Form No. OVSM-0116

2

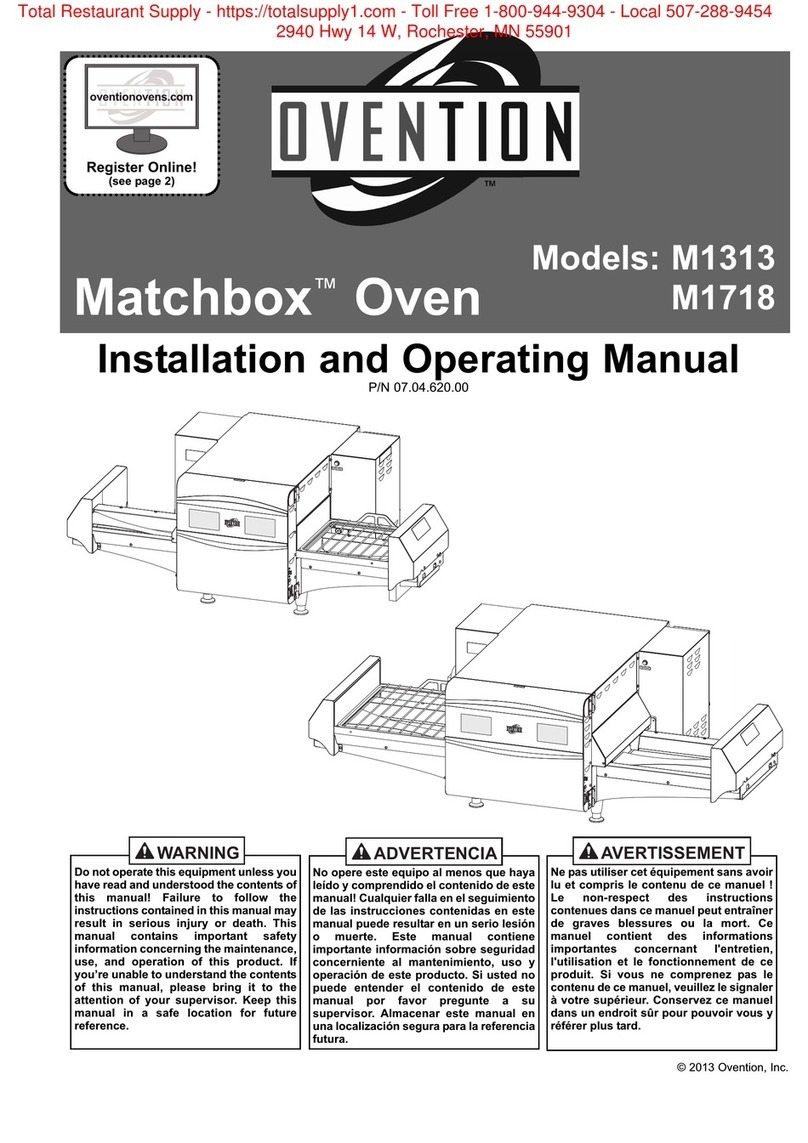

This manual provides the installation, safety, and operating

instructions for Ovention Shuttle Ovens. Ovention recommends

all installation, operating, and safety instructions appearing in

this manual be read prior to installation or operation of the oven.

Safety information that appears in this manual is identified by

the following signal word panels:

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE is used to address practices not related to personal

injury.

