OTC Tools 5292 User manual

© Bosch Automotive Service Solutions LLC

Sheet No.

Issue Date: Rev. B, April 28, 2014

Form No. 570918

Under Axle Jack

Max. Capacity: 27.5 Tons

655 Eisenhower Drive

Owatonna, MN 55060 USA

Phone: (507) 455-7000

Tech. Serv.: (800) 533-6127

Fax: (800) 955-8329

Order Entry: (800) 533-6127

Fax: (800) 283-8665

International Sales: (507) 455-7223

Fax: (507) 455-7063

Parts List &

Operating Instructions

for: 5292

No. 5292 Under Axle Jack is an air-operated lifting

device designed for jacking loaded trailers and trucks

using the manufacturer's recommended lift points on

the chassis.

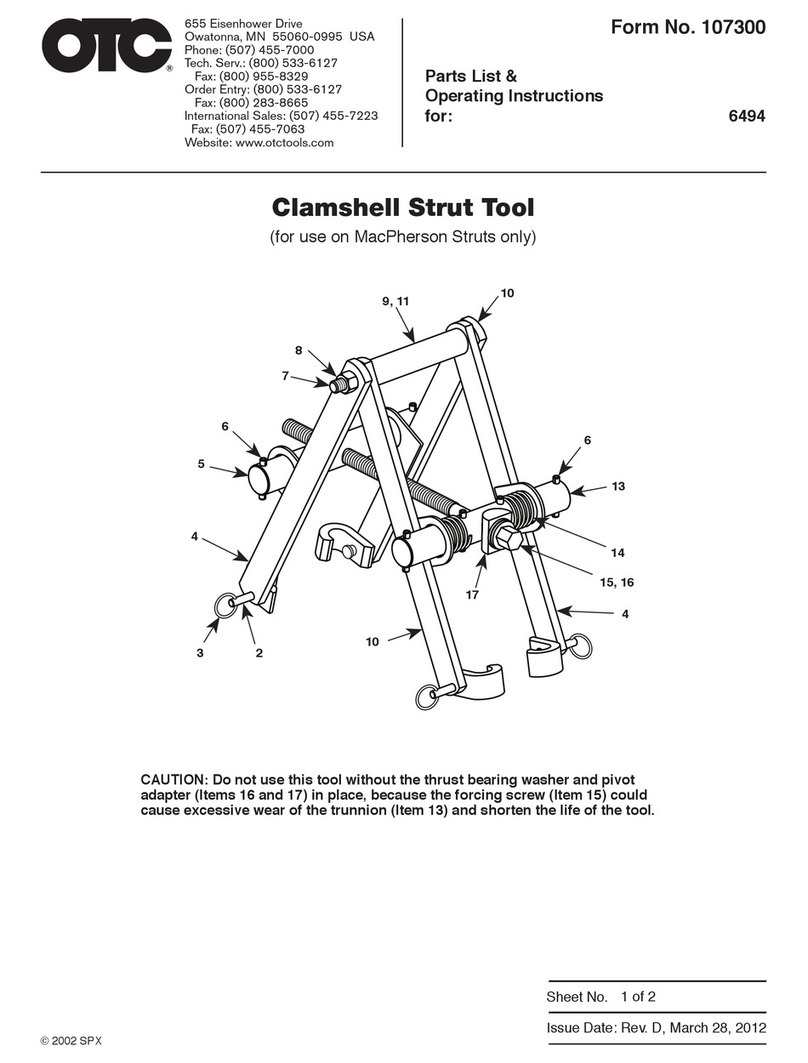

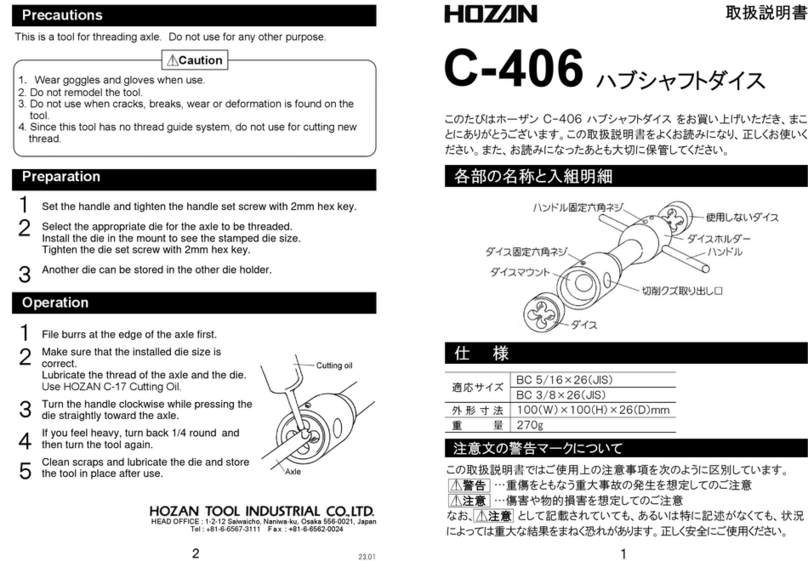

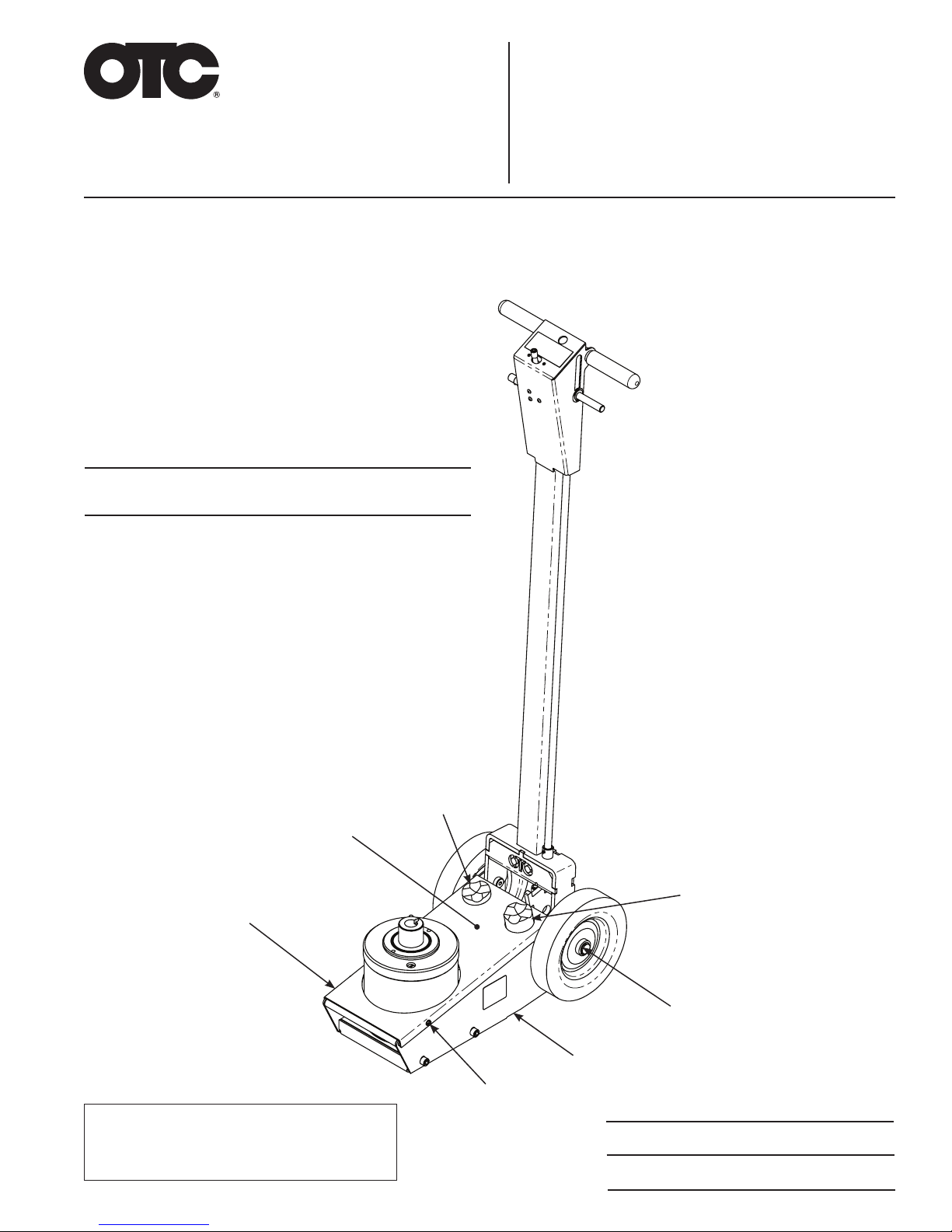

Item Part

No. No. Qty. Description

1 ì1 Tall Saddle

2 ì2 Retaining Ring

3 542068 1 Base

4 14456 2 Screw

(10-24 x .500; self-tapping;

apply Loctite

®

277

[or equivalent] and torque

to 30 ft. lbs.)

5 542073 1 Base Cover Plate

6 ì1Logo / Warning Decal

7 ì1 Short Saddle

1

2

3

4

5

6

1 of 5

7

Items marked with a star (ì) are

contained in replacement parts kits.

See sheet 3 of 5, back.

