OTARI MX-5050 Instructions for use

0S3-035

M X -5050 M K III-4

PROFESSIONAL RECORDER

INSTRUCTION AND MAINTENANCE MANUAL

CAUTION

To prevent fire or shock hazard:

Do not expose this appliance to rain or moist re.

Do not remove back.

No ser-serviceable parts inside.

Refer servicing to q alified service personnel.

SAFETY INSTRUCTIONS

1. Read Instr ctions — All the safety and operating instr ctions sho ld be read before

the appliance is operated.

2. Retain Instr ctions — The safety and operating instr ctions sho ld be retained for

f t re reference.

3. Heed Warnings -- All warnings on the appliance and in the operating instr ctions

sho ld be adhered to.

4. Follow Instr ctions — All operating and se instr ctions sho ld be followed.

5. Water and Moist re -- The appliance sho ld not be sed near water - for example, near

a batht b, washbowl, kitchen sink, la ndryt b, in a wet basement, or near a swimming

poo I , etc.

6. Carts and Stands -- The appI iance sho ld be sed only with a cart or stand that is

recommended by the man fact rer.

7. Ventilation — The appliance sho ld be sit ated so that its location or position does

not interfere with its proper ventilation.

For example, the appliance sho ld not be sit ated on a bed, sofa, r g, or sim ilar

s rface that may block the ventilation openings; or, placed in a b ilt-in

instal lation, s ch as a bookcase or cabinet that may impede the flow of air thro gh

the ventilation openings.

8. Heat -- The appl iance sho ld be sit ated away from heat so rces s ch as radiators,

heat registers, stoves, or other appliances (incl ding amplifiers) that prod ce heat.

9. Power So rces — The appliance sho ld be connected to a power s pply only of the type

described in the operating instr ctions or as marked on the appliance.

10. Gro nding or Polarization -- The preca tions that sho ld be taken so that the

gro nding or polarization means of an appliance is not defeated.

11. Power-Cord Protection -- Power-s pply cords sho ld be ro ted so that they are not

likely to be walked on pinched by items placed pon or against them, paying partic lar

attention to cords at pl gs, convenience receptacles, and the point where they exit

from the appliance.

12. Cleaning — The appliance sho ld be cleaned only as recommended by the man fact rer.

13. Non se periods — The power cord of the appliance sho ld be npl gged from the o tlet

when left n sed for a long period of time.

14. Object and Liq id Entry -- Care sho ld be taken so that objects do not fall and

liq ids are spilled into the enclos re thro gh openings.

15. Damage Req iring Service -- The appliance sho ld be serviced by q alified service

personnel when:

A. The power-s pply cord or the pl g has been damaged; or

B. Objects have fallen, or liq id has been spilled into the appliance; or

C. The appliance has been exposed to rain; or

D. The appliance does not appear to operate normal ly or exhibits marked change in

performance; or

16. Servicing -- The ser sho ld not attempt to service the appliance beyond that

described In the operating instr ctions.

All other servicing sho ld be referred to q alified service personnel.

MX-5050 MKIII-4

PROFESSIONAL TAPE RECORDER

INTRODUCTION

This manual rovides descri tive information, installation, o eration,

maintenance and normal adjustment instructions for the Otari MX-5050 MKltt-4

Professional Ta e Recorder.

MX-5050 MKH-4 Recorder

Co m m u n ic a t io n w ith O tari

— FOR SERVICE INFORMATION AND PARTS

OTARI PRODUCTS are manufactured under strict quality control and each unit

is carefully tested and ins ected rior to shi ment from our factory.

If, however, adjustment or technical su ort becomes necessary, re lacement

arts are required or technical questions arise, lease contact your nearest

Otari dealer or write to:

OTARI ELECTRIC CO., LTD.