INTRODUCTION

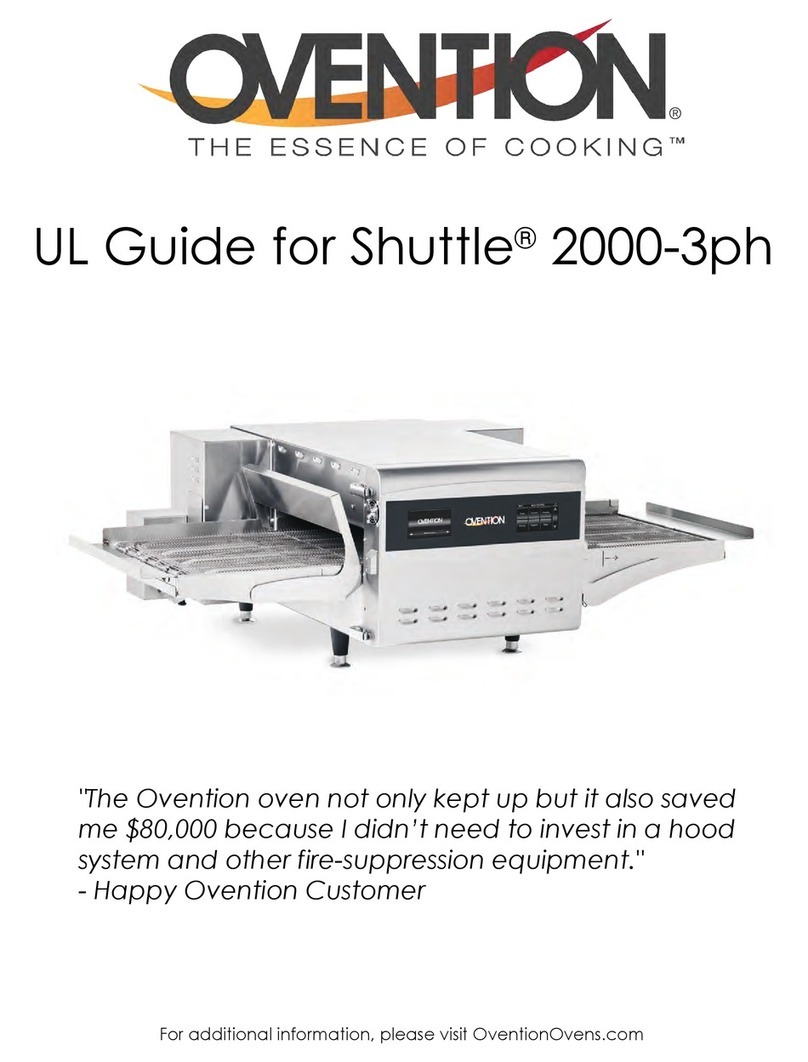

Ovention Shuttle®Ovens set a new standard in cooking quality,

speed, flexibility, and efficiency. A new discovery in air handling

not only speeds the cooking process, but “scrubs” and

recirculates the air through the oven—eliminating the need for

a hood system in most installations (non-catalyst [NC] models

require a hood system). Using icon-driven touchscreens,

operators can use, edit, and develop over 1000 custom menu

items. Menu items can be developed to include up to three

cooking stages, each with varying heat profiles, upper and lower

air velocity settings, and timing.

Ovention Shuttle Ovens are designed with multi-function

touchscreen controllers and conveyor belt that enable individual

cooking sequences as well as non-stop operation of the oven.

Shuttle doors on each side of the oven chamber maintain

control and efficiency when cooking items with specific settings.

Ovention Shuttle Ovens are products of extensive research and

field testing. The materials used were selected for maximum

durability, attractive appearance, and optimum performance.

Every unit is inspected and tested thoroughly prior to shipment.

Important Owner Information ..............................................2

Introduction...........................................................................2

Important Safety Information...............................................3

Model Description.................................................................4

Model Designation................................................................5

Specifications........................................................................5

Plug Configurations .............................................................5

Electrical Rating Chart .........................................................5

Temperature Range .............................................................5

Dimensions ..........................................................................6

Installation .............................................................................7

General ................................................................................7

Operation...............................................................................8

General ................................................................................8

Menu Item Information.........................................................8

Startup..................................................................................8

Cooking — Shuttle Mode.....................................................9

Cooking — Conveyor Mode ..............................................10

Shutdown ...........................................................................10

Programming Menu Items .................................................10

Editing Setpoint Temperatures...........................................13

Changing Temperature Unit of Measure............................13

Uploading from a USB Drive .............................................14

Maintenance ........................................................................15

General ..............................................................................15

Daily Cleaning....................................................................15

Monthly Cleaning ...............................................................15

Troubleshooting Guide ......................................................17

Options and Accessories...................................................18

imited Warranty.................................................................19

Authorized Parts Distributors............................Back Cover

IMPORTANT OWNER INFORMATION

Record the model number, serial number, voltage, and

purchase date of the unit in the spaces below (specification

label located on the left side of the unit). Please have this

information available when calling Ovention®for service

assistance.

Model No. ________________________________________

Serial No. ________________________________________

Voltage __________________________________________

Date of Purchase __________________________________

Business

Hours: 7:00 AM to 5:00 PM

Central Standard Time (CST)

(Summer Hours: une to September –

7:00 AM to 5:00 PM CST Monday through Thursday

7:00 AM to 4:00 PM CST Friday)

Telephone: 855-298-6836 (Ovention Hotline)

Additional information can be found

by visiting our web site at

www.oventionovens.com.

Need help?

Call our 24 hour, toll-free

Ovention Hotline

CONTENTS