Parts List & Operating Instructions Form No. 570918, Sheet 1 of 5, Back

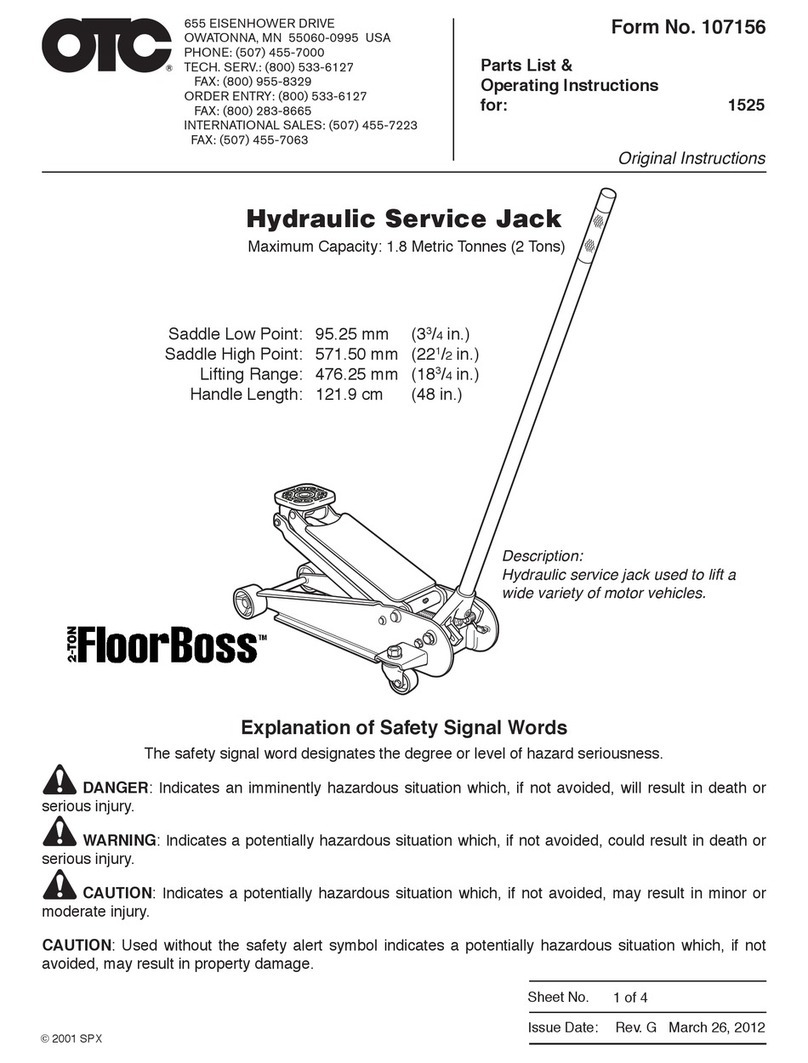

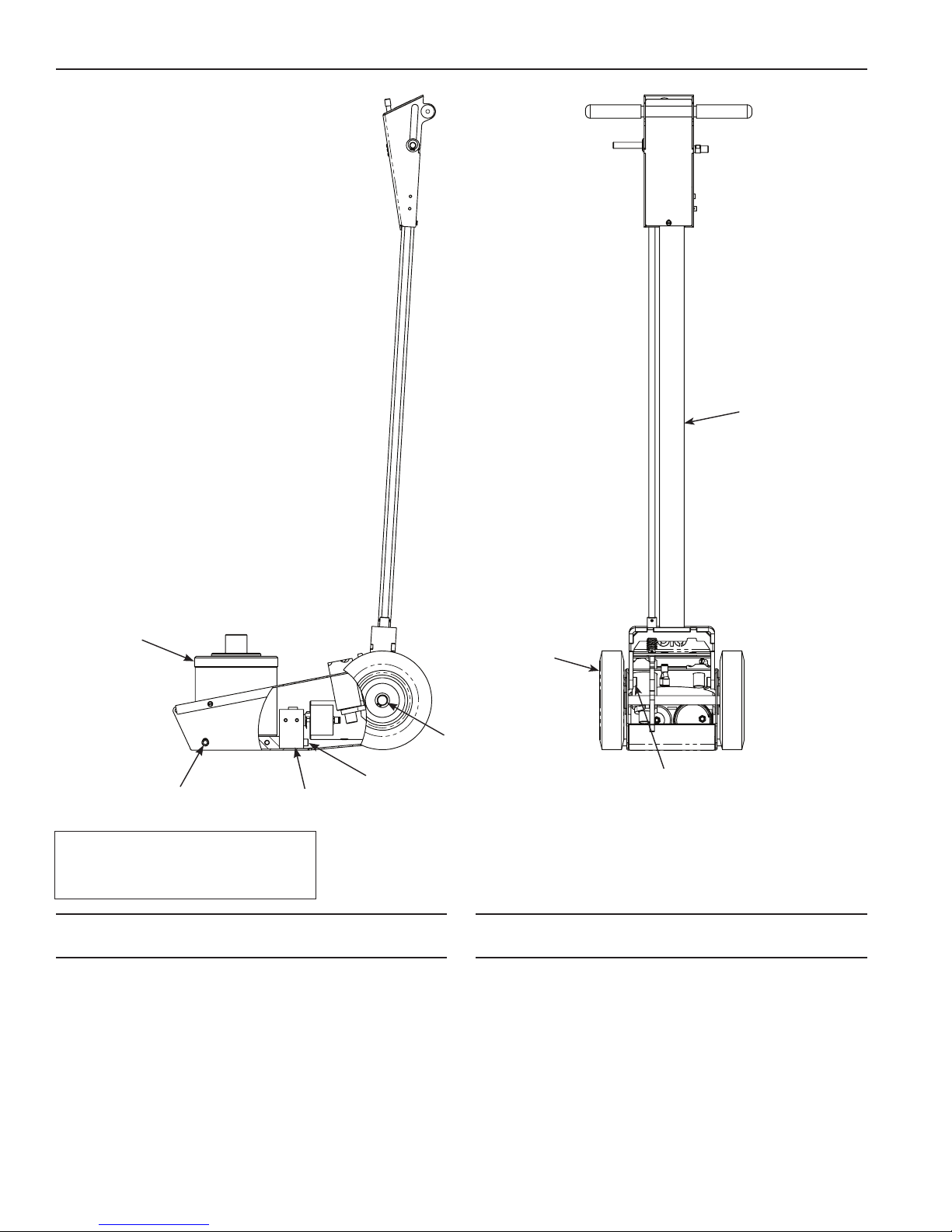

910

11

8

13

14, 15, 16, 17

18

Item Part

No. No. Qty. Description

8 542069 1 Hydraulic Assembly

9

ì

4 Socket Hd. Cap Screw (.375–16;

Apply Loctite®277 [or equivalent]

and torque to 30 ft. lbs.)

10 568052 1 Air Pump and Motor Assembly

(Assembly includes o-rings;

See parts list on sheet 3)

11

ì

2 Socket Hd. Cap Screw (.375–16;

Apply Loctite®277 [or equivalent]

and torque to 30 ft. lbs.)

12

ì

2 External Retaining Ring

13

ì

2 Wheel

14

ì

2 Shoulder Bolt

15

ì

4 Washer

16

ì

2 Lockwasher (3/8)

17

ì

2 Hex Nut (3/8-16)

18 570911 1 Handle Assembly

(parts list on sheet 2)

Parts included but not shown

554332 2 Warning Decal

Item Part

No. No. Qty. Description

Items marked with a star (ì) are

contained in replacement parts kits.

See sheet 3 of 5, back.

12

© Bosch Automotive Service Solutions LLC

Sheet No.

