Ouring 3DTALK T-real MINI User manual

Jiangsu Ouring 3D Technology Co., Ltd.

2

Contents

1. PRODUCT DESCRIPTION ..................................................................................................... 3

1.1 Product introduction ............................................................................................................. 3

1.2 Precautions............................................................................................................................ 4

2. PRODUCT OVERVIEW......................................................................................................... 5

2.1 Product appearance .............................................................................................................. 5

2.2 Product specification............................................................................................................. 8

3. OPERATING INSTRUCTIONS................................................................................................ 9

4. PRINTER OPERATION INTERFACE ..................................................................................... 30

5. REMOVING MODEL.......................................................................................................... 30

6. ROUTINE MAINTENANCE ................................................................................................. 31

7. WARRANTY ..................................................................................................................... 31

Jiangsu Ouring 3D Technology Co., Ltd.

3

1. Product Description

1.1 Product introduction

This document is a user guide for 3DTALK brand, T-real series MINI 3D printers. Please read the

document carefully before unpacking and using 3D printers of 3DTALK T-real MINI.

Jiangsu Ouring 3D Technology Co., Ltd.

4

1.2 Precautions (Please read the following content carefully.)

Note: Please do use the designated power adapter included in the machine.

Caution: Wear goggles during removal of auxiliary support materials, thus preventing material

chippings from hurting your eyes

Note: In the printing process, slight odor may be generated due to high temperature, but it will

not make person feel uncomfortable. You are recommended to use the machine in a well ventilated

environment.

Warning: The printer shall be repaired by the authorized repairing party only. Before

replacement of any component, please turn off the printer and cut off the power supply.

Warning: There is some dangerous factor upon removable components. Please keep your

fingers and body away from them.

Hot surface danger: During setting and working, do not contact the extruder. At this time, the

temperature of the extruder is very high.

Be careful of electric shock: Due to electric shock risks, please do not contact any internal

electronic component.

Jiangsu Ouring 3D Technology Co., Ltd.

5

2. Product Overview

2.1 Product appearance

I. Front view of printer

(1) Framework (2) Power button (3) Platform height adjusting knob

(4) Printing platform (5) Touch screen (6) extruder

(7) Filament guide tube (8) Nozzle (9) Filament

(10) Filament Holder

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

Jiangsu Ouring 3D Technology Co., Ltd.

6

II. Side view of printer

(1) USB interface (2) Network port (3) Power interface (4) Filament feeder

III. Coordinate axes

Note:

X-axis: Left and right Y-axis: Front and back Z-axis: Up and down

IV. Included accessories

(1

)

(2

)

(3

)

(4

)

Y-axis

Z-axis

axis

X-axis

Jiangsu Ouring 3D Technology Co., Ltd.

7

Note:

All screws in the list of accessories are spares and can be replaced according to the actual situations.

Regarding the accessory pictures in the list of accessories, the actual accessory appearances shall prevail.

PC matte paper

(With 2 sheets)

Jiangsu Ouring 3D Technology Co., Ltd.

8

2.2 Product specification

Specifications and characteristics

MINI Specifications and Characteristics

Technology

Printing Technology FDM (Fused Deposition Modeling)

Function

Building volume

Precision of layer height

Positioning precision

Nozzle diameter 0.2mm/0.4mm optional

Printing speed

(60mm/s-80 mm/s is suggested).

Number of nozzles 1

Working temperature of nozzle ≦280℃

Nozzle flow 24ml/h (fully solid model)

Support The software will generate automatically and easy to be

removed.

Cooling system Air cooling

Specification

Bare machine dimensions (with

filament) 350*251*366mm

Weight of bare machine 8.5KG

Packaging dimension 410*300*485mm

Packaging weight 15KG

Machinery

Body material High-strength sheet with metal spraying

Printing platform (material) Tempered frosted glass pane

LCD 3.5 inch full-color touch screen

Connectivity U-disk, wifi, Ethernet

XYZ movement system Linear guide rail

Stepper motor 42 stepper motor

Software

Document format

160x160x155mm

0.075mm (corresponding to 0.2mm nozzle)

60mm/s-200 mm/s

0.1mm (corresponding to 0.4mm nozzle)

0.2mm (corresponding to 0.4mm nozzle)

0.3mm (corresponding to 0.4mm nozzle)

X/Y/Z axis 11μm

*.3DT/.STL/.gcode /.PLY/.OBJ/.3MF

Jiangsu Ouring 3D Technology Co., Ltd.

9

Operating system

Windows / ios

Control software

Control system based on browser + touch screen control

Power supply

AC input

220V/50HZ

Requirement for power supply

Voltage: 220V, maximum power: 200W

Print Filament

PLA

Support

Environmental requirements

Room temperature: 15°C-30°C

Relative humidity: 20%-50%

Avoidance of machine movement and strong vibration during printing

Stable output of voltage

Jiangsu Ouring 3D Technology Co., Ltd.

