OTC Tools 5110 User manual

Sheet No.

Issue Date: Rev. J, October 19, 2015

© Bosch Automotive Service Solutions Inc.

Form No. 102753

Parts List &

Operating Instructions

for: 5110

1 of 4

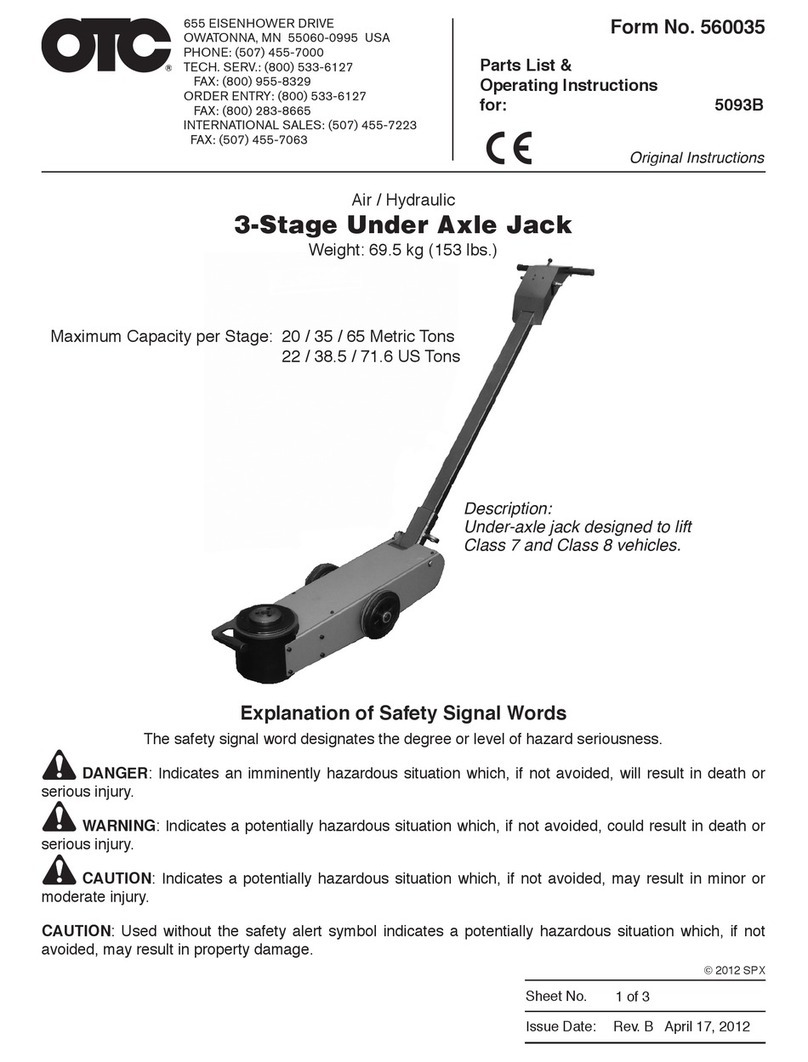

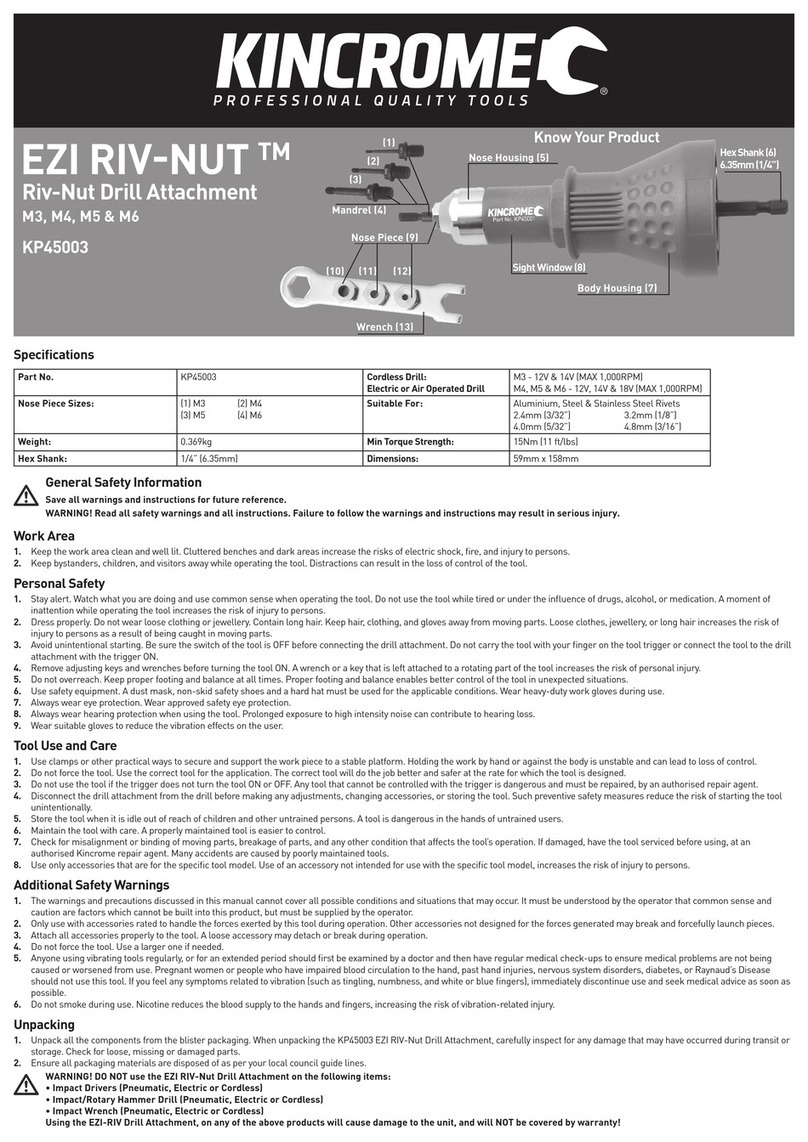

Air / Hydraulic Floor Service Jack

Max. Capacity: 10 Tons

Application: Designed to lift a wide range of motor vehicles.

This service jack is equipped with a manual foot and handle pump, along with an air-over hydraulic pump.

Rated Capacity: 20,000 lbs.

Air Supply: 90–175 psi

Weight: 410 lbs.

55 in.

73/8in. dia.

265/8in. raised height

63/4in.

lowered height

5 in. dia.

93/4in.

4 in. dia.

551/4in.

201/8in.

33/8in.

171/8in.

655 Eisenhower Drive

Owatonna, MN 55060 USA

Phone: (507) 455-7000

Tech. Serv.: (800) 533-6127

Fax: (800) 955-8329

Order Entry: (800) 533-6127

Fax: (800) 283-8665

International Sales: (507) 455-7223

Fax: (507) 455-7063

Website: www.otctools.com

TOP VIEW

SIDE VIEW

Shaded area reects

current revision.

