OSPRI LHSW200 User manual

LHSW200 User Manual V7.0

Product Description

CONTENTS

Chapter 1 Application Methods

Application Methods...................................................................... 01

Chapter 2 General Introduction

2.1 Product Parameter ..................................................................02

2.2 Product Feature ......................................................................02

Chapter 3 Structural Feature

3.1 Brief Description of Product Structure .....................................03

3.2 Brief Description of Product Parts ...........................................04

Chapter 4 Product Installation

5.1 Maintenance of Protection Window.........................................12

5.2 Maintenance of Collimation Lens........................................... 14

5.3 Maintenance of Focus Lens....................................................15

Chapter 5 Product Maintenance

4.1 LHSW200 Dimension Drawing................................................05

4.2 Welding Head Connection.......................................................06

4.2.1 Cooling Water Connection....................................................06

4.2.2 Gas Connection....................................................................07

4.2.3 Fixed Mount Installation for Wire Feeding…………………...08

4.2.4 Methods to Find the Focus………….......................………...08

4.3 QBH Fiber Connection......……………………………......……..09

Chapter 6 Wiring Connection

6.1 Wiring Diagram.......................................................................16

6.2 Controller Wiring Definition.....................................................16

6.3 Touch Screen Instruction........................................................18

Chapter 7 Technique Parameter

7.1 Welding Parameter Table ........................................................27

Chapter 1 Application Methods

01

Method 1:

Method 2:

2.1 Product Parameter

2.2 Product Feature

02

Chapter 2 General Introduction

Product Name Handheld Wobble Welding Head

Model LSHW200

Connector Type QBH

Wavelength 1080±10nm

Laser Power 2KW

Focus Length 125mm/150mm

Collimation Length 50mm

Nozzle M13*0.75

Wobbling Speed 0~4000mm/s

Wobbling Range 0~5mm

Gas Blowing Way Coaxial Blowing

Gas Pressure ≤1Mpa

Protection Window 20x3 mm

Net Weight 0.94KG

① User-friendly for maintenance with dual cartridges of protection windows

design,to extend service lifespan of focus lens;

② Made of high-precition industial machinery, 0.94KG in weight is portable

to carry;

③Various nozzles to meet different welding technical demands;

④ Water cooling for all optics and welding head cavity;

⑤ Capactive safety protection to avoid laser damage during handheld

operation;

⑥ Ergonomi design for comfortable operation

03

Chapter 3 Structural Feature

3.1 Brief Description of Product Structure

QBH Connector

Collimator

Protection

Window Cartidge Wobble&Focus

Part

Focus

Protection

Window

Welding

Protection

Window

Gas Blowing&Focusing

Module

04

3.2 Brief Description of Product Parts

① QBH Module: Locked connection between QBH fiber tip and handheld

welding head;

② Collimation Module: Convert the diverged beam into parallel beam;

③ Wobbling Focus Part: Focus the parallel beam into a spot and control

the wobbling trajectory of range 0~5mm;

④ Focus Protection Window Cartridge: Avoid dirts from entering onto the

focus lens, which can extend the service lifespan of focus lens;

⑤ Welding Protecion Window Cartridge: Prevent the dusts and spatters

entering the head and protect the focus lens;

⑥ Gas Blowing&Focusing Module: Adjusting focus, and blowing gas to

prevent the workpiece from being oxidized, by destroying the laser effect

on the workpiece surface of the ionosphere to form isolation the workpiece

and air.

Chapter 4 Product Installation

4.1 LHSW200 Dimension Drawing

05

For collimation length F50mm and focus length F150mm

Attention

Attention

1.Ensure standard and reliable grounding before power on;

2.Clean the QBH fiber tip carefully before connect it to the

welding head as any dirst and dust would caused optics

burned inside;

3.Clean and dust-free environment is required when

replacing protection window.

4.LHSW200 welding head is not allowed to work without

water cooling;

5.Hot plugging is forbiden;

6.Ensure the red light comes out of the nozzle before firing

the laser;

4.2 Welding Head Connection

06

4.2.1 Cooling Water Connection

Integrated design for water cooling system:

one inlet and one outlet cooling connection

Cooling Water

Hose φ6mm

Cooling Water

Hose φ6mm

4.2.2 Gas Connection

07

Attention:Gas should be filtered and dried otherwise the

protective window would be contaminated and damaged.

① Gas connector shoule be connected with φ6mm hose and input

protective gas, with suggested input flow <30L/Min, which will protect

the weld material surface and extend the lifespan of protective window.

