group.

At this point, it is possible to select another group, access the

parameters and modify them as described above.

To exit the parameter menu, do not press any key for approximately

30 seconds or press the ON / OFF key for 2 seconds until exiting the

programming mode.

2.3 - PARAMETER PROTECTION THROUGH PASSWORD

The B4U has the function of protecting the parameters by means of

a personal password, configuring it in the "PP" parameter within the

"-tS" group.

To have this protection available, we will program the desired

password number in the "PP" parameter.

Once the protection is activated, to access the parameter menu,

press the ON / OFF + LIGHT keys simultaneously for 5 seconds and

the display will show "rP", press the LIGHT key and the display will

show "0".

At this point, using the UP and DOWN keys we will establish the

password value that we programmed and press the LIGHT key to

confirm.

If the password is correct, the display will show the initials that identify

the first group of parameters "-SP" and it will be possible to program

the parameters as already described in the previous section.

Password protection is disabled by setting the parameter "PP" = oF.

Note: If we forget the password to access the parameters, we must

carry out the following procedure:

Turn off the power supply to the equipment and power it again while

pressing the LIGHT key for 5 seconds. This will give us access to the

parameters and, therefore, we can put the new password in the "PP"

parameter.

2.4 - PARAMETER PROGRAMMING LEVELS

The factory configuration of the B4U has that password protection

acts on all parameters.

After enabling the password in the "PP" parameter, we can make

certain parameters configurable while the rest are protected by

password.

To carry out this action we must follow the following procedure:

Access the parameter programming by entering the password and

select the parameter to configure.

Once we have located the parameter, if the SET LED flashes, it

means that the parameter is only configurable by setting the

password and therefore it is "protected". Otherwise, if the SET LED

is on steady, it means that the parameter can be set even without

setting the password and is therefore "unprotected").

To change the condition of the parameter, we will press the LIGHT

key and the UP key together.

The SET LED will change its state indicating the new level of

accessibility of the parameter (on = unprotected; flashing = protected

by password).

In the event that the password is enabled and some parameters are

"unprotected", when accessing the parameter programming, all the

parameters configured as "unprotected" will be displayed first without

any division by groups where we will find the parameter last. "RP"

through which it will be possible to access the "protected"

parameters.

OSAKA - USER MANUAL - B4U - v2 - PAG. 4

2.5 - RESET THE FACTORY SETTINGS OF THE PARAMETERS

The B4U allows you to reset the parameters to the factory default

values.

To return to the factory values or default values of the parameters, it

is enough to activate the password protection and once activated

when the display reads "rP" enter the password -48.

Once the password has been confirmed with the LIGHT key, the

display will show "---" for 2 seconds when the equipment resets the

parameters, does a little test and sets all the parameters to default

values.

2.6 - KEYBOARD LOCK FUNCTION

The B4U can fully lock the keyboard.

Such a function is useful when the controller is exposed to the public

and you want to prevent tampering.

The key lock function can be activated by programming the “Lo”

parameter to any value other than oF.

The value configured in the"Lo" parameter is timethatif the keyboard

remains untouched, the keyboard is fully locked automatically.

Therefore if we do not press any key during the time "It"the B4U will

automatically lock out normal keyboard operation.

When you press any key when the keypad is locked, the display will

show "Ln" to indicate that the lock is active.

To unlock the keyboard, we must press the LIGHT key for 8 seconds,

after that time the display will show "LF" and all the key functions will

be operational again.

2.7 - DISPLAY OF THE VARIABLES

The display normally shows the variable configured in the "dS"

parameter, but it is possible to show all the measurement and

operating variables by simultaneously pressing the ON / OFF +

DOWN keys for 5 seconds. The screen will alternately show the

initials that identify the first variable and its value.

With the UP or DOWN keys, we can see all the variables:

"P1" - Pr1 probe measurement

"P2" - Pr2 probe measurement

"P3" - Pr3 probe measurement

"Lt" - Minimum stored temperature Pr1

"Ht" - Maximum stored Pr1 temperature.

If the function related to the power supply voltage alarms is enabled

(parameter "LU" or "HU" different from oF), the variable P5 will also

appear.

The maximum values Lt and Ht will not be saved when the power

supply fails and can be reset by pressing the ON / OFF key for 3

seconds during the maximum display. After 3 seconds, the display

will show "---" for an instant to indicate that the cancellation has

occurred and will assume the maximum temperature measured at

that instant.

To exit the variables display mode, we will not press any of the 4 keys

for approximately 10 seconds.

3 - WARNINGS FOR USE

3.1 - PERMITTED USE

The B4U has been designed as a measuring and regulating device

in accordance with EN 60730-1 for operation at altitudes up to

2000m.

The use of the B4U in applications not expressly provided for in the

aforementioned standard must include all appropriate protection

measures.

The B4U must be adequately protected and out of the reach of

liquids, dust, grease and dirt. It must be accessible only with the use

of a secure tool or system (except the front one).

The B4U CANNOT be used in environments with a dangerous

atmosphere (flammable or explosive) without adequate

protection.

If used with the NTC probe that is supplied together with

the B4U, it will comply with the EN 13485 standard

("Thermometers to measure the temperature of air and products for

the transport, storage and distribution of refrigerated, frozen and

frozen food products") with the following designation: [air, S, A, 2, -

50 ° C .. + 90 ° C].

Remember that the B4U, when in operation, must be periodically

checked by the end user in accordance with the EN 13486 standard.

It is recalled thatthe installer must ensure that the standard regarding

electromagnetic compatibility is respected after the implementation

in the installation of the equipment, possibly using suitable filters..

In case of failure or malfunction of the B4U that could create

dangerous situations or damage to people, things, animals or product

(defrosting of food or changes in its ideal state), it is recalled that the

installation should be equipped with additional electronic or

electromechanical devices to guarantee the security.

4 - INSTALLATION WARNINGS

4.1 - MECHANICAL ASSEMBLY

The POWER UNIT B4U module is designed for installation with fixing

by 2 screws.

The DISPLAY B4U panel, with dimensions of 96 x 50 mm, is

designed to be paneled.

A 90 x 44 mm hole must be made and the DISPLAY B4U must be

inserted, fixing it with the special supports provided.

Avoid placing the B4U module in places exposed to high humidity or

dirt that may cause condensation or the introduction of conductive

parts or substances.

Make sure the B4U has adequate ventilation and avoid installation in

containers where other devices are installed that can cause the

devices to operate outside of the set temperature limits.

Install the devices as far as possible from sources that can generate

electromagnetic disturbances such as motors, contactors, relays,

solenoid valves, etc.

OSAKA - USER MANUAL - B4U - v2 - PAG. 5

4.1.1 - MECHANICAL DIMENSIONS, DRILLING AND FIXING.

4.2 -ELECTRIC CONNECTIONS

Make the connections by connecting a single conductor per terminal

and following the diagram shown, verifying that the supply voltage is

that indicated on the B4U and that the absorption of the actuators

connected to the B4U is not greater than the maximum allowed

current.