4-29-18, Minami Ogikubo,

Suginamiku, Tokyo, 167, Ja an

Phone: (03) 333-9631

Telex No.: UTRDENKI J26604

OTARI ELECTRIC DEUTSCHLAND GmbH

Gielen Strasse

4040 Neuss 1

F.R. Germany

TEL : 02101-274011 , 12

TLX :418517691

Another art of O tari's continuous technical su ort rogram for our

roducts is the continuous revision of manuals as the equi ment is im roved

or mod i f i ed.

In order to receive information and service a licable to your equi ment,

and for technical su ort to function ro erly, lease include the following

information, most of which can be obtained from the name late on the

equi ment when you communicate with Otari.

1. Model Number

2. Serial Number

3. Date of urchase

4. Name and address of dealer from whom unit was urchased

5. Power requirements (voltage and frequency)

6. Manual number to which you are referring

OTARI CORPORATION

2 Davis Drive, Belmont

California 94002, U.S.A.

Phone: (415) 592-8311

Telex No.: TWX 910-376-4890

* Addenda * (MX-5050 BQ-2,MK-3-4,MK-3-8)

********* External Ca stan S eed Control *********

For a s ecial a lication such as interfacing with synchronizers or cont

rollers,an external ca stan s eed control can be erformed to connecting them

to the "LOCATOR" connector located on the rear anel.

Ca stan s eed is controlled with the DC voltage (range:+-13V) which is fed to

the "LOCATOR" connector PIN No.l and No.2.

Ca stan s eed continuously varies in ro ortion to DC voltage;

At the -13V of DC voltage,ca stan s eed is minimum.

At the OV of DC vol tage,ca stan s eed is nominal. (1.5,7-1 / 2i s)

At the 13V (+8V on 15i s) of DC voltage,ca stan s eed is maximum.

To erform external ca stan s eed control, roceed as follows.

1. Referring to SECTION 5-5 "FUSE REPLACEMENT of the manual,ex ose the

Control P.C.B.

2. Position two DIP switches on the Control P.C.B.,SW-2 and SW-3,to

"NORMAL" and "EXT".

3. Referring to the Table-2 "Pin Assignment",solder res ective leads on

connector,mated with the "LOCATOR" connector.

Part No. of the mating connector : CN216203

4. Connect the equi ment to a synchronizer,or a controller.

Table-1 Control DC voltage and Ca stan s eed

★Nominal s eed ★Control DC voltage ★Ca stan s eed ★

★(i s) ★(V) ★(%) ★

★★-13 -60 ★

★15 ★0★0★

'k ★8 # ★+70 ★

★ ★ -13 ★-60 ★

★7-1/2 ★0★0★

★★13 ★+ 210 ★

#On 15 i s,Ca stan s eed is limited at the value of DC 8V.

-1-(Ver.l.0)

Table-2 Pin assignment of the "LOCATOR" connector

*PIN No. ★Descri ti on

k

Note

k

k

1 §★GND,F

k

GND of EXT. CONT

k

k

2 #

k

EXT.CONT

k

Ca stan s eed control

k

★

kk

DC voltage (range:+-l3V)

k

i

k

3

k

CLOCK

k

Tach ulses

k

kk k

(TTL logic convention)

k

★

k k

Frequency:40Hz at 15i s

k

k

4

k

DIR.(Rev/Fwd)

k

Trans ort Direction

k

kkk

(TTL logic convention)

k

k

5

k

N.C.

kk

k

6

k

15 i s

kk

★7

k

7-1 /2i s

k

>Ta e s eed command

k

k

8

k

(3-3/4i s)

k

y(24V/o en)

k

k

9

k

N.C.

kk

k

10

k

RECORD

k" k

k

11

k

F.FWD

k

Trans ort control

k

k

12

k

RWD

k

51 (TTL logic convention

k

k

13

k

PLAY

k

:active "LOW")

k

k

14

k

STOP

k

y

k

k

15

k

N.C.

kk

k

16

k

5V

k

Maximum load:50mA

k

if On PIN No. and 2 a single-conductor shielded cable should be used.

-2-(Ver.1.0)

CONTENTS

TABLE OF CONTENTS

Section Title Page

1 GENERAL INFORMATION

1-1 System Descri tion

...................................................................

