If the encoder is connected in the opposite direction, disconnected or

faulty the door will operate erratically (continuously opening halfway,

closing, latching and reopening etc.). This will continue until power is

switched off and problem rectified.

6.1 SETTING FUNCTION

6.1.1 From the FUNCTION SELECTOR switch to one of the 6 standard

program settings depending on the desired fire alarm position AND

monitored safety requirement (see FUNCTION table on page 11). If

no safety devices are to be used then only the fire alarm position is

critical.

6.1.2 For function 0, 3 & 6 (i.e. fail safe to open position) Fire Alarm input

operates the door and it remains in the open position for as long as

the contact is made.

6.1.3 For function 1, 4 & 7 (i.e. fail safe to closed position) Fire Alarm input

disables all activation allowing the door to close where it remains for

as long as the contact is made.

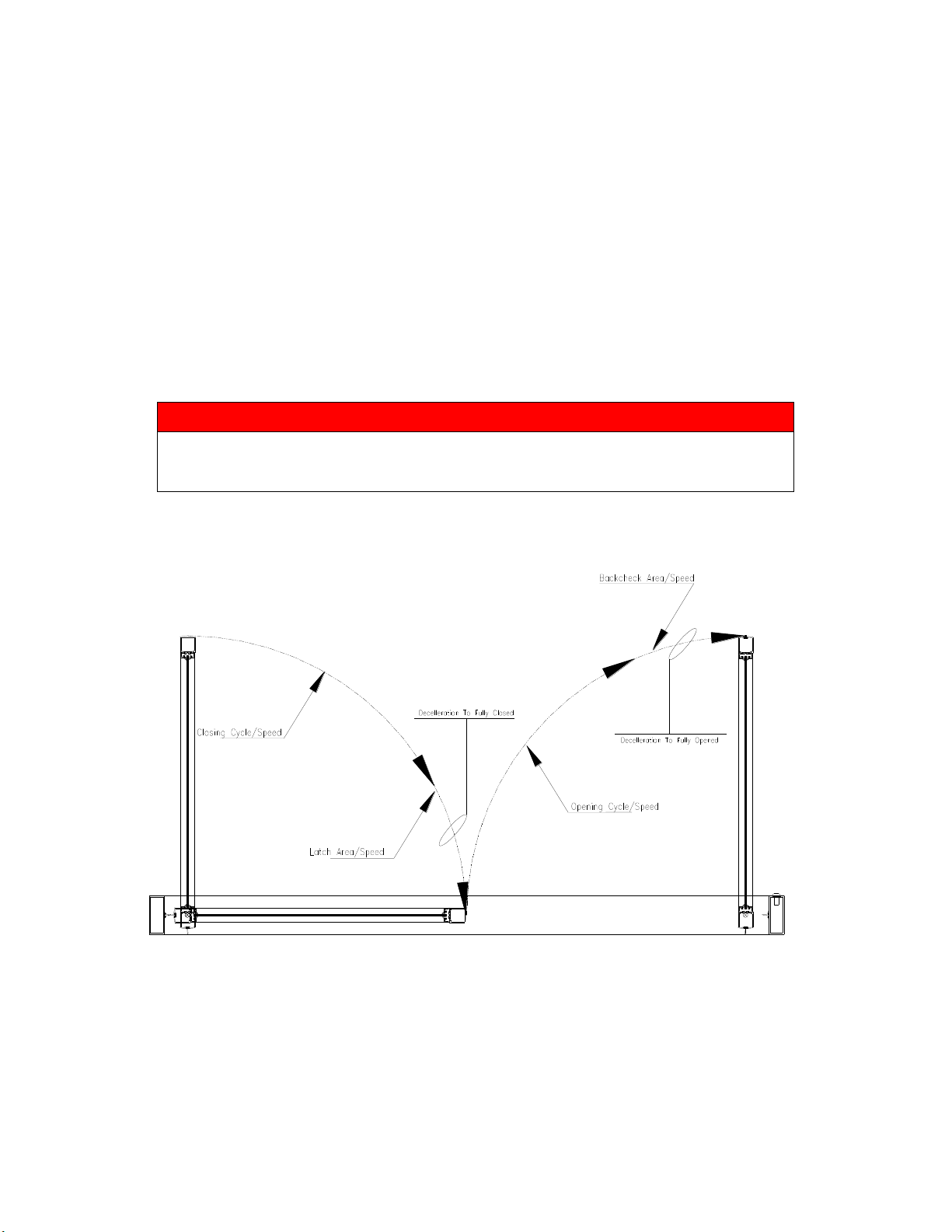

6.2 LEARNING CYCLE & SET UP (no safety sensors)

6.2.1 From start-up, the door will activate from either T9 & T10 (Fire Alarm)

or T27 & T28 (One Way). Activate the operator using the activation

device - the operator will perform one learning cycle. During the

learning cycle, the door opens and closes one time.

6.2.2 The speed of the learning cycle is adjusted automatically to

compensate for the door weight and is not set from a potentiometer.

6.2.3 The door drives to the fully open position where the control box sets

the parameters to the fully open setting (NB - remember to install

drive arm when door is in the open position).

6.2.4 When the door reaches the fully open position the control box

automatically sets the power required to keep the door open until

activation and/or timer is cleared

6.2.5 The door closes at the designated close speed (P6) up to latch

position (P5) where the speed is decreased automatically by the

control box allowing the door to close smoothly until fully closed.

6.2.6 If the door does not open at all during learning cycle:

- Check the door for binding.