The B4U is designed for permanent connection inside a panel, it is

not equipped with a switch or internal overvoltage protection devices.

Therefore, it is recommended to install a bipolar switch, marked as

the disconnecting device, which interrupts the electrical supply to the

appliance. This switch should be placed as close to the B4U as

possible and in a place that is easily accessible to the user.

Furthermore, it is recommended to adequately protect all circuits

connected to the B4U with devices (eg fuses) suitable for circulating

currents.

It is recommended to use cables with insulation that is appropriate

for the voltages, temperatures and operating conditions, and to

ensure that the cables related to the input sensors are kept away

from the power cables to avoidelectromagnetic disturbances.If some

cables used for wiring are shielded, it is recommended to ground

them from one side only.

Before connecting the outputs to the actuators, it is recommended to

verify that the set parameters are the desired ones and that the

application works correctly to avoid anomalies in the system that

could cause damage to people, things or animals.

4.2.1 - ELECTRICAL WIRING DIAGRAM

* Color legend Cable - Strip:

1 - Brown / 2 - White / 3 - Green / 4 - Blue / 5 - Red /

6 - Black.

5 - OPERATION

5.1 - ON / STAND-BY FUNCTION

The B4U, once turned on, can take 2 different conditions:

- ON: It means that it works with the normal control functions.

- STAND-BY: It means that the controller does not operate with any

control function and the display turns off, the Stand-by LED remains

on.

Going from the Stand-By state to the ON state is exactly the same as

turning on the B4U with the power supply.

In case of power failure, the B4U returns to the function that was just

before the power supply interruption.

The ON / Stand-By function can be selected in the following ways:

- Pressing the ON / OFF key for 1 second.

- Through digital input if parameter "1F / 2F / 3F / 4F" = 7.

5.2 -"NORMAL", "ECONOMIC" AND "TURBO" OPERATING

MODE

The B4U allows programming 3 regulation Set Points, one Normal -

"S1", one Economy - "SE" and one "Turbo" - "SH".

Associated with each of them is the relative differential (hysteresis)

normal - "d", Economic - "Ed" and "Turbo" "Hd".

Note: In the following examples, the Set Point is generically indicated

as "SP", in any case, the B4U will act according to the active Set

Point.

OPERATION IN "NORMAL-ECONOMIC MODE"

It can be used if necessary by switching to 2 different operating

temperatures (eg day / night or weekdays / holidays).

NORMAL / ECONOMY mode can be switched manually:

- Through digital input if parameter "1F / 2F / 3F / 4F" = 6

NORMAL / ECONOMY mode can be switched automatically:

- Through a delay time that elapses since the door is closed

(switching from Normal to Economic mode). This time is set in the

"Et" parameter.

- When the door is opened, if the Economic Set Point “SE” is active

(switching from Economic to Normal mode).

OSAKA - USER MANUAL - B4U - v2 - PAG. 6

- After closing the door, the time “Et” elapses and the Economic Set

Point “SE” is activated; Setting in the parameter "tt" the maximum

time that you want to allow operation in Economy mode with the door

closed (switching from Economy to Normal mode).

Example of automatic ECONOMIC-NORMAL mode operation.

During working hours, the door is opened frequently and the B4U

remains in NORMAL mode.

After the "Et" time has elapsed and the door has been closed for that

time, the B4U switches to ECONOMY mode. As soon as the door is

reopened, the B4U returns to normal mode.

For this automatic change function you must use a digital input

configured as"1F / 2F / 3F / 4F" = 1, 2 or 3 (door open input).

If "Et" = oF, the change from ECONOMIC mode to NORMAL through

digital input (configured as open door) will be disabled.

If "tt" = oF, the change from ECONOMIC mode to NORMAL for the

maximum time allowed in ECONOMIC mode with the door closed will

be disabled.

(1) - The time Et is reset every time the door is opened. In the case

of the example, the door is always closed.

(2) - Time tt stops when the door is opened and the B4U immediately

switches to NORMAL mode. In the case of the example, the door is

always closed.

When entering ECONOMY mode, the initials "Ec" will be shown on

the display.

In the event that the cabinet light is also used (output configured as

“L1”), the ECONOMIC mode selection is always associated with the

function of deactivating the auxiliary output.

“TURBO-NORMAL-ECONOMIC” MODE OPERATION:

The TURBO mode can be used manually when a rapid decrease in

product temperature is needed after the refrigerator is open.

Instead, it can be used automatically to allow product temperature

recovery at the end of ECONOMY operation.

TURBO mode can be switched manually:

- Through digital input if parameter "1F / 2F / 3F / 4F" = 8

TURBO mode can be switched automatically:

- Exiting ECONOMIC mode (only if "HC" = C3)

- Every time the B4U is started (only if "HC" = C3 and Pr1 greater

than SE + Ed).

In order for the TURBO mode to be automatically switched off, the

"tC" time must be expired or, if not, manually through the

programmed key or digital input, and the B4U will return to normal

mode.

When entering TURBO mode, the initials “tr” will appear on the

display alternating, every 10 seconds, with the normal screen.

Setting "HC" = C3 the operating cycle is as follows:

When turned on, the B4U automatically goes into the mode it was in

before shutting down (Normal or ECO) unless the start-up

temperature is higher than SE + Ed. In this case, a TURBO cycle is

automatically started.

After the time “tC”, the B4U automatically switches to NORMAL

mode.

If the door is opened frequently, the B4U will switch to NORMAL

mode, if instead the door is not opened during the "Et" time, it will

automatically switch to ECONOMY mode.

The B4U remains in ECONOMY mode until the door is reopened or,

if configured, until the "tt" timeout.

When it exits the ECONOMY mode, the B4U performs a TURBO

cycle to recover the temperature of the products, then returns to the

NORMAL operating mode, and so on.

(1) - The time Et is reset every time the door is opened. In the case

of the example, the door is always closed.

(2) - Time tt stops when the door is opened and the B4U immediately

switches to TURBO mode. In the case of the example, the door is

always closed.

5.3 - PROBE INPUTS CONFIGURATION AND DISPLAY

The parameters related to the configuration of the measurement

inputs are found in the group "-In". Using the parameter "uP" it is

possible to select the temperature measurement unit and the desired

measurement resolution (C0 = ° C / 1 °; C1 = ° C / 0.1 °; F0 = ° F / 1

°; F1 = ° F / 0.1 °).

The B4U allows the measurement to be calibrated, which can be

used to re-calibrate the equipment, according to the needs of the

application, by means of the parameter "C1" (input Pr1), "C2" (input

Pr2) and "C3" (input Pr3 ).

Parameters "P2" and "P3" allow selecting the use of the inputs by the

B4U according to the following possibilities:

= EP - Evaporator probe: the probe functions to control defrosts and

evaporator fans.

= Au - Auxiliary probe: It can be used as a display probe although it

is also possible to associate it with temperature alarms (Possibility of

using: product probe, anti-freeze probe, etc.)