1-1

1 — 1 — (1 ) Ta e Trans ort .......................................................................... 1-2

1 — 1 — (2) Record/Re roduce Electronics .................................................. 1-4

1-2 Standard Accessories ................................................................ 1-5

1-3 O tional Accessories ................................................................ 1-5

1- 4 S ecifications .......................................................................... 1-6

2 INSTALLATION

2- 1 Un acking and Ins ection

.......................................................

2-1

2-2 Location and Environment

.......................................................

2-2

2-3 Dimensions ................................................................................. 2-3

2-4 Standard Switch Position on Shi ment

....................................

2-4

2-5 Power and Signal Connection

...................................................

2-5

2—5—(1 ) AC Power Connection .................................................................. 2-7

2— 5—(2) Signal Connections

...................................................................

2-8

3 OPERATION

3- 1 Controls and Indicators ........................................................... 3-1

3-2 O erating Information

..............................................................

3-11

3—2— (1 ) Using the Reel Hold Down Knobs ................................................. 3-11

3—2—(2) Pre-O erating Procedure ........................................................... 3-12

3—2—(3) Re roduction .............................................................................. 3-14

3-2-(4) Normal Recording ....................................................................... 3-14

3—2— C 5 ) Recording with Selective Re roduction

....................................

3-16

3—2— (6) Fast Winding .............................................................................. 3-17

3— 2—(7) Editing and S licing Ta e

.......................................................

3-18

4 GENERAL INFORMATION OF MAINTENANCE

4- 1 Test and Maintenance Equi ment Requirements ........................ 4-1

CONTENTS

5 ROUTINE MAINTENANCE AND CONVERSION INFORMATION

5-1 Routine Maintenance

.................................................................

5-1

5-1 -(1) Clean i ng ..................................................................................... 5-1

5-1-C2) Demagnetizing ............................................................................ 5-3

5—1 — (3) Lubrication ................................................................................ 5-4

5-2 Ta e Re lacement ....................................................................... 5-6

5-3 Equalizer Change ....................................................................... 5-6

5-4 Line Voltage Conversion

..........................................................

5-7

5- 5 Fuse Re lacement ....................................................................... 5-8

6 TAPE TRANSPORT MAINTENANCE

6- 1 Trans ort Access

.......................................................

.

.............. 6-1

6-2 Brake Adjustment ....................................................................... 6-2

6-3 Ca stan Pinch Roller Pressure Adjustment

.............................

6-5

6-4 Ta e S eed Adjustment .............................................................. 6-7

6-5 Ta e Trans ort Timing Chart .................................................... 6-8

6- 6 Recording Process Timing Chart

..............................................

6-9

7 PERFORMANCE TESTING AND ELECTRONIC ALIGNMENT

7- 1 General Notice

..........................................................................

7-1

7-2 Test Ta es

.................................................................................

7-1

7-3 Test Conditions

...................................................................

.

7-2

7-4 Performance Tests ..................................................................... 7-3

7—4 — (1) Overall SignaI-to-Noise ........................................................... 7-3

7—4—(2) Overall Distortion Test ........................................................... 7-5

7—4—(3) Crosstalk Test

...........................................

.

............................... 7-6

7-4-(4) Erasure Test .............................................................................. 7-7

7—4—(5) Ta e S eed Measurement ............................................................. 7-8

7 — 4— (6) Flutter and Wow Test

................................................................

7-9

7-5 Access to Electronics Assembly ............................................... 7-11

7-6 Electronic Alignment

................................................................

7-12

7-6-(1) Re roduce System ....................................................................... 7-12

7—6—(2) Re roduce Head Azimuth Adjustment

.........................................

7-13

7-6-(3) Frequency Res onse .................................................................... 7-15

7-6-(4) SRL (Re ro Level) Adjustment

..................................................

7-17

7 —6—(5) SEL/REP. Level Adjustment ........................................................ 7-17

7-6-(6) Record System

............................................................................

