OTC Tools 5093B User manual

Sheet No.

Issue Date: Rev. B April 17, 2012

© 2012 SPX

Form No. 560035

Parts List &

Operating Instructions

for: 5093B

655 EisEnhowEr DrivE

owatonna, Mn 55060-0995 Usa

PhonE: (507) 455-7000

tEch. sErv.: (800) 533-6127

Fax: (800) 955-8329

orDEr Entry: (800) 533-6127

Fax: (800) 283-8665

intErnational salEs: (507) 455-7223

Fax: (507) 455-7063

Original Instructions

1 of 3

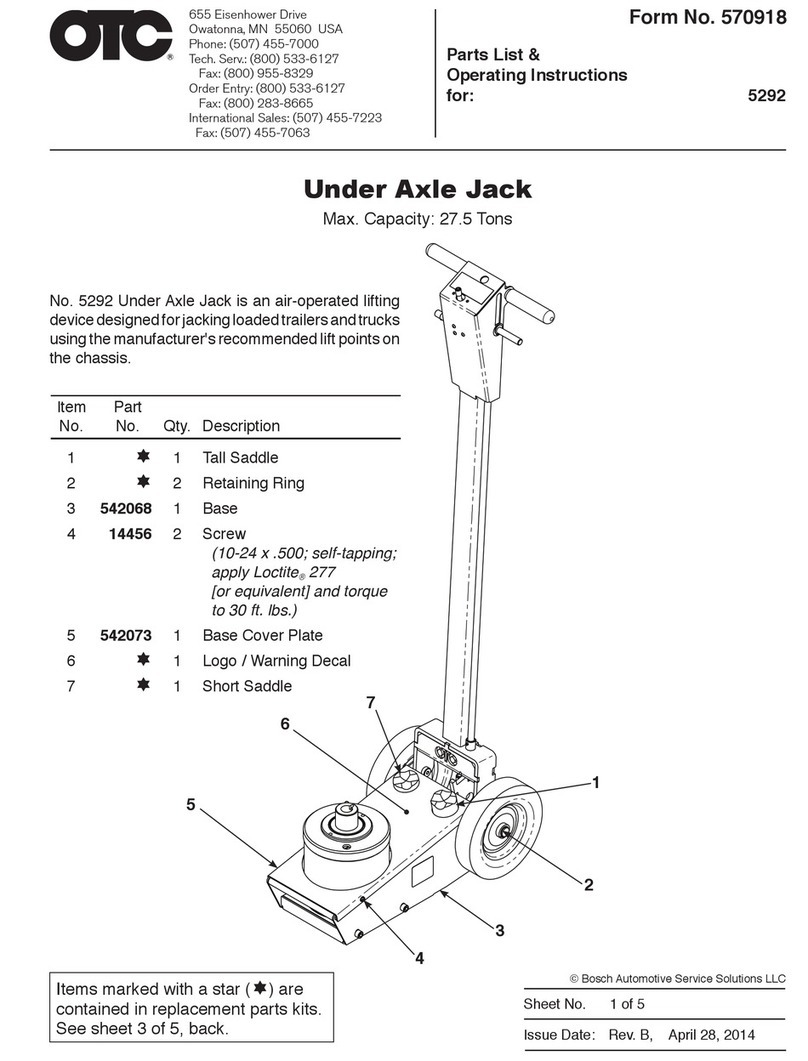

Description:

Under-axle jack designed to lift

Class 7 and Class 8 vehicles.

Air / Hydraulic

3-Stage Under Axle Jack

Weight: 69.5 kg (153 lbs.)

Explanation of Safety Signal Words

The safety signal word designates the degree or level of hazard seriousness.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

CAUTION: Used without the safety alert symbol indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

Maximum Capacity per Stage: 20 / 35 / 65 Metric Tons

22 / 38.5 / 71.6 US Tons

Parts List & Operating Instructions Form No. 560035, Sheet 1 of 3, Back

Safety Precautions

CAUTION: To prevent personal injury and/ or property damage,

•Study, understand, and follow all safety precautions and operating instructions before

using this jack. If the operator cannot read instructions, operating instructions and safety

precautions must be read and discussed in the operator’s native language.