= cd - Condenser probe: It can be used as a display probe although

it is also possible to associate it with temperature alarms, so that it

signals alarms related to condenser malfunction (eg dirty / plugged

condenser).

= dG - Digital input (see digital input functions)

If the input is not used, set "P2 and P3" = oF in the In folder.

It is not possible to configure the two inputs for the same function. If

the two inputs were configured for the same function, only the input

with the lower value will act.

Through the "Ft" parameter it is possible to set a software filter

relative to the measurement of the input value, so that we can reduce

the sensitivity and the rapid variation in temperature (increasing the

sampling time).

In addition to this filter, there are 2 other similar filters, but they are

used only to show the measurement of the Pr1 probe both for the

increase (parameter "du") and for the decrease (parameter "dd") and

thus avoid showing a rapid change in temperature.

The filter blocks the maximum reduction displayed at 0.1 ° every "dd"

second and the maximum increase displayed every "du" second.

At each connection, the filters are reset naturally.

In order to visualize the filtered measurement of Pr1, we will use the

parameter "dS" = F1, otherwise we will program "dS" = P1.

With the parameter "dS" it is possible to establish the standard

display of the screen between these options:

P1: Measurement of the Pr1 probe.

P2: Measurement of the Pr2 probe.

P3: Measurement of the Pr3 probe.

OSAKA - USER MANUAL - B4U - v2 - PAG. 7

SP: the active regulation set point (SP),

Ec: Measurement of the Pr1 probe in normal mode with the initials

“Ec” in the dispaly if the controller is in ECONOMIC mode.

F1: Measurement of the filtered Pr1 probe through the parameters

"dd" and "du".

oF: Numeric display off (OFF).

If one of the measurements is displayed ("dS" = P1, P2, P3, Ec, F1)

the "CU" parameter allows setting an offset that is applied to show

only the variable (all regulation controls will always be carried out

according to correct measurement of the calibration parameter).

Regardless of what is set in the "dS" parameter, it is possible to view

all the measurement and operating variables in a rotating manner, for

this see section 2.7 - VARIABLES DISPLAY.

Also remember that the display related to the Pr1 probe can be

modified by means of the screen lock function during defrost through

the "dL" parameter (see 5.8 - Defrost control).

5.4 - DIGITAL INPUT CONFIGURATION

The parameters related to the configuration of the digital inputs are

found in the group "-In".

The B4U Display has 1 digital input for power-free contacts whose

function is defined in parameter "1F" and whose action is delayed by

the time established in parameter "1t".

On the other hand, the Power Unit B4U can have a digital input

whose function is definedin the "4F" parameter plus another 2 power-

free digital inputs as an alternative to the measurement inputs Pr2

and Pr3.

To use these inputs as digital, set the relative parameter to "P2" or

"P3" = dG.

The configured function that these digital inputs perform is defined in

parameters "2F" and "3F".

The action time of digital input 2 can be delayed in parameter "2t"

while the action of digital inputs di3 and di4 is instantaneous and

cannot be delayed.

Parameters "1F", "2F", "3F", "4F" can be configured for the following

operations:

= 0 - Digital input not active

= 1 - Opening of the chamber door through normally open contact:

when the input is closed, the B4U alternately displays oP and the

variable set in the "dS" parameter. With this operating mode, the

action of the digital input also activates the time programmed in

parameter "oA", after which the alarm is activated to signal that the

door is open.

When the door is opened, if the ECONOMIC mode is activated, the

B4U returns to normal operation.

= 2 - Chamber door opening with fan lock through normally open

contact: similar to "1F / 2F / 3F / 4F" = 1 but with evaporator fan lock.

If open door alarms are generated (after time "oA") the output will be

deactivated.

= 3 - Chamber door opening with compressor and fan block and

through normally open contact: similar to "1F / 2F / 3F / 4F" = 2 but

with fan and compressor block. If open door alarms are generated

(after time "oA") the output will be deactivated.

= 4 - External alarm signaling with normally open contact: when the

digital input is closed and the alarm is activated, the B4U alternately

displays AL and the variable set in the "dS" parameter.

= 5 - External alarm signaling with deactivation of the control output

(excluding alarm and light outputs) by normally open contact: when

the digital input is closed, all the control outputs are deactivated and

the alarm is activated, the B4U displays alternately on the display AL

and the variable set in the "dS" parameter.

= 6 - Normal / Economic mode selection with normally open contact:

When the digital input is closed, the Economic mode will be selected.

When the input is open, Normal mode is selected.

= -1, -2, -3, etc. - Identical functions to the previous ones but with

inverse operating logic. Activating when the digital input contact

opens.

Note: In the event that the digital input is configured for this type of

function, the unit will consider the contacts as if they were in parallel

(considering this result as an OR function).

5.5 - CONFIGURATION OF THE OUTPUTS AND BUZZER

The parameters related to the configuration of the outputs are

contained in the group "-Ou".

The outputs of the B4U can be configured through the parameters

"o1", "o2", "o3" and "o4", with the following functions:

=ot - Compressor / Solenoid Control or Cooling Element.

=dF - Control of defrost heaters.

=Fn - Evaporator fans control.

=Au - Auxiliary output control.

=En - Allows the Control of a “silenceable” Alarm device through the

normally open and closed digital input during the alarm (See from

section 5.10 - ALARM FUNCTIONS).

=AL: Allows the Control of a “non-silenceable” Alarm device through

the normally open and closeddigital input during the alarm (See from

section 5.10 - ALARM FUNCTIONS).

=An: Allows the control of an alarm device with memory function

through the normally open and closed digital input during the alarm

(See from section 5.10 - ALARM FUNCTIONS).

=-t - Allows the control of a “silenceable” alarm device through a

normally closed and open contact in alarm.

= -L - Allows the Control of a “non-silenceable” Alarm device through

the normally closed and open digital input during the alarm. (See from

section 5.10 - ALARM FUNCTIONS).

= -n - Allows the control of an alarm device with memory function

through the normally open and closed digital input during the alarm

(See from section 5.10 - ALARM FUNCTIONS).

= on - Allows the control of a device that must be activated whenever

the instrument has voltage. If the equipment is in Stand-by, the output

will remain deactivated. This control is ideal for lighting showcases,

anti-humidity heating elements or other various functions.

= HE - To control a heating device in neutral zone (“r.HC” = nr).

= L1 - Showcase light connected to Normal / Economic mode. The

output will turn on when Normal mode is active and turn off when

Economy mode is chaotic.

= L2 - Internal camera light. The output is always off and if the digital

input is configured as door opening "1F", "2F", "3F" = 1, 2, 3), it will

turn on with the door opening.

= -d - Defrost output with normally open contact.

= A2 - Auxiliary output 2 control (Anti-fog resistance).

= oF - No function (output disabled).

If one of the outputs is configured as an auxiliary output ("o1", "o2",

"o3" and "o4" = Au), its function must be configured in the "Fo"

parameter and may be conditioned by the time programmed in the

"You" parameter.

