Ouring 3D TALK DS200 User manual

Jiangsu Ouring 3D Technology co.,Ltd

1

User Guide of 3D TALK DS200

Version:V3.0

Jiangsu Ouring 3D Technology co.,Ltd

2

Catalogue

1. Product Description.................................................................................................. 3

2. Product View……….................................................................................................... 5

3.Printer Preparation……………………….…………………………………………………………….…….…12

4. Software introduction…………………………………………………………………………………………19

5.Printing Process………………………………………………………………………….…………………….….45

6. Resin vat release film replacement instruction……………………….…………………………..48

7.Printer use instruction………………………………………………………………………………………….49

8.Warranty………………………………………………………………………………….………………………….52

Jiangsu Ouring 3D Technology co.,Ltd

3

1. Product Description

General

3DTALK-DS200 series printer is a high-tech digital 3D resin printer developed and

produced by Jiangsu Ouring 3D Technology Co., Ltd. (referred to as Ouring). Users of

3DTALK-DS200 are advised to read the product manual carefully before start. Ouring

reserves all rights. This manual is subject to upgrade without prior notice.

Precautions

Note: Do not allow children to operate the printer without adult supervision to avoid

injury.

Note: The printer should be placed on a horizontal table to avoid falling or causing

the resin flowing out from the vat.

Note: Do not place the printer in a damp or dusty environment, such as a bathroom

or transportation area.

Note: Please place and use the printer in a well ventilated environment. A small

amount of non-toxic odor will be produced during printing. Having a well-ventilated

area will ensure a more comfortable environment.

Note: Please lower the cabin door during printing. Do not use a metal blade to clean

the resin vat.

Note: To ensure the maximum print quality, please use original resin.

Jiangsu Ouring 3D Technology co.,Ltd

4

Note: Wear appropriate protective printer to avoid contact with resin. For example:

goggles, masks, protective gloves.

Note: Do not pour waste resin into the bottle and sink to avoid contaminating the

intact resin in the bottle and clogging the sewer, please place the waste resin in a

plastic bag and discard it in the sun after cured.

Note: For unrecoverable problems, please contact the factory after-sales staff or

sales representative.

Warning: Do not place objects on the top of the printer to avoid falling into the

printer and causing printing problems and safety hazards.

Warning: Keep the printer, resin, and alcohol away from fire.

Warning: Please use the power cord that comes with the printer, and ensure that the

power supply voltage is stable. The live, neutral, and ground wires are properly

connected properly, otherwise the printer may be damaged.

To ensure safety, kindly operate the printer carefully. Read and follow all safety

precautions described in the precautions.

