Osmobil PRO X User manual

OSMOBIL PRO X

Operating instructions

Current version as of January 2023.

All previous versions are replaced by this one.

VF Reinigungstechnik

Benjamin Volk & Tobias Becker GbR

Blankenfohrweg 11

32139 Spenge

T 05225 87198-15

info@vf-reinigungstechnik.de

www.gebaeudereinigung-shop.de

www.gardiner-teleskopstangen.de

www.vf-reinigungstechnik.de

Sparkasse Bielefeld

IBAN DE60 4805 0161 0003 4120 53

BIC SPBIDE3BXXX

Steuer-Nr. 324/5816/0846

Operating Instructions for Mobile Reverse Osmosis System OSMOBIL PRO X

VF Reinigungstechnik

Benjamin Volk & Tobias Becker GbR

Blankenfohrweg 11

32139 Spenge

T 05225 87198

-

15

info@vf-reinigungstechnik.de

www.gebaeudereinigung-shop.de

www.gardiner-teleskopstangen.de

www.vf-reinigungstechnik.de

Sparkasse Bielefeld

IBAN DE60 4805 0161 0003 4120 53

BIC SPBIDE3BXXX

Steuer-Nr. 324/5816/0846

OSMOBIL PRO

Technical data:

Permeat per hour max. 410 l

electrical

Connected load

0,375 kW

Total salt content

Input water

max. 1000 ppm

Saltrejectionrate mind. 95%

Ratio 30-50%

Input water pressure 2,0-6,0 bar / 30-90 psi

Inout water temperature 8°C-25°C / 45°F-80°F

Suitable inlet water Municipal water acc.

German Drinking Water Ordinance

Ambient temperature 3°C-40°C / 37°F- 104°F

Mains connection 230 V u. 50 Hz

Dimensions 85x60x55

Weight (dry) 49 kg

Operating Instructions for Mobile Reverse Osmosis System OSMOBIL PRO X

VF Reinigungstechnik

Benjamin Volk & Tobias Becker GbR

Blankenfohrweg 11

32139 Spenge

T 05225 87198

-

15

info@vf-reinigungstechnik.de

www.gebaeudereinigung-shop.de

www.gardiner-teleskopstangen.de

www.vf-reinigungstechnik.de

Sparkasse Bielefeld

IBAN DE60 4805 0161 0003 4120 53

BIC SPBIDE3BXXX

Steuer-Nr. 324/5816/0846

EG-Konformitätserklärung

Hiermit erklären wir, dass die mobile Umkehrosmoseanlage „OSMOBIL PRO X“

mit Blick auf Ihre Konzeption und Bauart in der von unserem Hause in den Verkehr

gebrachten Art den zutreenden EG-Richtlinien entspricht.

Durch jede Änderung an der Anlage, die nicht mit unserem Hause abgestimmt ist,

verliert diese Erklärung ihre Gültigkeit.

Zutreende EG-Richtlinie:

EG Richtlinie Maschinen (2006/42/EG)

Hersteller: VF Reinigungstechnik Bezeichnung der Anlage: OSMOBIL PRO X

Blankenfohrweg 11 Seriennummer: siehe Typenschild

32139 Spenge

Tel. 05225.87198-15

Unterzeichner: Tobias Becker (geschäftsführender Gesellschafter)