The "Fo" parameter can be configured for the following functions:

= oF - No function

= 1 - Delayed regulation output.

The auxiliary output is activated with the delay programmed in the

parameter "tu" with respect to the output configured as "ot". The

output will deactivate as soon as the "ot" output is deactivated. This

type of operation can be used as control of a second compressor or

with a parallel control that is useful for the regulation process. It

prevents two devices from starting at the same time, causing high

occasional electricity consumption.

= 2 - Activation by LIGHT key or digital input. The output is activated

by pressing the LIGHTkey or by activating the digital inputs,provided

they are configured as ("1F / 2F / 3F / 4F" = 9). The key and digital

input functions are bistable, which means that on the first press of the

key, the output turns on, while the second press turns off.

The output configured as auxiliary can be turned off automatically

after a certain time programmable in the "tu" parameter. With "tu" =

oF the output is activated and deactivated manually using the LIGHT

key, otherwise, the output, once activated, will automatically

deactivate after the programmed time. This function can be used, for

example, to control the camera light, anti-fog resistance or other

functions.

= 3 - Activation by LIGHT key or digital input even when the B4U is

in Stand-By. The output is activated in the same way as "Fo" =2 even

when the B4U is in Stand-By.

If one of the outputs is configured as auxiliary output 2 ("1F / 2F / 3F

/ 4F" = A2), its activation and deactivation can be managed with the

DOWN key and operation can be conditioned by the time set in the

parameter "tA "present in group "-tS".

OSAKA - USER MANUAL - B4U - v2 - PAG. 8

The output configured in this way can be turned off automatically after

a certain time programmable in the "tA" parameter. With "tA" = oF,

the output is activated and deactivated manually using the DOWN

key, otherwise, the output, once activated, will automatically

deactivate after the programmed time.

The "Bu" parameter also allows the internal buzzer to be configured:

= oF - The buzzer is deactivated

= 1 - The buzzer is activated only to signal alarms

= 2 - The buzzer is activated briefly only to signal keypad tampering

(does not signal alarms)

= 3 - The buzzer is activated to signal alarms (with continuous sound)

and keypad tampering.

= 4 - The buzzer is activated to signal alarms (with intermittent sound)

and keypad tampering.

5.6 - TEMPERATURE REGULATION

The parameters related to the temperature control functions are

found in the "-rE" folder.

The B4U temperature control is ON / OFF and acts on the outputs

configured as "ot" and "HE" depending on the measurement of the

Pr1 probe, the active Set Point "S1" (or "SE", " SH "), the control

differential" d "(or" Ed "," Hd ") and the operating mode of the" HC

"parameter.

By means of the "HC" parameter it is possible to obtain the following

functions:

= C (Cooling) or = H (Heating)

Relative to the operating mode programmed in the "HC" parameter,

the equipment automatically considers the differential with a positive

value for a Refrigeration control ("HC" = C) or with a negative value

for the Heating control ("HC" = H). .

= nr (NEUTRAL ZONE)

In the case of programming the parameter "HC" = nr, the output

configured as "ot" works with cooling action (as "HC" = C) while the

output configured as "HE" works with heating action.

In this case, the regulation on the outputs can be done through the

desired active Set Point "S1", "S2", "S3", "SE", "SH" and the

regulation differential ("d" or "Ed" or "Hd") and the B4U automatically

considers the cooling action with a positive value and the heating

action with a negative value.

= HC (COOLING AND HEATING WITH 2 INDEPENDENT SET

POINTS)

If the parameter "HC" = HC is programmed, the output configured as

"ot" works with Cooling action (as "HC" = C) while the output

configured as "HE" works with Heating action.

In this case, the regulation Set point for the "ot" output will be "SP",

"SE", "SH" while for the "HE" output it is through the Set "SH".

The regulation differential for the "ot" output is the active one between

"d" or "Ed" or "Hd" is assumed automatically by the B4U to have

positive values in the cooling action while for the "HE" output the

differential will be "Hd" considered with negative values during the

heating action.

In this mode, the activation of the TURBO cycle makes the B4U work

with the Neutral Zone and the Set Point SH.

= C3 (Cooling with three automatic modes)

The B4U always works in cooling mode since this programming

activates the automatic switching of the three Normal-Economic-

Turbo modes.

All the types of protections described in the parameters (P1, P2, P3)

always act through the output configured as "ot".

In the event of a probe error, it is possible to make the output

configured as "ot" continue to operate cyclically according to the time

programmed in parameter "t1" (activation time) and "t2" (deactivation

time). When a Pr1 probe error occurs, the B4U proceeds to activate

the "ot" output during time "t1" and deactivate it through time "t2", as

long as the error remains. When programming "t1" = oF, the output

in probe error conditions will be deactivated. Programming "t1" in any

value and "t2" = oF, the output in probe error conditions will always

be active.

It is recalled that the operation of the B4U through digital inputs can

be configured as follows: "Compressor protection and start delay",

"defrost", "open door" and "external alarm with output lock".

5.7 - COMPRESSOR PROTECTION FUNCTIONS AND START-UP

DELAY

The parameters related to the compressor protection functions are

available in the "-Pr" folder.

The compressor protection function helps to avoid very frequent

starts of the compressor or it can also be useful to carry out a control

in time for the relay output destined to an actuator or load.

This function allows you to program 3 types of timing in the activation

of the output configured as "ot" as appropriate to the regulation

system.

The protection consists of preventing several starts during the

protection time.

1 - First control (Parameter P1). The first time foresees a delay in the

activation of the output "ot" according to the time programmed in the

parameter "P1" (start-up delay).

OSAKA - USER MANUAL - B4U - v2 - PAG. 9

2 - Second control (Parameter P2). The second time foresees a delay

of the control relay, in order to ensure a minimum time between the

stop and the start of the relay parameter "P2" (delay after switching

off or minimum stop time).

3 - Third control (Parameter P3). The third time foresees not allowing

starts unless the time programmed in parameter “P3” between

consecutive starts has been exceeded (delay after consecutive

starts).

If the protection is operating, preventing the operation of the relay for

the programmed time, the LED of the relay output will be flashing.

Furthermore, by setting a time in the "od" parameter, it is possible to

set a delay and avoid the activation of all the outputs after supplying

voltage and turning on the B4U.

During this delay phase we will display od alternating to the normal

programmed display.

The “od” delay function is disabled by programming as = oF.

5.8 - DEFROST CONTROL

The defrost control mode acts on the output configured as "ot", "dF"

and "-d".

The parameters related to the defrost control functions are grouped

in the "-dF" folder.

The type of defrost that the B4U will carry out is programmed in the

"dt" parameter, which can be programmed as:

= EL - WITH ELECTRIC HEATING (or also by compressor stop): with

this mode, during defrost, the "ot" output remains deactivated while

the "dF" output is activated. If the "dF" output is not used, a defrost

will be carried out by stopping the compressor.