Jiangsu Ouring 3D Technology co.,Ltd

5

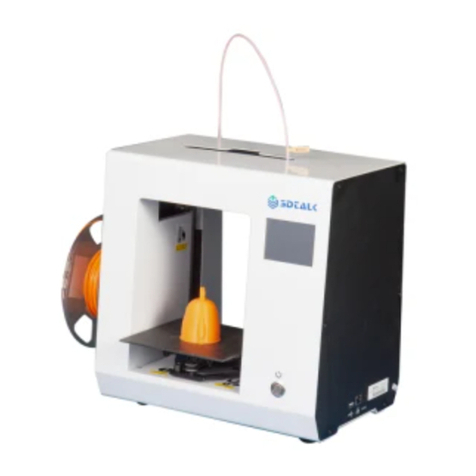

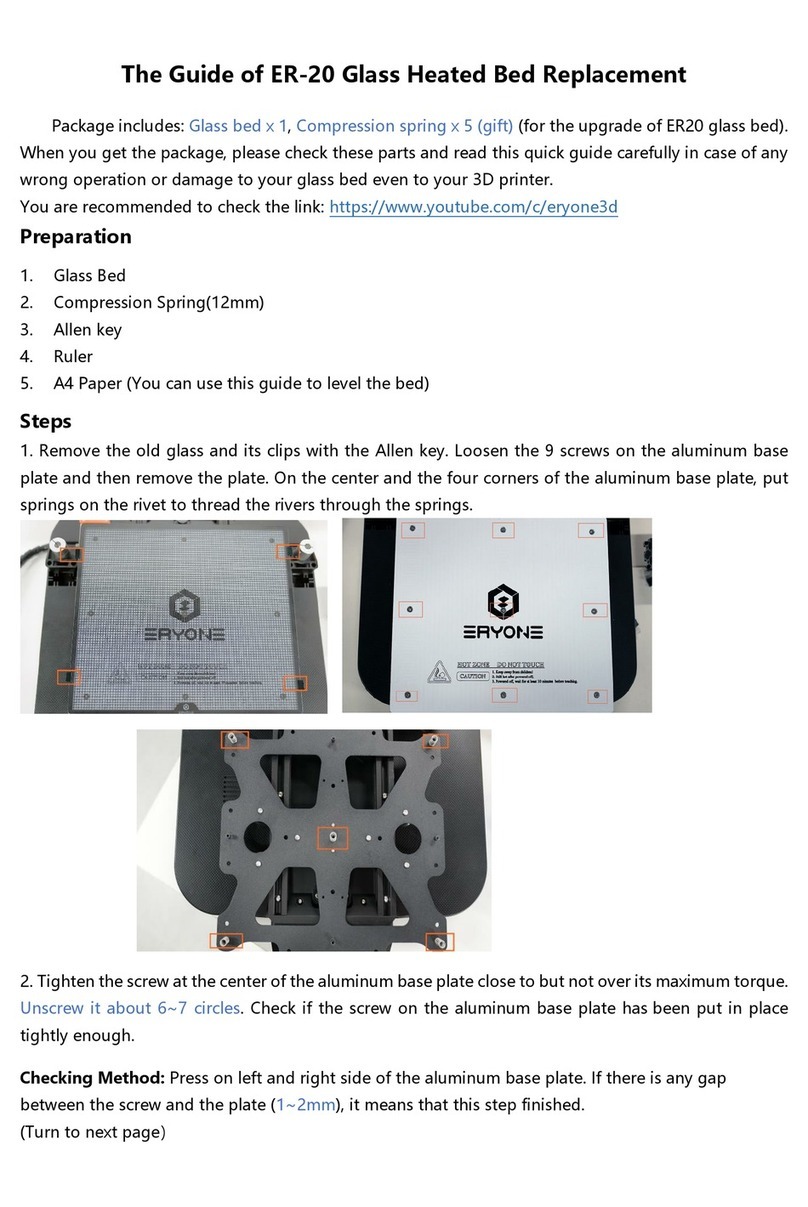

2.Product View

USB connector

Touch screen

Open Handle

Screen button

Building plate

Resin vat

Jiangsu Ouring 3D Technology co.,Ltd

6

Spare Parts

Flat shovel X 1

Open end wrench

(6-7mm)

Hex wrench(2、2.5、3mm)

Protective gloves X 2 set

Protective glasses X 1

USB Drive X 1

Resin vat X 2

Cleaning Vat X 1

Resin Scraper X 1

Cleaning brush X 1

Sandpaper(80 mesh)X 2

Dental Model Resin

1000ml

Power socket

Jiangsu Ouring 3D Technology co.,Ltd

7

Pliers X1

Note:

The photos of accessories listed here should be based on the real accessories.