Datum/Unterschrift des Herstellers: 02.12.2022

Operating Instructions for Mobile Reverse Osmosis System OSMOBIL PRO X

VF Reinigungstechnik

Benjamin Volk & Tobias Becker GbR

Blankenfohrweg 11

32139 Spenge

T 05225 87198

-

15

info@vf-reinigungstechnik.de

www.gebaeudereinigung-shop.de

www.gardiner-teleskopstangen.de

www.vf-reinigungstechnik.de

Sparkasse Bielefeld

IBAN DE60 4805 0161 0003 4120 53

BIC SPBIDE3BXXX

Steuer-Nr. 324/5816/0846

Table of contents

1 General and overview

1.1 Introduction

1.2 Overview

1.3 Function

1.4 Intended use

1.5 X-Flow system

1.5.1 X-Flow system for direct connection of a high-pressure pump

1.5.2 X-Flow system for classic work with washing brushes and co.

2 Production of pure H2O

2.1 Setting up the workplace

2.2 The right water source

2.3 Hoses and couplings

2.4 Check ush valve and start water supply

2.5 Switch on pump

2.6 Run ush mode

2.7 Production mode

2.8 Connecting telescopic poles and co.

2.9 Measuring the water quality of the ultrapure water („permeate“)

2.10 Finishing the work

2.11 Start-up video !!!

2.12 Set-up diagram - cleaning

3 Maintenance, care and safety

3.1 Changing the pre-lter

3.2 When must the pre-lter be changed?

3.3 Replacing the battery on the 2-channel TDS meter incl. video !!!

3.4 When do I have to change the membrane incl. video!!!

3.5 Annual inspection

3.6 Decommissioning - shutdown in winter up to 12 weeks

3.7 General operating instructions and safety

3.7.1 Installation requirements and protection against water damage

3.7.2 General operating instructions

3.7.3 Safety instructions and special dangers

3.8 Troubleshooting

3.8.1 Your water value is not correct?

3.8.2 Your unit delivers too little water?

3.8.3 Your pump makes loud noises and „nails“ in production mode?

3.8.4 You are producing too little water?

3.8.5 The pump does not switch on?

3.8.6 The tds meter display is „frozen“?

3.8.7 The tds meter‘s display is o?

4 Warranty

Operating Instructions for Mobile Reverse Osmosis System OSMOBIL PRO X

VF Reinigungstechnik

Benjamin Volk & Tobias Becker GbR

Blankenfohrweg 11

32139 Spenge

T 05225 87198

-

15

info@vf-reinigungstechnik.de

www.gebaeudereinigung-shop.de

www.gardiner-teleskopstangen.de

www.vf-reinigungstechnik.de

Sparkasse Bielefeld

IBAN DE60 4805 0161 0003 4120 53

BIC SPBIDE3BXXX

Steuer-Nr. 324/5816/0846

1 Introduction

1.1 Introduction

Dear user,

herewith you receive the manual for your new reverse osmosis system „OSMOBIL PRO X“.

It describes in simple terms the basic functions and components of the device. In addition,

it provides important information for your safety as a user and to avoid misuse and damage

to the device or the environment.

Attention: Please read the instructions completely and carefully. This will prevent damage

and misuse! The unit may only be operated by competent persons who have read these

instructions.

1.2 Overview

1: Membrane housing 6: Water meter

2: Pressure gauge 7: City water inlet

3: Clean water outlet (2x) 8: Power connection (removable)

4: Pump pressure adjustment 9: Flush valve

5: 2-channel TDS meter 10: Waste water outlet

11: Waste water hose

1

2

4

1

35

6

7

8910

11

Operating Instructions for Mobile Reverse Osmosis System OSMOBIL PRO X

VF Reinigungstechnik

Benjamin Volk & Tobias Becker GbR

Blankenfohrweg 11

32139 Spenge

T 05225 87198

-

15

info@vf-reinigungstechnik.de

www.gebaeudereinigung-shop.de

www.gardiner-teleskopstangen.de

www.vf-reinigungstechnik.de

Sparkasse Bielefeld

IBAN DE60 4805 0161 0003 4120 53

BIC SPBIDE3BXXX

Steuer-Nr. 324/5816/0846

1.3 Function

The OSMOBIL PRO X is based on two special reverse osmosis membranes. This enables

production capacities of a maximum of 410 litres of pure water per hour (depending on

the water pipe and water temperature). The unit is designed to produce pure H2O without

an additional buer tank and with minimal running costs (less than 1,- € per 1.000 litres

of ultrapure water). For this purpose, city water is pressed under high pressure (up to 15

bar) through a special membrane which only allows the H2O molecule to pass. The other

components dissolved in the water remain in front of this membrane and are ushed out of

the unit with the concentrate. In this way, the produced ultrapure water reaches a quality

of approx. 0.5-1% residual salt content (or 99-99.5% salt retention). The only compo-

nent that needs to be replaced regularly is the pre-lter, which is located in a transparent

housing at the front of the unit (please refer to chapter 4 „Maintenance, care and safety“).

