THE 415 COMPACT OPERATOR

GENERAL CHARACTERISTICS

The FAAC 415 Compact Operator is an automatic gate

operator for a swinging gate leaf. The 415 Compact

Operator is useful in residential applications and can

accommodate a gate leaf up to 14 ft (4.3 m) long.

The self-contained 415 Compact Operator consists of an

electric motor that drives a worm screw housed in an

aluminum casing.

The locking the 415 Operator provides in the fully

opened and fully closed positions is a service device

rather than a security device. Additional, external locks

are recommended under the following conditions:

∗ It is a solid-faced gate.

∗ The length of the gate leaf is 6 ft (2 m) or longer.

∗ The installation requires tight security.

∗ The site is subject to vandalism.

∗ The site is subject to strong or very gusty wind

In two-operator gate installations, both (master/slave)

operators are wired to one control panel.

The electronic control panel is a microprocessor-based

controller that accepts a wide range of product

accessories and reversing devices, thus allowing for

flexible gate system design.

Also for the protection and proper operation of the 415

Operator, each operator has built in limit switched so

positive stops are not needed.

Built-in security and anti-crushing measures of the 415

Operator include built in reverse on contact and a

torque adjustment that controls the force transmitted to

the gate leaf through the 415 Operator.

The Manual Release mechanism is a key accessed

device that disengages (or engages) the cylinder on 415

Operator. When the drive is disengaged, you can open

and close the gate leaf by hand. Such manual operation

of the gate is necessary during installation and useful

during prolonged power failures.

The torque of the 415 Operator is set during Basic

Programming of the 425 D Control Panel. (see page 19

for Basic Programming).

Reversing devices (such as inductive loops and

photocells) should be installed to provide non-contact

reversing operation.

WARNING: To insure that the installation meets the UL

325 Standards. A set of photo beam (Part Number

785163) must be installed anywhere that an entrapment

with the gate leaf(s) could happen.

The 425 D also has a built in battery back-up system

that can be used with the addition of 2 12V 7.5ah

batteries. The batteries must be wired in series to

provide 24VDC to the control panel during power

outages. Connect the batteries to the +/- on the 425D

control panel (see Fig. 16)

During prolonged power outages the manual release

may be used if needed.

Page 6

October, 2005

415 L LS Operator And

425 D Control Panel Installation Manual

Make sure that the gate structure is solidly built. Add

reinforcing crosspieces if necessary to the gate leaves.

Make sure that the gate moves smoothly on its hinges

without excessive friction by swinging it opened and

closed by hand. If necessary, lubricate all the gate's

moving parts.

Positive stops are not needed with the 415 Operator due

to built in limit switches.

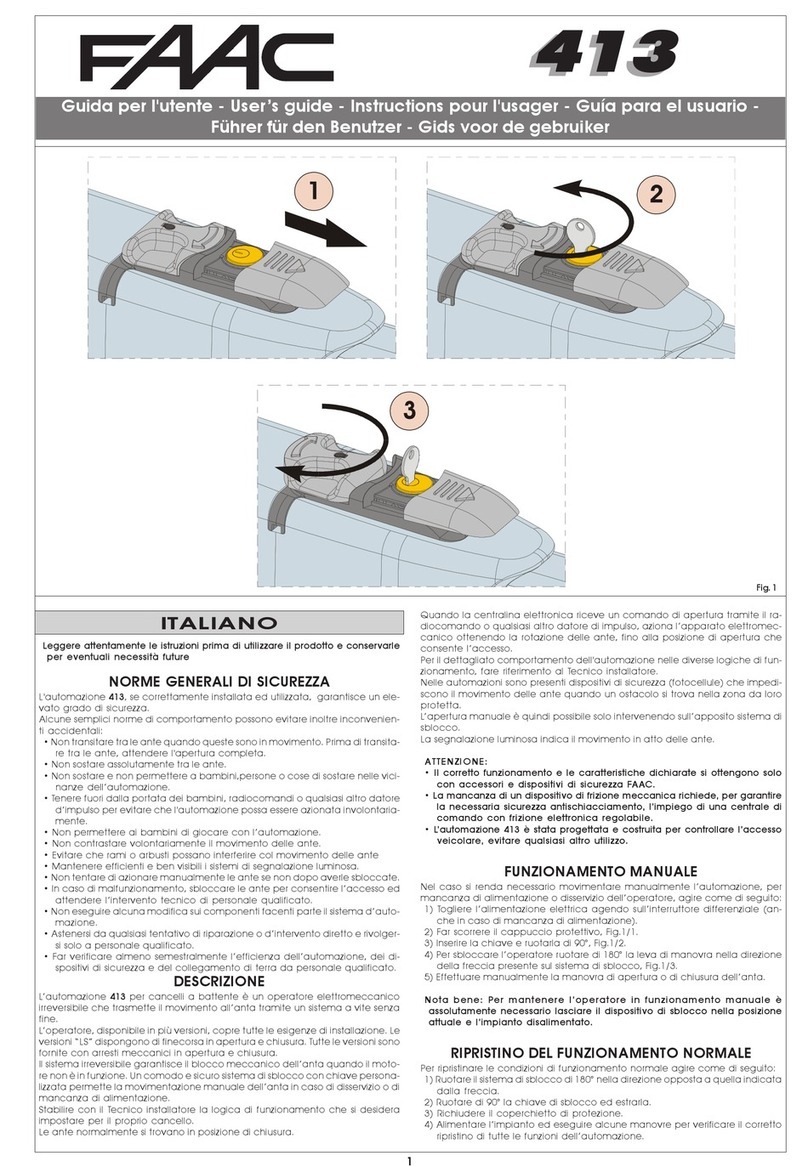

MANUAL RELEASE MECHANISM

To manual release the 415 Operator perform the

following steps as shown in Figure 2.

1. Slide the key access cover toward the front of the

operator.

2. Insert the key and turn it counterclockwise 1/4 turn.

INSTALLATION INSTRUCTIONS

Installing the 415 Operator involves preparing the gate,

installing the operator(s), installing the control panel,

programming control panel, and connecting other

operational controls.

Note: The following installation instructions assume

you are fully capable of installing an electromechanical

operator on a gate. This manual does not instruct you

in designing a gate, installing a gate (whether on

masonry, wood, or metal posts), or basic electrical

wiring. The installation tasks discussed in this manual

are tasks particular to the 415 Operator.

PREPARE THE GATE

Before you install the 415 Operator, you need to prepare

the gate itself for the operator. Be sure to do the

following: