Ouring 3DTALK Future User manual

Jiangsu Ouring 3D Technology Co.,Ltd

1

Jiangsu Ouring 3D Technology Co.,Ltd

2

Contents

1.INSTALLING SOFTWARE…………………………..……………………………………………….………..……2

1.1 Production Introduction………………………..……………………………………………………….…………3

1.2 Important safety warning…….…………………………………..………………………………………..….…4

1.3 Filament Storage………………………………………..……………………………………………………..……5

2. PRODUCT PROFILE………………………………………………….…………………………………..…..……6

2.1 Product Appearance ……………………………………………………………………………………………6

2.2 Spare Accessories…………………………………………………………………………..………………….11

2.3 Specification………………………………………………………………………………………………………13

3. INSTALLING AND DEBUGGING PRINTERS………………………………………………………………16

3.1 Install the printer………………………………………………………..……………….…………………….16

3.2 Changing filament………………………………………………………..…………………………..……….22

3.3 Extruder calibration………………………………………………………..…………………………..…….23

3.4 build plate leveling ……………………………………………………..…………………………………….24

3.5 Setting”and Advanced Setting”Introduction……………..………………………….……..…….25

Jiangsu Ouring 3D Technology Co.,Ltd

3

1. Installing software

1.1 Product Description

Production Introduction

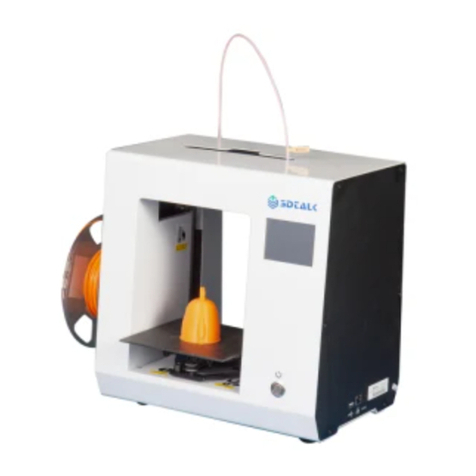

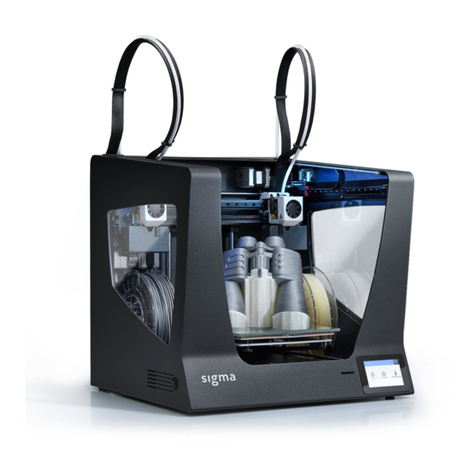

3DTALK Future is a high-tech and digitized 3d printer researched and produced by

Jiangsu Ouring 3D Technology Co.,Ltd (Ouring for abbreviation). 3DTALK Future

printer supplies filaments with feeding motor from filament guide tube to extruder,

where filament will be melted and extruded by thin line, extruder move according to

coordinate system of platform, platform falls with each layer finished till mode

complete. This 3d printer provide you with different color of filament to help you

achieve your creativity with no waiting. New customer of 3DTALK Future need to read

this user guide carefully before unpacking, ouring will retain all its rights and we will

constantly update this document under no special notification.

Jiangsu Ouring 3D Technology Co.,Ltd

4

1.2Important safety warning

Modification or disassembly without special approval will make the the failure of the

equipment warranty.

Please observe all the safety rules in this section,and follow all the precautions and

warnings in this guide. In order to get the correct printing,please operate carefully and

not to touch the hot surface

Please do use the designated power adapter included in the machine.

In the printing process, slight odor may be generated due to high temperature,

but it will not make users feel uncomfortable.You are recommended to use the

machine in a well ventilated environment.

The machine shall be repaired only by the authorized repairing technician.

Before replacement of any component, turn off the printer and cut off the power

supply.

Removable components are dangerous. Please keep your fingers and body away

from them.

Hot surface danger: When setting and working, do not touch the extruder. At

this time, the temperature of the extruder is very high.

Be careful of electric shock: Due to electric shock risks, please do not touch

any internal electronic component.

Jiangsu Ouring 3D Technology Co.,Ltd

5

1.3 Filament storage

Although all polymers will degrade over time,but the following conditions can help you

ensure the quality of the material

1.Only unpack the package when you need to use

2.Seal the package of filament under dry environment of temperature 18~29℃

3.Run out the filaments within 12 months after you receive it

Jiangsu Ouring 3D Technology Co.,Ltd

6

2. Product Profile

2.1 Product Appearance

Front view of the printer

1、Touching Screen

2、extruder

3、Printing plate

4、Power Button

5、USB port

Jiangsu Ouring 3D Technology Co.,Ltd

7

Side view of printer

1、cooling fan

2、camera

3、filament holder

4、LED light

Jiangsu Ouring 3D Technology Co.,Ltd

8

Back view of the printer

1、quick plug

2、feeding motor

3、filament break sensor

4、filament

5、Power port (DC/220V/50Hz)

6、Power button

Jiangsu Ouring 3D Technology Co.,Ltd

9

extruder illustration

1、quick plug

2、extruder heating cube

3、nozzle

4、extruder heating stick

5、cooling fan

6、auto-leveling detector

Jiangsu Ouring 3D Technology Co.,Ltd

10

1、extruder flat cable

2、printing guide tube

3、tube holder

xyz axis illustration

Jiangsu Ouring 3D Technology Co.,Ltd

11

2.2 Spare accessories

Filament holder power plug USD

Allen wrench PLA filament (1KG) Nozzle

(0.2mm)

Flat shovel nipper pliers L shape socket

spanner

solid gum PC sand paper filament guide

tube

Spare screws printing plate detaching tube

assistor

Jiangsu Ouring 3D Technology Co.,Ltd

12

Note: All screws in the accessories list are spares and can be replaced according to the

actual situations.

All of the colors of PLA filaments listed in the accessory list are random

Regarding accessory pictures in the accessories list, the actual accessory appearances

shall prevail.

Jiangsu Ouring 3D Technology Co.,Ltd

13

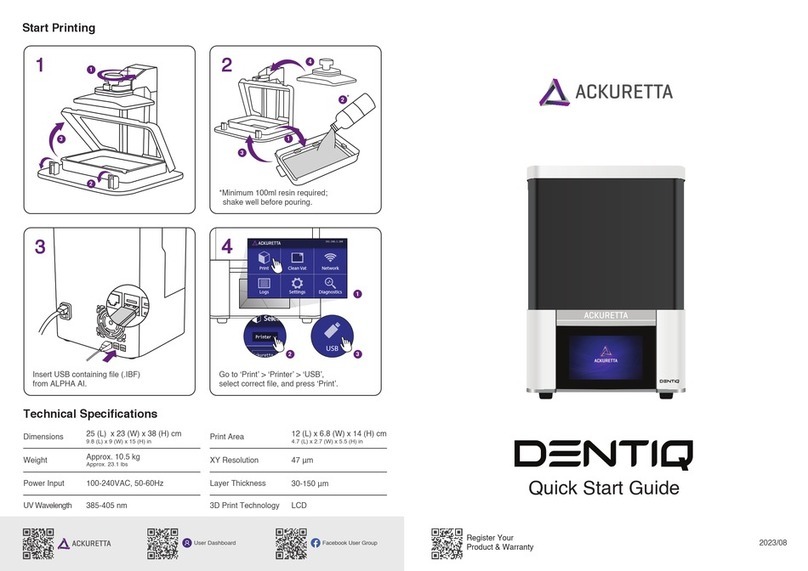

2.3 Specification

Specification data

FutureSpecifications and Characteristics

parameters

Build volume 205*205*255mm Nozzle diameter

Layer thickness

under 0.1mm Printing speed

Positioning

precision Z axis2.5um,X/Y axis11um Extruder quantity

1

Printing

precision <0.2mm Extruder

temperature ≦260℃

Build plate Heatable ≤110℃Nozzle flow

leveling automatic support

The software will generate

automatically and easy to

be removed.

Resume

printing from

power off

available filament running

out reminding available

appearance Status notice of breathing

light

size

Max 120mm/s

60mm/s-80mm/s

0.075mm-0.3mm

0.2mm nozzle for thickness

0.2mm/0.4mm

45ml/h(fully solid model))

Jiangsu Ouring 3D Technology Co.,Ltd

14

Printer

dimension Package

dimension 565*525*635mm

N.W ≈26.3kg G.W ≈29kg

power

structure

Framework High strength sheet metal

spraying connectivity USB/WIFI

Build plate aluminum alloy XYZ moving

structure

Z axis high precision

screw rod

LCD 4.3 inch full color Stepping motor 42 motor

software

Document

format

App control

Cloud slicing

PC system

requirement Windows64 bit/mac Available for both android

and ios

filament

PLA available

466*472*550mm

200V-240V 50Hz 200W

.stl/.3dt/.gcode/.ply/.obj/.

3mf

Jiangsu Ouring 3D Technology Co.,Ltd

15

Environmental requirements

Room temperature: 15°C-30°C

Relative humidity: 20%-50%

Avoidance of machine movement and strong vibration during printing.

Stable output of voltage

Installing and Debugging Printers

Jiangsu Ouring 3D Technology Co.,Ltd

16

3. Installing the printer

3.1Installing the printer

step 1

unpack the package, take out the printer .Hold the metal plates of the

two sides and lift out the printer out of the carton box

step 2

remove the fixed ribbon of z axis and take off the foam

Step3

hold the center of both sides of build plate ,move the plate holder lightly in

order to have enough space to take off the foam , filaments, tools and the

printing plate under the plate holder.

Step4

take out the filament guide tube from start up box, plug the port with

metal ring into the quick plug of filament feed at the back of printer, Until

the wire feeding pipe from the gear 1mm and make a quick plug contact to

buckle down (picture 1), then the filament guide tube is sheathed on the

other end of the managed device and inserted into the nozzle end quick

Jiangsu Ouring 3D Technology Co.,Ltd

17

plug, until the tube cannot continue downward into the (picture 2), and

black tube natural decline to the spray head can quickly plug

filament feeder guide tube installation

picture 1

extruder guide tube installation illustration

picture 2

feeder guide tube competed sketch

if you need to remove the guide tube at the nozzle,you just need to press

Jiangsu Ouring 3D Technology Co.,Ltd

18

down detaching tube assistor, and at the same time pull out the guide

tube.

If you need to remove the guide tube at the feeder motor ,you just need to

keep pressing the black cushion pad at the quick plug,and at the same

time,pull out the feeding guide tube.

step 5

Insert the extruder flat cable plug into the extruder jack and press it down

until the cable plug is deadlocked automatically.The cable and the guide

tube should be fixed by the fixing clamp.

extruder flat cable installation illustration

feeding guide tube and cable fixing illustration

(the color of fixing clamp is in kind prevail)

Step6

Install the build plate

Jiangsu Ouring 3D Technology Co.,Ltd

19

Picture 1 picture 2 picture 3

Firstly swivel open the fixing clamp of the build plate(picture1)

then take out the platform, stick the sand paper on the plate, and put it

on platform holder(picture 2)

Finally, rotate the platform holder to lock the print platform tightly(picture

3)

(Attention:Before putting the build plate,please stick the PC sand paper

on the build plate smoothly)

Step7

use allen wrench to fix the filament hold on the back of the printer

Step8

Install the filament

Hang the filament on the filament holder,and feed the filament through

filament snapping detector into filament feeder(picture 1). press down the

holder of feeder and insert filament till into extruder.

Jiangsu Ouring 3D Technology Co.,Ltd

20

(picture 1)(picture 2)

Table of contents

Other Ouring 3D Printer manuals