Table of Contents

1 General Description............................................................................................. 3

2 Mechanical Installation...................................................................................... 6

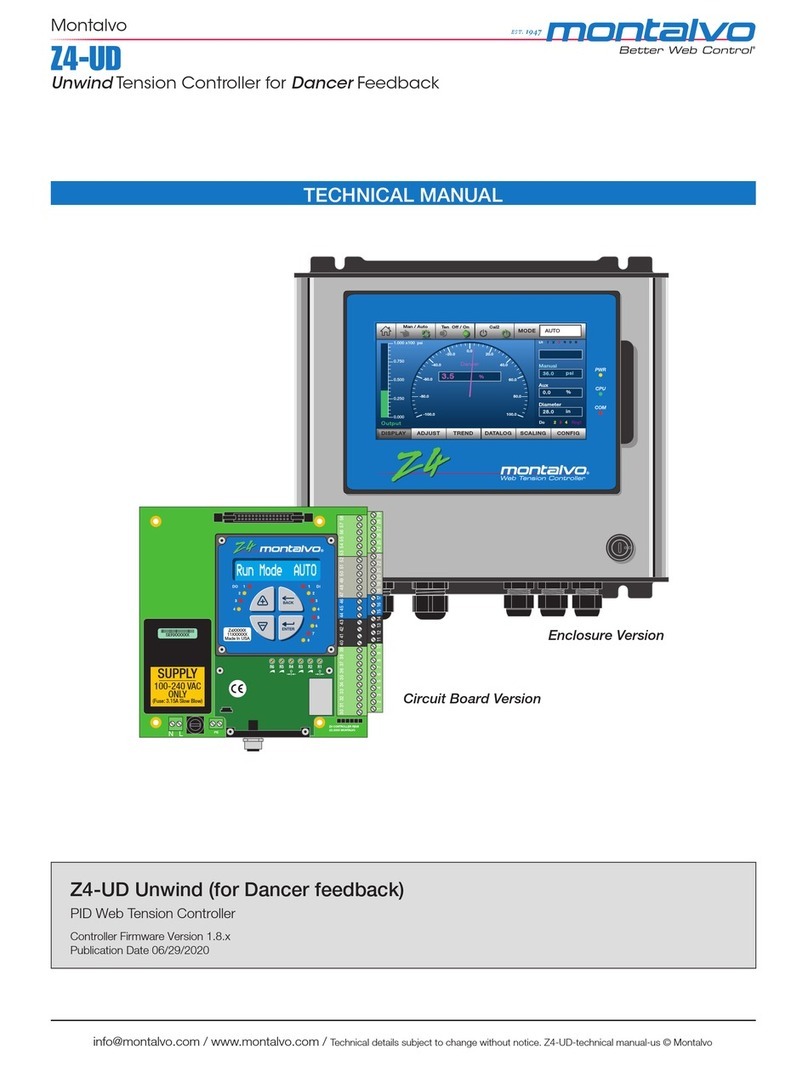

2.1 Circuit Board (controller) Dimensions................................................................... 6

2.2 HMI (remote interface) Dimensions...................................................................... 7

2.2 Enclosure Dimensions......................................................................................... 8

3 Electrical Installation........................................................................................... 9

3.1 Warning, EMC, and Safety .................................................................................. 9

3.2 Basic Diagrams B Version (circuit board only).................................................... 10

3.3 Basic Diagrams R Version (circuit board with remote HMI)................................. 11

3.4 Basic Diagrams E Version (circuit board and HMI in Enclosure) ......................... 12

3.5 Terminal Blocks................................................................................................. 13

3.6 Installation - Load Cell....................................................................................... 14

3.7 Installation - Tension Calibration ........................................................................ 15

3.8 Installation – Regulated Output ......................................................................... 16

3.9 Installation – Power Supply (VAC and VDC)....................................................... 17

3.10 Digital Input (24V).............................................................................................. 18

3.11 Digital Output (24V)........................................................................................... 21

3.12 Analog Input (0 to 10V) ..................................................................................... 21

3.13 Analog Output (0 to 10V) .................................................................................. 24

3.14 Analog Output (AUX1 Output) (0 to 10V) ........................................................... 24

3.15 Voltage to Current Converter............................................................................. 25

4 Tuning ......................................................................................................................... 26

4.1 Tuning of Z4 Controller...................................................................................... 26

5 Conguration and System Setup.............................................................. 27

5.1 Conguration Menu [Cong Menu] .................................................................... 27

5.2 Options Selection Menu [Options Menu] ........................................................... 28

5.3 Regulator Parameter [Regulator Menu] ............................................................. 29

5.4 Roll Change [Roll Change Menu]....................................................................... 30

5.5 Starting the Machine [Start Menu] ..................................................................... 32

5.6 Stopping the Machine [Stop Menu] ................................................................... 34

5.7 Machine at Stop [Hold Menu]............................................................................ 37

5.8 Diameter [Diameter Menu]................................................................................. 38

5.9 Taper [Taper Menu] ........................................................................................... 41

5.10 Digital Output [Digital Output Menu] .................................................................. 42

5.11 Splice [Splice Menu].......................................................................................... 44

5.12 Range Expander [Range Exp Menu].................................................................. 49

5.13 Aux1 Input [Aux1 Input Menu]........................................................................... 54

5.14 Aux2 Input [Aux2 Input Menu]........................................................................... 55

5.15 Aux1 Output [Aux1 Output Menu] ..................................................................... 56

5.16 Aux2 Output ..................................................................................................... 56

5.17 Variable Wrap Angle [Wrap Angle Menu] ........................................................... 56