7-17

CONTENTS

7—6—(7 ) Record Head Azimuth Adjustment

..............................................

7-17

7-6-(8) Record Bias Adjustment

............................................................

7-18

7-6-(9) Overall Frequency Res onse

.....................................................

7-22

7—6—(10) Monitor In ut Level ana VU Meter Level Adjustment

...............

7-23

7—6—(11) Test OSC Level Adjustment ....................................................... 7-24

7—6—(12) Record Level Adjustment ........................................................... 7-25

7— 6—(13) Peak Indicator Trigger Level Adjustment ............................... 7-25

8 MAJOR COMPONENT REPLACEMENT

8- 1 Reel Motor Assembly Re lacement ............................................. 8-1

8—1 — (1) Reel Table Re lacement and Height Adjustment

........................

8-1

8-1-(2) Reel Motor Re lacement

................................

........................... 8-2

8-1-(3) Brake Arm Assembly and Brake Solenoid Re lacement

...........

8-3

8-2 Power Transformer Re lacement

................................................

8-4

8-3 Ca stan Motor Re lacement

.......................................................

8-4

8-4 Pinch Roller Re lacement ......................................................... 8-5

8-5 Head Assemb I y Re I acement

.......................................................

8-6

8—5—(1) Descri tion ................................................................................ 8-6

8-5-(2) Head Stack Re lacement

............................................................

8-7

8-5-(3) Record and Re roduce Head Adjustment

....................................

8-9

8— 5—(4) Erase Head Alignment ................................................................ 8-9

9 TROUBLESHOOTING

9- 1 Preliminary Procedures

............................................................

9-1

9- 2 Troubleshooting Hints .............................................................. 9-1

10 PARTS LISTS AND SCHEMATICS

10- 1 Safety Com onents ..................................................................... 10-2

10-2 Assembly Hardware Coding ...................................................... 10-3

10-3 Parts Lists and Ex loded View

................................................

10-4

10-4 Pin Identification

...................................................................

10-28

CONTENTS

LIST OF ILLUSTRATIONS AND TABLES

Figure Title Page

1- 1 MX-5050 MKH-4 Major Com onents .................................................. 1-3

2- 1 Dimensions

......................................................................................

2-3

2-2 MIC ATT ............................................................................................ 2-4

2-3 Adjusting Panel .............................................................................. 2-4

2- 4 In ut/Out ut Assembly Connector Wiring

......................................

2-9

3- 1 Reel Hold Down Knob ....................................................................... 3-12

3-2 Ta e Threading ................................................................................ 3-13

3-3 Ta e S licing Block ....................................................................... 3-18

5-1 Lifting the Head Cover .................................................................. 5-2

5-2 Demagnetizing

.................................................................................

5-4

5-3 Lubrication ..................................................................................... 5-5

5-4 Voltage Selection Terminal ........................................................... 5-7

5-5 Access for Line Voltage Conversion

...........................................

5-8

5-6 Main Power Fuse Location

..............................................................

5-9

5-7 Internal Fuse Location ................................................................... 5-10

5- 8 Rotating Control P.C.B.................................................................... 5-11

6- 1 Ta e Trans ort Access .................................................................... 6-1

6-2 Brake Measurement ........................................................................... 6-4

6-3 Brake Assembly Location

................................................................

6-4

6-4 Pinch Roller Pressure Measurement ............................................... 6-6

6-5 Pinch Roller Pressure Adjustment

................................................

6-6

6-6 Ca stan Servo Control P.C.B........................................................... 6-7

6-7 Control Timing Chart

.....................................................................

6-8

6- 8 Recording Process Timing Chart .................................................... 6-9

7- 1 Filter Schematics ........................................................................... 7-3

7-2 Test Ta e Loading ........................................................................... 7-9

7-3 Electronics Access ......................................................................... 7-12

7-4 Re roduce System Block and Level Diagram

.................................

7-13

7-5 Head Assembly .................................................................................. 7-14

7-6 Location of Record/Re roduce Electronics ................................... 7-16

7-7 Overall Frequency Res onse

...........................................................