= on - WITH HOT GAS or CYCLE REVERSAL: with this mode,

during defrost, the "ot" and "dF" outputs are activated.

= no - KEEPING THE REGULATION ON THE COMPRESSOR

OUTPUT: with this mode, during defrost, the "ot" output continues to

function as temperature regulation while the "dF" output is activated.

= Et - WITH ELECTRIC HEATING AND THERMOSTAT: with this

mode, during defrost, the "ot" output is deactivated while the "dF"

output acts as a thermostatic temperature regulator of the defrost

evaporator.

With this selection, the end of the defrost is always the maximum

duration time programmed in parameter dE.

During defrost, the "dF" output acts as a temperature regulation

control in heating mode with Set = "tE", with a fixed hysteresis of 1 °

C and with cooling of the temperature measured by the probe

configured as evaporator probe ( EP).

In this mode, if the evaporator probe is not enabled or has an error,

the defrost acts as in the EL option (therefore, during the defrost, the

“dF”output will always remain active).

5.8.1 - START AUTOMATIC DEFROST

Automatic defrosts can occur:

- By time intervals (regular or dynamic);

- By evaporator temperature;

- By continuous running time of the compressor.

In order to avoid unnecessary defrosts, when the evaporator

temperature (EP probe) is higher than the one programmed in the

“tS” parameter, the defrosts will NOT be activated.

- Defrost at regular time intervals.

Through the parameter "dC" it is possible to set the counting mode

at defrost intervals as can be seen below:

= rt- At real time intervals. The "di" interval counts the time since the

B4U was started.

This mode is the one currently used in refrigeration systems.

= ct- At intervals of compressor operation time. The interval “di” is

counted as the sum of the operating times of the output ot (output

on).

This mode is normally used in refrigeration systems with compressor

stop in defrost.

= cS- Defrost cycle at each compressor stop. The regulator starts a

defrost cycle every time the ot output is deactivated, when the Set

Point is reached or at the end of the interval established with the “di”

parameter.

If “di” = oF, the defrost is only carried out when the compressor

stops.

This mode is only carried out in special machines that, after each cold

cycle, need to have the battery free of ice in conditions of maximum

efficiency in each cycle of the compressor.

To allow automatic defrost at intervals, after setting the "dC"

parameter in the desired way between rt, ct or cS, with the "dE"

parameter we will select the time interval between the end of defrost

and the beginning of the next one.

In these modes, it is possible to configure the first defrost at the start

of the B4U in the "Sd" parameter.

This allows the first defrost to be carried out at a time interval other

than "dE".

If you want to perform a defrost at each start-up of the B4U, program

the parameter "Sd" = oF. This will make a defrost immediately upon

start-up (provided that the conditions established with the "tE"

parameters are met).

This allows the evaporator to be permanently in defrost, even when

frequent power interruptions occur that could cause the cancellation

of several defrost cycles.

If, on the other hand, you want all the defrosts to take place at the

same time interval, set "Sd" = "di".

By setting "di" = oF, all defrosts are deactivated (including the first,

regardless of the time set in the "Sd" parameter).

- Defrosts by dynamic time intervals

Note: For this function it is necessary to use the evaporator probe.

To activate the "Defrosts by Dynamic Intervals" function, we must

configure the "dC" parameter as desired between rt, ct or cS and the

"dd" parameter at any value.

In case of setting "dd" = 0, the defrost intervals are those established

by the user and the "Defrosts by Dynamic Intervals" system will be

deactivated.

This mode allows you to dynamically reduce the defrost interval time

("di" or "Sd" in the case of being the first defrost), anticipating if

necessary the execution of thedefrost, all based on an algorithm that

detects a drop in the heat exchange performance of the refrigerator.

The algorithm estimates a reduction in heat exchange based on the

increase in the temperature difference between Pr1 (chamber

control) and the evaporator probe (probe configured as EP). The

result is stored by the B4U when the regulation temperature is close

to the Set point configuration.

The advantage of defrost by dynamic time intervals is that it allows

programming the defrost intervals longer than normal and working in

such a way that it is the system conditions that determine whether to

anticipate the execution of a defrost if necessary.

If the time entered is too short, it is possible that the “Dynamic Interval

Defrosts” do not give them time to act.

OSAKA - USER MANUAL - B4U - v2 - PAG. 10

If the system is configured correctly, it is possible to avoid many

UNNECESSARY defrosts and consequently Energy Savings and

Efficiency.

Through the parameter - "dd" - PERCENTAGE OF TIME

REDUCTION FOR DEFROST. It is possible to set the percentage of

time reduction in which the B4U reduces the times between defrosts

if the system conditions require it.

Setting the parameter "dd" = 100% to the first increase in the stored

temperature difference (greater than 1 ° C) between the chamber

(Pr1) and the evaporator probe (EP), the defrost starts immediately.

For correct operation, the B4U needs a first reference value between

the temperature difference of the chamber and the evaporator, in this

way, all the variations in the active Set Point, in the differential “rd” or

in a defrost execution , eliminate this first reference value and any

reduction could not be made until the acquisition of a new reference

value.

Operation example "dynamic interval defrost system" with reduction

"dd" = 40% and end of defrost by temperature.

- Defrost by evaporator temperature.

The B4U activates a defrost cycle when the evaporator temperature

(EP probe) falls below the temperature set in parameter “tF” and

when the time set in parameter “St” has elapsed to guarantee a

defrost when the evaporator reaches a very low temperature which

is usually a symptom of low heat exchange compared to normal

operating conditions.

When “tF” = oF the function will be disabled.

- Defrost due to continuous compressor operation time.

The B4U activates a defrost cycle when the compressor is activated

continuously for time “cd”.

This function is used for the continuous operation of the compressor

for a long period of time which is usually a symptom. of a low

exchange caused by ice on the evaporator.

Programming "cd" = oFthe function will be disabled.

4.8.2 - MANUAL DEFROST

To start a manual defrost cycle, keep the UP / DEFROST key

pressed for about 5 seconds, if the conditions are correct, the DEF

LED will light up and the B4U will carry out a defrost cycle.

To interrupt a defrost cycle in progress, press and hold the UP /

DEFROST key for about 5 seconds.

4.8.3 - DEFROST END

The duration of the defrost cycle can be by time or, if the evaporator

probe is used (Pr2 probe configured as EP), by temperature range.

If the evaporator probe is not used, the cycle duration is set in the

"dE" parameter (by programming "dE" = oF, the interval or manual

defrosts will be disabled).

On the other hand, if the evaporator probe is used, the end of the

defrost occurs when the temperature measured by this probe set as

EP exceeds the temperature set in parameter "tE".

If this temperature is not reached within the time set in parameter

“dE”, the defrost will be interrupted.

To avoid unnecessary defrosting when the evaporator temperature

is high, the "tS" parameter allows setting the temperature referring to

the evaporator probe below which the defrosts will be activated.

Therefore, in the indicated modes, if the temperature measured by

the evaporator probe (EP) is higher than that set in the "tS" parameter

and also in the "tE" parameter, defrosts are prevented.