Parts List & Operating Instructions Form No. 102753, sheet 1 of 4, back

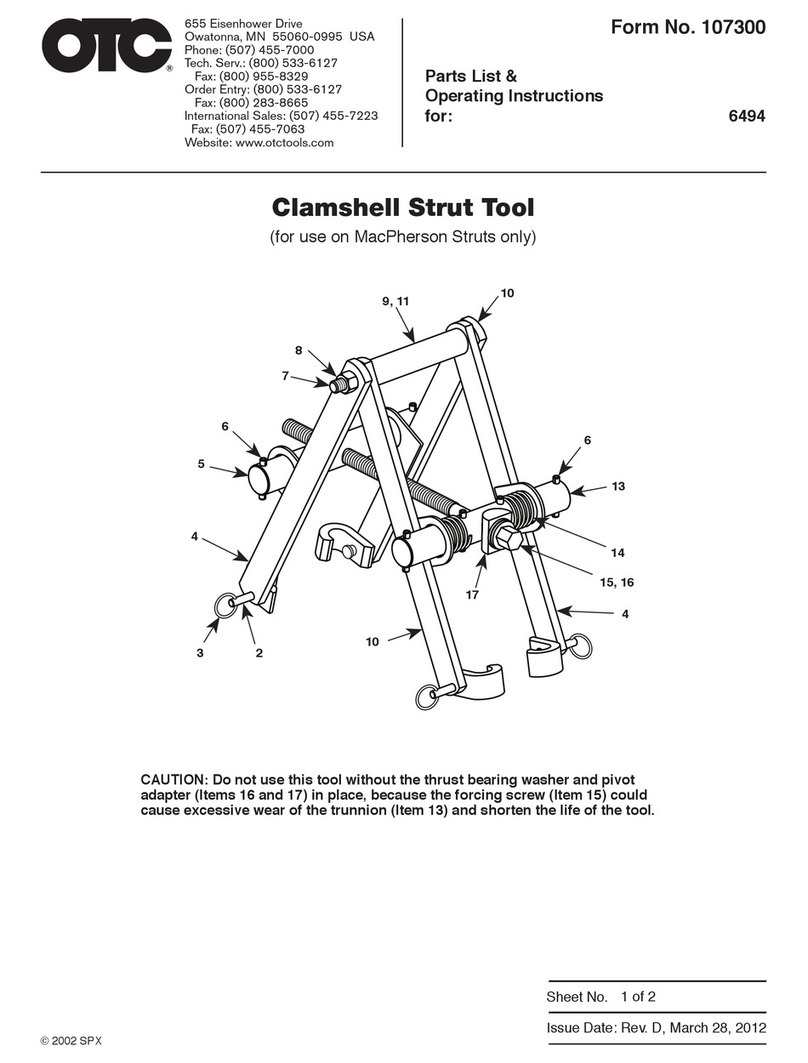

23

29

30, 8

31

32

33

35 36 37 38

39, 40

26, 27

27, 28

41

A

A

24

26, 27

25

28

25

24

View A-A

42

SIDE VIEW

1, 2, 3 45 6, 7 89 10

11, 7

12

13

14

15

16 17 18 19 20

21, 22

3

1

41

TOP VIEW

43

44

Sheet No.

Issue Date: Rev. J, October 19, 2015

© Bosch Automotive Service Solutions Inc.

1 5110-01 4 External Retaining Ring (11/2 in. dia.)

2 5110-02 2 Flat Washer (11/2 x 14 ga.)

3 5110-03 4 Flanged Bearing (1.5 x 1.625 x 1.5)

4 5110-04 2 Roll Pin (5/16 in. dia.; 2 in. lg.)

5 5110-05 2 Leveling Link

6 5110-06 8 Hex Nut (5/8-11 UNC)

7 5110-07 10 Lockwasher (5/8in. dia.)

8 5110-08 4 External Retaining Ring (1 in. dia.)

9 5110-09 1 Roll Pin (3/16 in. dia. x 2 in. lg.)

10 5110-10 4 Pan Hd. Screw (10-32 UNC x 1/2in. lg.)

11 5110-11 2 Cap Screw (5/8-11 UNC x 11/2in. lg.)

12 5110-12 2 Swivel Caster (4 in. dia.; steel wheel)

13 5110-13 1 Frame Weldment (RH)

14 5110-14 2 Wheel and Grease Fitting Subassembly

15 5110-15 1 Front Axle

16 5110-16 1 Lift Pad Retainer

17 5110-17 4 Threaded Shaft (3/4in. dia.)

18 5110-18 1 Top Cover

19 5110-19 1 Frame Rail Weldment (LH)

20 5110-20 2 Special Nut

21 5110-21 2 Hex Nut (3/4-10 UNC)

22 5110-22 2 Split Lockwasher (3/4in. external tooth)

23 5110-23 1 Handle Subassembly

24 5110-24 1 Pump Pivot Link Weldment

25 5110-25 2 Pump Link

26 5110-26 1 Rear Pin Pump Link

27 5110-27 4 Heavy Duty External Retaining Ring (7/16 in. dia.)