7-19

7-8 Record System Block and Level Diagram

........................................

7-20

7-9 Bias Current v.s. Out ut and Distortion

....................................

7-20

CONTENTS

Figure Title Page

7-10 In ut v.s. Out ut and Distortion ................................................. 7-21

7-11 Location of Record/Re roduce Electronics

..................................

7-21

7- 12 Location of AMP. Control Electronics

.........................................

7-24

8- 1 Reel Motor Mounting ....................................................................... 8-1

8-2 Brake Assembly ................................................................................ 8-2

8-3 Location of DC Servo Ca stan Motor ............................................. 8-5

8-4 Pinch Roller Removal ..................................................................... 8-6

8-5 Head Assembly

.................................................................................

8-8

8- 6 Head Alignment ................................................................................ 8-8

Table Title Page

1-1 Standard Accessories

.....................................................................

1-5

1-2 O tional Accessories ..................................................................... 1-5

1- 3 S ecifications ................................................................................ 1-6

2- 1 Standard Switch Position on Shi ment

.........................................

2-4

2- 2 Rear Connector Panel .................................................................... 2-5

3- 1 Ta e Trans ort Controls and Indicators

.......................................

3-1

3- 2 Record/Re roduce Electronics Controls and Indicators

.............

3-7

4- 1 Test and Maintenance Equi ment .................................................... 4-1

4-2 Flutter Test Ta es ......................................................................... 4-2

4- 3 Re roduce Alignment Test Ta e ...................................................... 4-2

5- 1 Record Level ................................................................................... 5-6

5- 2 Fuse Information

............................................................................

5-10

6- 1 Braking Force S ecifications

.......................................................

6-3

7- 1 SignaI-to-Noise S ecifications .................................................... 7-4

7-2 Flutter and Wow S ecification ...................................................... 7-11

7-3 Equalizer Time Constants & Fluxivity .......................................... 7-16

7-4 Standard Level ................................................................................ 7-24

9- 1 Troubleshooting Hints for Am lifiers

.........................................

9-2

9-2 Troubleshooting Hints for Trans ort

...........................................

9-2

10-1 Safety Com onent ............................................................................. 10-2

SECTION 1

SECTION 1

GENERAL INFORMATION

The MX-5050 MK 1-4 Recorder is a rofessional quality two-s eed audio ta e

recorder/re roducer, designed for o timum erformance and long life.

It accommodates a 1/2-inch wide ta e and two 7 1/2 i s (19.05 cm/sec.) and

15 i s (38.1 cm/sec.) ta e s eeds.

1-1 SYSTEM DESCRIPTION

Among the many rofessional features of the MX-5050 M K i-4 are:

selective re roduction (SEL/REP), automatic motion sensing control

by a ro rietary micro rocessor, an edit control that ermits ta e

s illing, dynamic braking, an electronic ta e timer, an adjustable

cueing control for audible monitoring in fast forward and rewind, a

dual frequency bui 11-in test and cue-tone osci I lator, adjustable

record bias, equal ization ana level controls, XLR ty e connectors

for in ut and out ut lines, se arate line and micro hone in ut level

controls for each channel, a VU meter with a eak indicator for each

channel, selecting switches for in ut and out ut levels, and a

memory sto for automatically sto ing the ta e at a desired

osition exce t in record mode.

1-1

SECTION 1

1-1-(1) TAPE TRANSPORT

Al I com onents of the ta e trans ort system are mounted on a rigid

aluminium base for stability.

The trans ort design incor orates two 6- ole induction motors for the

ta e reels and a dc servo motor (Direct drive) for the ca stan.

A itch control is available to adjust the control range of the ta e

s eed within +7% of the nominal s eed for sound a lication.

The trans ort accommodates ta e reels of 10 1/2 inches in NAB hub

conf i gurat i ons.

In addition to the editing controls, a ta e-s licing block (Figure 3-

3) mounted on the head cover holds the ta e for easy editing,

cutting, and a lying s licing ta e.