1.4 Intended use

The unit has been designed primarily for the following activities:

- Production of pure H2O for cleaning work

1.5 X-ow system / shut-o and water quantity control

The OSMOBIL PRO X has an X-Flow system. Depending on the maximum possible water

ow at the two pure water outlets (permeate), this system controls the respective amount

of water that the OSMOBIL PRO X makes available on the pure water side and regulates

the pure water amount down to „zero“ if necessary.

This system has two essential meanings:

1.5.1 : X-Flow system for direct connection of a high-pressure pump.

Especially for solar and lamella cleaning, high-pressure pumps are often used to drive the

water-driven rotating brushes (e.g. from the company Cleantecs).

In this case, the respective pumps (e.g. Kränzle HD 12/130 TS) can be connected directly

to one of the two clean water outputs of the OSMOBIL PRO X. Decoupling by means of

an additional buer tank is no longer necessary. This means that high-pressure pumps can

also be used which cannot provide suction themselves. In addition, the OSMOBIL PRO X

automatically regulates the clean water quantity down to „zero“ if the high-pressure pump

does not draw o any water. In this case, the wastewater output (concentrate) continues

to run stably. However, the system takes 50% less water from the tap. The concentrate

line must always be able to drain freely. This applies fundamentally to the operation of the

unit!

1.5.2: X-Flow system during classic work with washing brushes & co.

The X-Flow system permanently checks the clean water outlet and the respective back

pressure. As a result, the system always delivers as much water as necessary and as little

as possible. In everyday use, this saves up to 25% of the water that the OSMOBIL PRO X

draws less from the tap.

Operating Instructions for Mobile Reverse Osmosis System OSMOBIL PRO X

VF Reinigungstechnik

Benjamin Volk & Tobias Becker GbR

Blankenfohrweg 11

32139 Spenge

T 05225 87198

-

15

info@vf-reinigungstechnik.de

www.gebaeudereinigung-shop.de

www.gardiner-teleskopstangen.de

www.vf-reinigungstechnik.de

Sparkasse Bielefeld

IBAN DE60 4805 0161 0003 4120 53

BIC SPBIDE3BXXX

Steuer-Nr. 324/5816/0846

2 Production of ultra pure H2O

2.1 Setting up the work site

First of all, you should organise a city water and electricity supply of sucient capacity at

the respective work site. When doing this, make sure that in later operation vehicles, doors

or other conditions do not cause hoses to the unit or away from the unit to be kinked or

blocked. This could damage the unit.

Caution: Also, it must be ensured that live parts such as cables or cable reels, sockets, etc.

are strictly separate from water-carrying parts (hose, pump, unit, etc.). Despite the built-in

personal protection plug, we ask you to observe this for your own safety. In addition, the

appliance must not be placed under water or under permanently owing water.

Also, always choose a location for the unit that is insensitive to leaking water or has a oor

drain. It is best to place the appliance outdoors or on a tiled oor with a drain. Alterna-

tively, the unit can be placed in a suciently large tub. If, due to improper use, hoses burst,

the pressure relief valve on the unit „opens“ or water escapes in any other way, the possi-

ble consequential damage can be prevented in this way.

2.2 The right water source

Attention: When choosing the water source, special attention must be paid to the origin

of the water to be used for production. In its normal conguration, the OSMOBIL PRO X

is only intended for the use of approved city water in accordance with the German Drin-

king Water Ordinance! The use of other water can cause considerable damage to your

OSMOBIL PRO X and primarily to the membrane bodies - and that after only a few litres

of production! Therefore, make sure that you only use city water of drinking quality, which

complies with the German Drinking Water Ordinance!

If you have no knowledge of the water sources at the respective location, please be sure

to talk to people who have knowledge of the local water supply (e.g. your clients, building

technicians, etc.) before starting work. If, for example, you use water from a well, a cistern,

a rain barrel or something else, your unit may be damaged after just a few minutes! A sud-

den failure of the water supply (e.g. in agriculture due to animal feeding) can also cause

damage to your unit. If there is no drinking water supply on the respective construction

site or if you have to work frequently under such conditions, please contact your specialist

dealer. Possibly, the respective problem can be solved by additional pre-lters.

