NANOSYSTEMFABRICATIONFACILITY(NFF),HKUST

Version1.0Pa

e 10 of 24

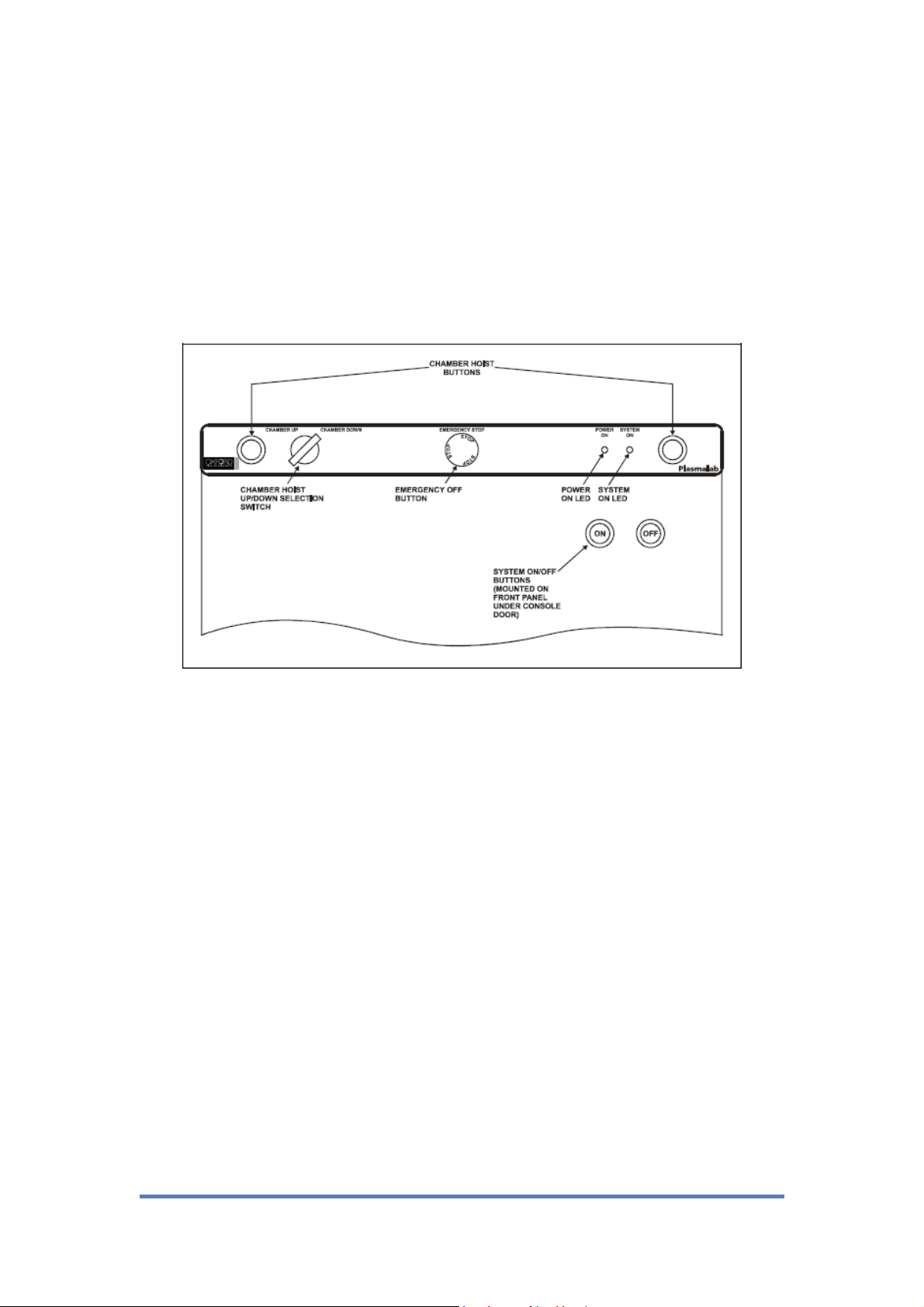

Emergency off and Interlock facilities

Emergency off (EMO) and interlock facilities are provided to shut down the machine

in an emergency and to stop process until the system is fully initiated. An emergency

off switch, with normally-closed contacts, is mounted on top of the console. The

switch is activated by pressing a red “Emergency Off” button.

PLC interlock chain

The interlock chain is monitored by the software, but acts independently. It is also

supplemented by machine protection sensors, which operate only via the software.

To enable RF power:

1. The 600 mbar vacuum switch (‘Vacstat’) must be at low pressure

2. The process chamber lid must be closed (or its hoist down)

3. The primary process pump must be running

4. The primary process pressure gauge (normally a capacitance manometer) must be

on scale

5. The load lock inter-chamber valve (where fitted) must be closed

6. Customer-supplied external alarm devices must be at safe state

7. The inert gas purge to the primary process pump must be flowing.

To enable process gases:

1. RF power must be enabled.

2. The gas box lid must be closed.

3. Specific gases can be set in the gas box hardware to be mutually exclusive, so

they cannot be turned on together.