Issue Date: Rev. B, April 28, 2014

Parts List & Operating Instructions Form No. 570918

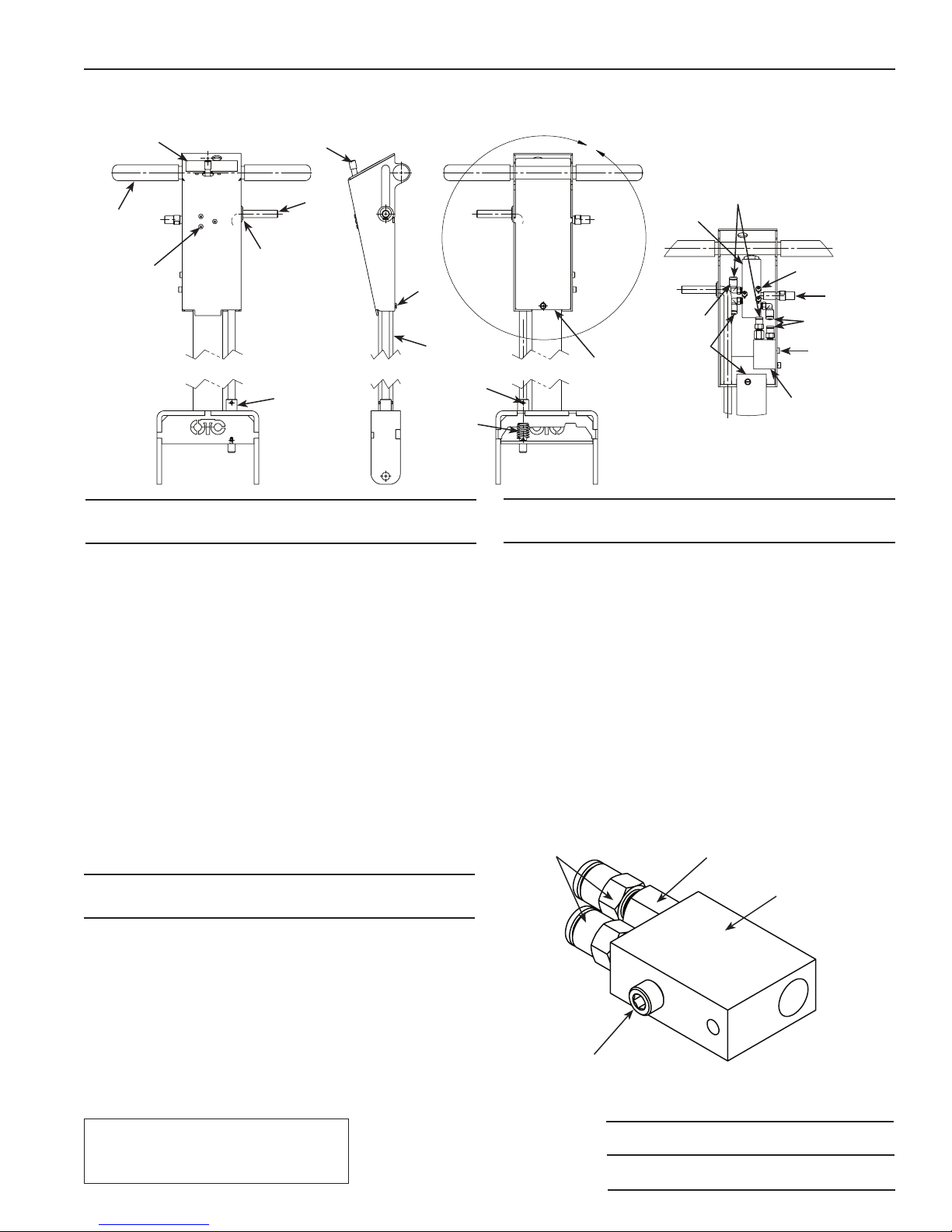

Item Part

No. No. Qty. Description

20 554333 1 Control Decal

21

ì

2 Handle Grip

22

ì

3 Button Hd. Cap Screw (8-32)

23 563599 1 Handle Adapter Pin

24

ì

1 Retaining Ring

25

ì

1 Washer (1/2")

26 542070 1 Handle Lock Rod

27 570914 1 Air Switch Knob

28

ì

1 Screw (10-24 x .500)

29 568399 1 Handle Weldment

30

ì

1 Compression Spring

31

ì

2 Roll Pin

32 542064 1 Cover Plate

33 555032 - Tubing (1092 mm length)

34

ì

3 Push-to-Connect Fitting

35 554112 1 Valve

36 555032 - Tubing (235 mm length)

37

ì

3 Locknut (M4 x .70)

38

ì

1 Nipple (.250 NPT x .125 NPT)

39

ì

- Tubing (63.5 mm length)

40

ì

1 Socket Hd. Cap Screw

41 553772 1 Vacuum Generator Assembly

(see parts list below)

Item Part

No. No. Qty. Description

No. 570911 Handle Assembly

2 of 5

x

DETAIL x

21

22

27

24, 25 37

20

34

23

26

28

29

32

35

39

40

38

No. 553772 Vacuum Generator Assembly

Item Part

No. No. Qty. Description

45 554113 2 Push-to-Connect Fitting

(8 mm)

46 566336 1 Venturi Nozzle

47

ì

1 O-ring (nitrile)

48 566335 1 Venturi Valve Block

50 554114 1 Socket Head Cap Screw

51

ì

1 O-ring (uoroelasomer)

46, 47

48

50, 51

45

31

30

Items marked with a star (ì) are

contained in replacement parts kits.

See sheet 3 of 5, back.

33

36

41

DETAIL X

NOTE: Wrap 555032 tubing with

570915 black air line tube to protect it

within the handle assembly.