10

3. Operating Instructions

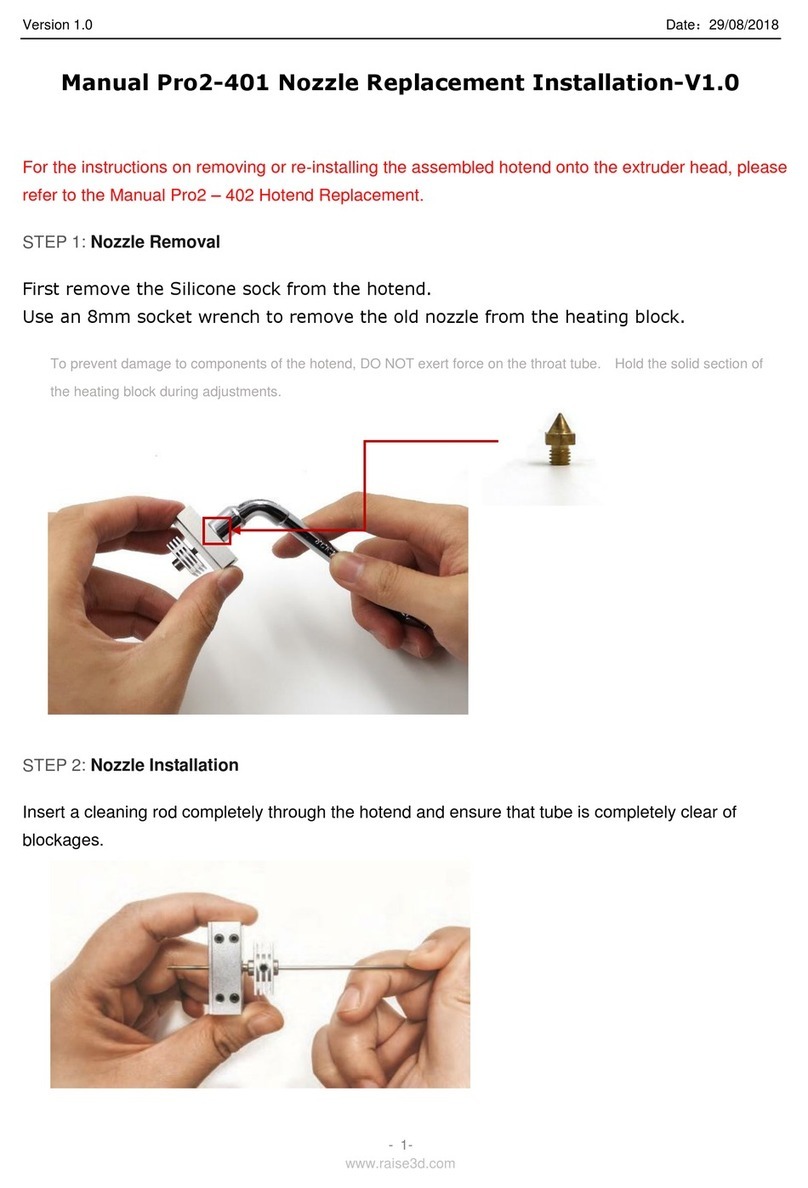

Installing printing build plate

Step 1:Remove the print board from the protective foam and place it on the three knob

magnets of printer.

Step 2: Install the filament holder.

Step 3: Install the filament guide tube.

The printing board is equipped

with a strong magnet to

automatically adhere to the

printing build plate.

Fix both screws

Press down the blue spring washer to place the

white filament guide tube.

Do the same operation at the other end.

Jiangsu Ouring 3D Technology Co., Ltd.

11

Step 4: Turn on the power supply and press down the power switch on the front panel.

Step 5: Filament Extrude and Takeback

Filament Extrude

1. Hang the PLA filament to the tray support already mounted

2.Manually press down the handle of the filament feeder to separate the two gears and at the

same time, pass the material wire between the two gears and push continuously to the print

head of the wire tube.

Press down

the handle.

Manually

feed the

filament

upwards

here.

Jiangsu Ouring 3D Technology Co., Ltd.

12

3.Click this button on the main screen

4. Click , select the appropriate wire change temperature, and then click (factory

original PLA material temperature is suggested as 190 °C, display temperature is the current

setting temperature), when the interface [current temperature] reaches the set temperature,

the wire feeder will feed the filament to the printhead and then flow out.

5.After the filament flows out, click on the screen

Jiangsu Ouring 3D Technology Co., Ltd.

13

Filament Takeback

1. Click this button on the main screen, and then click on the next page

2. When the [current temperature] of the interface reaches the set temperature, the feeder

will take the filament out of the nozzle within 5 seconds, then press the feeder handle to

pull the filament out.

3.When the filament runs out of the printer, click on the screen to stop the operation

Jiangsu Ouring 3D Technology Co., Ltd.

14

Leveling of printing build plate

The correct leveling of the printing build plate is a guarantee of print quality.

The MINI printer adopts a semi-automatic leveling operation that integrates build plate leveling

and print gap adjustment into one. It just needs a few steps to adjust the gap between the

nozzle and the build plate.

Note:

If it is equipped with masking tape or matte paper, please stick it before adjustment.