• Onlyqualiedoperatorsmayinstall,operate,adjust,maintain,clean,repair,inspect,or

transport this jack.

•Inspect the condition of the jack before each use; do not use if damaged, altered, or in

poor condition.

•Wear eye protection that meets ANSI Z87.1, CE EN166, AS/NZS 1337, and OSHA

standards.

•The rated capacity for each stage of the jack is shown on the product decal, as well as in

this document. Do not exceed the rated capacity of each stage.

•Use on a hard, level surface with the wheels level.

• Liftonlyonareasofthevehicleasspeciedbythevehiclemanufacturer.

•Center load on jack saddle. Off-center loads can damage seals and cause jack failure.

•This is only a lifting device. Immediately after lifting, support vehicle with appropriate

means.

•Stay clear of a lifted load.

•Do not use this jack for anything other than its intended purpose. Do not use the jack to

move or dolly a vehicle.

•No alteration shall be made to this product.

•Use only those repair parts called out in the replacement parts list in this document. Items

found in the parts list have been carefully tested and selected by OTC.

Sheet No.

Issue Date: Rev. B April 17, 2012

© 2012 SPX

Parts List & Operating Instructions Form No. 560035

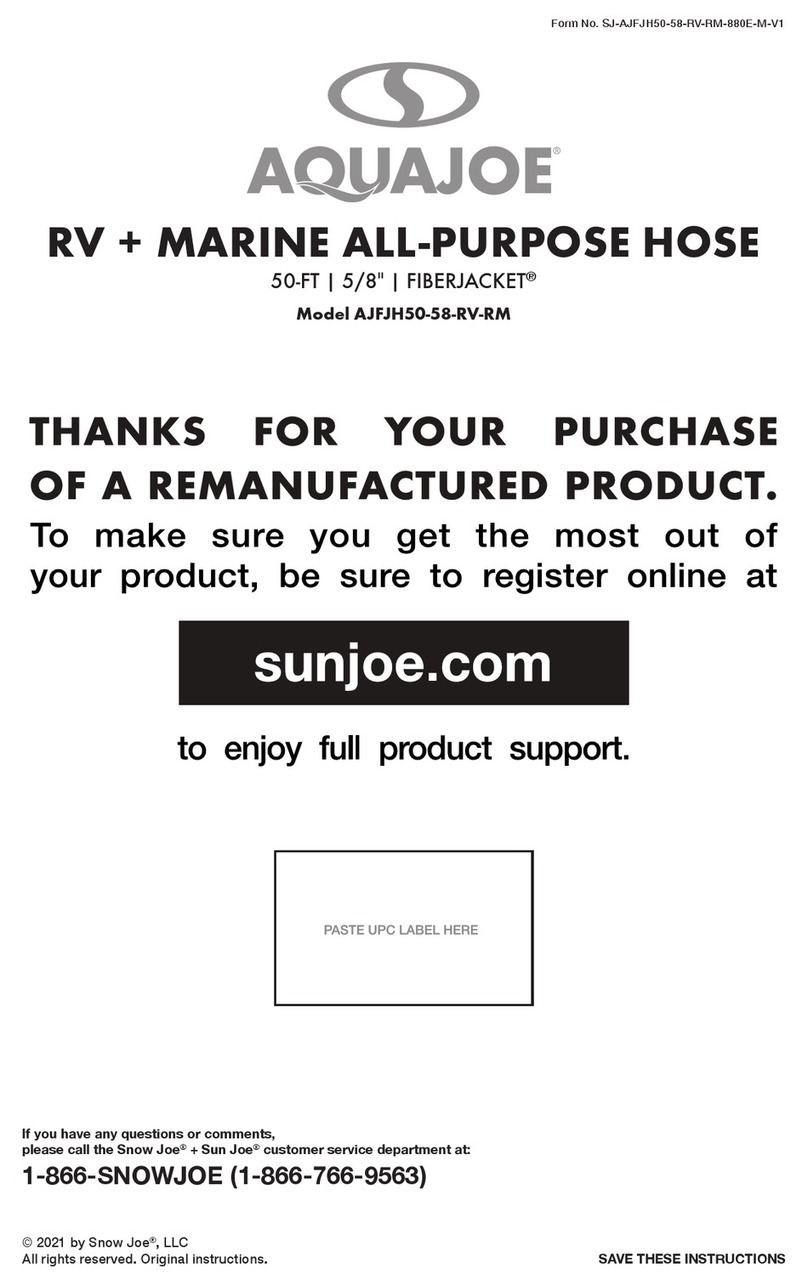

Figure 2

Shop

Air

Control

Lever

Handle

Position

Lever

2 of 3

Setup

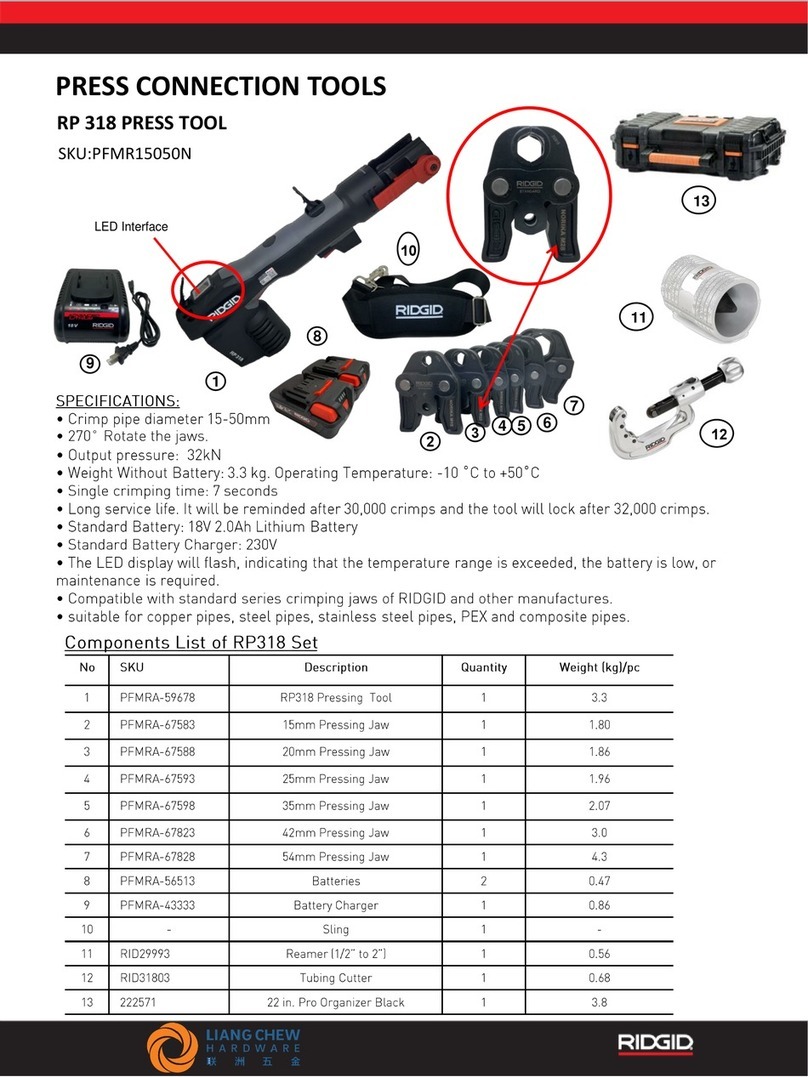

1. See Figure 1. Loosen and remove the four screws holding the upper

cover. Remove the upper cover.