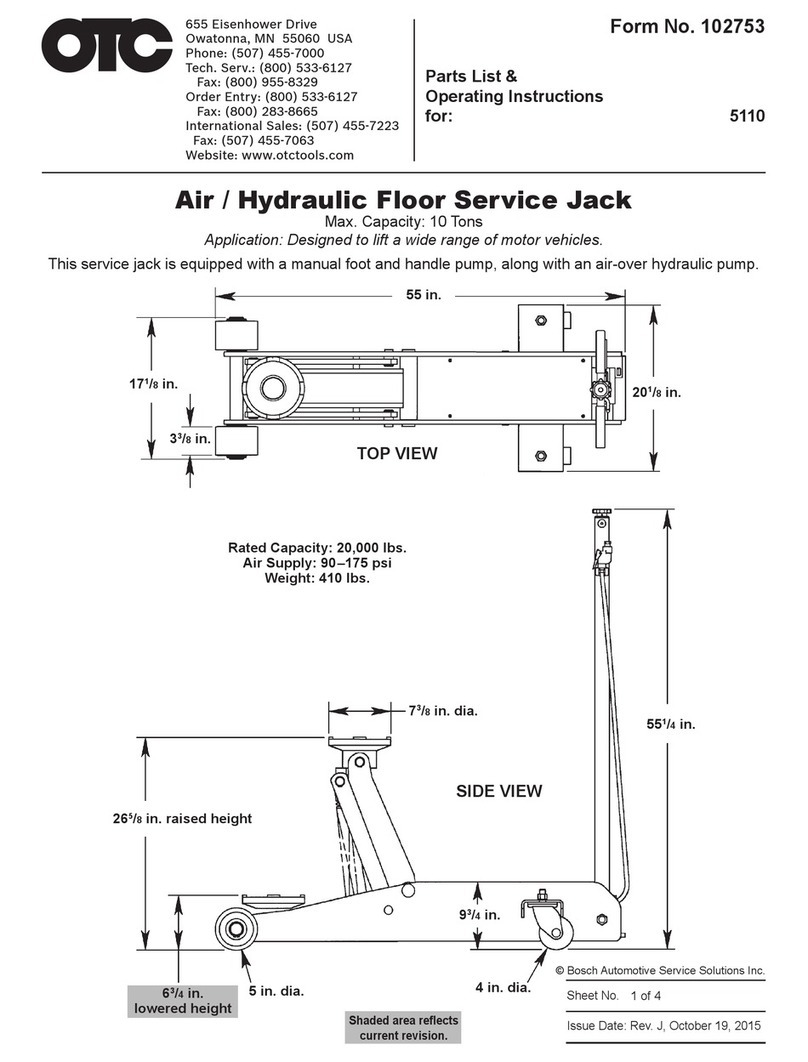

Parts List & Operating Instructions

No. 542069 Hydraulic Assembly

54

55

56

57

52, 53

58, 59

60

61

62

63

64

65

66

67, 68

Item Part

No. No. Qty. Description

52

ì

1 Fill Plug

53

ì

1 O-ring

54 548124 1 Reservoir Cap

55 542080 1 Base

56

ì

1 Push-to-Connect Fitting

57

ì

1 ExhaustMufer

58

ì

1 Screen Filter

59

ì

1 Filter Retainer

60

ì

1 Seal

61

ì

1 Wear Ring

62

ì

1 O-ring

63 558437 1 Piston Wear Ring

64

ì

1 U-cup

65 566495 1 Gland Nut

(torque to 100 ft-lbs)

66

ì

2 Seal

67

ì

1 Spring

68

ì

1 Dowel Pin

69 542085 1 Extension Screw

70 548123 1 Reservoir Tube

71 542084 1 Piston

72

ì

1 O-ring

73

ì

1 External Retaining Ring

Item Part

No. No. Qty. Description

Form No. 570918, Sheet 2 of 5, Back

69

71

66

70

73

Items marked with a star (ì) are

contained in replacement parts kits.

See sheet 3 of 5, back.

72

© Bosch Automotive Service Solutions LLC

Sheet No.

