2

1.0. GENERAL DESCRIPTION

This tritium monitor consists of dual 2-liter ionization chambers with an integral

electrometer coupled to the electronic circuits for display and control inside one fiberglass

reinforced plastic molded enclosure suitable for wall mounting.

One ionization chamber, referred to as the measurement or upstream chamber,

measures in a positive manner. The second ionization chamber, referred to as the

compensation or downstream chamber, is identically constructed but subtracts from the

measurement of the upstream chamber. This is how dual chambers serve to cancel the

effects of external gamma fields and provide differential measurements.

Ionization chambers respond not only to the airborne radioisotope, which circulates

through the ionization chamber, but also respond to the presence of external high-energy

radiation capable of ionizing the air inside. Therefore, ionization chambers will respond

to X-rays and gamma radiation as well. Additional gamma radiation suppression can be

accomplished by using lead shielding. The electrometer serves to transform this current

into a form and magnitude suitable for display, alarm, and external uses, as the ionization

current itself is very weak.

The monitor contains all signal processing, alarm and external interface circuits, read out,

and all required power supplies. The signal processing circuits serve to reject unwanted

signals and to translate the electrometer signal voltage into a form and magnitude

suitable for display, alarm and external uses as well.

The alarm circuits provide a visual signal and relay outputs for remote connection to

denote that a preset level of measurement has been exceeded or certain malfunctions.

2.0. PHYSICAL DESCRIPTION

The Model Triathalon-H3 is a single range, ionization chamber monitor for the measurement

of tritium in a NEMA 4X enclosure suitable for permanent installation and for continuous duty.

The enclosure has a hinged door with a polycarbonate window. Behind the hinged door is a

front panel that is hinged so that it can be opened for servicing the various components

inside. The sample inlet and exhaust fittings are located on the left side of the enclosure.

Fittings for Tritium and Total Tritium measurement are located on the right side of the

enclosure. Wiring conduit connections are provided on the bottom of the enclosure and

consist of AC power conduit and control wiring conduit.

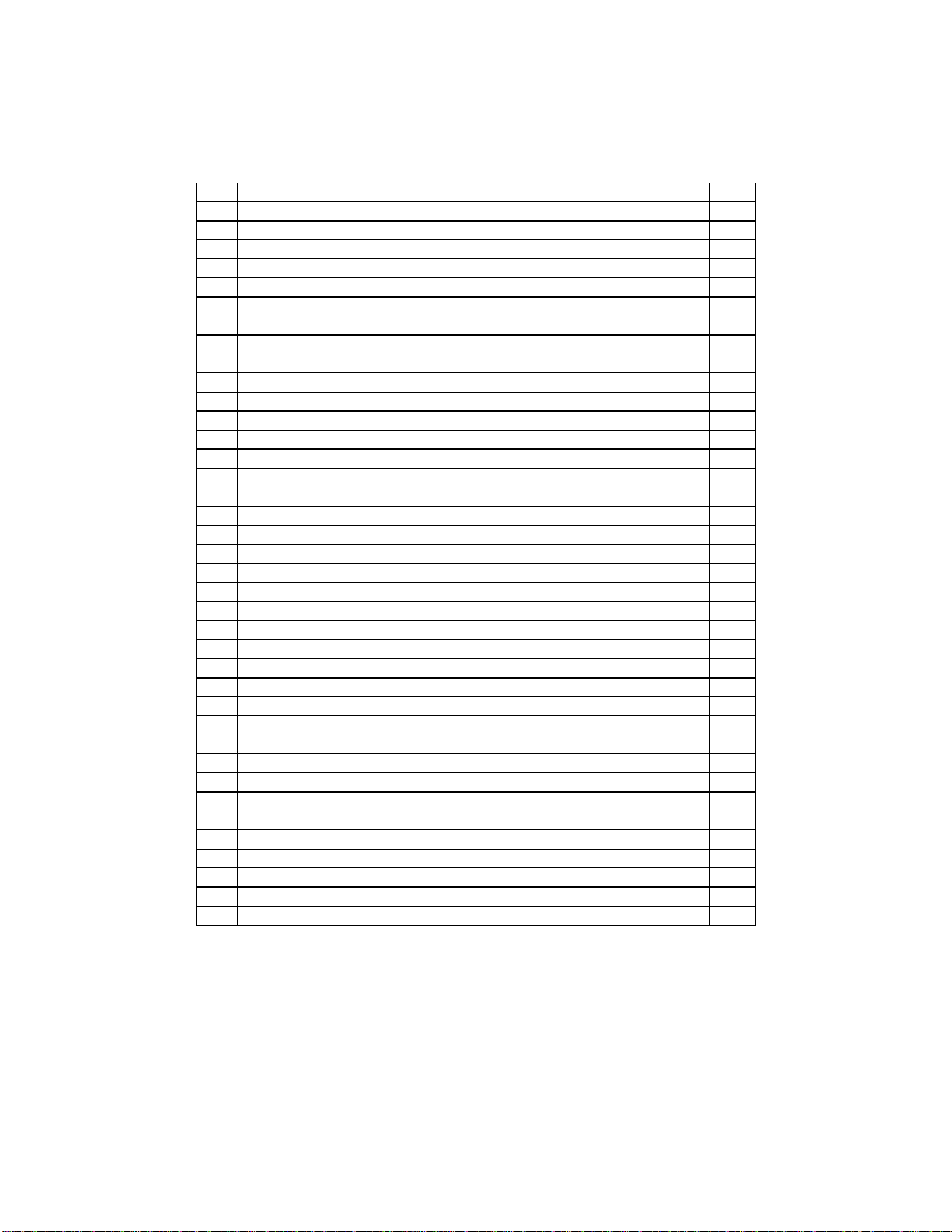

The following are located on the front panel:

Fuse holder, main power switch, ‘ON’ and ‘OFF’ indicators.

An LCD color touch screen serves the majority of control and display functions. These

include the tritium measurement, alarm set points and indication.

A 0-10 LPM adjustable flowmeter to indicate and control the sample flow.

The following are attached to the enclosure subpanel inside the enclosure:

Dual 2 liter ionization chamber;

Sample pump, differential pressure switch used for sensing a low flow condition, and all

DIN rail mounted electrical connections.

The following are located on the outer left side of the enclosure:

Stainless steel tubing connections for sample inlet and exhaust

HEPA filter for downstream sample stream.

The following are located on the outer right side of the enclosure:

Hose connections for a desiccant column used for noble gas compensation mode

HEPA filter for downstream sample stream.