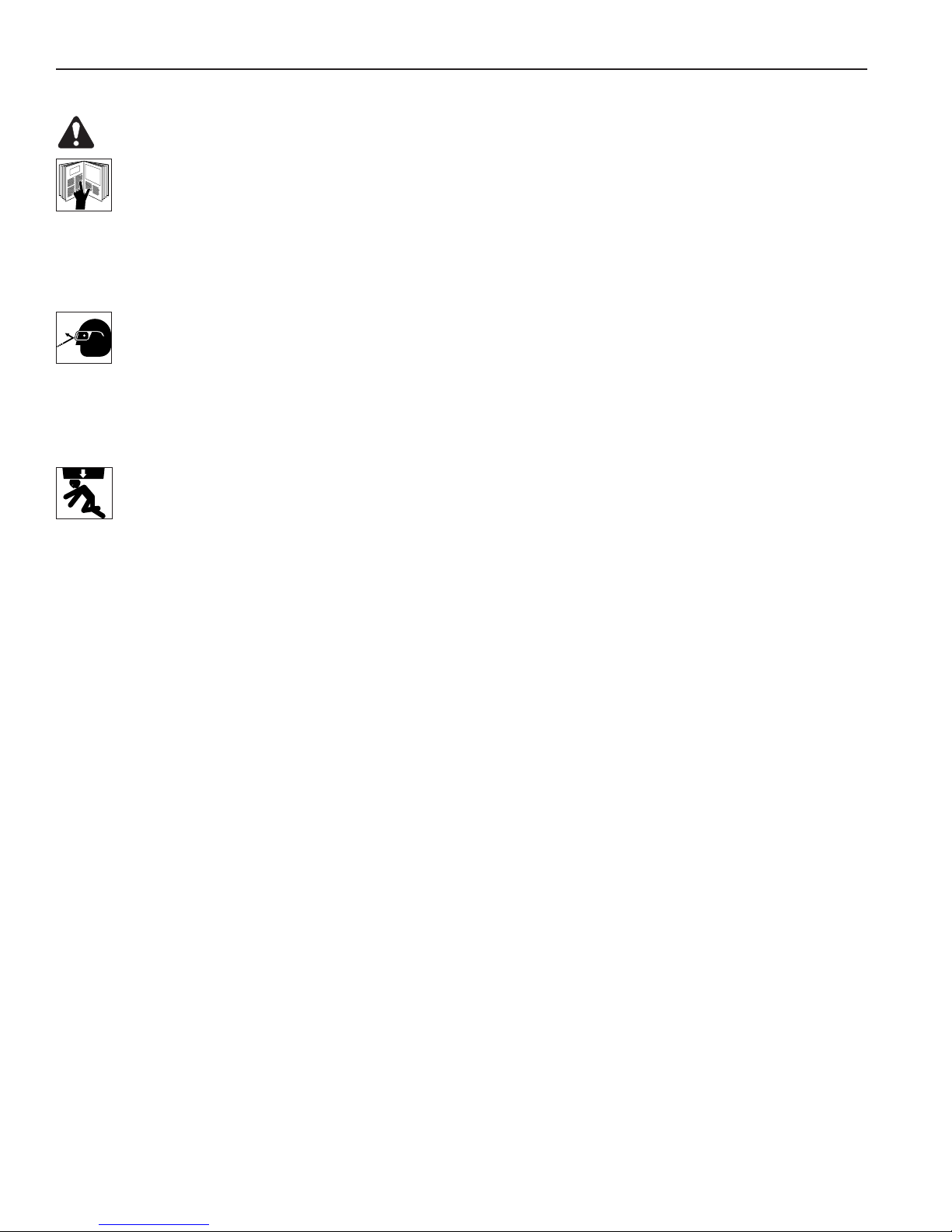

2. Note the handle position lever shown in Figure 2. Use the lever to

place the handle in Position 4 (horizontal) as shown in Figure 3.