Momentary contact ushbutton switches on the trans ort are used to

select o erational modes: record, lay, sto , rewind, fast forward,

and edit.

These modes exce t edit mode can be controlled from a remote location

by using an o tional remote control unit.

1-2

* Addenda * (MX-5050 BQ-2.MK-3-4,MK-3-8)

********* External Ca stan S eed Control *********

For a s ecial a lication such as interfacing with synchronizers or cont

rollers,an external ca stan s- eed control can be erformed to connecting them

to the "LOCATOR" connector located on the rear anel.

Ca stan s eed is controlled with the DC voltage (range:+-l3V) which is fed to

the "LOCATOR" connector PIN No.l and No.2.

Ca stan s eed continuously varies in ro ortion to DC voltage;

At the -13V of DC voltage,ca stan s eed is minimum.

At the 0V of DC voltage,ca stan s eed is nominal. (15,7-l/2i s)

At the 13V (+8V on 15 i s) of DC voltage,ca s tan s eed is maximum.

To erform external ca stan s eed control , roceed as follows.

1. Referring to SECTION 5-5 "FUSE REPLACEMENT of the manual ,ex ose the

Control P.C.B.

2. Position two DIP switches on the Control P.C.B.,SW-2 and SW-3,to

"NORMAL" and "EXT".

3. Referring to the Table-2 "Pin Assignment",solder res ective leads on

connector.mated with the "LOCATOR" connector.

Part No. of the mating connector : CN216203

4. Connect the equi ment to a synchronizer,or a controller.

Table-1 Control DC voltage and Ca stan s eed

★Nominal s eed tc Control DC voltage ★Ca stan s eed ★

★(i s) ★(V) ★(%) ★

★★-13 ★-60 ★

★15 ★0★0★

★★8 * ★+ 70 ★

★★-13 ★-60 ★

★7-1/2 ★0*0★

★★13 ★+210 ★

ff On 15i s,Ca stan s eed is limited at the value of DC 8V.

-1- (Ver.l.0)

Table-2 Pin assignment of the "LOCATOR" connector

*PIN No. *Descri tion ★Note ★

★1 # ★GND.F

k

GND of EXT. CONT ★

★2 # ★EXT.CONT

k

Ca stan s eed control ★

★

k k

DC voltage (range:+-13V)

k

k

3★CLOCK

k

Tach ulses

k

★*

k

(TTL logic convention)

k

★★

k

Frequency:40Hz at 15i s

k

★4★DIR.(Rev/Fwd)

k

Trans ort Direction

k

★★

k

(TTL logic convention)

k

5★N.C.

kk

★6

k

15 i s *V

k

k

7*7-1/2i s ★”Ta e s eed command

k

*8★(3-3/4i s) ★(24V/o en)

k

k

9

k

N.C.

kk

★10

k

RECORD

k

11 ★F.FWD ★Trans ort control ★

★12 ★RWD *> (TTL logic convention ★

★13 ★PLAY ★ractive "LOW") ★

k

14 ★STOP

k

★

k

15 ★N.C. ★

k

*16 ★5V ★Maximum load:50mA

k

§ On PIN No.1 and 2,a single-conductor shielded cable should be used.

-2- (Ver.1.0)