2.3 Hoses and couplings

The permanently installed concentrate/waste water line is connected to the city water

inlet when the unit is delivered and at rest. In this way, the unit is also directly airtight and

no water can escape. First disconnect the waste water hose from the city water inlet if

you want to produce pure water. Next, connect the supply water hose to the „city water“

connection on the back of the unit. For this purpose, please use at least hoses with a 3/4“

diameter (or larger). Accordingly, you must rst disconnect the concentrate hose from the

city water inlet in order to be able to work.

In addition, the waste water (concentrate) from the unit must be discharged via the per-

Operating Instructions for Mobile Reverse Osmosis System OSMOBIL PRO X

VF Reinigungstechnik

Benjamin Volk & Tobias Becker GbR

Blankenfohrweg 11

32139 Spenge

T 05225 87198

-

15

info@vf-reinigungstechnik.de

www.gebaeudereinigung-shop.de

www.gardiner-teleskopstangen.de

www.vf-reinigungstechnik.de

Sparkasse Bielefeld

IBAN DE60 4805 0161 0003 4120 53

BIC SPBIDE3BXXX

Steuer-Nr. 324/5816/0846

manently installed hose. This waste water is not contaminated or „toxic“. It only contains

twice as much hardness / minerals as the previous city water.

Please always ensure that the waste water ows freely and do not use any „water stop

couplings“ for this, should the original coupling ever be removed. In addition, the waste

water pipe may be extended to a maximum of 5 metres!

2.4 Check ush valve and start water supply

Now you should make sure that the „ush valve“ is set to „ush“ (the lever must point

to the right at a 90° angle). Then you can rst switch on the water supply or turn on the

tap. Before doing this, it makes sense to also rinse the line and hoses that are being used

without connecting the OSMOBIL PRO X. Rust residues and deposits can be rinsed out in

this way and will not enter the unit or the pre-lter.

2.5 Switch on the pump

Then connect the personal protection plug to the mains. Then press the green „RESET“

button on the OSMOBIL PRO X‘s personal protection plug. Now the pump starts. After a

short time, the tanks will have lled up and the water will ow 100% out of the „concen-

trate“ or waste water outlet („red sticker“ on the back, never connect a telescopic rod or

the city water here!).

2.6 Execute ush mode

The mode that is now active is called „ush mode“. This mode is used to clean the system,

as residues deposited inside and the remaining „concentrate“ are thus ushed out of the

membranes. The ushing mode must always be activated for a few minutes before star-

ting work and after nishing (see below) to ensure a long „life“ of your membranes. It is

normal that the pump sometimes „nails“ a little or makes noises when work begins. These

will subside during production operation at the latest. Then the pump should work quietly.

Attention: Please always follow the rule for switching on the OSMOBILS PRO X: „First

water, then power!“.

2.7 Production mode

If you now want to start producing water, simply set the ush valve down to „Produce“.

The necessary pressure then builds up in the system and provides pure water if required

(if at least one „consumer“ is connected to the two water outlets). The pump should run

quietly in this state (in ush mode it can sometimes „nail“ a little).

Attention: Please pay attention to the pressure gauge on the machine at the beginning of

water production. The machine should run at a maximum of 15 bar in operating mode when

pure water is drawn o. This value can be exceeded, especially in industrial objects with

extremely strong water pressure, and may possibly cause damage to your machine! Please

note that you need a normal pre-pressure (approx. 2-6 bar). If your unit makes loud, nailing

noises during the production process, interrupt the operation and look for a solution in the

chapter „Troubleshooting“.

If the X-Flow system is active (no removal of clean water while the machine is running),

Operating Instructions for Mobile Reverse Osmosis System OSMOBIL PRO X

VF Reinigungstechnik

Benjamin Volk & Tobias Becker GbR

Blankenfohrweg 11

32139 Spenge

T 05225 87198

-

15

info@vf-reinigungstechnik.de

www.gebaeudereinigung-shop.de

www.gardiner-teleskopstangen.de

www.vf-reinigungstechnik.de

Sparkasse Bielefeld

IBAN DE60 4805 0161 0003 4120 53

BIC SPBIDE3BXXX

Steuer-Nr. 324/5816/0846

the pressure displayed on the pressure gauge can go up to 18 bar!

2.8 Connecting telescopic poles and co.

Now you can connect one or two „consumers“ (washing brushes, high pressure pump,

rotating brush and co.) to the green marked water outlets on the front of the machine and

start cleaning. Please use connections in the format „Gardena male“ as couplings here.