Issue Date: Rev. B, April 28, 2014

Parts List & Operating Instructions Form No. 570918

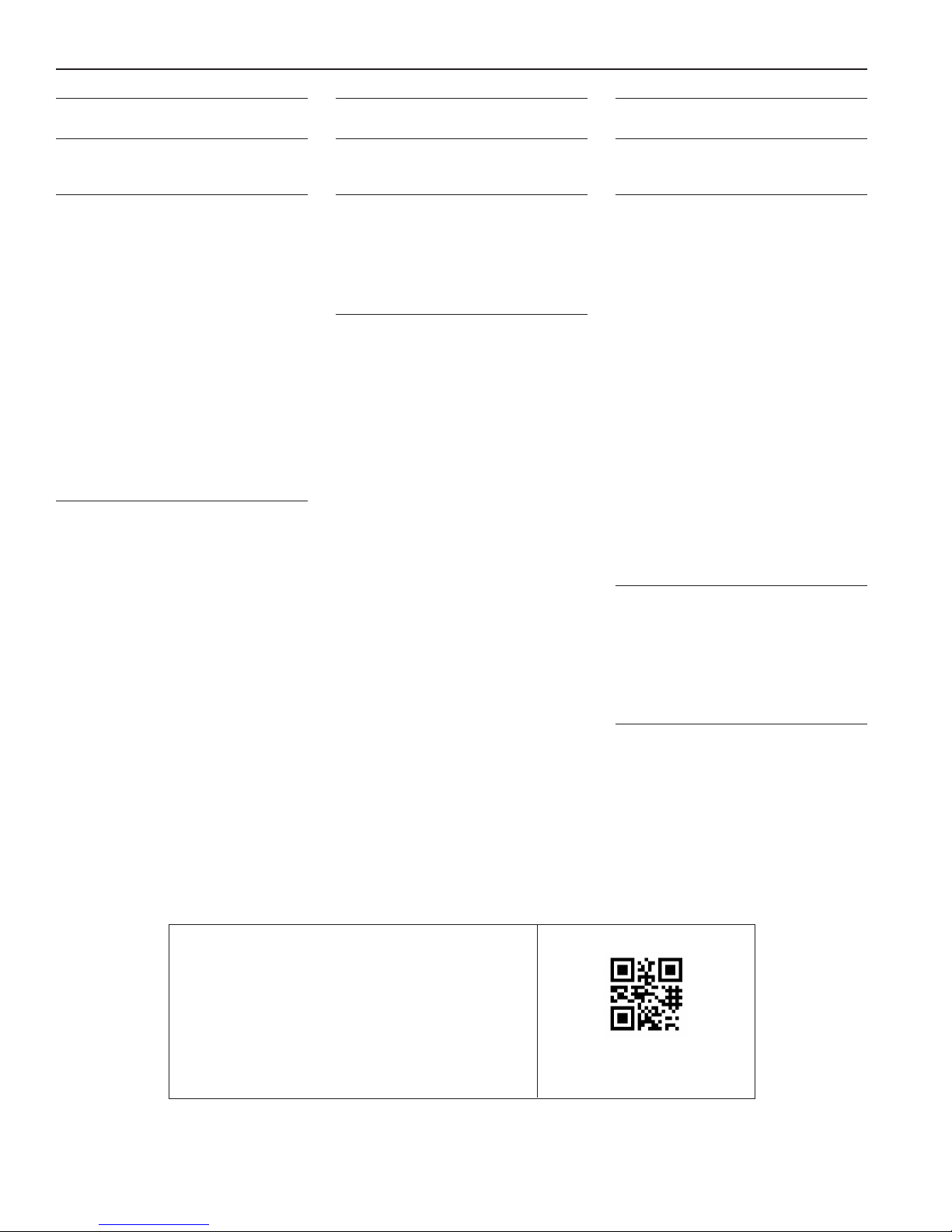

Item Part

No. No. Description

74 555014 Block Assembly

75 555016 Air Motor

76 555017 Air Motor Plunger Assembly

77 572561 Release Valve

k555018 Air Motor Seal Kit

3 of 5

No. 568052 Air Motor Assembly

75

74

75

77

76

77 74

k

k

k

k

k

k

k

k

k

k

k

Parts List & Operating Instructions

Item

No. Qty. Description

No. 563502

Fastener Kit

9 4 Socket Hd. Cap Screw

(.375–16)

11 2 Socket Hd. Cap Screw

(Loctite®; torque to 30 ft.lbs.)

14 2 Shoulder Bolt

15 6 Washer

16 2 Lockwasher (3/8)

17 2 Hex Nut (3/8-16)

22 3 Button Hd. Cap Screw (8-32)

25 1 Washer (1/2 in.)

34 3 Screw (10-24 x .500)

No. 563503

Handle Hardware Kit

34 3 Push-to-Connect Fitting

37 3 Locknut (M4 x .70)

38 1 Nipple

(.250 NPT x .125 NPT)

33 6.5 ft. Tubing

36

39

40 1 Socket Hd. Cap Screw

No. 563504

Handle Grip Kit

21 2 Handle Grip

No. 563505

Hardware Kit

1 Warning Decal

2 2 Retaining Ring

6 1 Logo / Warning Decal

24 1 Retaining Ring

30 1 Spring

31 2 Roll Pin

67 1 Spring

68 1 Dowel Pin

1 Y-tting

No. 563506

Seal Repair Kit

2 O-ring

47 1 O-ring (nitrile)

51 1 O-ring (uoroelasomer)

52 1 Fill Plug

53 1 O-ring

56 1 Push-to-Connect Fitting

57 1 ExhaustMufer

58 1 Screen Filter

59 1 Filter Retainer

60 1 Seal

61 1 Wear Ring

62 1 O-ring

64 1 U-cup

66 2 Seal

72 1 O-ring

73 1 External Retaining Ring

No. 563507

Saddle Kit

1 1 Tall Saddle

7 1 Short Saddle

No. 563508

Wheel Repair Kit

12 2 Retaining Ring

13 2 Wheel

Item

No. Qty. Description

Item

No. Qty. Description

Form No. 570918, Sheet 3 of 5, Back

This document contains product parts lists as well as

information regarding operation and maintenance.

Items listed in the parts list have been carefully tested

and selected by OTC.

Therefore: Use only OTC replacement parts.

Product questions may be directed to the OTC Technical

Services Department at (800) 533-6127. Get parts at OTCparts.com.

© Bosch Automotive Service Solutions LLC

Sheet No.

Issue Date: Rev. B, April 28, 2014

Parts List & Operating Instructions Form No. 570918

Assembly and Setup

1. Remove the wheels from the jack, leaving the spacer washers in place.

2. Using the hardware supplied, assemble the handle to the jack base.

3. Place the wheels back onto the wheel shaft. Verify the wheels do not rub on the frame and secure in place

with a snap ring.