28 5110-28 1 Front Pin Pump Link

29 5110-29 1 Lift Pad

30 5110-30 1 Lift Pad Pivot Shaft

31 5110-31 1 Spring (115/32 in. dia. x 12.5 in. lg.)

32 5110-32 1 Lift Pad Bracket Weldment

33 5110-33 1 Front Pin Leveling Link

35 5110-35 1 Power Unit

36 5110-36 1 Flex Shaft

37 5110-37 2 Spring (15/16 in. O.D.)

38 5110-38 1 Roll Pin (3/16 in. dia. x 3/4in. lg.)

39 5110-39 1 Cap Screw (3/4-10 UNC x 9.5 in. lg.; grade 8)

40 5110-40 1 Hex Nut (3/4-10 UNC)

41 5110-41 2 Grease Fitting (3/16 in. drive)

42 5110-42 1 Foot Pump Pivot Weldment

43 525394 1 Air Motor Assembly

44 531439 1 Air Hose with Fittings

223119 1 Optional — Seal Repair Kit to Service Pump/Ram

518087 1

Optional — Seal Repair Kit (Use on jacks with a

serial no. of 78-003914 and higher. Use also on

power units purchased in November, 2002, and later.)

Parts List & Operating Instructions Form No. 102753

Description

Item

No.

Part

No.

No.