Performance Parameter

3D Technology LCD

Printer Size (L * W * H)= 525 * 460 * 725mm

Working Tem

Print Size

XY Resolution 75um 2560 X 1600px

Z-axis Resolution

0.05mm、0.1mm)

Light source 405nm UV LED

Interface USB

Control 5 inch touch screen

File format stl、.obj、amf、3mf etc

.zip

Resin vat

Cooling system Liquid cooling system

Sealing Dustproof, anti-static

0.6um(layer thickness suggested :0.016mm、0.025mm、

Detachable integrated resin vat

18℃~ 28℃

(X * Y * Z)= 192 * 120 X*188mm

Jiangsu Ouring 3D Technology co.,Ltd

8

Resin Professional Dental model resin, Dental Ortho Resin, Dental

Guide resin

Transfer

Power input

Environmental Requirements

Avoid placing the resin in the following environment: high temperature

environment, local heat source, oxidizing environment, freezing environment,

direct sunlight, ultraviolet radiation, inert gas coverage, dust environment.

The stability of print quality is affected by the heat and humidity, so please

ensure the proper operating conditions. (Temperature 18 - 28 ° C / humidity 40 -

80% RH)

Please place the printer in a clean office environment that meets the above

conditions.

In view of the size of the printer, please prepare a table top with a width of

≥500mm2 and a height of about 600mm.

One computer.(system version-Windows7 or above)

CPU - lnter i3 above

RAM - 4GB above

Graphics card – Nvdia series,1G and above,supporting OpenGL4.1)

Model cleaning alcohol (90% ~ 95%), alcohol vat, ultrasonic cleaner (optional),

UV curing box (optional) etc

Touch Screen Introduction

Boot Interface

In the [File] tab, select the print file stored in the printer and the inserted USB

disk of the printer for printing.

AC110/240V 50/60Hz 400W

USB drive, wifi

Jiangsu Ouring 3D Technology co.,Ltd

9

[Local file] is stored in the model print file of the printer. All files printed by the

printer will be stored in this location.

[Udisk file] After the USB disk is inserted into the printer, the print model file will

be recognized by the printer

Operate the related selected files by using the [Print],[Pause],[Stop], and

[Delete] buttons.

Set interface

[Network] controls the printer through the LAN. (Development tools are not

supported for use current now.)

[Language] Users can set the language version of the printer to a localized

language.

[Material Vat Clean] When there are many impurities in the bottom of the

Jiangsu Ouring 3D Technology co.,Ltd

10

printer resin vat, this function can be used to cure the resin at the bottom of the

vat, solidify the impurities and remove the cured resin.

[Operation Control] Controls the Z-axis of the printing build plate to move up &

down and return to zero.

Note:

The bottoming operation in Operation Control must confirm that there is no solid

impurities inside the printing build plate and resin vat. It can be operated after being

leveled

[Light Path Control]

[Water Cooled Switch] Manually turn on the water-cooling system of the printer

[Light board switch] manually open the LED light board

[Preset Image] Calibrate the light intensity pattern

[Full Screen Image] Check whether the screen is damaged or not

[Setting]

[Administrator Login] Enter the parameter login password: 123456

[Parameter] User can set the printing parameters in printer (draw “√” in

[Parameter Settings] and save, the model file will be printed according to the

parameters of this page, and the printing parameters set in the software will be

invalid.)

[Parts Replace] Count the use time of the lamp board and screen. When it needs to

be replaced, please click the corresponding button to time the parts.

[Light Calibration] Calibrates the light intensity of the light board.

Jiangsu Ouring 3D Technology co.,Ltd

11

About Interface

Display the model, hardware version, software version, and IP address of the

device

Dental Resin Introduction

Resin Mode

Color

Character

Dental

Application

Dental Model Resin

Beige

High precision, smooth

surface, no irritating odor

Prosthodontic

s

Dental Ortho Resin

Beige

High temperature

resistance 150 ° C, high

strength, high toughness,

matte surface, no irritating

odor, punchable

Orthodontics

Dental Guide Resin

Transparent

High transparency, high

strength, high toughness,

non-toxic treatment by

traditional means

Medical

Guiding

Jiangsu Ouring 3D Technology co.,Ltd

12

3.Printer Preparation

Printer installation

1.Take out the fixed strip and protective cotton of the printer from the packing box

and place the printer on the horizontal tabletop.