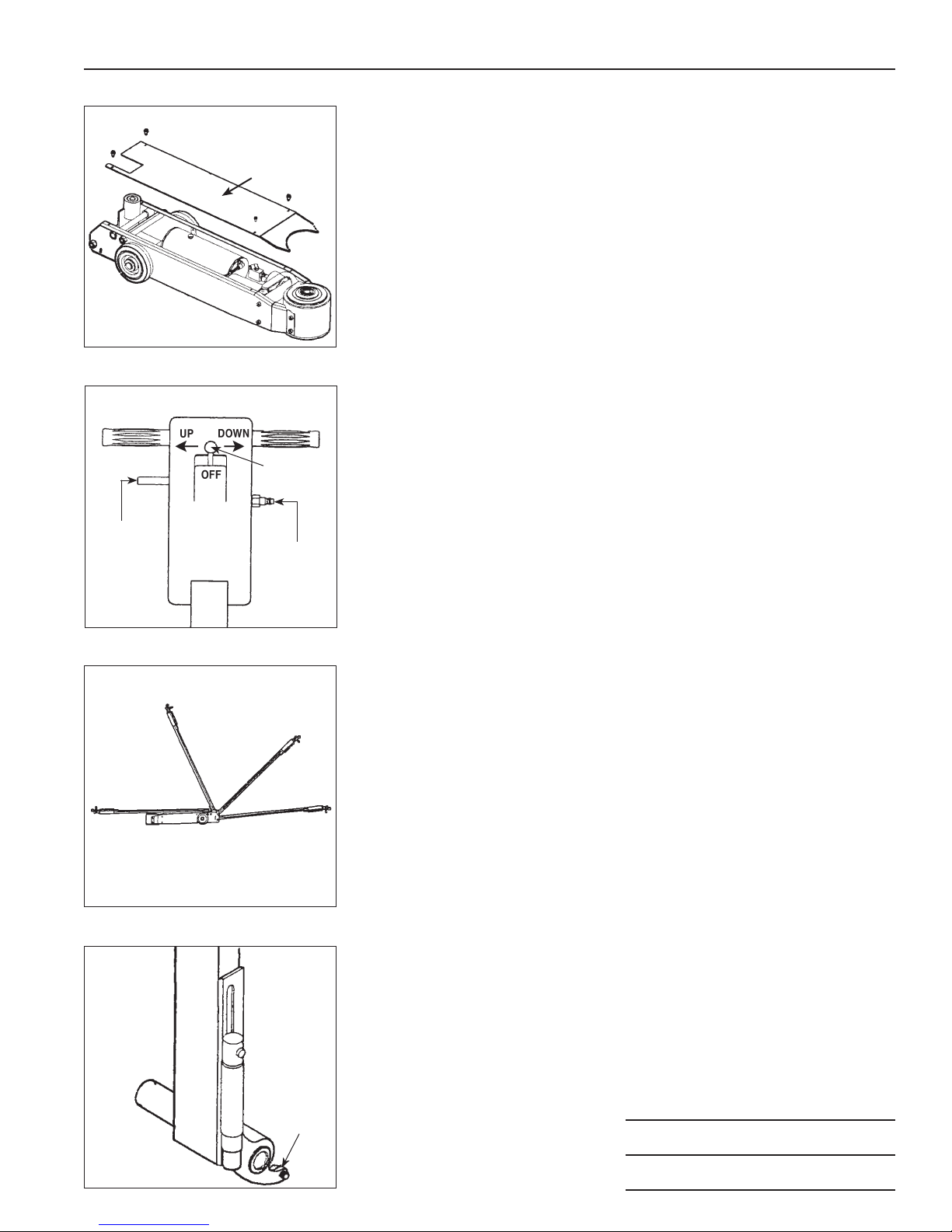

3. Insert the bolt and washer near the bottom of the handle assembly.

See Figure 4.

Note: When storing the jack for a long period of time, remove the bolt

and washer to place the handle in Position 1.

4. Install the upper cover.

Operating Instructions

1. Verify the control lever is in the OFF position. See Figure 2.

2. Connect shop air supply to the jack. Recommended air pressure is

7–10 BAR (100–145 psi). Install an air lter / lubricator in the shop

air line, because water in the air line will damage the jack.

3. Move the control lever to the UP position to raise the saddle to the

contact point. Move the control lever to OFF.

Note: The extension may be used in the uppermost position if required

to meet the contact point.

4. Check the placement of the jack: lift only on areas of the vehicle as

specied by the vehicle manufacturer; center the load on the jack

saddle; avoid jack wheel obstructions such as gravel, tools, or uneven

expansion joints.

