OV _FT-0113

2

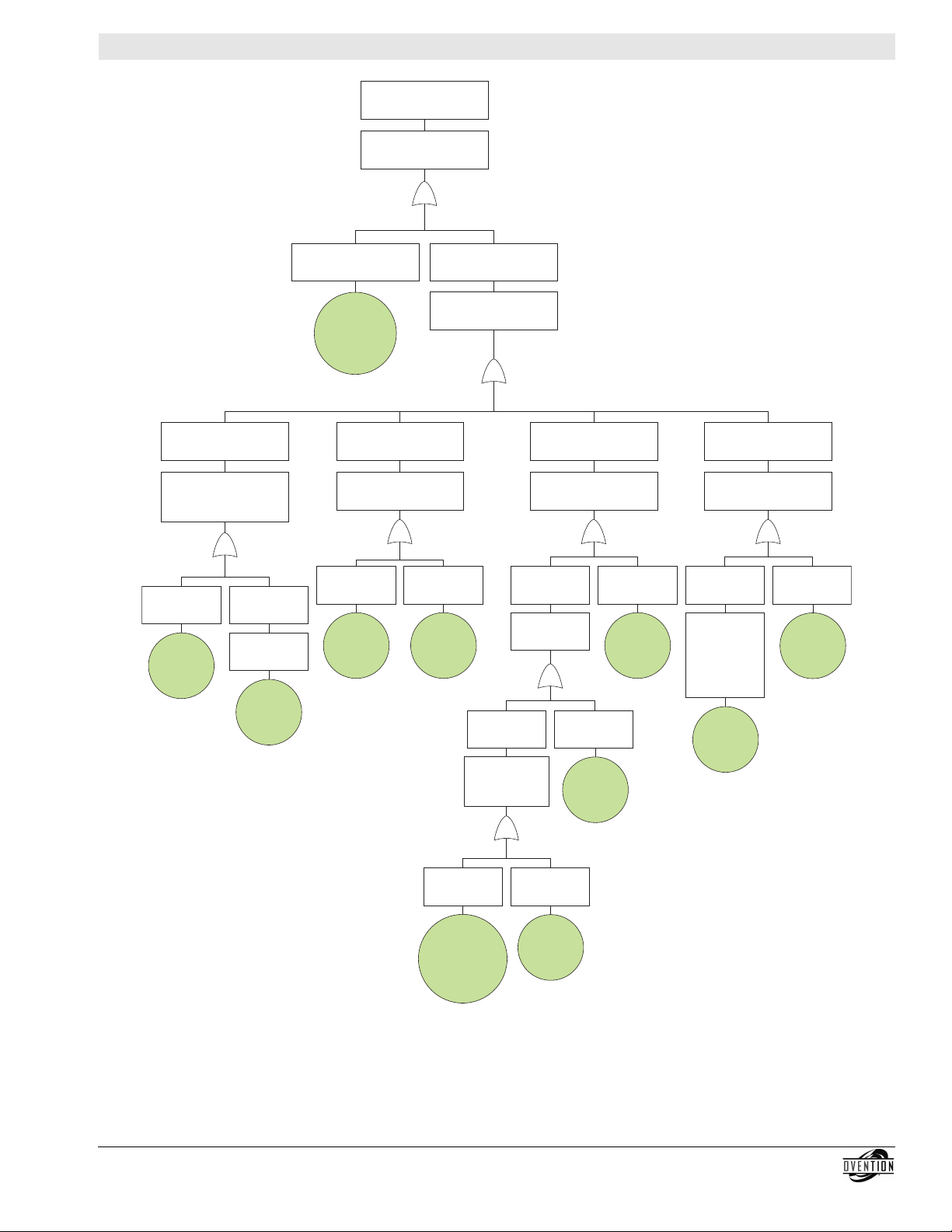

Oven Doesn’t

Perform As

Intended

Oven Doesn’t

Warm Up

GO TO PAGE 3

Screens Are Blank

GO TO PAGE 4

Screens Are

Unresponsive

GO TO PAGE 5

Slider Doesn’t

Complete Travel Or

Doesn’t Move At All

GO TO PAGE 6

Oven Doesn’t

Cook Right

GO TO PAGE 7

Red Screen

Displayed When

Starting A Cook

GO TO PAGE 8

Check Fans

Is Lit (Red Light)