2.9 Measuring the water quality of the ultrapure water

Before starting the cleaning work, please read the water quality at the water outlet („Per-

meate“, green sticker, bottom right on the display of the meter).

The water quality is displayed in „PPM“. This unit means „parts per million“ and refers to

the „remaining foreign molecules per 1 mil of water“.

For the water quality required in each case, the following applies approximately:

0-30 PPM - perfect quality for facade, PV and solar cleaning

0-15 PPM - perfect quality for window cleaning

Important for cleaning operations with the produced H2O: Within the rst 30-60

seconds after the unit is switched on, it is not unusual for the water level to be

still around 20-30 ppm or higher. This will regulate itself downwards within a short

period of time. In addition, with new units or newly installed membranes, it is important to

make sure that up to 10,000 litres of water must be produced with the new unit or memb-

rane before the membranes reach their full capacity.

Once the necessary water quality has been achieved, you can start with the desired work.

If you do not achieve the required water quality, you will nd useful tips in the Trouble-

shooting“ section. Important for resting phases of the machine: It is normal for the con-

ductivity to rise during idle phases of the machine and can reach a very high value!

2.10 Ending the work

If you want to nish the work, rst set the „rinse valve“ to the position

„Flush“. Use the time of ushing to stow hoses and telescopic poles.

Then switch o the pump. To do this, use the test switch on the personal protection plug

or simply disconnect the power supply.

Attention: When always follow the rule „First power, then water“! Then stow away the

unit.

2.11 Video for commissioning

Below you will nd a practical video on how to commission the OSMOBIL PRO X:

https://youtu.be/zLWF9B8oq5w

Operating Instructions for Mobile Reverse Osmosis System OSMOBIL PRO X

VF Reinigungstechnik

Benjamin Volk & Tobias Becker GbR

Blankenfohrweg 11

32139 Spenge

T 05225 87198

-

15

info@vf-reinigungstechnik.de

www.gebaeudereinigung-shop.de

www.gardiner-teleskopstangen.de

www.vf-reinigungstechnik.de

Sparkasse Bielefeld

IBAN DE60 4805 0161 0003 4120 53

BIC SPBIDE3BXXX

Steuer-Nr. 324/5816/0846

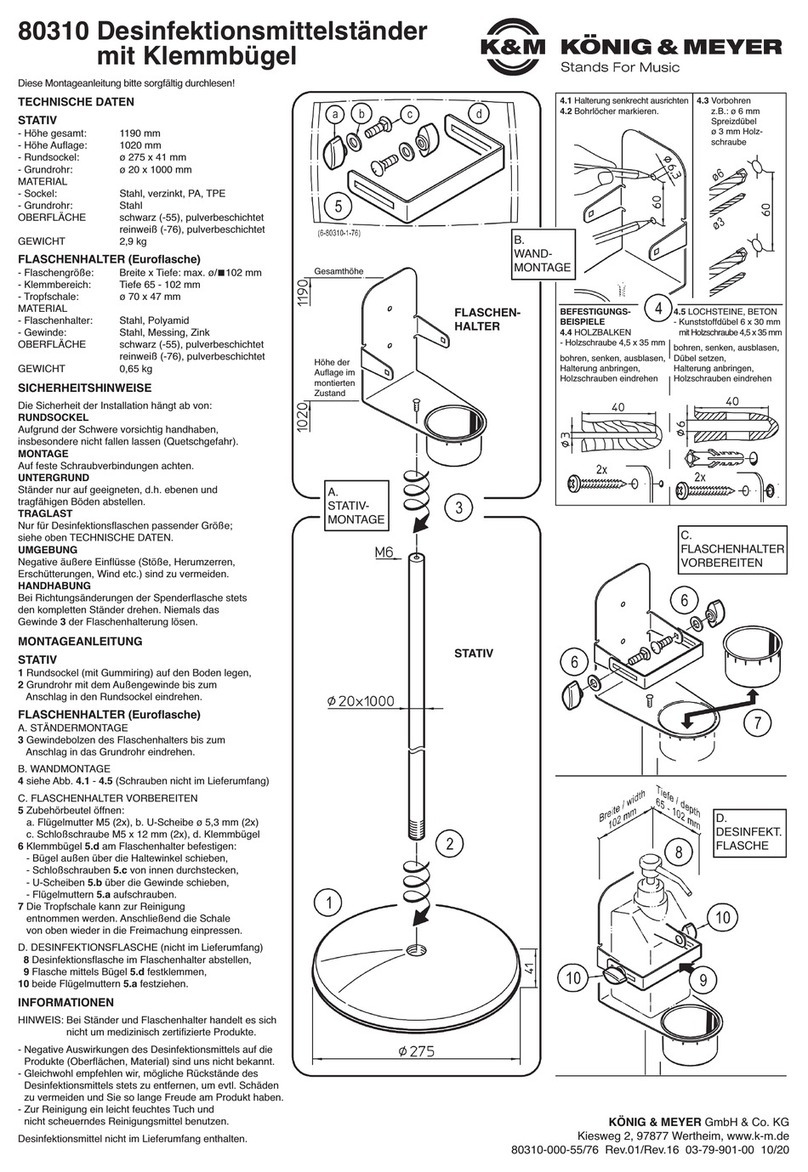

2.12 Assembly diagram - cleaning

3 Maintenance, care and safety

3.1 Changing the pre-lter

The only lter or component that needs to be changed regularly on your OSMOBIL PRO X

is the pre-lter in the transparent housing at the back of your unit. To change it, unscrew

the transparent lter housing counter-clockwise and remove it together with the lter

cartridge. If the housing is too tight (this usually only happens if the replacement intervals

have not been adhered to), you can obtain a suitable lter spanner from your specialist

dealer.

Then pour o the water and remove the lter cartridge. You can now dispose of it and

replace it with a new one. Filter cartridges are available from your specialist dealer. Only

original OSMOBIL lters should be used. If necessary, you should now clean the lter cup

by simply rinsing it out. When inserting the lter cup into the unit, make sure that the lter

cartridge is upright and that the lter cup is clean and also turned straight onto the thread.

Caution: With every new lter, two new white sealing plates come with it, which sit on

the top and bottom of the short sides of the lter. Sometimes these come loose and stick

to the lter cup or the top of the cup. When screwing in a new lter, this can lead to 3 or

4 gaskets being in the lter cup instead of 2 (top and bottom). Then the cup cannot be

closed completely and leaks.

3.2 When must the pre-lter be changed?

The capacity of the pre-lter depends on various factors. For this reason, it should be

changed when one of the following points applies:

Drain

Tapwater

OSMOBIL PRO X

Permeat / Ultra Pure Water Brush or Cleaning

System

Concentrate / Waste water

Operating Instructions for Mobile Reverse Osmosis System OSMOBIL PRO X

VF Reinigungstechnik

Benjamin Volk & Tobias Becker GbR

Blankenfohrweg 11

32139 Spenge

T 05225 87198

-

15

info@vf-reinigungstechnik.de

www.gebaeudereinigung-shop.de

www.gardiner-teleskopstangen.de

www.vf-reinigungstechnik.de

Sparkasse Bielefeld

IBAN DE60 4805 0161 0003 4120 53

BIC SPBIDE3BXXX

Steuer-Nr. 324/5816/0846

Service life: After 3 months at the latest, otherwise the existing lter may rot and damage

the membrane.

Capacity: If your appliance does not deliver enough water.

Flow rate: After 50,000 litres of water ow.

3.3 Replacing the battery on the 2-channel TDS meter

The meter is permanently switched on after initial start-up.

The battery life varies between 6-24 months depending on use.

If the display is o, this is usually due to an empty battery.

Here you can nd a video that we created for the exchange of the batteries:

https://youtu.be/oAVevy1kDdc

3.4 When do I have to change the membrane?

Basically, the installed membranes run without wear. However, replacement must be ex-

pected after 1-2 million litres of water ow. In the course of time, problems with the water

value or the water quality or the water quantity may occur due to improper use, damage

caused by falling or transport, frost or other events. If this is the case, your dealer will help

you nd out if your membranes are damaged or if there is another problem. If the memb-

ranes need to be replaced, you can open the membrane housings and simply replace the

membrane bodies. Your dealer will be happy to explain this to you.