Req'd

2 of 4

Parts List & Operating Instructions Form No. 102753, sheet 2 of 4, back

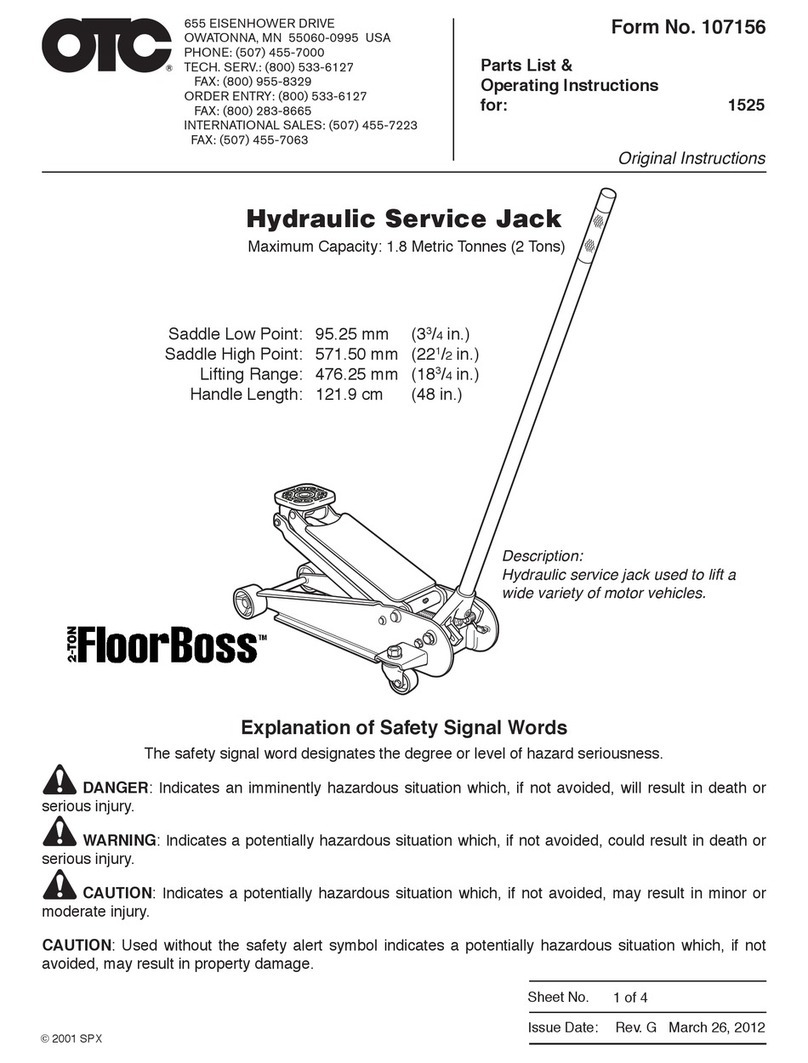

518087 Seal Repair Kit

Hydraulic Unit

525394 Air Motor Assembly

13 4 5

26

7

5

1

3 4 5

23

1 Seal,

5/8in. O.D. x 3/8in. I.D. x 1/4in. Type B

2 Back-up Ring, 15/16 in. x 3/4in. x .040 in. Thick

3 Back-up Ring, 33/4in. x 3/8in. x .055 in. Thick

4 Seal, 21/2in. I.D. x 31/4in. O.D. x 3/8in.

5 O-ring, 5 in. I.D. x 51/4in. O.D. x 1/8in. CS

6 Quad Seal, 2 in. I.D. x 23/8in. O.D. x 3/16 in. CS

7 O-ring,

7/16 in. I.D. x 5/16 in. O.D. x 1/16 in. CS

Item

No. Description

1 Seal, Shuttle Valve

2 O-ring, 2 1/4in. x 1/16 in. x 21/8in.

3 Quad Ring, 3 in. O.D. x 25/8in. x 3/16 in.

4 Seal, 11/4in. O.D. x 1 in. I.D. x 1/8in. W

5 Seal, .277 in. I.D. x .528 in. O.D. x .188 in. Type B

6 Spring (This spring may be ordered separately

under No. 525198.)

Item

No. Description

6

Sheet No.

Issue Date: Rev. J, October 19, 2015

© Bosch Automotive Service Solutions Inc.

Safety Precautions

Caution: To prevent personal injury and damage to equipment,

•Study, understand, and follow all instructions, including ASME PALD Part 10 for service

jacks.

•If the operator cannot read these instructions, operating instructions and safety

precautions must be read and discussed in the operator’s native language.

•Before using the service jack to lift a vehicle, refer to the vehicle service manual to

determine recommended lifting surfaces on the vehicle chassis.

•Wear eye protection that meets ANSI Z87.1 and OSHA standards.

•Inspect the jack before each use; do not use the jack if it’s damaged, altered, or in poor

condition. Take corrective action if any of the following conditions are found: cracked

or damaged housing; excessive wear, bending, or other damage; leaking hydraulic

uid; scored or damaged piston rod; loose hardware; modied or altered equipment.

•A load must never exceed the rated lifting capacity of the jack.

•Only use the jack on a hard, level surface.

•Use the jack for lifting purposes only. Stay clear of a lifted load. Place support stands

under the axles before working on the vehicle.

•Center the load on the jack saddle. Off-center loads can damage seals and cause jack failure. Lift

only dead weight.

•Do not use blocks or other extenders between the saddle and the load being lifted.

•

Do not modify the jack or use adapters unless approved or supplied by OTC. Do not adjust the safety

valve.

•Lower the jack slowly and carefully while watching the position of the jack saddle.

• Use only approved hydraulic uid (Mobil DTE #11 or equivalent). The use of alcohol, hydraulic brake

uid, or automatic transmission uid (ATF) could damage seals and result in jack failure.

This guide cannot cover every situation, so always do the job with safety rst.

Operating Instructions

1. Connect the shop air supply to the jack. (90–175 psi of clean, dry air is required for the capacity of this

jack.)

2. Position the jack under the vehicle using the manufacturer’s recommended lifting points on the chassis.

3. Close the release valve by turning the knob clockwise (CW) as far as it will go.

4. Press the air valve lever to raise the jack saddle until it touches the vehicle.

5. Check the placement of the jack; the load must be centered on the jack saddle. CAUTION: Avoid wheel

obstructions such as gravel, tools, or uneven expansion joints. The jack must be free to roll forward

11 inches during lifting, and backward 11 inches during lowering. The load could become unstable,

or even fall off the saddle, if the rolling movement of the jack is impaired.