Examples of completion of defrost:

The defrost shown as A ends when it reaches the temperature "tE".

Defrost B ends when time "dE" ends because it does not reach

temperature "tE". And defrost C is not activated since the

temperature is higher than "tS".

Example of electric defrost with temperature control of the

evaporator:

The defrost ends at the expiration of time "dE". During defrost, the

output configured as “dF” is activated / deactivated as an ON / OFF

temperature controller in a heating function with hysteresis of 1º in

order to keep the defrost temperature constant at the value

programmed in “tE”.

The active defrost is shown on the display when the DEF LED lights

up.

At the end of defrost, it is possible to delay the start-up of the new

compressor (output "ot") for the time set in parameter "td" to allow the

evaporator to drain.

During this delay, the DEF led blinks to indicate the drain status.

5.8.4 - DEFROST INTERVALS AND DURATION IN CASE OF

EVAPORATOR PROBE ERROR

In the event of an evaporator probe error, defrosts will be done with

"Ei" intervals and with "EE" duration.

In the event that a probe error occurs during the time remaining for a

defrost or for a defrost to end, the start or end will occur with respect

to the shortest time programmed in the parameter relative to probe

error conditions.

These functions are available when the evaporator probes are used,

the duration of the defrosts is normally done by programming a time

longer than normal as safety (the measured temperature value of the

probe offers to finish the first defrost) and, in the If the "Defrost by

Dynamic Intervals" function is used, the interval between defrosts is

normally programmed with a time greater than the normal time that

is normally programmed in the equipment that does not have the

function.

5.8.5 - DEFROST SCREEN LOCK

Using the "dL" and "dA" parameters, the behavior of the display is set

during a defrost.

The "dL" parameter allows blocking the display of the display in the

last temperature measurement of the Pr1 probe ("dL" = on) during

the defrost and until the end of the defrost and the Pr1 temperature

has not returned to the value of the last reading , or to the value ["SP"

+ "d"]) or when the time programmed in parameter "dA.

OSAKA - USER MANUAL - B4U - v2 - PAG. 11

It also allows the display of the acronym "dF" ("dL" = Lb) during the

defrost and, after the defrost is finished, the message "Pd" will appear

until, after the defrost, the Pr1 temperature has not returned to the

set value. the last reading, or to the value ["SP" + "d"]) or when the

time programmed in parameter "dA" expires.

Otherwise ("dL" = oF), the display will show the temperature

measured by the Pr1 probe during a defrost.

5.9 - EVAPORATOR FAN CONTROL

The evaporator fan control works through the output configured as

"Fn" depending on certain control states of the B4U and the

temperature measured by the evaporator probe (probe configured as

"EP").

The parameters related to the fan control functions are found in the

"-Fn" folder.

If the evaporator probe is not used oris in error, the output configured

as "Fn" is activated only according to the parameters "tn", "tF" and

"FE".

With the parameters "tn" and "tF" it is possible to set the behavior of

the evaporator fans when the regulation output configured as "ot"

(compressor) is deactivated.

When the output "ot" is deactivated, it is possible to make the output

configured as "Fn" continue to operate cyclically according to the

times programmed in the parameter "tn" (activation time of the

evaporator fan at compressor stop) and " tF "(evaporator fan

deactivation time at compressor stop).

When the compressor stops, the B4U keeps the evaporator fans on

for time "tn", then turns them off for time "tF" and so on until the output

"ot" remains off.

When programming "tn" = oF, the “Fn” output will be deactivated

when the “ot” output is deactivated (the evaporator fans are off when

the compressor is stopped or the fans are running together with the

compressor).

By programming "tn" at any value and "tF" = oF, the "Fn" output will

remain activated even when the "ot" output is deactivated (the

evaporator fans are on when the compressor is stopped).

The "FE" parameter allows setting whether the fans should always

be on regardless of the defrost status ("FE" = on) or turn off during

defrost ("FE" = oF).

In the latter case, by setting the time in the "Fd" parameter, it is

possible to delay the restart of the fans after the end of the defrost.

When this delay is active, the FAN LED flashes to indicate the delay

in progress.

When the evaporator probe is used for the fan, it is conditioned by

the parameters "tn", "tF and" FE, and acts as a temperature control.

In fact, it is possible to configure the fans to deactivate when the

temperature measured by the evaporator probe is higher than the

value programmed in the "FL" parameter (temperature too high) or

also when it is lower than the value programmed in the "LF"

parameter. "(very low temperature).

Associated with these parameters there is a programmable

differential in the parameter "dF"

.

Note: Special attention should be paid to the correct use of the

temperature-based fan control functions, since in a typical

refrigeration application, the evaporator fan stops due to thermal

change.

Remember that the operation of the evaporator fans can also be

conditioned by the "door open" function of the digital inputs.

5.10 - ALARM FUNCTIONS

The parameters related to the fan control functions are found in the

"-AL" folder.

The B4U alarm conditions are:

- Probe error: "E1", "-E1", "E2," -E2 "," E3 "," -E3 "

- Temperature alarm: "H1", "L1", "H2", "L2"

- External alarms: "AL", "Pr", "HP", LP "

- Open door alarm: "oP"

The alarm function acts on the internal buzzer, if it is configured with

the "Bu" parameter, and on the desired output, if it is configured with

the "o1", "o2", "o3", "o4" parameters.

The buzzer can be configured to signal alarms by setting the

parameter "Bu" = 1 or 3 or 4 and always functions as an alarm that

can be silenced. This means that, when activated, it can be

deactivated by briefly pressing any key.

Alarms can be configured to signal them by configuring the outputs.

The possible alarms that can be configured are the following:

= On - When you want the output to activate in alarm condition and

to be able to deactivate (silence) manually by pressing any key on

the B4U.

= AL - When the output is desired to activate in alarm condition but

cannot be manually deactivated and therefore deactivates only when

the alarm condition is canceled (typical application for a light signal).

= An - When you want the output to activate in alarm condition and

to remain active even when the alarm condition has ceased (alarm

memory). Therefore, deactivation (stored alarm acknowledgment)

can only be performed manually by pressing any key when the alarm

status has been cleared (typical application for light signal).

= -t - When the operation described as En is desired but with inverse

operation logic (output activated in normal condition and deactivated

in alarm condition).

= -L - When the operation described as AL is desired but with inverse

operation logic (output activated in normal condition and deactivated

in alarm condition).

= -n -When the operation described as An is desired, but with inverse

operation logic (output activated in normal condition and deactivated

in alarm condition).

5.10.1 - TEMPERATURE ALARMS

The B4U has two temperature alarms, each with fully configurable

maximum and minimum thresholds.

The temperature alarm functions act according to the measurements

of the probes, what is configured in parameters "1y" and "2y", the

alarm thresholds programmed in parameters "1H" and "2H"

(maximum alarms), "1L" and "2L" (minimum alarms) and the relative

differentials "1d" and "2d".