High purity of N2 and Argon gas is suggested to process

Protective Gas

Hose φ6mm

08

Due to the different datum of every laser source,

here we introduce methods to find the focus

point:

a) Loosen the part ①, fit the tube part ② where

the smallest point of red light appears ( this

point does not coincide with the laser focus)

b) Turn off the ‘PE Protect’ in control panel and

set the laser power at 150W approximately.

Then aim the hand-held welding head at the

stainless steel sheet and, point the laser and

move the head up and down. The focus point is

where the spark is greatest;

c) To set laser power to 250W around and

operate in the same way with alumium sheet

instead of stainless steel will help find the focus

point more precisely.

4.2.3 Fixed Mount Installation for Wire Feeding

4.2.4 Methods to Find the Focus

4.3 QBH Fiber Connection

09

① Put the welding head horizontally, then take out dust-proof cover;

Note: In case the fiber head is with original dust-proof gasket, users

can choose whether install dust-proof cover or not according to actual

demand.

Dust-proof Cover

② Cover the dust-proof cover which is in the white accessory box, onto the

fiber laser tip;

10

③ Turn the QBH connector into the open state, that is, screw it to the

limit position counterclockwise (where can hear a “thud”)

④ Align the red dot on the fiber head with the red dot on the QBH

connector, and slowly insert the fiber tip into the QBH connector.

Red Dot Mark

11

⑤ Turn the QBH connector to the locked state, that is, screw it toward

the limit position clockwise (where can hear a “thud” sound). Then lift

the swivel nut up and screw the nut clockwise again until the fiber tip is

compressed tightly. (Clockwise: toward the direction of the “locked”

icon)

Note: Wrape with masking tape after plugging fiber tip.

Chapter 5 Product Maintenance

12

Loosen the two M2.5 screws and pull out

the cartridges

5.1 Maintenance of Protection Window

In case poor welding performance occurs while welding protection

window is normal, but burning points on the SKL-A (ceramic piece) the

collimator protection window or focus protection window possibly is

polluted or damaged. In this condition, please pull out the protection

window drawer to check the windows.

5.1.1 Disassembly of Welding Protection Window

13

The structure of welding protection window as shown below:

Protection Window

Clamp Ring

Protection Window

PMD20T3

O Sealing Ring

21×15×3

14

Remove the three screws in sequence as shown above, and

disassemble the collimation protection window and lens to

maintenance with lens dismantling tool. Please mind the proper

direction of collimation lens when assembling it.

④ Hold the wiping swabs with right hand to gently wipe both sides of the

lens in a single direction from bottom to top or from left to right, and blow

the lens surface with the rubber air blow to confirm that there is no foreign

matters on the cleansed lens surface.

5.2 Maintenance of Collimation Lens

5.2.1 Disassembly of Collimation Lens

5.2.2 Cleaning of Collimation Lens

① Tools:dust-free wiping swabs, isopropyl alcohol, dry and pure compressed air.

② Spray isopropyl alcohol onto the dust-free wiping swabs.

③ Gently pinch the both sides of the lens with the left thumb and index finger.

⑤ The cleansed lens must be installed into the cutting head’s body as soon

as possible or stored in other clean and sealed container.

15

Remove the two parts in sequency as shown above, and disassemble

the focus lens to maintenance with lens dismantling tool. Please mind

the proper direction of collimation lens when assembling it.

5.3 Maintenance of Focus Lens

5.3.1 Disassembly of Focus Lens

5.3.2 Cleaning of Focus Lens

① Tools:dust-free wiping swabs, isopropyl alcohol, dry and pure compressed air.

② Spray isopropyl alcohol onto the dust-free wiping swabs.

③ Gently pinch the both sides of the lens with the left thumb and index finger.

④ Hold the wiping swabs with right hand to gently wipe both sides of the

lens in a single direction from bottom to top or from left to right, and blow

the lens surface with the rubber air blow to confirm that there is no foreign

matters on the cleansed lens surface.

⑤ The cleansed lens must be installed into the cutting head’s body as

soon as possible or stored in other clean and sealed container.