2.Open the printer compartment door and take out all the protection devices and

random accessories from the printer

3. Remove the protective film on the display screen

4. Wipe the new resin vat inside and outside with the wet wipes and dry it naturally.

Then mark the following figure and place the vat correctly in the printer

compartment (see the picture below).

5. Rotate the four positioning screws downwards to fix the vat to ensure that the vat

does not shake (see the picture below).

Jiangsu Ouring 3D Technology co.,Ltd

13

Build Plate Leveling

Note: When the model fails to print before the first printing and during the use of

printer, please perform the build plate leveling operation. If the printing work is

normal, you do not need to do this. When leveling the build plate, please make sure

that there are no materials, no impurities, and no objects in the vat to prevent the

falling printing build plate crushing the release film and other parts.

Follow the steps below to complete the build plate leveling:

Printer components introduction

(1) Locking handle

(2) Hand screw

(3) Locking screw

(4) Locating pin

(5) Printing build plate

1.Rotate the four locking screws on the Z-axis bracket through the tool wrench

counterclockwise and loosen them to the height of the screw as far as possible from

the bottom black bracket (see the picture below)

Jiangsu Ouring 3D Technology co.,Ltd

14

2. Manually rotate the four units hand screw on the Z-axis bracket counterclockwise

to the highest position (See below picture)

If the hand screw cannot be rotated counterclockwise, please hold the printing build

plate, loosen the locking handle and then try to rotate.

3. After the hand screw is rotated, please be sure to position each positioning pin

and the positioning hole, tighten the locking handle to make sure that the printing

build plate is not shaken.

Warning: Do not turn the locking handle counterclockwise to prevent the printing

build plate from falling off and damaging the printer.

Jiangsu Ouring 3D Technology co.,Ltd

15

4.Click the [Reset] button, when the printing build plate stops moving upwards, click

the [Bottom] button, the printing build plate can freely descend into the vat. (See the

picture below)

5.When the printing build plate is lowered into the vat, loosen the locking handle to

ensure that the printing build plate and the release film are fully fitted (see the figure

below)

Jiangsu Ouring 3D Technology co.,Ltd

16

6. Align the four positioning pins on the Z-axis bracket with the four positioning holes

on the printing build plate. (See below pictures)

7. Rotate the four units hand screw down to ensure that the printing build plate is

completely attached to the bottom surface of the vat without sloshing (see the

picture below).

Jiangsu Ouring 3D Technology co.,Ltd

17

8. Use hand to turn the locking handle clockwise to tighten it (see the picture below)

9. Use a tool wrench to rotate the four locking screws clockwise to tighten (see the

picture below)

Jiangsu Ouring 3D Technology co.,Ltd

18

10. Click once the arrow ▲above the [Reset] button, and then click the [Reset]

button to raise the build plate to the top of the printer, and finish the leveling.

Filling resin material

1. Shake the material inside the bottle before pouring it into the resin vat,to keep

the density of resin uniform

2. Make sure there is no obvious solid impurity in the vat before pouring the resin

material.

3. Wear the protective gloves, goggles, and mask, then pour the resin material into

the vat; (the amount of resin material should be poured according to the level mark

of the vat)

Jiangsu Ouring 3D Technology co.,Ltd

19

4. Keep the printer door closed, if there is any resin material in the vat.

Warning: When there is resin material in the vat, it is forbidden to open the

cabin door frequently to prevent daylight curing.

4.Software introduction

Software overview

The main function of the slicing software is to convert the model file into the slice

format required for 3D printer processing, it includes simple model editing functions

(such as scaling, rotation, mirror symmetry, model copying, etc.) and auxiliary

processing (such as automatic layout, automatic support, etc.) and other functions.

Jiangsu Ouring 3D Technology co.,Ltd

20

Sliced software homepage

Software installation process

1. Choose [Next] button

Table of contents

Other Ouring 3D Printer manuals