GO TO PAGE 9

Abnormal Noises

From Oven

GO TO PAGE 10

An Unexpected

Screen Displays

GO TO PAGE 11

Snowy Screen

Displays

GO TO PAGE 11

No Sound From

Oven Speaker

GO TO PAGE 12

Slider Banks Into

End Of Travel

GO TO PAGE 13

“Oven Too Cold”

Or “Oven Too Hot”

Message Displays

GO TO PAGE 14

Oven Clock

Doesn’t Keep

Correct Time

GO TO PAGE 11

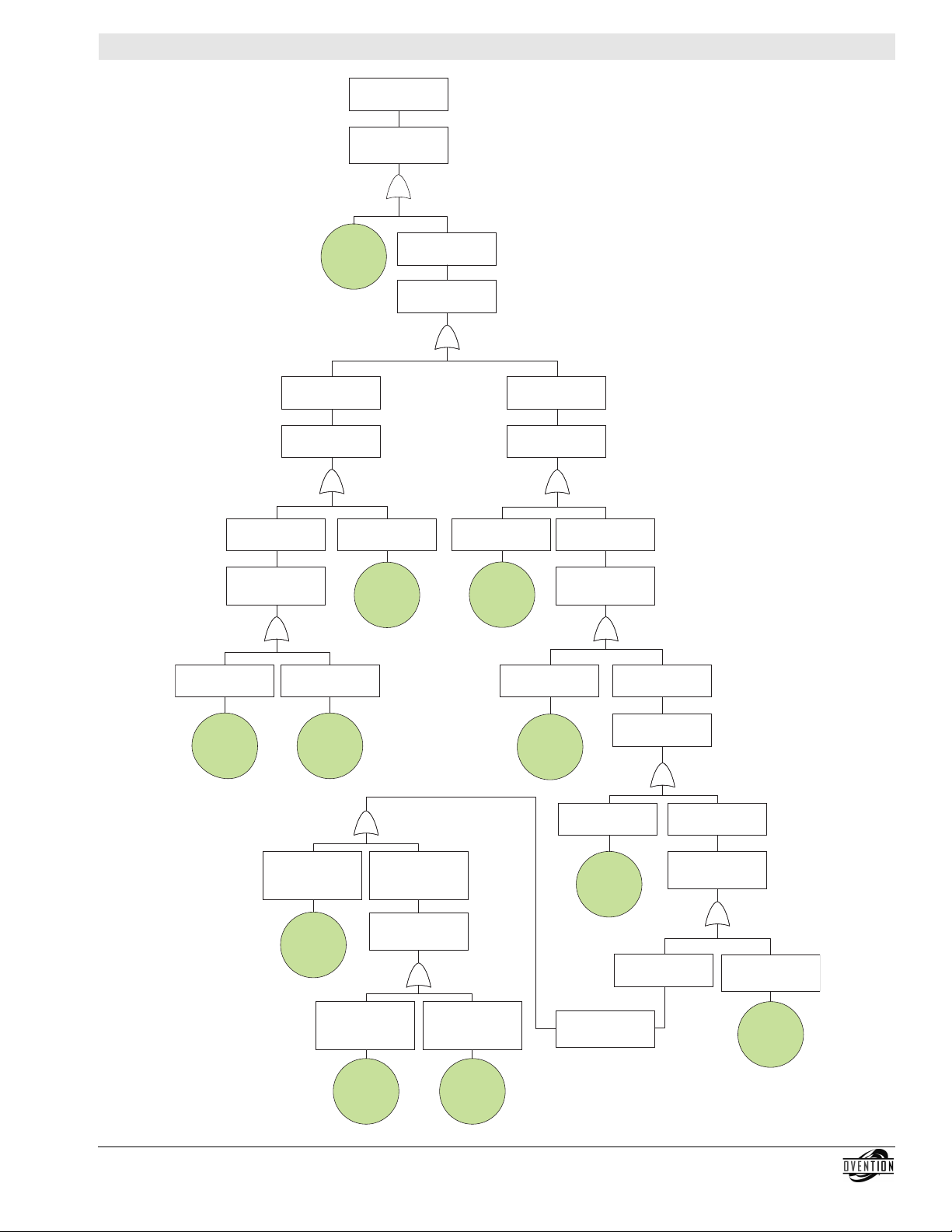

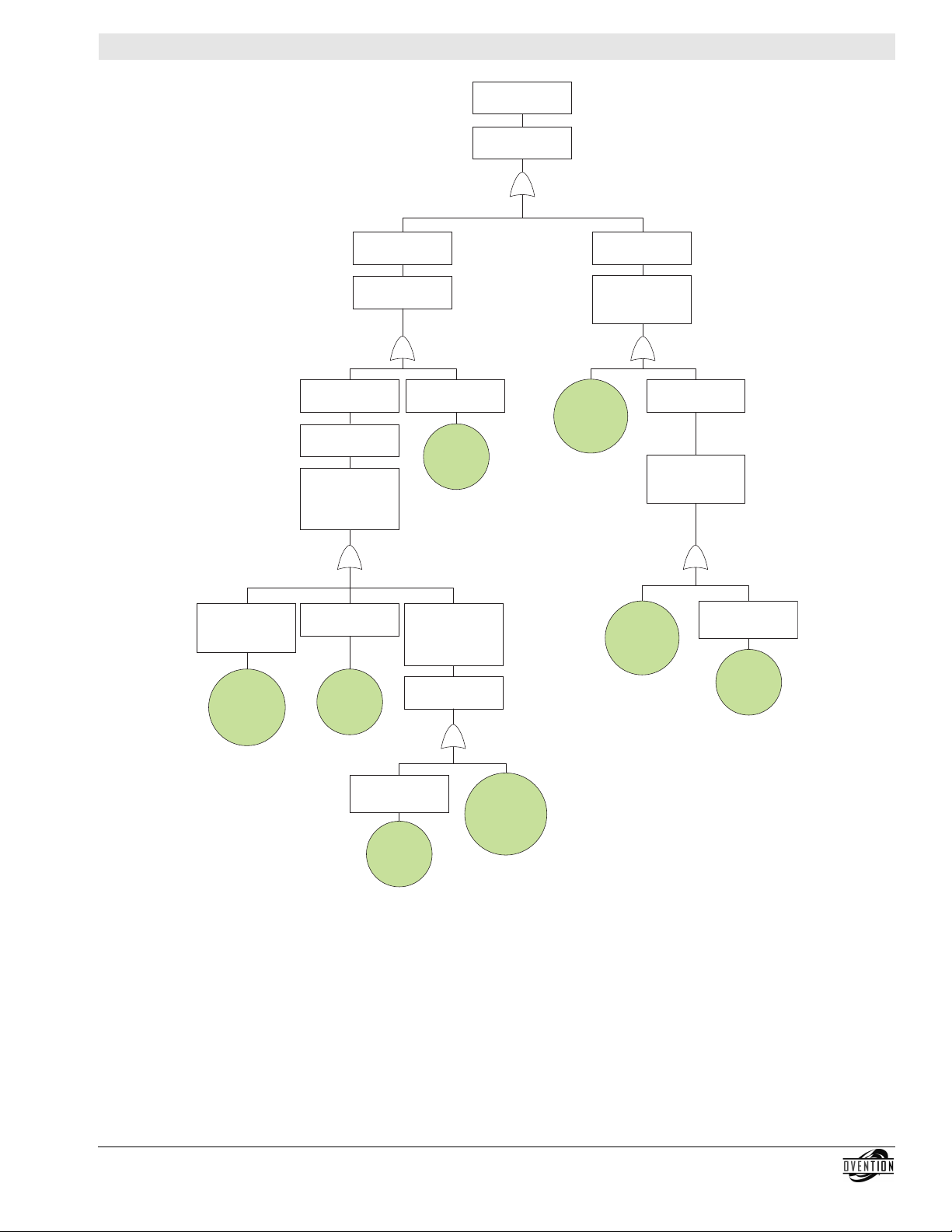

TOP LEVEL EVENT:

Oven Doesn’t Perform As Intended

Introduction

A Diagnostic Fault Tree is an excellent tool for troubleshooting

and solving problems that interrupt normal operation of a unit.

The fault tree is designed to grow from the “top level event” of

the unit not performing as intended. It is created by performing

an extensive “fault tree analysis” that considers all possible

causes of a unit failure.

Use the Diagnostic Fault Tree by starting at the Top Level Event

on this page. Review the definitions below to understand the

terminology and symbols used in the fault tree.

Definitions

Top Level Event = The highest level event in the hierarchical

fault tree.

Intermediate Event = An event in the hierarchical fault tree that

logically leads to the top level event, but is at a lower level than

the top event.

Basic Initiating Event = An event in the hierarchical fault tree

that is at the end of a branch in the tree. It is the lowest level in

a particular branch that is considered during the fault tree

analysis. The fault tree may have many branches, each with

one or more basic events.

Undeveloped Event = An event that is not further developed

either because it is of insufficient consequence or because

information is unavailable.