16

button cable

communication

cable

wire feeder cable

Wiring Diagram

6.2 Controller Wiring Definition

PIN Defintion Description

1. DA+ analog output (control the peak power of laser source)

9. DA- analog output GND

4. PWM+ pulse width modulation (control laser output duty cycle)

13. PWM- pulse width modulation ground

3. Enable enable output signal (PNP)

11. Red Light red light output signal (PNP)

15. 24V 24V power output

8. 24V 24V power output

12. 0V 0V output

Chapter 6 Wiring Connection

6.1 Wiring Diagram

A、CN1(DB15 Female):

17

Pin Description Pin Description

1 button signal input

(connect with the yellow wire)

8 24V controller

output

2 nozzle touched signal

(connect with the grenn wire)

14 0V controller

output

3 protective gas solenoid valve output

(PNP type)

15 24 controller

output

7 0V,controller output

C、CN3(DB9 Female):

RS232 communication port-Connect to the 7-inch hand-

touched controller screen;

B、CN2(DB15 Male):

Pin Definition Description

1 DIR+ Direction +

2 DIR- Direction -

3 PUL+ Pulse +

4 PUL- Pulse -

D、CN4(DB9 Male):

Connect to the drive of wire feeder ’s motor, the pulse

equivalent of the motor is set to 1000P/R;

E、POWER (3-pins power plug)

24V: Connect to switch power supply 24V;

0V:Connect to switch power supply COM;

PE:Ground Connection

F、3-pins 15V power plug

+15V:Connect to switch power supply +15V;

0V:Connect to switch power supply COM;

-15V:Connect to switch power supply -15V

18

1. Page Options: There are four pages to switch- technique, operation,

setting and test;

2. HMI Version: It indicates current version of the HMI interface;

3. Controller Version: It indicates the current program version;

4. Technique: There are 20 groups of weldign parameters available,from

No.1~No.20 each group of parameters can be saved repectively;

6.3 Touch Screen Instruction

1

2

3

4

Table of contents

Other OSPRI Welding Accessories manuals

Popular Welding Accessories manuals by other brands

Kemppi

Kemppi PFU 210e operating manual

ROBOD

ROBOD RINO TEXTILE MAX Manual for Use, Storage and Maintenance

Clarke

Clarke Weld WSC2 User instructions

Abicor Binzel

Abicor Binzel iCAT mini ABIROB G operating instructions

Sperian

Sperian Optrel STAR quick start guide

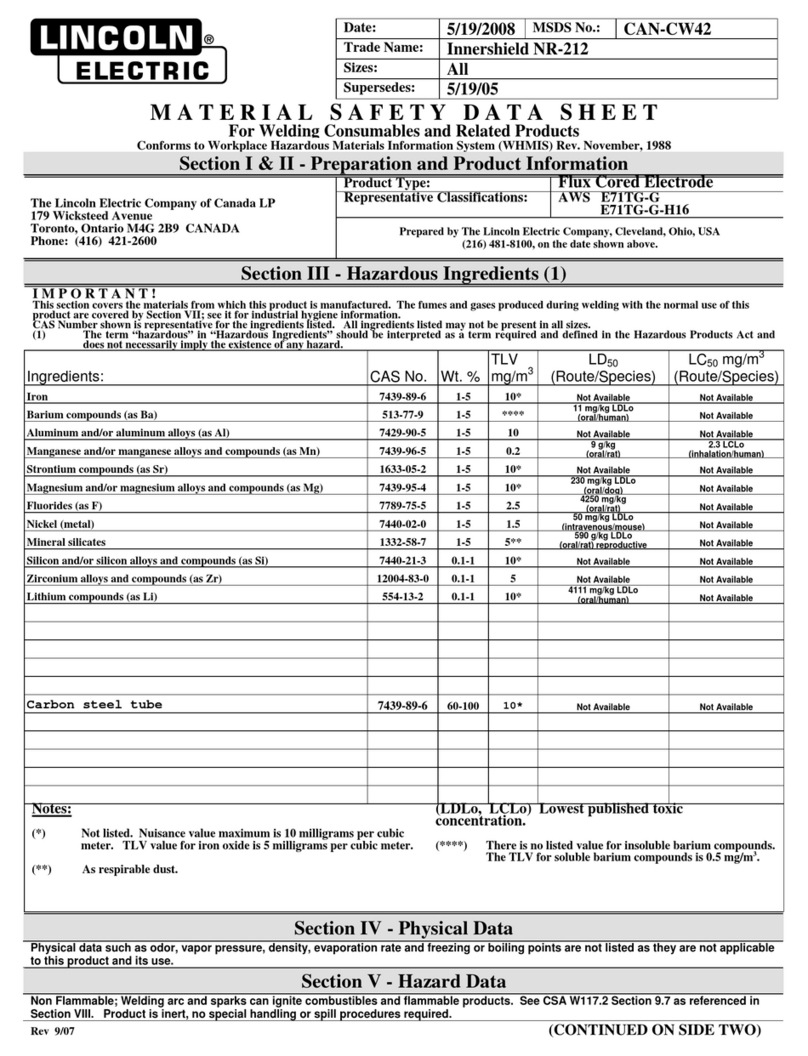

Lincoln Electric

Lincoln Electric Innershield NR-212 datasheet