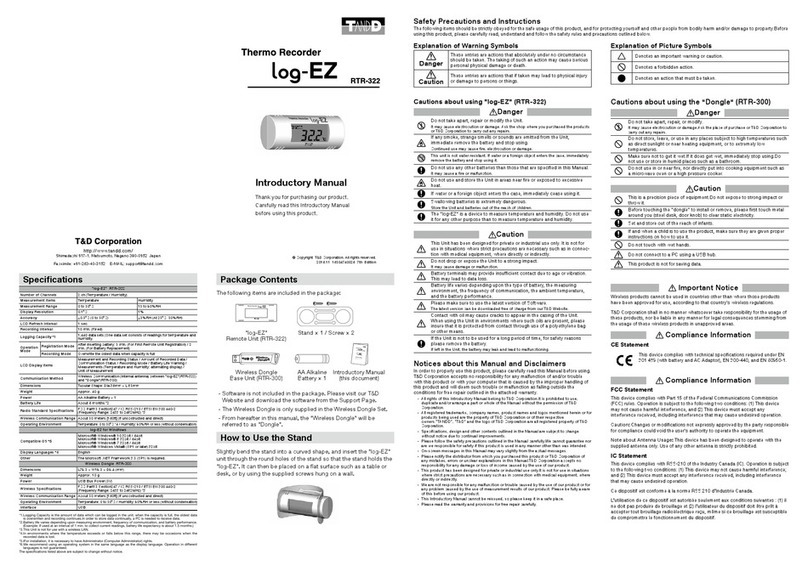

********** TAPE SPEED ADJUSTMENT **********

# Re lace the SECTION 6 "TAPE SPEED ADJUSTMENT" of the manual.

The ta e s eed can be adjusted by turning the s eed adjustment ots on the

Ca stan servo control P.C.B. which are turned for res ective ta e s eed,and

multi-turn ot (VR-1) on the control P.C.B. which govern all ta e s eeds.

This adjustment follows the "TAPE SPEED MEASUREMENT" in SECTION 7.

Note that the PITCH CONTROL should be laced in the "IN" fixed osition during

the ta e s eed adjustment.

For ta e s eed adjustment,referring Fig-1 and roceed as follows.

1. Referring to SECTION 5-5 "FUSE REPLACEMENT" of the manual,ex ose the

Control P.C.B.

2. Position two DIP switches on the Control P.C.B.,SW-2 and SW-3,to "TEST"

and "INT".

3. Adjust the ta e s eed by turning the s eed adjustment ots on the

Ca stan servo control P.C.B.

4. Position two DIP switches on the Control P.C.B.,SW-2 and SW-3,to "TEST"

and "EXT".

5. Adjust the ta e s eed at 15i s by turning multi-turn ot (VR-1) on the

Control P.C.B.

Adjustment for other ta e s eeds are not necessary.

At this oint,do not adjust the ta e s eed by turning the s eed adjust

ment ots on the Ca stan servo control P.C.B.

6. For normal o eration, osition two DIP switches on the Control P.C.B.

,SW-2 and SW-3,to "NORMAL" and "INT".

7. For external ca stan s eed control o eration, osition two DIP switches

on the Control P.C.B..SW-2 and SW-3,to "NORMAL" and "EXT".

-3- (Ver. 1.0)

Fig-1 Location of the ots and switches on the P.C.B.

CAPSTAN SERVO CCNTRGL P.C.30AR0

Ho

M

M : 7 1/2 i s

H : I 5 i s

SW-2 VR-1 SW-3

Issued by OTARI ELECTRIC ENGINEERING DIVISION

on 01/24/1982

-4- (Ver.1.0)

SECTION 1

Figure 1-1 MX-5050 MKn-4 Major Com onents

1-3

SECTION 1

1-1 -(2) RECORD/REPRODUCE ELECTRONICS

FEATURES

(1 ) The RECORD/REPRODUCE am lifier unit is interconnected to tne

trans ort unit by just the connectors.

(2) Available sound a lications are a SEL/REP. function for

overdubbing: SOUND WITH SOUND, SOUND ON SOUND, etc., carried out

by the PUNCH-IN and PUNCH-OUT functions of the trans ort

controI.

131 This machine rovides both in ut and out ut level switches,

selectable on the rinted circuit board.

(41 For o timum erformance corres onding to the ta e used, the

Record bias, level, and equalizer controls can be accurately

adjusted from the adjusting anel.

(5) Low frequency com ensation controls are rovided for ossible

accurate alignment of low frequency characteristics to meet the

ta e to be used.

1-4

Other manuals for MX-5050

3

This manual suits for next models

1

Table of contents

Other OTARI Voice Recorder manuals