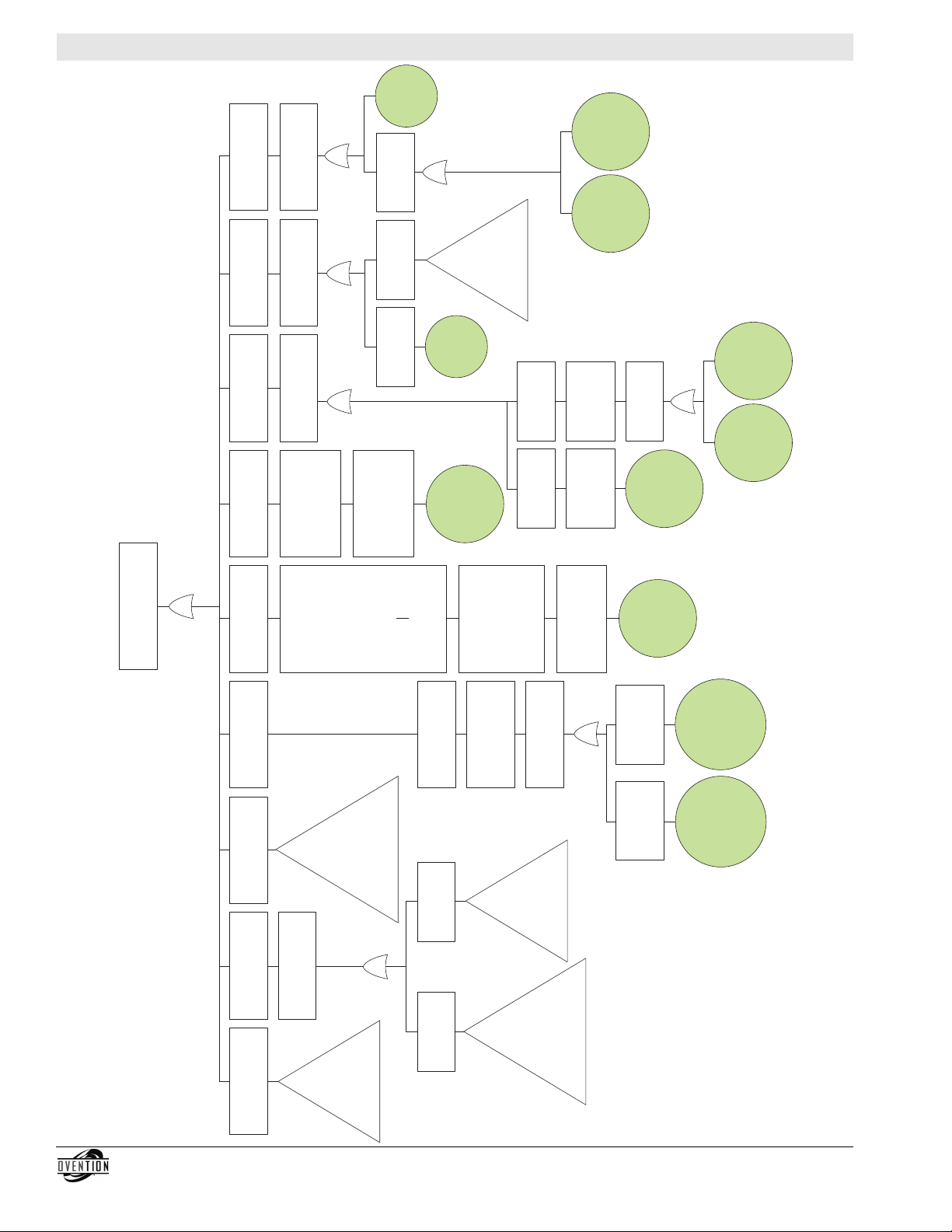

Symbols

The following symbols are used in this fault tree analysis. Each

symbol is shown along with its description.

Intermediate Event

The Intermediate Event symbol is used to

specify a failure event that occurs due to one or

more causes acting through logic gates below it

in the fault tree.

Basic Initiating Event

The Basic Initiating Event symbol is used to specify

a failure event that does not require any further

development. In other words, it is a “leaf” on the

fault tree and has no events or gates below it in the

tree.

“Or” Logic Gate

The Or logic gate symbol is used to show that the

output fault (everything below) will occur only if one or

more of the input faults (everything above) take place.

Transfer

This symbol is used to modularize a fault tree. For

example, if there is a sequence of events that

occurs in more than one place in the fault tree, then

it can be removed and placed into a separate sub-

tree and just referenced by the main fault tree.