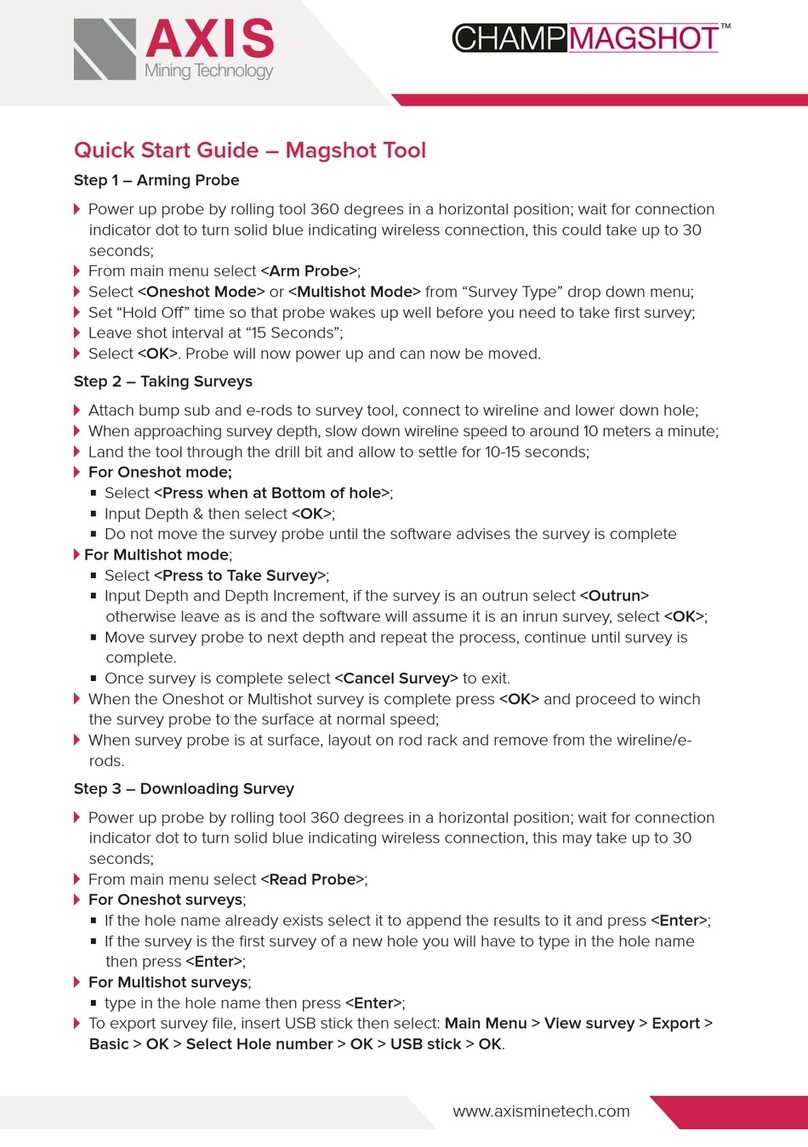

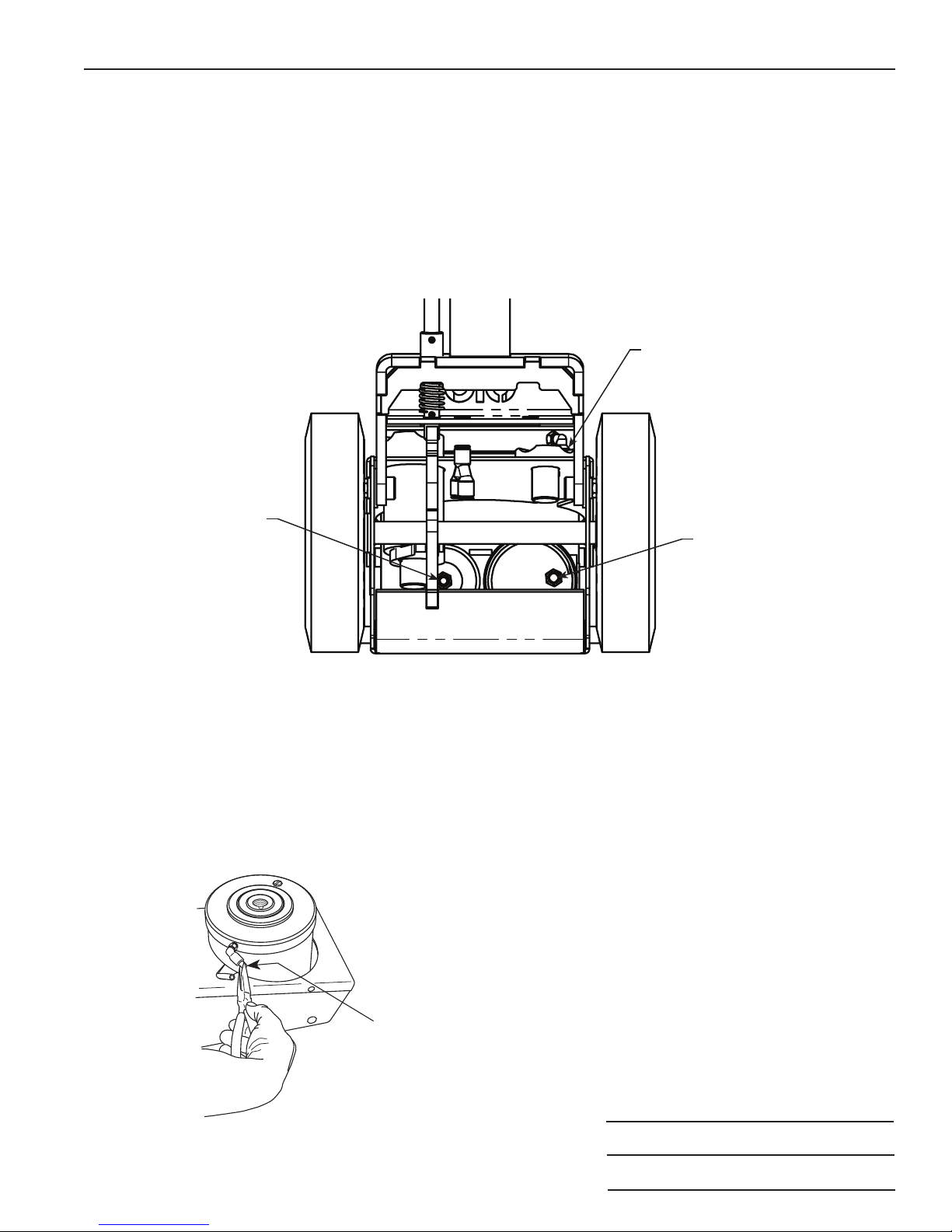

4. Connect the hoses as shown in Figure 1.

Figure 1

View from back of jack

Connect end of blue

hose from Y tting here.