5. Move the control lever to UP to nish lifting the vehicle.

6. Immediately place approved support stands under the vehicle at points

recommended by the vehicle manufacturer. Slowly and carefully lower

the vehicle onto the support stands by pushing the control lever to

the DOWN position.

Bleeding Air from the Jack

Air can accumulate within a hydraulic system during shipment or after

prolonged use. This entrapped air causes the jack to respond slowly or

feel “spongy.” To remove the air:

1.

Move the control lever to DOWN, and hold it there for a few seconds.

2. Move the control lever to UP to complete a load-free lifting cycle.

3. Move the control lever to DOWN to retract the jack pistons. The

pistons should react in a smooth motion; if not, repeat Steps 1–3.

Figure 1

Upper

Cover

Figure 3

Disengage trigger lever to move handle to

one of four positions:

1) collapsed; 2) storage: 3) movement:

and 4) horizontal.

1

2

3

4

Figure 4

Bolt &

Washer

Parts List & Operating Instructions Form No. 560035, Sheet 2 of 3 Back

Replacement Parts

Item Part

No. No. Description

1 561789 Power Unit

2 561795 Base

3 561794 Piston (64.9 metric tons)

4 561793 Piston (34.9 metric tons)

5 561792 Piston (20 metric tons)

6 561791 Saddle Kit

7 561790 Power Unit Handle

8 561788 Hydraulic Unit Seal Kit

9 561801 Release Valve & Hose Kit

10 561806 Top Cover

11 561807 Frame / Reservoir

9

10

12

11

13

14

15

16

17

9 (blue)

18

19

1

13

14

16

9 (red)

9 (black)

9(green)

1

2

3

4

5

6

7

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

12 561805 Wheel

13 561798 Valve Body

14 561796 Air Pump

15 561799 Regulator Valve Assembly

16 561797 Regulator

17 561800 Air Valve

18 561803 Handle

19 561802 Air Fitting

20 560806 Extension

Item Part

No. No. Description

20

Sheet No.

Issue Date: Rev. B April 17, 2012

© 2012 SPX

3 of 3

Parts List & Operating Instructions Form No. 560035

Inspection and Maintenance

CAUTION: To prevent personal injury,

• Onlyqualiedpersonnelshallperforminspectionsandrepairstothisjack.

•Before each use, an approved inspector must inspect the jack for bends, cracks, dents, elongated

holes, or missing hardware. If damage is found, discontinue use.

•Use only those repair parts called out in the parts list in this document. Items found in the parts

list have been carefully tested and selected by OTC.

•Disconnect the air supply hose from the jack before perfoming any maintenance or repair procedure.

See Figure 2 for the location of the air supply connection.

Inspection

Before each use, an approved inspector must inspect the jack for bends, cracks, dents, elongated holes, or

missing hardware. If damage is found, discontinue use.

Maintenance

•Periodically lubricate the moving parts of the jack using lubricating oil or grease.

•Use only anti-wear hydraulic jack oil (215 SUS viscosity at 100° F). The use of alcohol, hydraulic brake

uid, or transmission oil could damage the seals in the cylinder and result in jack failure.

•Periodically check the oil level in the cylinder: 1) Retract the pistons completely. 2) Remove the ller plug.

The oil level should be between the two marks on the rod. Rell as needed using approved hydraulic uid.

3) Install the ller plug.

•The greatest single cause of failure in hydraulic units is dirt. Keep the jack clean and well lubricated to

prevent foreign matter from entering the hydraulic system.

•Whenever the jack is not in use, fully retract the pistons to reduce the risk of corrosion.

Repair

When repairing the jack, use only those repair parts called out in the replacement parts list in this

document. Items found in the parts list have been carefully tested and selected by OTC.

Disposal

At the end of the useful life of the jack, dispose of the jack according to all state, federal, and local

regulations.

PRODUCT INFORMATION

Recordserialnumberandyearofmanufactureforfuturereference.Seeproductidentication

label on unit for information.

5093B

Serial Number: Year of Manufacture:

Table of contents

Other OTC Tools Tools manuals