Before starting the adjustment, please make sure the printing build plate is clean & tidy

and no sprinkle left at the extruder of nozzle.

Loosen the three fixing screw holes under the three knobs on the lower side of the printing

build plate (clockwise tightening, counterclockwise release). The tool is in the starting kit

that comes with the printer)

1.Click on the main interface, and click on the next interface to enter the leveling

interface and click [Start Leveling] ,to move the nozzle to the leveling initial position.

Jiangsu Ouring 3D Technology Co., Ltd.

15

2.Click the [Next] button, after the nozzle and the build plate stop moving, place an A4 paper

between the build plate and the nozzle, and adjust the distance between the them by adjusting

the knob on the lower side of the nozzle.. This level is leveled out when the distance reaches a

slight friction as twitching the A4 paper. Click the [Next] button, the method is the same as

above. The three points of the printing build plate are adjusted and the leveling is completed.

Print file selection

Click in the main interface to open the print file selection interface.

[Local file]: The model printed by the printer and the uploaded model will be stored here.

[USB file]: The model is derived from the model file inserted into the U disk of the printer.

When the U disk is unplugged, the file disappears.

Select the file you want to print before printing. Click the Print button to start printing.

(The model file turns red when selected.)

Precautions before printing:

Jiangsu Ouring 3D Technology Co., Ltd.

16

1. Ensure that there is printed material in the nozzle.

2. Ensure that the vertical distance of each point on the printing build plate is equal to the

nozzle.

3. Ensure that the distance between the printing build plate and the nozzle is moderate.

Jiangsu Ouring 3D Technology Co., Ltd.

17

4.Printing Operation Interface

Jiangsu Ouring 3D Technology Co., Ltd.

18

5.Removing model

Here are the following steps to remove the models from the print build plate.

Shovel the model down with a spatula -For small size models

Grasp the front of the printing build plate with your hand, lift up and remove the build

plate, and shovel the model-For large side models

Note:

1.Before removing the printed work from the print build plate, make sure the printer has

finished work.

2.Be sure to move the shovel away from your body. Improper use of the flat shovel can cause

personal injury.

3.The appearance of the flat shovel may differ from the picture shown below.

4.Be careful when using tools to remove the model, in case of scratching the matte paper.

5.After the model is removed, kindly put the printing build plate back on the stand and clean

the printing build plate.

Jiangsu Ouring 3D Technology Co., Ltd.

19

6. Routine Maintenance

1.Printer shall be stored in a dry and ventilated working environment. In case of out of use for a

long time, the filament can be withdrawn from the nozzle and sealed with packaging

membranes, thus preventing dampness and deterioration.

2.Frequently clean on the printing materials attached to the nozzle is needed.

3.If the model is adhered to the printing plate tightly, it can be effectively removed by the

method of soaking in warm water.

4.The warranty is one year. In case of any non-artificial damages within the warranty, the

manufacturer will provide the warranty services.

5.The printer shall not be dismantled without the permit of the manufacturer's engineers,

otherwise the warranty will be invalid.

6.All warranty policies shall be kept consistent with the manufacturer.

7.If the equipment is out of use for a long time, the guide rail shall be applied with anti-rust oil.

Jiangsu Ouring 3D Technology Co., Ltd.

20

7. Warranty

The consumers can enjoy our warranty services since the date of purchasing our genuine 3D

printer equipment. In order to enable the consumers to enjoy the warranty rights normally,

please do follow the following clauses. Failing to meet the following clauses or exceeding the

warranty period is beyond our warranty service scope.

Warranty principles:

1.The 3DTALK T-real MINI printers purchased from proper channels authorized by our company

can enjoy the replacement service by virtue of the proof of purchase within 7 days from the

purchasing date provided that the products generate quality faults under normal operating

conditions (non-artificial damages) without overhauling, the attached accessories and packages

are intact and our technicians demonstrate that the faults are generated in normal use.

2.The 3DTALK T-real MINI printers purchased from proper channels authorized by our company

can enjoy one-year free maintenance and lifetime maintenance services since the purchasing

date.

3.In case of the following cases, the warranty will become invalid and the maintenance services

will be charged with the corresponding costs for accessories and labors.

①The damages are caused by human factors, including use in abnormal working environment

and damages caused by nonconformance to the operation instructions.

②The users dismantle, repair or refit the printer without permit or employ any party other

than the maintenance department of the manufacture to repair the printer.

③The damages are caused by force majeure such as fire, flood, earthquake and lightning strike.

④The valid proof of purchase cannot be provided and the user information file cannot be

verified.

⑤The-purchasing date cannot be verified.

Warranty method:

1.When you apply for warranty, please provide your proof of purchase, for example, the invoice.

2.Please call our customer service hotline to transfer to the engineer.

3.Our after sales service engineers will remotely coordinate with you in solving the problem.

(Email, Instagram, QQ, Facetime, Alitalk etc all available)

4.If the products cannot be well solved remotely, you can express the printer to our company

for repair by our professional personnel.

After-sales service hotline (China): 0086 85630888-8006

Table of contents

Other Ouring 3D Printer manuals