Contents

1 Features............................................................................................................................4

2 Application.........................................................................................................................4

3 Safety Symbols used in this Manual.................................................................................5

4 Safety Guidelines..............................................................................................................5

5 Responsibility for Operation or amage...........................................................................6

5.1 Warranty.....................................................................................................................6

6 Before Starting..................................................................................................................6

6.1 Transport....................................................................................................................6

6.2 Installation..................................................................................................................7

6.3 Storage.......................................................................................................................7

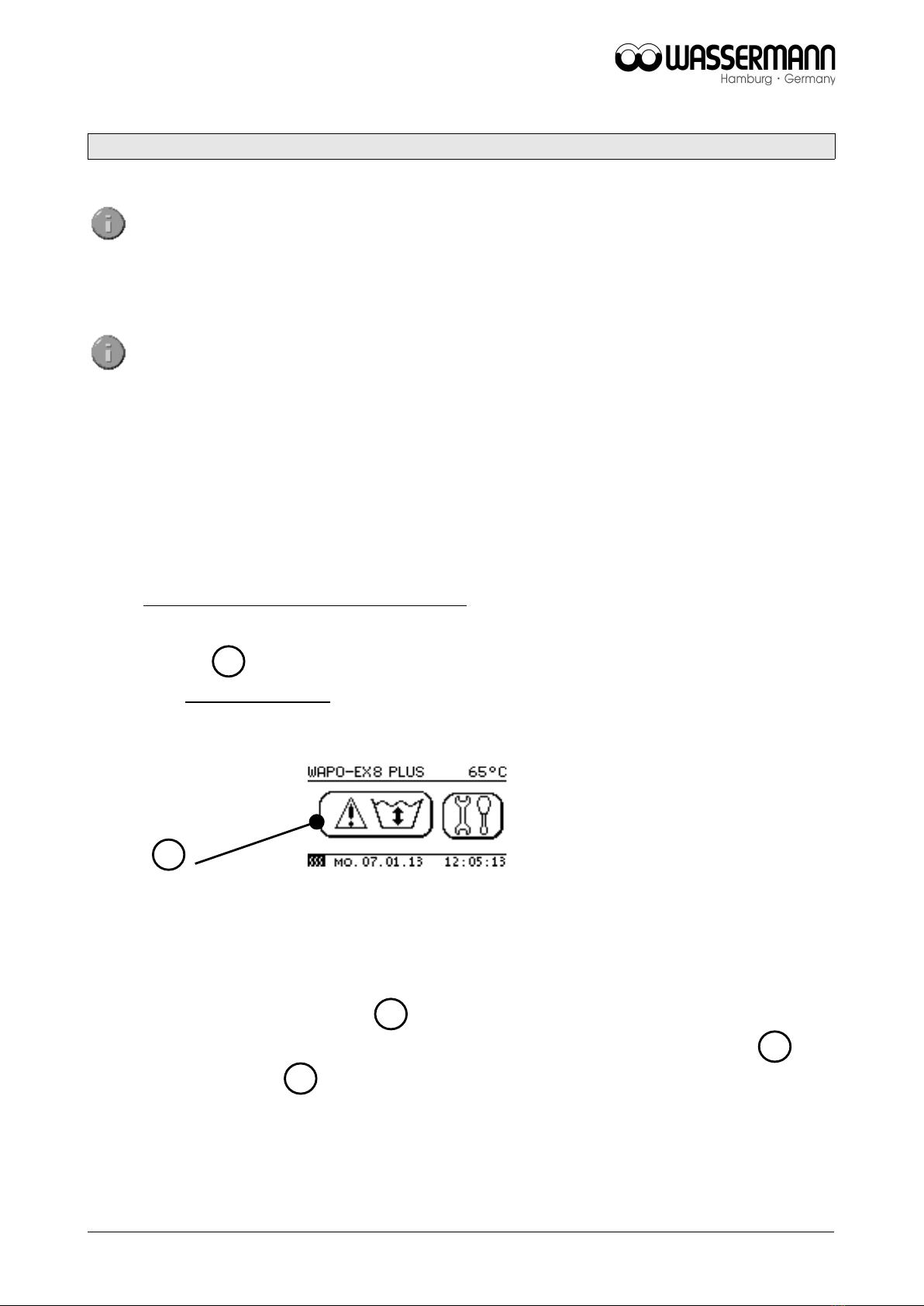

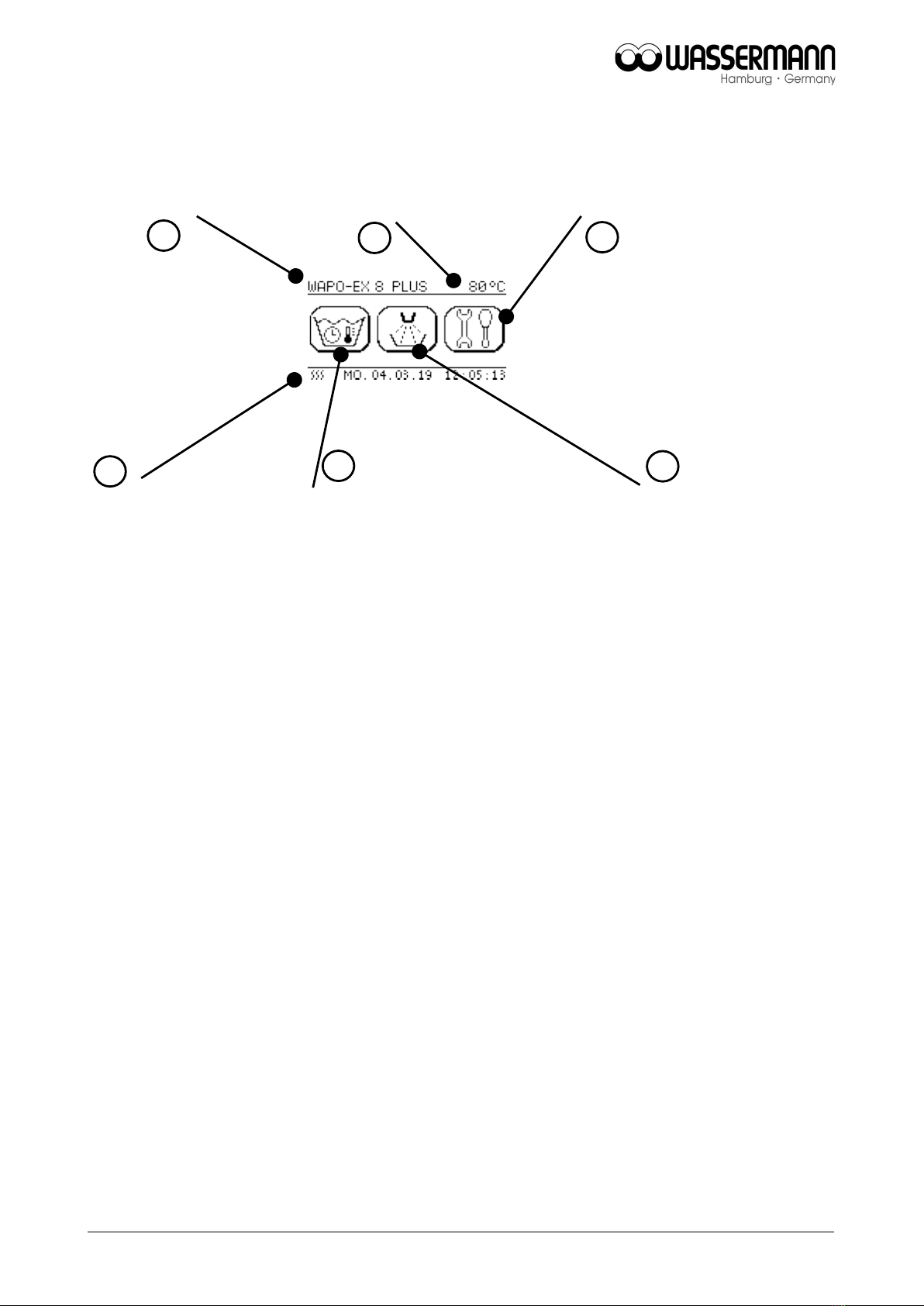

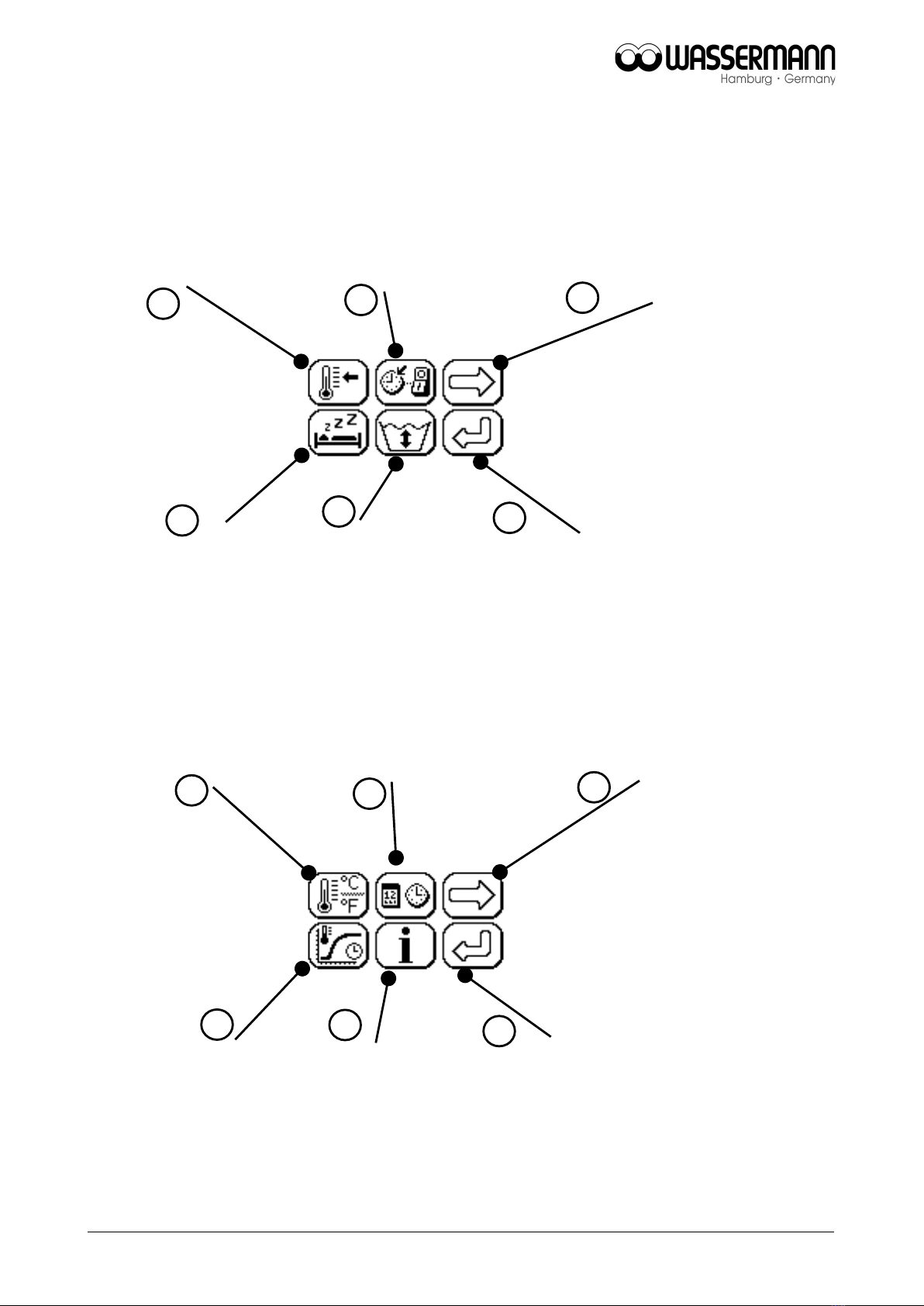

7 Installation/ Start-up/ Menu Functions..............................................................................8

8 Operation........................................................................................................................18

8.1 General Operating Instructions................................................................................18

8.2 Boiling Out Operation...............................................................................................20

8.3 Hand Shower............................................................................................................20

8.4 Polymerisation Operation.........................................................................................21

9 Troubleshooting..............................................................................................................22

10 Maintenance..................................................................................................................23

10.1 Cleaning.................................................................................................................23

10.2 Servicing.................................................................................................................24

10.3 Repairs...................................................................................................................24

10.4 Spare Parts.............................................................................................................24

10.5 Service Hotline 0049 (0)40 730 926 -20/ -24.........................................................24

10.6 Scope of elivery/ Accessories..............................................................................24

11 Technical ata..............................................................................................................25

12 isposing of the Unit.....................................................................................................26

12.1 Information on isposal for Countries within the EU.............................................26

13 EU eclaration of Conformity.......................................................................................27