Click here for a video that we have made on how to replace the membranes:

https://youtu.be/V8LFHziNrL8

3.5 Annual inspection

In order to maintain the performance and water quality of your osmosis unit in the long

term, we recommend an annual inspection by your specialist dealer. During this inspection,

your membrane is cleaned, maintained and, if desired, preserved. In addition, the unit is

checked for leaks and the electronics are checked for function. If desired, your unit can

also be UVV inspection including the corresponding documentation.

Operating Instructions for Mobile Reverse Osmosis System OSMOBIL PRO X

VF Reinigungstechnik

Benjamin Volk & Tobias Becker GbR

Blankenfohrweg 11

32139 Spenge

T 05225 87198

-

15

info@vf-reinigungstechnik.de

www.gebaeudereinigung-shop.de

www.gardiner-teleskopstangen.de

www.vf-reinigungstechnik.de

Sparkasse Bielefeld

IBAN DE60 4805 0161 0003 4120 53

BIC SPBIDE3BXXX

Steuer-Nr. 324/5816/0846

3.6 Decommissioning - shutdown in winter for up to 12 weeks

If your unit is not used for a longer period of time during the winter months or for other

reasons, you must take care of a few things to protect your membrane from damage:

1. Ensure frost-free storage of the unit.

2. Put a new pre-lter in the unit (important!).

3. Rinse the entire system again with city water for several minutes.

4. Connect the hose from the waste water outlet to the waste water inlet so that your

unit is airtight.

5. Repeat steps 2.-4. after 12 weeks at the latest. The switch-on dates should be

documented in order to keep track of them.

Caution: If the steps are not followed correctly, the membranes may be damaged during

the resting phase! In addition, any previous damage to a membrane (e.g. due to well wa-

ter) can become more pronounced due to a rest phase.

3.7 General operating instructions and safety

3.7.1 Installation preconditions and protection against water damage

- Only install the unit in areas that are insensitive to water and have a oor drain!

- To avoid puddles, pools of water or damage to meadows and elds, you can extend

the waste water hose to a maximum of 5 metres. Here, no couplings or at most

Gardena couplings without water stop are to be used at the end of the hose!

- Observe the respective conditions, regulations and guidelines at the place of

installation!

3.7.2 General operating instructions

- Hot water must not get into the unit (max. 25°C)!

- Protect your unit from knocks and falls!

- Store your unit frost-free!

- Inform yourself about the water supply!

- Only city water may be fed into the unit!

- Always ensure free water drainage!

- Do not leave the unit running unattended!

3.7.3 Safety instructions and special dangers

- If you discover any damage to cables and hoses or other water- or electricity-

carrying components of the unit, these must be repaired immediately by a suitable

specialist.

- Before carrying out any maintenance or repair work, always ensure that the

power supply to the appliance is disconnected and that all water-carrying parts are

depressurised.

Operating Instructions for Mobile Reverse Osmosis System OSMOBIL PRO X

VF Reinigungstechnik

Benjamin Volk & Tobias Becker GbR

Blankenfohrweg 11

32139 Spenge

T 05225 87198

-

15

info@vf-reinigungstechnik.de

www.gebaeudereinigung-shop.de

www.gardiner-teleskopstangen.de

www.vf-reinigungstechnik.de

Sparkasse Bielefeld

IBAN DE60 4805 0161 0003 4120 53

BIC SPBIDE3BXXX

Steuer-Nr. 324/5816/0846

- The water produced by the OSMOBIL PRO X is not suitable for drinking!

- Do not touch any electrical components if your hands are wet!

- When using the device, strictly separate the power supply and the water supply

from each other.

- Protect the appliance and especially the live parts from rain, splash water or other

sources of water.

3.8 Troubleshooting

3.8.1 Your water value is not correct?

- Switch the unit o completely and switch it on again in rinse mode.

Wait a few minutes in rinse mode. Then switch to production mode and measure the

water level regularly. As a rule, the water level regulates itself after a few minutes.

- Operate the unit for 30 minutes in rinse mode. Then measure the water level again

in operating mode.

- Your membrane may be damaged by misuse (well water, unsuitable water source,

overpressure, frost). In these cases, please contact your specialist dealer.

- In some cases, if the input water is extremely hard and a membrane has been used

for several years, the water value may remain permanently too high. Please contact

your specialist dealer. The problem can usually be solved by changing the

membrane.