Connect end of blue

hose from Y tting

here.

Connect black hose

from handle here.

5. Refer to Figure 2 and the following steps to connect the hydraulic assembly.

•Locatethettingonthehydraulicassembly.

•Pullthettingcollarbackandremovethepin.

• Connect the blue hose from the air motor.

Figure 2

Remove pin

4 of 5

Parts List & Operating Instructions

Safety Precautions

CAUTION: To prevent personal injury and damage to equipment,

•Study, understand, and follow all instructions before operating this device.

•Wear protective eyewear that meets the requirements of ANSI Z87.1 and OSHA.

•Do not exceed the rated capacity of the jack.

•Use the jack only on a hard, level surface.

•This jack is a lifting device only. Immediately after lifting, support the vehicle with

appropriate means.

•Do not move or dolly the vehicle while it is on the jack.

• Lift only on areas of the vehicle as specied by the vehicle manufacturer.

•No alterations shall be made to this product.

Operating Instructions

1. Lubricate the air inlet on the jack with 1/2 oz. clean lubricating oil; lack of oil can cause pump

malfunction.

2. Connect the air supply. (90 – 120 psi of clean, dry air is required for the capacity of this jack.)

3.Setthevehicle’sparkingbrakesand/orblockthewheels.

4.Positionthejackunderthevehicleatthevehiclemanufacturer’srecommendedliftingpointonthechassis.

5. Move the air valve lever to the right to raise the jack saddle until it touches the vehicle. Check the placement

of the saddle lugs. Finish lifting the vehicle.

6. Place approved safety stands under the vehicle at points that will provide stable support. Before making

repairs, lower the vehicle onto the safety stands by moving the air valve lever to the left to retract the

cylinder. Note: Keep the air supply attached to the jack.

Bleeding Air from the Under Axle Jack

Air can accumulate within a hydraulic system during shipment or after prolonged use. This entrapped air

causes the jack to respond slowly or feel “spongy.” To remove the air:

1. Connect the air supply to the jack.

2. Move the air valve lever to the left until the cylinder is fully retracted.

3. Move the air valve lever to the right until the cylinder is fully extended.

4.Repeatsteps2–3veormoretimes.

Form No. 570918, Sheet 4 of 5, Back

© Bosch Automotive Service Solutions LLC

Sheet No.

Issue Date: Rev. B, April 28, 2014

Parts List & Operating Instructions Form No. 570918

Preventive Maintenance

Important: The greatest single cause of failure in hydraulic units is dirt. Keep the under axle jack clean

and well lubricated to prevent foreign matter from entering the system. If the jack has been exposed

to rain, snow, sand, or grit, it must be cleaned before it is used.

1. Store the jack in a well-protected area where it will not be exposed to corrosive vapors, abrasive dust, or

any other harmful elements.

2. Regularly lubricate the moving parts.

3. Replace the oil in the reservoir at least once per year. To check the oil level, disconnect the air supply, place

theunderaxlejackonlevelground,andcompletelyretracttheram.Removethellerplug/dipstick,wipe

it clean, and reinstall it, threading it in all the way. Remove the dipstick again and note the oil level. The oil

level should be between the two marks on the dipstick. Add or remove approved anti-wear hydraulic jack

oil as needed, and install the dipstick. CAUTION: The use of alcohol, hydraulic brake uid, detergent

motor oil, or transmission oil could damage the seals and result in jack failure.

4. Inspect the jack before each use. Take corrective action if any of the following problems are found:

a. Cracked or damaged housing d. Scored or damaged piston rod

b. Excessive wear, bending, or other damage e. Loose hardware

c.Leakinghydraulicuid f.Modiedoralteredequipment

Troubleshooting Guide

Repairproceduresmustbeperformedinadirt-freeenvironmentbyqualiedpersonnelwhoarefamiliar

with this equipment.

Trouble Cause Solution

Erratic action 1. Air in system.

2. Oil viscosity too high.

3. Internal leakage in cylinder.

4. Cylinder sticking or binding.

1. Follow the instructions in this document, "Bleeding

Air from the Under Axle Jack".

2. Change to a lower viscosity oil.

3. Replace worn packings. Look for excessive

contamination or wear.

4. Look for dirt, gummy deposits, or leaks. Check for

misalignment, worn parts, or defective packings.

Jack does not lift 1. Low / no oil in reservoir.

2. Air-locked system.

3. Load is above capacity of jack.

4. Delivery valve and / or bypass valve not

working correctly.

5. Packing worn out or defective.

1. Fill with oil and bleed system.

2. Follow the instructions in this document, "Bleeding

Air from the Under Axle Jack".

3. Use correct equipment.

4. Clean to remove dirt or foreign matter. Replace oil.

5. Replace power unit.

Jack lifts only partially 1. Not enough oil. 1. Check oil level.

Jack advances slowly 1. Low air pressure.

2. Seals are leaking.

3. Pump not working correctly.

1. Adjust air pressure to 90–175 psi.

2. Take jack to OTC authorized service center for repair.

3. Take jack to OTC authorized service center for repair.

Jack lifts load, but does not hold 1. Cylinder packing is leaking.

2. Valve not working correctly (delivery,

release, or bypass).

3. Air-locked system.

1. Replace seals.

2. Take jack to OTC authorized service center for repair.

3. Bleed system.

Jack leaks oil 1. Worn or damaged seals. 1. Take jack to OTC authorized service center for repair.

Jack will not retract 1. Release valve is closed. 1. Open or clean release valve.

Jack retracts slowly 1. Cylinder damaged internally. 1. Take jack to OTC authorized service center for repair.

Sound of air leaking when lever is

in retract position.

1. This is normal.

5 of 5

Table of contents

Other OTC Tools Tools manuals