Through the parameters "1y" and "2y" "it is possible to program the

alarm thresholds" 1H "," 2H "," 1L "," 2L "and they must be considered

as absolute or relative to the Set Point.

Depending on the desired operation, the parameters "1y" and "2y"

can be configured with the following values:

= 1: Absolute referring to Pr1 with message display (HL).

= 2: Relative to Pr1 with message display (HL).

= 3: Absolute referring to Au probe with message display (HL)

= 4: Relative to Au probe with message display (HL).

= 5:Absolute referring to cd probe with message display (HL). = 6:

Absolute referring to Pr1 without message display.

= 7: Relative to Pr1 without message display.

= 8: Absolute referring to Au probe without message display.

= 9: Relative to Au wave without message display.

= 10: Absolute referring to cd probe without message display.

By means of some parameters it is possible to delay the notification

of these alarms. These parameters are:

"1P" and "2P" - are the delay times of the temperature alarms at the

start of the B4U, which if there are alarms at start-up, they will wait

for the time programmed in these parameters to pass.

If there are no alarm conditions at connection, the relative time "1P"

and "2P" will not be taken into account.

"DA" - It is the delay time of temperature alarm 1 during a defrost.

Note: Alarm 1 during defrosts and during time "dA" after the end of

defrosts is deactivated, while alarm 2 during defrosts is always

activated.

"1t", "2t" - They are the delay time for the activation of temperature

alarms 1 and 2.

Temperature alarms 1 and 2 are activated when the delay times

expire and after the times "1t" and "2t", when the measured

temperature of the probe set by the alarm rises above or falls below

the respective threshold of maximum and minimum alarm.

OSAKA - USER MANUAL - B4U - v2 - PAG. 12

Using the parameters "1A" and "2A" it is possible to program the

action of the alarms through the regulation outputs and the alarm

outputs (buzzer included).

This allows, for example, to intervene directly by deactivating the

regulation outputs in the event of temperature alarms, as in probes

configured as “Au” (for example “anti-fog” function) or “cd” (for

example “dirty condenser function ”).

By configuring alarms with respect to the same probe, the B4U allows

managing pre-alarm signaling (for example not activating the alarm

and / or buzzer outputs) or warning alarms (activating the alarm and

/ or buzzer outputs).

The alarm thresholds can be programmed using the parameters

"1H", "2H", "1L" and "2L" if the alarms are absolute ("1y" and "2y" =

1, 3, 5, 7, 9, 10 ).

Or through the values ["SP" + "1H", "2H"] and ["SP" + "1L", "2L"] if

the alarms are relative ("1y" and "2y" = 2, 4, 6 , 8).

The maximum and minimum temperature alarms can be disabled by

setting the parameters "1H", "2H", "1L" and "2L" = oF.

5.10.2 - EXTERNAL ALARMS OF DIGITAL INPUTS

The B4U can signal external alarms by activating one or more digital

inputs configured as "1F / 2F / 3F / 4F" = 4, 5, 12, 13, 14.

At the same time that the configured alarms (buzzer and / or outputs)

are signaled, the B4U signals the alarm by showing the alarm

acronyms (AL, Pr, HP, LP) alternately with the variable configured in

the "dS" parameter.

The mode "1F / 2F / 3F / 4F" = 4 does not perform any action on the

control outputs, while the other modes require the deactivation of the

output "ot" or of all the control outputs when the digital input is

activated .

Alarm

Output “ot” (check)

Other control outputs

(“Fn”, “dF”, “Au”, “HE”)

AL (4)

Without effect

AL (5)

OFF

Pr

OFF

No effects

HP

OFF

No effects

LP

OFF

No effects

5.10.3 - DOOR OPEN ALARM

The B4U can signal an open door alarm by activating the digital input

with function programmed as "1F / 2F / 3F / 4F" = 1, 2 or 3.

When the digital input is activated, the equipment signals that the

door is open by displaying the acronym "oP" on the display,

alternately with the variable set in the "dS" parameter.

After the delay set in the "oA" parameter, the B4U signals the open

door alarm by activating the configured devices (buzzer and / or exit),

and naturally it will continue to show the initials "oP" on the display.

When the door open alarm intervenes, the normally activated outputs

(fans or fans + compressor) are also deactivated.

5.10.4 - VOLTAGE CONTROL ALARM

The parameters related to the voltage control alarm functions are

found in the "-UA" folder.

The B4U can automatically deactivate the control outputs when the

mains voltage (measured by the B4U through its power supply) is

lower or higher than the values configured in the following

parameters:

"LU" - Low voltage alarm (expressed in Vx10).

"HU" - High voltage alarm (expressed in Vx10). When the alarm is

activated and after the delay programmed in the "Ud" parameter, the

B4U deactivates all the control outputs, signals an alarm by activating

the configured device (output and / or buzzer) and the initials "HU"

are shown on the display. (in case of high voltage alarm) or “LU” (in

case of low voltage alarm) alternately with the parameter variable

"dS".

If the function related to grid voltage alarms is enabled (parameter

"LU" or "HU" other than oF) in the variables display mode, the

variable P5 representing the grid voltage will also appear (if the value

decreased by 150 V. The mains voltage expressed in volts measured

by the B4U will be V = P5 + 150).

If the voltage measurement is not correct, it can be changed by

scrolling through the "OU" parameter.

5.11 - OPERATION OF THE "ON / OFF" AND "LIGHT" KEYS

By pressing the ON / OFF button for at least 1 second it is possible

to change the state of the B4U from on to off and vice versa.

By pressing the LIGHT button for at least 1 second it is possible to

activate / deactivate the light output (“L1”) or the auxiliary output if it

is configured as "Fo" = 2.

5.12 - ACCESSORIES

The B4U is equipped with a TTL communication port with a 5-pole

connector that allows the connection of some accessories described

below.

5.12.1 - PARAMETER CONFIGURATION BY "KEY USB"

Via the TTL port and the KEY USB device it is possible to transfer

the operating parameters to and from the B4U.

The KEY USB device is used for serial programming of controllers

that must have the same parameter settings, or to save a copy of the

controller programming for quick transfer to another.

The KEY USB has a USB connection input, which allows connection

to a PC, with which, through the Osaka Set Up configuration

software, it is possible to configure the parameters.

For more information, consult the user manual.

OSAKA - USER MANUAL - B4U - v2 - PAG. 13

5.12.2 - SIGNAL DUPLICATOR

The X2 remote display device can be connected to the Power Unit

B4U using a special cable that can have a maximum length of 10

meters. The X2 device, powered directly by the B4U, shows the

temperature measured by the Pr1 probe through a 2 ½ digit display.

For more information, see the user manual of the X2 device.

5.12.3 - RS485 COMMUNICATION WITH "KEY TTL"

Through the KEY TTL device (TTL / RS485 interface) and the

appropriate TTL cable, it is possible to connect the B4U to an RS485

serial communication network into which other instruments

(regulators or PLC) are inserted and generally connected to a PC

with a monitoring system.