6. Finish lifting the vehicle.

7. Place approved support stands under the vehicle at points that will provide stable support. Before making

repairs on the vehicle, lower it onto the support stands by SLOWLY and carefully turning the release knob

counterclockwise (CCW).

3 of 4

Parts List & Operating Instructions Form No. 102753

Preventive Maintenance

CAUTION: The greatest single cause of failure in hydraulic units is dirt. Keep the service jack clean and

well lubricated to prevent foreign matter from entering the system. If the jack has been exposed to rain, snow,

sand, or grit, it must be cleaned before it is used.

1. Store the jack in a well-protected area where it will not be exposed to corrosive vapors, abrasive dust, or

any other harmful elements.

2. Lubricate rotating and sliding parts at least once per month.

3. Lubricate the air inlet on the jack using 1/2 oz. clean lubricating oil; lack of oil may cause pump malfunction.

4.Greasethejackonceamonthusingagoodbearinggrease.(Therearegreasettingslocatedonthepivot

tube of the lift arm, the block on the rod end of the cylinder, and on all four wheels of the jack.)

5. Keep warning labels and instructional decals clean and readable. Use a mild soap solution to wash the

external surfaces of the jack.

6. Replace the oil in the reservoir at least once per year.

7. Inspect the jack before each use. Take corrective action if any of the following problems are found:

a. Cracked or damaged housing d. Scored or damaged piston rod

b. Excessive wear, bending, or other damage e. Loose hardware

c.Leakinghydraulicuid f. Modiedoralteredequipment

Adding Hydraulic Fluid

1. Remove the jack from service, and place it on a level surface.

2. Lower the lift arm completely.

3. Disassemble the top cover by removing the four pan head screws.

4.Cleanaroundthesurfaceoftheoilllplug;thiswillhelppreventcontaminationofthehydraulicoilsystem.

5.Removetheoilllplug,andcheckthehydraulicoillevel.Theuidshouldbevisibleandjustcoveringthe

hydrauliccylinder.Iftheuidlevelislow,addahigh-gradehydraulicuidequivalenttoMobilDTE#11until

the oil level just covers the cylinder.

6.Installtheoilllplug.Cleanupanyspilledoil,andsecurethetopcoverbackontotheframe.

7. Test the jack for normal operation. If the lift pad doesn’t rise to the correct height, repeat Steps 2–6, adding

two more ounces of oil. If this doesn’t solve the problem, call the OTC Technical Services Dept.

Parts List & Operating Instructions Form No. 102753, sheet 3 of 4, back

Sheet No.

Issue Date: Rev. J, October 19, 2015

© Bosch Automotive Service Solutions Inc.

Troubleshooting Guide

Repairproceduresmustbeperformedinadirt-freeenvironmentbyqualiedpersonnelwhoarefamiliarwith

this equipment. CAUTION: All inspection, maintenance, and repair procedures must be performed when

the jack is free of a load (not in use).

Trouble Cause Solution

Failure to lift a load

Failure to hold a load

Air motor won’t run, or runs

erratically

Reservoir leaks

1. Low oil level

2. Air line leaks.

3. Inadequate air pressure.

4. Release knob open.

5. Jack is overloaded.

1. Release knob not closed.

1. Leak in air line.

2. Air piston is sticking.

3. Inadequate air pressure.

1.Looseoilllplug.

2.Reservoirisoverlled.

1. Refer to the section Adding

Hydraulic Fluid.

2. Locate leak, tighten connections,

and/or replace hose.

3. Set air pressure at 90–175 psi.

4. Close release knob.

5. Use equipment that has the

correct capacity for the job.

1. Turn release knob clockwise to

tighten securely.

1. Locate leak, tighten connections,

and/or replace hose.

2. Add small amount of oil to jack’s

air inlet to lube air motor.

3. Set air pressure at 90 –175 psi.

1.Tightenoilllplug.

2. Drain some oil from reservoir.

4 of 4

Parts List & Operating Instructions Form No. 102753

This page intentionally left blank.

Table of contents

Other OTC Tools Tools manuals