3.8.2 Your machine delivers too little water?

- Replace the pre-lter.

- Check the respective water tap. The water pressure here can vary. The following

applies as a general rule: a low inlet water pressure leads to the appliance producing

less water.

- Your pump may be incorrectly adjusted. You may have to increase the pressure via

the adjustment on the front (but only as far as the pump continues to operate

smoothly and does not „nail“). In addition, the system pressure must not exceed 15

bar in operating mode. Please reduce the pressure again after use. If you do not feel

condent in handling the pump screw, please contact your specialist dealer!

- In a few cases, very hard incoming water can lead to calcication of the system.

Your specialist dealer will be happy to advise you on how to proceed in such cases.

- Please use a hose with a diameter of at least 3/4“ as a supply line to the unit. A

thinner hose can restrict the water production and cause the pump to „nail“.

Basically, the following applies: „Thick hose towards the OS MOBIL PRO X, thin

hose away from the OSMOBIL PRO X“.

- The use of non-approved drinking water can clog („block“) your membrane or

cause the pump to „nail“. („blocked“) or destroyed (e.g. by „iron“, „silicic acid“

etc.). Please contact your specialist dealer.

Operating Instructions for Mobile Reverse Osmosis System OSMOBIL PRO X

VF Reinigungstechnik

Benjamin Volk & Tobias Becker GbR

Blankenfohrweg 11

32139 Spenge

T 05225 87198

-

15

info@vf-reinigungstechnik.de

www.gebaeudereinigung-shop.de

www.gardiner-teleskopstangen.de

www.vf-reinigungstechnik.de

Sparkasse Bielefeld

IBAN DE60 4805 0161 0003 4120 53

BIC SPBIDE3BXXX

Steuer-Nr. 324/5816/0846

3.8.3 Your pump makes loud noises and „nails“ in production mode?

- Replace the pre-lter.

- Low pre-pressure („too weak a line“) is often the problem.

- Use a thicker hose leading from the tap to the unit.

- Try shortening the supply line from the tap to the appliance.

- Use a dierent water source.

- Use a pressure booster upstream of the OSMOBIL PRO X. Your specialist dealer will

be happy to advise you.

- You may have to reduce the pump‘s output via the pump pressure adjustment opti

on on the front. If you do not feel condent in handling the pump screw, please

contact your specialist dealer!

3.8.4 You are producing too little water?

- Low water temperatures can reduce the performance of your system.

- Your pre-lter needs to be changed.

- The use of unapproved drinking water may have clogged („blocked“) or destroyed

(„iron, gravel“) your membranes. („blocked“) or destroyed („iron“, „silicic acid“,

etc.). Please contact your specialist dealer.

- The respective water source has too low an outlet pressure - see chapter

3.8.5 The pump does not switch on?

- Check the respective power supply.

- In many cases, a defective personal protection plug is to blame if the pump cannot

be switched on. This safety component is particularly sensitive to moisture.

Changing this plug usually solves the problem. Your specialist dealer will be happy

to advise you.

3.8.6 The display of the meter is „frozen“?

- Please remove the battery briey and insert it again. The meter may have stopped

due to temperature uctuations or long periods of inactivity.

- Replace the batteries.

3.8.7 The display of the meter is o?

- Please replace the batteries according to the video (see chapter 3.3).

4 Warranty

All OSMOBIL water systems are subjected to extensive quality control and testing before

delivery and are only supplied to commercial customers. The construction of the units is

already designed for unconditional reliability and durability. Should there nevertheless be

any problems or a reason for complaint within the warranty period (12 months), please

direct the respective claim for replacement to VF Reinigungstechnik. Please note that the

warranty only covers units that are structurally unchanged and have been operated strictly

according to the specications in this manual.

Table of contents

Popular Cleaning Equipment manuals by other brands

Silvercrest

Silvercrest SRB 4 A1 Operating instructions and safety instructions

Caviblaster

Caviblaster 2828-E Operation & maintenance manual

Bieffe

Bieffe BF009PL3 Use and maintenance manual

Host

Host Liberator extractorVAC Safety & maintenance guide

Makita

Makita DCL284F instruction manual

Bissell

Bissell CrossWave Cordless 2551 Series Battery removal instructions