Through the PC it is possible to acquire all the operating data and

program all the configuration parameters of the B4U.

The software protocol adopted by the B4U is of the MODBUS-RTU

type widely used in many PLCs and supervision programs available

on the market.

If the B4U is used in an RS485 network, program the station address

in the "AS" parameter.

The baud rate (baud rate) of the serial link cannot be configured and

is fixed at 9600 baud.

The KEY TTL converter is powered directly by the Power Unit B4U.

For more information, see the user manual of the KEY TTL device.

6 - PROGRAMMABLE PARAMETERS TABLE

Description of all the parameters available on the thermostat.

Some of them may not be present, either because they depend on

the type of thermostat or because they are automatically deactivated

as unnecessary.

Param.

Description

Rank

Def

Note

]SP

S. - Parameters Relative to the Set Point

1

SH

Turbo Set Point or

Minimum Set point and

Superheat Set point in HC

mode

-99 ÷ HS

-4.0

2

SE

Economic Set Point

(maximum set point)

LS ÷ 99

8.0

3

S1

Set Point

SE ÷ SH

4.0

]In

i. - Parameters related to inputs

4

uP

Measurement unit and

resolution (decimal point)

C0 = ° C with resolution 1 °

F0 = ° F with 1 ° resolution

C1 = ° C with 0.1 °

resolution

F1 = ° F with 0.1 °

resolution

C0 / F0 / C1 / F1

C1

5

Ft

Measurement filter

oF / 0.1 ÷ 9.9 ÷

20 sec

2.0

6

C1

Pr1 probe calibration

-30 ÷ -9.9 ÷ 9.9

÷ 30 ° C / ° F

0.0

7

C2

Probe Pr2 Calibration

-30 ÷ -9.9 ÷ 9.9

÷ 30 ° C / ° F

0.0

8

C3

Pr3 probe calibration

-30 ÷ -9.9 ÷ 9.9

÷ 30 ° C / ° F

0.0

9

CU

Display offset

-30 ÷ -9.9 ÷ 9.9

÷ 30 ° C / ° F

0.0

10

P2

Use of Pr2 input:

oF = not used

EP = evaporator probe (1)

Au = Auxiliary probe

cd = condenser probe

r1 = do not use

dG = digital input

oF / EP / Au /

cd / r1 / dG

oF

11

P3

Use of Pr3 input:

See P2

oF / EP / Au /

cd / r1 / dG

oF

12

1F

Digital input di1 operating

logic:

0 = No function

1 = Door opening

2 = Door opening with fan

lock

3 = Door opening with fan

and compressor lock

4 = External alarm AL

5 = External alarm AL with

control output deactivation

6 = Active Set Point

Selection (SP-SPE)

7 = On / Off

8 = Run “Turbo” mode

9 = Auxiliary output

activation

10 = NOT operational

11 = NOT operational

12 = PrA external alarm with

compressor output

deactivation

13 = HP external alarm with

compressor output

deactivation

14 = LP external alarm with

compressor output

deactivation

-14 / -13 / -12 / -

11 / -10 / -9 / -8 /

-7 / -6 / -5 / -4 / -

3 / -2 / -1 /

0/1/2/3 /

4/5/6/7/8/9/10/1

1/12/13/14

0

13

1t

Digital input 1 delay

oF / -01 ÷ -59

(sec) ÷ 01 ÷ 99

(min)

oF

14

2F

Digital input di2 operating

logic: see 1F

-14 ... 0 ... 14

0

15

2t

Delay digital input di2

oF / -01 ÷ -59

(sec) ÷ 01 ÷ 99

(min)

oF

16

3F

Operating logic input Pr3

as digital:

see 1F

-14 ... 0 ... 14

0

17

4F

Operating logic input Pr4

as digital:

see 1F

-14 ... 0 ... 14

2

OSAKA - USER MANUAL - B4U - v2 - PAG. 14

18

Et

Economy mode activation

delay time when the door

is closed

oF = function disabled

oF / -01 ÷ -59

(min) ÷ 01 ÷ 99

(hrs)

oF

19

tt

Maximum operating time in

economy mode.

oF = function disabled

oF / -01 ÷ -59

(min) ÷ 01 ÷ 99

(hrs)

oF

20

dS

Variable normally

displayed on the display:

P1 = Pr1 probe

measurement

P2 = Pr2 probe

measurement

P3 = Pr3 probe

measurement

P4 = Pr4 probe

measurement

Ec = Pr1 measurement in

normal mode and Eco

message in Eco mode

SP = Active Set Point

oF = display off

F1 = Measurement of

probe Pr1 filtered with par.

"Du" and "dd"

P1 / P2 / P3 / P4

/ Ec / SP / rE /

oF / F1

F1

]dF

d. - parameters related to defrost control

21

dt

Defrost type:

EL = Electric defrost /

compressor stop

in = Hot gas defrost / cycle

inversion

no = No compressor output

conditioning

Et = Electric / thermostatic

defrost

EL / in / no / Et

EL

22

dC

Defrost start mode

rt = at intervals by time

when connecting the

equipment

ct = at intervals per

compressor operating time

(compressor output

activated)

cS = Defrost for each

compressor stop

(compressor output off due

to reaching Set + rt

interval)

cL = Do not use

rt / ct / cS / cL

rt

23

di

Interval between defrosts

oF / -01 ÷ -59

(min) ÷ 01 ÷ 99

(hrs)

4

24

Sd

First defrost delay on

connection. (oF = Defrost

on connection).

oF / -01 ÷ -59

(min) ÷ 01 ÷ 99

(hrs)

4

25

dd

Percentage reduction at

dynamic defrost intervals

0 ÷ 100%

0

26

dE

Maximum defrost duration

(evaporator 1)

oF / -01 ÷ -59

(sec) ÷ 01 ÷ 99

(min)

20

27

dL

Display lock in defrost:

oF = Not active

on = active with last

measurement

Lb = active with message

(“dF” in defrost and “Pd” in

Post-Defrost)

oF - on - Lb

Lb

28

tE

Defrost end temperature

(evaporator1)

- 99 ÷ -9.9 ÷ 9.9

/ 10 ÷ 99 ° C / °

F

5.0

29

Ei

Interval between defrosts

in case of evaporator

probe error

oF / -01 ÷ -59

(min) ÷ 01 ÷ 99

(hrs)

4

30

EE

Defrost duration in case of

evaporator probe error

oF / -01 ÷ -59

(sec) ÷ 01 ÷ 99

(min)

20

31

tS

Temperature from which

the defrost starts.

- 99 ÷ -9.9 ÷ 9.9

/ 10 ÷ 99 ° C / °

F

2.0

32

tF

Temperature that forces

the start of the evaporator

defrost.

- 99 ÷ -9.9 ÷ 9.9

/ 10 ÷ 99 ° C / °

F

-99

33

St

Defrost start delay due to

evaporator temperature

oF / -01 ÷ -59

(sec) ÷ 01 ÷ 99

(min)

1